The discipline involves the design, development, testing, and production of aircraft and spacecraft. It encompasses a broad range of technologies, integrating principles from aerodynamics, propulsion, materials science, structural analysis, and control systems. An example includes the creation of a new satellite designed for Earth observation, requiring expertise in orbital mechanics and communication systems.

This field is critical for advancements in air transportation, space exploration, and national security. Its contributions lead to more efficient aircraft, advanced satellite technologies, and enhanced defense systems. Historically, it has been a driving force behind technological innovation, pushing the boundaries of what is possible in flight and space.

The following sections will delve into specific areas of focus within this complex domain, exploring recent breakthroughs and future challenges. Key considerations will include sustainable aviation, autonomous systems, and the exploration of deep space. These topics reflect the evolving nature of the field and its continued relevance in addressing global needs.

Essential Considerations for Aspiring Professionals

Success in this demanding field requires a combination of technical proficiency and professional acumen. The following points outline key areas for development and strategic planning.

Tip 1: Master Fundamental Principles: A comprehensive understanding of mathematics, physics, and computer science is paramount. These form the bedrock of all advanced studies and practical applications. Examples include proficiency in calculus for aerodynamic analysis and linear algebra for structural modeling.

Tip 2: Cultivate Strong Analytical Skills: The ability to critically evaluate complex problems and develop innovative solutions is crucial. This involves breaking down systems into their constituent parts, identifying key parameters, and assessing potential risks and benefits. Case studies of past engineering failures can provide valuable insights.

Tip 3: Develop Proficiency in Simulation Software: Familiarity with industry-standard software such as ANSYS, MATLAB, and CAD/CAM tools is essential for design, analysis, and simulation. Practical experience with these tools enhances employability and productivity.

Tip 4: Seek Internships and Research Opportunities: Hands-on experience in relevant industries or research labs provides invaluable practical skills and networking opportunities. Participation in projects involving aircraft design, satellite construction, or propulsion systems offers a competitive edge.

Tip 5: Focus on Specialization: Given the breadth of the field, focusing on a specific area such as aerodynamics, propulsion, or avionics can lead to deeper expertise and enhanced career prospects. Concentrated study in a particular area allows for the development of specialized skills and knowledge.

Tip 6: Stay Abreast of Technological Advancements: The field is constantly evolving, so continuous learning and professional development are crucial. Regularly attending conferences, reading technical journals, and participating in online courses are effective strategies.

Tip 7: Enhance Communication Skills: The ability to effectively communicate technical information to both technical and non-technical audiences is vital for collaboration and project success. Practice presenting technical data clearly and concisely in written reports and oral presentations.

By focusing on these areas, aspiring professionals can build a strong foundation for a successful and rewarding career. Continuous improvement and a commitment to excellence are essential for navigating the challenges of this dynamic industry.

The subsequent sections will further explore the application of these principles in real-world scenarios and address the future trajectory of this critical sector.

1. Design of Aircraft

Aircraft design constitutes a core element of the broader scope of aerospace engineering. It directly embodies the application of theoretical principles and technological advancements to create functional and efficient flying vehicles, illustrating the practical manifestation of aerospace engineering knowledge.

- Aerodynamic Optimization

Aerodynamic optimization is fundamental to aircraft design, influencing lift, drag, and overall performance. Computational fluid dynamics (CFD) simulations and wind tunnel testing are crucial in refining wing shapes and fuselage designs. Real-world examples include the winglet designs on modern airliners, which reduce drag and enhance fuel efficiency. These optimizations are critical for ensuring aircraft operate efficiently within the parameters defined by aerospace engineering.

- Structural Integrity and Materials Selection

Ensuring structural integrity is paramount for safety and longevity. Finite element analysis (FEA) is used to assess stress distribution and identify potential failure points. Materials selection, often involving advanced composites and alloys, balances strength with weight considerations. The use of carbon fiber reinforced polymers in the Boeing 787 Dreamliner exemplifies this principle, reducing weight and improving fuel economy. These design decisions are directly informed by the material science and structural analysis aspects of aerospace engineering.

- Propulsion System Integration

The integration of propulsion systems is a critical aspect of aircraft design, influencing performance metrics such as speed, range, and fuel consumption. Engine placement, air intake design, and exhaust nozzle configuration are carefully considered. The efficient integration of turbofan engines on modern commercial aircraft demonstrates the application of propulsion principles, enabling long-distance travel with minimal fuel consumption. The selection and positioning of these systems are integral to fulfilling the engineering requirements of aerospace vehicles.

- Control Systems and Avionics

Sophisticated control systems and avionics are essential for safe and efficient operation. Fly-by-wire systems, autopilot functionalities, and navigation systems are integrated to enhance maneuverability and situational awareness. Modern aircraft rely heavily on these systems to maintain stability and navigate complex airspace. The development and integration of these control and navigation technologies showcase the complex interdependencies within the realm of aerospace vehicle development.

These facets highlight the interconnectedness of aircraft design with the broader principles of aerospace engineering. The creation of any new aircraft necessitates a holistic approach, integrating aerodynamic principles, structural considerations, propulsion system requirements, and advanced control systems to achieve optimal performance and safety, thus epitomizing the practical application of the broader field.

2. Development of Spacecraft

The development of spacecraft represents a critical application of the overarching discipline. It necessitates the integration of diverse engineering principles to create vehicles capable of operating in the unique and challenging environment of space. Spacecraft development exemplifies the practical manifestation of aerospace engineering knowledge.

- Orbital Mechanics and Trajectory Design

Orbital mechanics dictates the motion of spacecraft and informs trajectory design for missions. Precise calculations are necessary to achieve desired orbits and execute maneuvers. The planning of a mission to Mars, for example, involves complex trajectory calculations to minimize fuel consumption and mission duration. This application is a direct result of the scientific principles that govern the movement of objects in space and the specialized knowledge within aerospace engineering.

- Spacecraft Propulsion Systems

Propulsion systems provide the means for spacecraft to alter their orbits, maintain orientation, and execute course corrections. Ion propulsion, chemical rockets, and advanced propulsion concepts are employed based on mission requirements. The use of ion propulsion on deep-space missions, such as the Dawn spacecraft, illustrates the application of advanced propulsion technology to achieve specific objectives. These systems are integral to the success and capabilities of spacecraft developed under the umbrella of aerospace engineering.

- Environmental Control and Life Support Systems (ECLSS)

For crewed spacecraft, ECLSS are vital for maintaining a habitable environment. These systems regulate temperature, pressure, air quality, and water supply. The International Space Station relies on sophisticated ECLSS to support long-duration human presence in space. The design and operation of these systems reflect the critical integration of various engineering disciplines within the context of spacecraft development.

- Communication and Data Handling Systems

Reliable communication and data handling systems are essential for transmitting data to and from spacecraft. These systems must operate effectively across vast distances and under challenging conditions. Deep Space Network antennas are critical for communicating with spacecraft exploring the outer solar system. The design of these communication systems integrates signal processing, antenna theory, and other aspects of electrical and aerospace engineering.

These facets collectively highlight the deep connection between spacecraft development and the larger field. The successful creation of any spacecraft mandates a holistic approach, integrating orbital mechanics, propulsion systems, life support, and communications to fulfill mission objectives. These elements are emblematic of the advanced engineering principles and complex interdependencies inherent in the broader scope of aerospace engineering.

3. Aerodynamics principles

Aerodynamics constitutes a cornerstone of the discipline, impacting aircraft and spacecraft design profoundly. As a direct consequence of its influence, understanding and applying aerodynamic principles are essential for optimizing vehicle performance, stability, and control. Ineffective application of these principles leads to reduced efficiency, increased drag, and potentially catastrophic instability. The design of aircraft wings, for example, is directly dependent on airfoil shapes that generate lift through pressure differentials, a core concept in aerodynamics.

Further analysis reveals the practical significance of this relationship. Consider the development of high-speed aircraft. Aerodynamic considerations related to compressibility, wave drag, and shockwave formation become paramount. Engineers apply advanced techniques, such as designing swept wings and utilizing area ruling, to mitigate these effects. These design adaptations, driven by aerodynamic principles, enable aircraft to achieve supersonic and hypersonic speeds without compromising stability or fuel efficiency. The Concorde supersonic transport is a prime example, where careful aerodynamic design facilitated efficient supersonic flight.

In summary, aerodynamics principles are integral to the broader discipline, serving as a foundational element in the design and operation of all aerospace vehicles. Challenges in aerodynamics, such as turbulent flow modeling and high-speed flow control, continue to drive research and innovation. Effective integration of these principles ensures that the field remains at the forefront of technological advancement, enabling the creation of increasingly efficient, safe, and capable aircraft and spacecraft.

4. Propulsion systems

Propulsion systems are integral to the field, serving as the primary means by which aircraft and spacecraft overcome gravity and atmospheric resistance. Their design and implementation are directly influenced by the broader principles of aerodynamics, thermodynamics, and materials science, all core components within aerospace engineering. The effectiveness of these systems determines a vehicle’s range, speed, payload capacity, and overall mission capability. Consequently, innovations in propulsion technology frequently lead to significant advancements in aerospace vehicle performance. For instance, the development of high-bypass turbofan engines dramatically improved the fuel efficiency of commercial airliners, extending their range and reducing operating costs. This enhancement directly exemplifies how advancements in one area of aerospace engineering can impact the entire industry.

The practical application of propulsion systems varies considerably depending on the specific requirements of the aerospace vehicle. Aircraft typically rely on air-breathing engines, such as turbofans and turbojets, which utilize atmospheric oxygen for combustion. Spacecraft, conversely, require self-contained propulsion systems, such as chemical rockets or ion thrusters, capable of operating in the vacuum of space. Each type of system presents unique engineering challenges related to efficiency, reliability, and specific impulse. Furthermore, the integration of these propulsion systems into the overall vehicle design is critical, requiring careful consideration of factors such as weight distribution, aerodynamic drag, and thermal management. The successful launch and operation of the James Webb Space Telescope, for example, relied on a sophisticated combination of chemical rockets for initial ascent and smaller thrusters for precise orbital adjustments, demonstrating the complex integration required for space missions.

In summary, propulsion systems represent a critical sub-discipline within aerospace engineering. Their performance characteristics directly influence the capabilities of both aircraft and spacecraft. Continued research and development in this area are essential for achieving future advancements in air transportation, space exploration, and national security. Challenges such as improving engine efficiency, developing sustainable fuels, and exploring novel propulsion concepts remain at the forefront of aerospace engineering research, highlighting the ongoing need for innovation in this vital field.

5. Materials science

Materials science is intrinsically linked to the broader definition. The performance capabilities of aircraft and spacecraft are fundamentally limited by the properties of the materials from which they are constructed. The selection and development of suitable materials are not merely supportive functions but essential prerequisites for aerospace innovation. Strong, lightweight materials enable greater fuel efficiency and payload capacity in aircraft. Similarly, materials resistant to extreme temperatures and radiation are critical for spacecraft operating in the harsh environment of space. The development of titanium alloys, for example, revolutionized aircraft design by providing high strength-to-weight ratios and corrosion resistance. Consequently, this enhanced performance and durability in airframes and engine components.

The relationship between materials science and the aerospace definition extends beyond merely selecting existing materials. It encompasses the design and synthesis of entirely new materials tailored to specific aerospace needs. Composite materials, such as carbon fiber reinforced polymers, exemplify this approach. These materials offer exceptional strength and stiffness while being significantly lighter than traditional metals. This translates to reduced structural weight in aircraft and spacecraft, leading to improved fuel efficiency and increased payload capacity. Furthermore, advanced coatings and surface treatments developed through materials science provide protection against corrosion, erosion, and extreme temperatures. These surface enhancements prolong the lifespan of aerospace components and reduce maintenance requirements.

In summary, materials science is an indispensable component of the aerospace definition. It is not a mere supporting discipline but a critical enabler of aerospace innovation. The development of advanced materials, driven by the specific requirements of aerospace applications, directly translates into improved performance, safety, and reliability of aircraft and spacecraft. Challenges remain in areas such as developing materials capable of withstanding hypersonic speeds and extreme radiation environments. Continued research and development in materials science are essential for pushing the boundaries of what is possible in flight and space exploration.

6. Structural analysis

Structural analysis is an indispensable component within the broader scope, providing the methodologies for ensuring the integrity and reliability of aerospace vehicles. It employs computational and experimental techniques to assess the behavior of structures under various loading conditions, thereby safeguarding against failure and optimizing design efficiency.

- Finite Element Analysis (FEA)

FEA constitutes a primary tool in structural analysis, enabling engineers to simulate the response of complex structures to external forces. By discretizing a structure into smaller elements, FEA allows for the calculation of stress distribution, deformation, and stability. The design of aircraft wings, for instance, relies heavily on FEA to ensure they can withstand aerodynamic loads without catastrophic failure. This technique is critical for validating designs before physical prototyping and testing, conserving resources and accelerating the development process.

- Load Path Analysis

Load path analysis involves tracing the transmission of forces through a structure to identify critical load-bearing elements. This process is essential for understanding how loads are distributed and for optimizing the structural layout to minimize weight and maximize strength. In spacecraft design, load path analysis is crucial for ensuring that launch loads are effectively transferred through the vehicle without causing damage to sensitive components. This analysis informs material selection and structural reinforcement strategies.

- Material Behavior Modeling

Accurate modeling of material behavior is paramount for reliable structural analysis. This involves characterizing the mechanical properties of materials, such as elasticity, plasticity, and creep, under various temperature and loading conditions. The selection of materials for aircraft engine components, for example, requires detailed knowledge of their behavior at high temperatures to prevent failure due to thermal stress and fatigue. Material behavior modeling contributes to more accurate predictions of structural performance and lifespan.

- Experimental Testing and Validation

Experimental testing serves as a critical validation step in structural analysis, providing empirical data to verify the accuracy of computational models. This may involve subjecting structural components to static or dynamic loads in a laboratory setting and measuring their response using strain gauges, accelerometers, and other sensors. Full-scale aircraft testing, for example, is conducted to validate the structural integrity of the design under realistic flight conditions. These tests provide confidence in the safety and reliability of aerospace vehicles.

The integration of these facets within structural analysis ensures that aerospace vehicles are designed to withstand the extreme conditions they encounter during operation. The interplay between computational modeling, material characterization, and experimental validation is essential for achieving safe, efficient, and reliable aerospace designs. Continued advancements in structural analysis techniques and tools are critical for pushing the boundaries of what is possible in flight and space exploration.

7. Control systems

Within the broader scope, control systems represent a critical subdiscipline responsible for ensuring stability, maneuverability, and precise navigation of aerospace vehicles. Their design integrates principles from electrical engineering, computer science, and mechanical engineering, forming an essential component of the overall system.

- Flight Control Systems

Flight control systems in aircraft manage aerodynamic surfaces to control altitude, direction, and speed. Modern fly-by-wire systems replace mechanical linkages with electronic signals, enhancing precision and responsiveness. The Airbus A380, for instance, relies on a complex fly-by-wire system to manage its large size and maintain stability during flight. These systems contribute directly to safety, efficiency, and overall operational performance.

- Attitude Control Systems

Attitude control systems in spacecraft maintain desired orientation in space, crucial for pointing scientific instruments or maintaining communication links. Reaction wheels, thrusters, and control moment gyros are used to adjust the spacecraft’s attitude. The precise attitude control of the James Webb Space Telescope, for example, is vital for its ability to collect high-resolution astronomical data. Such systems are essential for accomplishing mission objectives and ensuring data quality.

- Guidance, Navigation, and Control (GNC) Systems

GNC systems integrate sensors, algorithms, and actuators to guide vehicles along predetermined trajectories. Inertial navigation systems, GPS receivers, and star trackers provide position and orientation information, which is then used to calculate control commands. Intercontinental ballistic missiles (ICBMs) employ sophisticated GNC systems to accurately deliver payloads over long distances. These systems are vital for achieving mission goals with precision and reliability.

- Engine Control Systems

Engine control systems regulate engine parameters such as fuel flow, air intake, and exhaust nozzle position to optimize performance and efficiency. Electronic engine controls (EEC) or full authority digital engine controls (FADEC) use sensors and microprocessors to maintain desired engine thrust and prevent stall or over-temperature conditions. Modern jet engines rely on FADEC systems to achieve optimal performance and fuel efficiency across a wide range of operating conditions. Such systems are critical for safe and efficient operation of aerospace propulsion systems.

These interconnected elements highlight the centrality of control systems within the overall scope. The effectiveness of control systems directly impacts the performance, safety, and success of aerospace missions. Ongoing advancements in sensor technology, control algorithms, and actuation systems continue to drive progress, enabling more sophisticated and autonomous aerospace operations.

Frequently Asked Questions Regarding Aerospace Engineering

The following section addresses common inquiries pertaining to the definition and scope of aerospace engineering, providing concise and informative answers.

Question 1: What constitutes the core focus of aerospace engineering?

Aerospace engineering primarily concerns itself with the design, development, testing, and production of aircraft and spacecraft. It integrates multiple engineering disciplines to achieve efficient and safe operation in both atmospheric and extraterrestrial environments.

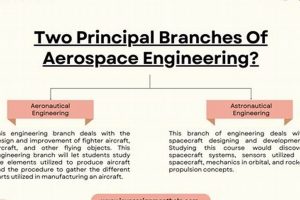

Question 2: How does aerospace engineering differ from aeronautical engineering?

Aeronautical engineering focuses specifically on aircraft that operate within Earth’s atmosphere. Aerospace engineering encompasses both aeronautical engineering and astronautical engineering, the latter dealing with spacecraft and related technologies operating outside Earth’s atmosphere.

Question 3: What are the primary disciplines involved in the curriculum?

A typical curriculum includes coursework in aerodynamics, propulsion, structural analysis, materials science, control systems, and orbital mechanics. These disciplines provide the foundational knowledge required for designing and analyzing aerospace vehicles.

Question 4: What career paths are typically available to graduates?

Graduates often find employment in aircraft manufacturing, space exploration, defense, research and development, and government agencies. Specific roles may include design engineer, test engineer, systems engineer, and project manager.

Question 5: What are some current challenges facing professionals in this field?

Current challenges include developing sustainable aviation technologies, creating more efficient propulsion systems, reducing the weight of aerospace structures, mitigating space debris, and advancing autonomous aerospace systems.

Question 6: How does the development of new materials impact the field?

The development of new materials significantly impacts aerospace engineering by enabling the creation of lighter, stronger, and more heat-resistant components. Advanced materials are crucial for improving fuel efficiency, increasing payload capacity, and withstanding extreme operating conditions.

In summary, aerospace engineering is a multifaceted discipline with a broad range of applications. It requires a strong foundation in science and mathematics, along with a commitment to continuous learning and innovation.

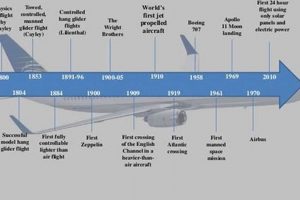

The next section will explore the historical context and significant milestones that have shaped this field.

Conclusion

This exploration has clarified the multifaceted nature, encompassing the design, development, and production of aircraft and spacecraft. The integration of disciplines such as aerodynamics, propulsion, materials science, structural analysis, and control systems defines the field’s comprehensive approach to achieving flight and spacefaring capabilities.

Continued progress hinges on addressing critical challenges and fostering innovation. The advancement of sustainable technologies, novel propulsion methods, and robust materials remains essential for realizing future milestones in air and space travel. Recognizing this complexity and committing to ongoing research will secure continued progress within the aerospace sector.