The role involves the creation and development of components, systems, and vehicles for flight within and beyond the Earth’s atmosphere. These professionals apply engineering principles to conceptualize, analyze, and refine designs that meet specific performance requirements, safety standards, and regulatory guidelines. For example, one might be responsible for designing a more efficient wing for a commercial airliner or developing the structural framework for a spacecraft.

The contributions of individuals in this field are vital to advancements in air travel, space exploration, and national security. Through meticulous design and rigorous testing, they ensure the reliability and efficiency of flight vehicles and systems. Historically, their work has driven significant technological leaps, from the development of jet engines to the creation of reusable spacecraft. This field blends creativity with analytical thinking, demanding a strong understanding of physics, materials science, and engineering design principles.

Subsequent sections will delve into the specific responsibilities, required skills, and career paths available to individuals pursuing this critical occupation. It will also examine the emerging technologies and future trends shaping the landscape of this challenging and rewarding profession.

Guidance for Aspiring Professionals

This section provides crucial insights for individuals seeking a career focused on the creation and refinement of flight-related technology. These recommendations are derived from industry best practices and address key aspects of professional development.

Tip 1: Cultivate a Strong Foundation in Fundamental Principles: A thorough understanding of mathematics, physics, and materials science is paramount. These core subjects form the bedrock upon which all design decisions are made. For instance, comprehending fluid dynamics is critical when designing aerodynamic surfaces.

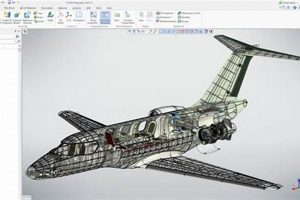

Tip 2: Develop Proficiency in Computer-Aided Design (CAD) Software: Mastery of industry-standard CAD tools is essential for creating detailed models and drawings of aerospace components. Experience with software such as CATIA, SolidWorks, or NX allows for efficient design iteration and collaboration with manufacturing teams.

Tip 3: Seek Internships and Practical Experience: Engaging in internships at aerospace companies or research institutions provides invaluable hands-on experience. This exposure allows one to apply theoretical knowledge to real-world challenges and gain familiarity with industry processes.

Tip 4: Focus on Specialization: The aerospace field is vast and encompasses diverse areas like aerodynamics, propulsion, structures, and avionics. Choosing a specific area of focus allows for deeper expertise and increased career opportunities. For example, specializing in composite materials can lead to a career designing lightweight and strong aircraft structures.

Tip 5: Hone Analytical and Problem-Solving Skills: The ability to analyze complex problems, identify potential solutions, and rigorously test design concepts is crucial. This involves utilizing simulation software, conducting experiments, and interpreting data to optimize performance.

Tip 6: Maintain Awareness of Industry Trends: The aerospace sector is constantly evolving, with new technologies and materials emerging regularly. Staying informed about advancements such as electric propulsion, additive manufacturing, and sustainable aviation fuels is essential for long-term career success.

Tip 7: Emphasize Collaboration and Communication: Success in this field depends on effective teamwork and clear communication with engineers, technicians, and project managers. The ability to articulate design choices, explain technical concepts, and actively listen to feedback is highly valued.

By focusing on these critical areas, aspiring individuals can significantly enhance their prospects for a successful and impactful career. The pursuit of excellence in these areas will not only lead to professional advancement but also contribute to the ongoing evolution of air and space travel.

The subsequent article sections will further examine the day-to-day responsibilities and long-term career trajectories associated with this demanding but ultimately rewarding profession.

1. Conceptualization and innovation

Within the realm of aircraft design, the capacity for fresh ideas and pioneering approaches is paramount. These drive improvements in safety, efficiency, and capability. The following points highlight key facets of conceptualization and innovation as they relate to the development of flight vehicles.

- Problem Definition and Needs Analysis

This initial phase involves clearly defining the requirements and constraints of a new design or improvement. This includes identifying performance gaps, regulatory demands, and market opportunities. For example, understanding the need for reduced carbon emissions in commercial aviation can drive the conceptualization of more fuel-efficient engine designs or novel aircraft configurations.

- Ideation and Concept Generation

This stage focuses on generating a wide range of potential solutions to the identified problem. It often involves brainstorming sessions, utilizing biomimicry principles, and exploring unconventional designs. The development of blended wing body aircraft, for instance, emerged from efforts to improve aerodynamic efficiency through radical departures from traditional aircraft shapes.

- Concept Evaluation and Selection

The various concepts generated are then critically evaluated based on factors such as feasibility, cost-effectiveness, performance potential, and risk. This often involves preliminary analysis, simulation, and prototyping to assess the viability of each concept. The selection of a specific wing airfoil for a new aircraft, for example, requires rigorous evaluation of its lift, drag, and stall characteristics under various flight conditions.

- Prototyping and Testing

Once a concept is selected, a prototype is often created to validate its design and performance. This may involve building a physical model for wind tunnel testing or developing a virtual prototype for computational fluid dynamics (CFD) simulations. The development of a new flight control system, for example, would necessitate extensive testing in a flight simulator to ensure its stability and responsiveness.

These facets are interconnected and crucial for driving progress. By fostering a culture of innovation, aircraft engineers can push the boundaries of what is possible, leading to safer, more efficient, and more capable aircraft for a wide range of applications. As an example, the recent advancements in electric aircraft technology are a direct result of ongoing innovation in battery technology, motor design, and aircraft architecture, demonstrating the field’s continued commitment to progress.

2. Aerodynamic Optimization

Aerodynamic optimization, a core competency of the professional in the field of aviation, directly impacts the performance, efficiency, and safety of flight vehicles. The design and development of aircraft components, such as wings, fuselages, and control surfaces, fundamentally rely on principles that minimize drag, maximize lift, and ensure stable flight characteristics. These professionals utilize computational fluid dynamics (CFD) simulations, wind tunnel testing, and theoretical calculations to iteratively refine designs, striving for optimal aerodynamic performance across a range of operating conditions. The consequence of ineffective aerodynamic design is increased fuel consumption, reduced payload capacity, and potentially compromised stability, all critical factors in aircraft operation.

Real-world examples of this relationship are abundant. Consider the development of winglets on commercial airliners; the utilization of these small, vertical extensions at the wingtips directly reduces induced drag, leading to significant fuel savings over long-haul flights. The shaping of a modern fighter aircraft fuselage is another pertinent instance; its design minimizes wave drag at supersonic speeds, allowing for higher speeds and improved maneuverability. Further, design engineers in this sector contribute to the advancement of rotor blade profiles for helicopters, optimizing them for increased lift generation and reduced power consumption.

In summary, proficiency in aerodynamic optimization is not merely a desirable skill; it is a cornerstone of the profession. The ability to create and refine aerodynamically efficient designs directly translates to safer, more economical, and higher-performing flight vehicles. Challenges remain in optimizing designs for complex flow phenomena and integrating advanced technologies; however, continued innovation in this area is essential for the future of air and space travel.

3. Structural Integrity Analysis

Structural integrity analysis is a critical component of the responsibilities undertaken by professionals in the aerospace design engineering field. This analysis involves the application of engineering principles and computational tools to assess the ability of aircraft and spacecraft structures to withstand the various loads and stresses encountered during flight operations. The primary goal is to ensure the safety and reliability of the vehicle by preventing structural failure, which could have catastrophic consequences.

The importance of structural integrity analysis stems from the extreme conditions that aerospace vehicles must endure, encompassing aerodynamic forces, pressure differentials, thermal gradients, and vibrations. Finite element analysis (FEA) is frequently employed to simulate these conditions and predict the resulting stress distributions within the structure. For instance, the analysis of an aircraft wing structure under maximum aerodynamic load can identify areas of high stress concentration, allowing for design modifications to mitigate potential failure points. Another case is the detailed assessment performed on the International Space Station modules to ensure they can withstand the stresses of launch and maintain structural integrity in the vacuum of space.

Ultimately, structural integrity analysis is an indispensable element of the design process. It enables engineers to optimize structural designs, select appropriate materials, and implement necessary reinforcement measures. By rigorously analyzing the structural behavior of aerospace vehicles, engineers mitigate risks, enhance safety, and contribute to the overall success of air and space missions.

4. Systems integration expertise

The role necessitates a comprehensive understanding of how disparate components and systems interact to achieve overall vehicle functionality. Systems integration expertise forms a critical element, ensuring that various subsystems function cohesively and efficiently. Without it, optimized components risk failing when incorporated into a larger, uncoordinated system. This directly affects performance parameters such as fuel efficiency, payload capacity, and operational safety. For example, integrating a new, highly efficient engine into an existing aircraft design requires careful consideration of its compatibility with the aircraft’s fuel, electrical, and control systems. Improper integration could lead to performance degradation, system failures, or even catastrophic events.

A real-world illustration involves the development of advanced avionics systems. These systems comprise numerous sensors, processors, and displays that must seamlessly communicate and operate together. The systems integration expertise of the aerospace engineer is paramount in ensuring that these components are compatible, that data is transmitted accurately and efficiently, and that the overall system meets stringent safety and performance requirements. Furthermore, the design of unmanned aerial vehicles (UAVs) demands even more acute systems integration capabilities due to the complex interaction between flight control systems, communication links, sensor payloads, and power management systems.

In summary, systems integration expertise is not merely a supplementary skill but an intrinsic aspect of the role in the aerospace design field. It underpins the ability to create functional, reliable, and high-performance aircraft and spacecraft. The growing complexity of aerospace systems necessitates a deepened understanding of integration principles and a capacity to manage complex interactions between diverse technological elements. Overcoming integration challenges will be key to future advancements and ensuring the continued safety and efficiency of aerospace operations.

5. Materials selection proficiency

Materials selection proficiency constitutes a critical competency for design engineers working in the aerospace sector. The performance, safety, and longevity of aircraft and spacecraft are directly influenced by the materials employed in their construction. Engineers must possess a deep understanding of material properties, including strength, stiffness, density, corrosion resistance, and thermal behavior, to make informed decisions that optimize design outcomes. This expertise extends to both traditional aerospace materials, such as aluminum alloys and titanium, and advanced materials like composites, ceramics, and high-temperature alloys.

The selection of materials for a specific application requires careful consideration of the operating environment, loading conditions, and regulatory requirements. For example, the selection of materials for the exterior skin of a high-speed aircraft necessitates accounting for elevated temperatures caused by aerodynamic heating. Similarly, the design of composite structures for aircraft wings demands a thorough understanding of fiber orientation, resin properties, and manufacturing processes to ensure structural integrity. The Boeing 787 Dreamliner, with its extensive use of carbon fiber reinforced polymer (CFRP) in the fuselage and wings, exemplifies the importance of materials selection proficiency. The implementation of CFRP reduced weight, improved fuel efficiency, and lowered maintenance costs compared to traditional aluminum designs. Conversely, instances of improper material selection have led to structural failures, highlighting the practical significance of this expertise. Fatigue cracking in earlier aircraft designs prompted the development of more fatigue-resistant aluminum alloys and improved inspection techniques.

In conclusion, materials selection proficiency is not merely a desirable skill, it is an indispensable requirement. The ability to choose appropriate materials, accounting for the complex interplay of performance, cost, and regulatory factors, is essential for ensuring the safe and efficient operation of aircraft and spacecraft. The ongoing development of novel materials and manufacturing processes presents both opportunities and challenges, requiring design engineers to continuously update their knowledge and expertise in this crucial area.

6. Regulatory compliance adherence

Adherence to stringent regulatory standards is not merely a procedural requirement but an intrinsic aspect of design engineering within the aerospace domain. The implications of non-compliance extend beyond potential fines, directly impacting safety, operational effectiveness, and public trust in the aerospace industry.

- FAA Certification and Airworthiness Standards

The Federal Aviation Administration (FAA) sets forth comprehensive regulations governing aircraft design, manufacturing, and operation. A professional must ensure that all designs meet stringent airworthiness standards, encompassing structural integrity, flight performance, and system reliability. For instance, compliance with Part 25 of the Federal Aviation Regulations (FARs) dictates specific requirements for transport category aircraft, including mandatory testing and analysis to demonstrate safety under various flight conditions. Failure to adhere to these standards can result in denial of certification, grounding of aircraft, and potential legal repercussions.

- Environmental Regulations and Emissions Standards

Increasingly, regulations related to environmental impact are shaping design decisions. Organizations such as the International Civil Aviation Organization (ICAO) establish standards for aircraft noise and emissions. Engineers must incorporate design features that minimize noise pollution and reduce greenhouse gas emissions, such as advanced engine technologies and aerodynamic improvements. Non-compliance with these regulations can restrict access to certain airspace and result in significant financial penalties.

- Safety Management Systems (SMS) Integration

The integration of Safety Management Systems (SMS) principles into the design process represents a proactive approach to risk mitigation. Engineers are responsible for identifying potential hazards during the design phase and implementing safety features to minimize the likelihood and severity of accidents. This includes designing redundant systems, incorporating fail-safe mechanisms, and conducting thorough hazard analyses. Failure to integrate SMS principles can lead to designs that are inherently unsafe, increasing the risk of accidents and compromising passenger safety.

- Export Control and International Regulations

The aerospace industry is subject to strict export control regulations, particularly concerning technologies with potential military applications. Design engineers must be aware of regulations such as the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR) and ensure that designs do not violate these restrictions. This includes safeguarding sensitive technical data and preventing unauthorized access to controlled technologies. Non-compliance with export control regulations can result in severe penalties, including fines, imprisonment, and loss of export privileges.

These facets underscore the vital role of adherence to regulatory standards in ensuring the safety, environmental responsibility, and ethical conduct within the profession. By integrating regulatory considerations into every stage of the design process, engineers contribute to a safer, more sustainable, and more trustworthy aerospace industry.

7. Performance enhancement dedication

Performance enhancement dedication, as it pertains to those who engage in aerospace design, is not merely a desire for incremental improvement; it constitutes a foundational ethos. This dedication directly influences the design process, leading to advancements in areas such as fuel efficiency, payload capacity, speed, and maneuverability. Without a consistent focus on enhancing performance metrics, innovation stagnates, and progress in aviation and space travel is hampered. The cause-and-effect relationship is clear: dedicated effort toward performance improvement yields tangible results in vehicle capabilities. For instance, persistent efforts to reduce aircraft weight through advanced materials have resulted in significant fuel savings for airlines, translating directly to economic and environmental benefits.

Consider the development of scramjet engines. The pursuit of hypersonic flight necessitates constant performance refinement in propulsion systems. Design engineers involved in this endeavor dedicate themselves to overcoming challenges related to high-temperature materials, combustion efficiency, and aerodynamic drag. Their iterative design processes, incorporating computational modeling and experimental validation, reflect a deep-seated commitment to maximizing engine performance. Another example involves the development of advanced flight control systems that enable greater maneuverability and stability in aircraft. The complex algorithms and hardware components of these systems are continuously refined to enhance aircraft responsiveness and safety.

In conclusion, performance enhancement dedication is an indispensable attribute for design engineers in the aerospace field. It is the driving force behind innovation, leading to more efficient, capable, and safer aircraft and spacecraft. This dedication necessitates a continuous cycle of analysis, experimentation, and refinement, ensuring that aerospace technology consistently pushes the boundaries of what is possible. The practical significance of this understanding lies in recognizing the critical role of these professionals in shaping the future of air and space travel.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding the function, providing concise and informative responses.

Question 1: What are the fundamental differences between designing commercial aircraft versus military aircraft?

Designing commercial aircraft places a primary emphasis on fuel efficiency, passenger comfort, and operating economics, adhering to strict safety regulations. Military aircraft design prioritizes performance characteristics such as speed, maneuverability, and payload capacity, often accepting higher operational costs and maintenance demands. Different regulatory frameworks and operational environments further differentiate the design process.

Question 2: How crucial is knowledge of specific CAD/CAM software packages for entry-level positions?

Proficiency in industry-standard CAD/CAM software, such as CATIA, SolidWorks, or NX, is highly beneficial. While entry-level positions may not require expert-level skills, a working knowledge of these tools significantly enhances employability and allows for more immediate contributions to design projects. Demonstrated experience through academic projects or personal endeavors is often viewed favorably.

Question 3: What are the most common challenges encountered during the design phase of aerospace projects?

Common challenges include managing complex system integrations, mitigating weight constraints, ensuring structural integrity under extreme conditions, and adhering to stringent regulatory requirements. Balancing competing design objectives, such as performance versus cost, also presents a significant challenge. Effective communication and collaboration among multidisciplinary teams are crucial for overcoming these obstacles.

Question 4: How has the increasing use of composite materials affected design methodologies?

The increased adoption of composite materials has necessitated a shift towards more sophisticated design and analysis techniques. Unlike traditional metallic materials, composites exhibit anisotropic properties, requiring specialized FEA software and expertise in laminate theory. Manufacturing considerations, such as layup procedures and curing processes, also play a more prominent role in the design process.

Question 5: What role does sustainability play in contemporary aerospace design?

Sustainability considerations are increasingly integrated into aerospace design, driven by both regulatory pressures and market demands. This includes efforts to reduce fuel consumption through aerodynamic improvements, develop alternative propulsion systems (e.g., electric or hybrid-electric), and utilize more sustainable materials. Life cycle assessment (LCA) techniques are employed to evaluate the environmental impact of design choices.

Question 6: What emerging technologies are likely to have the greatest impact on the profession in the next decade?

Several emerging technologies are poised to transform the aerospace engineering landscape. These include additive manufacturing (3D printing) for rapid prototyping and customized component fabrication, advanced artificial intelligence (AI) and machine learning (ML) for design optimization and predictive maintenance, and the development of hypersonic propulsion systems for high-speed flight. Quantum computing may also contribute to breakthroughs in materials science and computational analysis.

Understanding these key aspects provides a clearer perspective on the scope, challenges, and opportunities inherent in the function.

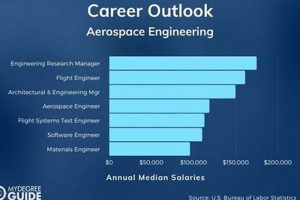

The subsequent article sections will explore potential career paths and future outlook within the industry.

Conclusion

This exploration has illuminated the multifaceted nature of the role. It demands a potent combination of theoretical knowledge, practical skills, and unwavering dedication to both safety and performance. The analysis of core attributes underscores the depth of expertise required, ranging from aerodynamic optimization and structural integrity analysis to systems integration and regulatory compliance. Each aspect is inextricably linked to the overall success and reliability of flight vehicles.

The continued advancement of air and space travel hinges on the capabilities and innovations of these dedicated professionals. As technology evolves and challenges emerge, the demand for highly skilled individuals in this field remains strong. The pursuit of excellence in aerospace design engineering is not only a career path but a contribution to progress, shaping the future of flight and exploration for generations to come. The rigorous demands are matched by the potential for significant impact, driving advancements that redefine the limits of what is achievable.