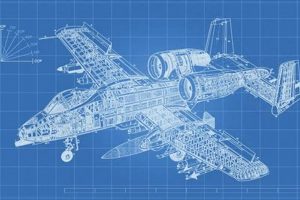

The discipline integrates multiple engineering branches, including aerodynamics, propulsion, materials science, and structural analysis, to design, develop, and test aircraft and spacecraft. One prominent entity in the space sector exemplifies the application of these principles through the design and manufacturing of rockets and spacecraft with the goal of reducing space transportation costs and enabling the colonization of Mars.

Such endeavors are crucial for advancing space exploration, satellite technology, and national security. Innovations in reusable rocket technology, advanced materials, and autonomous systems are driving down the cost of access to space. This subsequently fosters new opportunities for scientific research, commercial ventures, and resource utilization beyond Earth’s atmosphere, impacting global economies and future technological advancements.

The following sections delve into specific advancements and challenges within this field, focusing on areas like propulsion systems, vehicle design, and the complexities of space mission planning. Further analysis examines the integration of cutting-edge technologies and the evolving regulatory landscape governing activities beyond our planet.

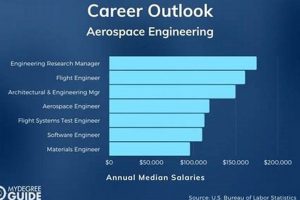

Guidance for Aspiring Professionals

Navigating a career path within the space sector requires focused preparation, technical proficiency, and a dedication to innovation. The following recommendations are designed to offer structured guidance.

Tip 1: Emphasize Foundational Knowledge: A strong grasp of mathematics, physics, and computer science is paramount. These disciplines form the bedrock of the industry and enable engineers to address complex problems effectively.

Tip 2: Cultivate Specialization: Identifying and developing expertise in a niche area, such as propulsion systems, orbital mechanics, or avionics, enhances an individual’s marketability and contribution to specialized projects.

Tip 3: Pursue Advanced Education: A master’s degree or doctorate can provide in-depth knowledge and research experience, positioning candidates for leadership roles and involvement in cutting-edge research and development.

Tip 4: Gain Practical Experience: Internships, co-op programs, and research assistantships offer invaluable hands-on experience and exposure to real-world engineering challenges. Active participation in student design teams and competitions further demonstrates practical skills.

Tip 5: Develop Systems Thinking: Understand the interconnectedness of various engineering disciplines and the importance of considering the system as a whole when designing and analyzing complex aerospace systems. This involves comprehending how different components interact and impact overall performance.

Tip 6: Stay Current with Industry Trends: Actively follow industry publications, attend conferences, and engage with professional organizations to remain abreast of emerging technologies, market trends, and regulatory changes. Continuous learning is essential for career advancement.

Tip 7: Build a Strong Network: Actively connect with professionals in the field through networking events, online forums, and professional societies. Building relationships can open doors to mentorship opportunities, collaborations, and career prospects.

By adhering to these guidelines and focusing on continuous improvement, individuals can better position themselves for success in a dynamic and challenging industry. Such preparation contributes to not only individual career growth but also to advancements in the broader field.

The next section will examine specific career paths and opportunities within the industry, highlighting the roles and responsibilities associated with various positions.

1. Reusable Rocket Technology

Reusable rocket technology represents a paradigm shift in space access, and its implementation is central to the engineering approach of a prominent entity in the aerospace sector. This technology, directly impacting launch costs, relies on complex integration of aerodynamics, propulsion, and advanced materials science. The capacity to recover and reuse a substantial portion of a launch vehicle, most notably the first stage booster, leads to significant reductions in the overall expense per launch. This contrasts sharply with traditional expendable launch systems, where each mission necessitates the construction of a new rocket.

The engineering challenges inherent in reusable rocket systems are considerable. Precise trajectory control during descent and landing, robust thermal protection systems to withstand atmospheric reentry, and rapid refurbishment processes are critical elements. Successful implementation demands innovative design solutions and meticulous attention to detail across multiple engineering disciplines. For example, the Falcon 9 rocket employs grid fins for aerodynamic control, cold gas thrusters for precise orientation, and a landing leg system for stable touchdown. These components must function reliably under extreme conditions, necessitating rigorous testing and iterative improvements.

The practical significance of reusable rocket technology extends beyond mere cost reduction. It accelerates the pace of space exploration and development, allowing for more frequent and affordable access to orbit. This, in turn, fosters opportunities for commercial satellite deployment, scientific research, and eventually, ambitious endeavors such as interplanetary travel. Continued refinement of reusable systems holds the key to unlocking the full potential of space and transforming it from an exclusive domain into a more accessible frontier.

2. Propulsion System Innovation

Propulsion system advancements are intrinsically linked to the realization of goals within commercial spaceflight. The pursuit of reusable launch vehicles, a signature endeavor of the organization, hinges on the development of engines capable of withstanding repeated use and delivering high performance. For instance, the development of the Raptor engine, designed for the Starship program, aims to achieve unprecedented thrust and efficiency through a full-flow staged combustion cycle, a departure from traditional rocket engine designs. This innovation is a direct response to the demand for a propulsion system suitable for interplanetary travel and large-scale payload delivery, thereby reducing the cost per unit mass transported to orbit.

Further illustration of this connection can be seen in the iterative improvements made to the Merlin engines used in the Falcon 9 and Falcon Heavy rockets. Each iteration has focused on enhancing thrust-to-weight ratio, increasing combustion efficiency, and simplifying manufacturing processes. These incremental changes, while seemingly minor, contribute significantly to the overall reliability and performance of the launch vehicles. The ability to precisely control engine thrust and vectoring is also crucial for successful landing maneuvers, highlighting the synergistic relationship between propulsion system design and the broader architecture of reusable rocket technology.

In summary, continuous improvements and revolutionary designs in propulsion systems are fundamental to the overall success of initiatives in commercial spaceflight. The focus on reliability, efficiency, and reusability directly supports ambitious missions, drives down launch costs, and fosters a more sustainable and accessible space economy. This focus, however, faces ongoing challenges related to material science, combustion instability, and thermal management, necessitating sustained investment in research and development.

3. Mission Cost Reduction

Mission cost reduction is a central driver within the aerospace sector, particularly evident in the strategic objectives of a prominent company in the field. This pursuit influences design choices, operational strategies, and technological innovations, fundamentally shaping the economics of space access.

- Vertical Integration and In-House Manufacturing

Vertical integration, encompassing the design, manufacturing, and launch operations within a single entity, allows for greater control over the supply chain and reduces reliance on external vendors. This in-house capability fosters economies of scale and facilitates rapid iteration based on real-world performance data. For example, the fabrication of rocket engines and avionics systems internally minimizes markups and allows for customized solutions tailored to specific mission requirements.

- Economies of Scale Through Standardized Design

Employing standardized designs across multiple launch vehicles and spacecraft components allows for increased production volumes, thereby lowering the unit cost of manufacturing. This approach leverages commonality in tooling, training, and logistical support, resulting in significant cost savings. The use of a common engine architecture across different rocket stages exemplifies this strategy.

- Software Automation and Streamlined Operations

Automating mission control functions, launch procedures, and post-flight analysis reduces the need for extensive human intervention, leading to lower operational costs. Software-driven automation minimizes errors, accelerates turnaround times, and allows for more efficient resource allocation. An example is the implementation of autonomous flight safety systems that require minimal oversight from ground control personnel.

- Reusable Hardware and Refurbishment Processes

The development of reusable rocket stages, specifically the first stage boosters, is a cornerstone of cost reduction efforts. Implementing efficient refurbishment processes, including rapid inspection, repair, and re-certification procedures, maximizes the lifespan of reusable hardware and minimizes the cost per flight. Innovations in materials science and non-destructive testing techniques contribute to the feasibility and reliability of reusable components.

The combined effect of these strategies is a substantial decrease in the cost of launching payloads into orbit, directly impacting the viability of commercial space ventures and enabling new possibilities for scientific exploration and technological development. These advancements underscore the integral relationship between strategic engineering choices and the economic feasibility of space missions.

4. Rapid Prototyping Methods

Rapid prototyping methods are critical to accelerating development cycles and fostering innovation within the aerospace sector, particularly within organizations aiming for frequent design iterations and reduced time-to-market. These methods leverage advanced technologies and streamlined workflows to quickly create tangible models and functional prototypes, enabling engineers to test concepts and identify design flaws early in the development process.

- 3D Printing and Additive Manufacturing

3D printing allows for the rapid creation of complex geometries and customized components directly from digital designs. This capability is especially valuable for producing lightweight structural elements, rocket engine parts, and specialized tooling. For instance, the creation of complex injector heads for rocket engines, which would be difficult and time-consuming using traditional manufacturing techniques, becomes feasible with 3D printing, allowing for iterative design improvements based on performance testing.

- Computational Fluid Dynamics (CFD) Simulations

CFD simulations provide a virtual environment for testing aerodynamic performance, thermal behavior, and structural integrity of designs before physical prototypes are built. This approach allows engineers to identify potential issues, such as flow separation or excessive stress concentrations, and optimize designs accordingly. For example, CFD simulations can be used to refine the shape of a rocket’s nose cone to minimize drag during atmospheric flight.

- Hardware-in-the-Loop (HIL) Testing

HIL testing integrates real-time simulations with physical hardware to evaluate the performance of control systems and avionics under realistic operating conditions. This method allows engineers to test the interaction between software and hardware components, identify potential integration issues, and validate system functionality before actual flight. For instance, HIL testing can be used to evaluate the performance of a rocket’s guidance, navigation, and control system during simulated launch scenarios.

- Agile Development and Iterative Design

Agile development principles emphasize iterative design cycles, frequent testing, and continuous feedback to rapidly improve product designs. This approach encourages collaboration between engineers from different disciplines, promotes early identification of design flaws, and allows for flexible adaptation to changing requirements. This method can involve wind tunnel tests with rapidly manufactured wing prototypes, incorporating gathered data to make design adjustments and quickly retest.

In essence, the deployment of rapid prototyping methods provides a strategic advantage by reducing development time, minimizing costs, and fostering a culture of innovation. The ability to quickly iterate on designs and validate performance through simulations and physical testing allows the sector to push the boundaries of what is possible in space exploration and commercial spaceflight, ultimately contributing to more reliable, efficient, and cost-effective space access.

5. Interplanetary Travel Goals

Interplanetary travel, once relegated to the realm of science fiction, now stands as a tangible objective driving innovation and development. The engineering challenges inherent in reaching and establishing a presence on other planets require the integration of advanced technologies and strategic design principles.

- Propulsion System Development

Achieving interplanetary voyages mandates propulsion systems capable of generating substantial thrust, achieving high exhaust velocities, and operating reliably over extended durations. The development of advanced rocket engines, such as those utilizing cryogenic propellants or nuclear thermal propulsion, is critical. For example, the ongoing development of methane-fueled engines is intended to leverage potential in-situ resource utilization on Mars, thereby reducing the reliance on Earth-based supplies. This propulsion capability directly impacts mission duration, payload capacity, and overall mission feasibility.

- Radiation Shielding and Life Support Systems

Long-duration space travel exposes astronauts to significant levels of cosmic radiation and requires self-sustaining life support systems. Engineering solutions encompass the development of advanced shielding materials, closed-loop environmental control systems, and reliable food production techniques. For instance, research into water recycling and in-space resource utilization, such as extracting water ice from Martian soil, is vital for minimizing resupply requirements and ensuring crew survival. These advancements are essential for mitigating health risks and enabling long-term human presence beyond Earth.

- Autonomous Navigation and Landing Systems

Interplanetary missions require autonomous navigation capabilities due to the communication delays inherent in deep space travel. Precision landing systems are also crucial for safely delivering payloads and crews to designated locations on other planets. The development of sophisticated sensors, algorithms, and control systems is paramount. For example, the use of terrain-relative navigation enables spacecraft to autonomously identify landing sites and adjust their trajectories in real-time, ensuring a safe and accurate touchdown. These automated systems are necessary for mitigating risks and ensuring mission success in remote and unpredictable environments.

- In-Situ Resource Utilization (ISRU)

The long-term sustainability of interplanetary settlements depends on the ability to utilize resources available on other planets. ISRU technologies encompass the extraction, processing, and utilization of local materials to produce water, oxygen, fuel, and building materials. For example, the Sabatier process, which combines carbon dioxide and hydrogen to produce methane and water, could be employed on Mars to generate propellant for return trips to Earth. ISRU significantly reduces the logistical burden and cost associated with resupplying missions from Earth, thereby enabling long-term human presence and exploration.

These facets, collectively, illustrate the engineering challenges and technological advancements required for realizing interplanetary travel objectives. The pursuit of these goals is a catalyst for innovation in diverse engineering disciplines, ultimately driving progress in both space exploration and terrestrial technologies.

Frequently Asked Questions

This section addresses common inquiries regarding the intersection of aerospace engineering principles and the operational strategies of a prominent space exploration company. The following questions and answers aim to provide clarity on pertinent topics.

Question 1: What are the primary engineering disciplines involved in developing reusable rocket technology?

Reusable rocket development necessitates expertise across various engineering domains. Core disciplines include: aerodynamics (for stable flight and reentry), propulsion (for efficient ascent and descent), materials science (for withstanding extreme temperatures and stresses), structural analysis (for ensuring vehicle integrity), and avionics (for precise control and navigation).

Question 2: How does vertical integration contribute to reducing mission costs?

Vertical integration, encompassing in-house design, manufacturing, and launch operations, reduces reliance on external suppliers and streamlines processes. This approach fosters greater control over the supply chain, enables rapid iteration based on performance data, and minimizes markups associated with external vendors. Efficiencies gained translate directly into lower mission costs.

Question 3: What role does rapid prototyping play in advancing space technology?

Rapid prototyping methods, such as 3D printing and computational fluid dynamics, enable engineers to quickly create tangible models and virtual simulations of designs. This allows for early identification of design flaws, accelerated development cycles, and reduced time-to-market for innovative solutions. Iterative design and testing contribute to more reliable and efficient systems.

Question 4: What are the key challenges associated with developing propulsion systems for interplanetary travel?

Propulsion systems for interplanetary travel must generate substantial thrust, achieve high exhaust velocities, and operate reliably over extended durations. Challenges include developing engines capable of withstanding long-term operation in the harsh space environment, managing cryogenic propellants to minimize boil-off, and ensuring efficient combustion to maximize performance. Advanced materials and innovative engine designs are critical.

Question 5: How does in-situ resource utilization (ISRU) contribute to the feasibility of long-term space exploration?

ISRU, which involves utilizing resources available on other planets, reduces the logistical burden and cost associated with resupplying missions from Earth. Technologies for extracting water, oxygen, fuel, and building materials from local resources minimize reliance on Earth-based supplies, enabling long-term human presence and exploration. ISRU is essential for establishing sustainable settlements beyond Earth.

Question 6: What are the primary factors driving the ongoing efforts to reduce the cost of space access?

Key drivers include reusable rocket technology, standardized designs, automated operations, and vertical integration. Reusable hardware significantly reduces the cost per flight, while standardized components lower manufacturing expenses. Automation streamlines processes, and vertical integration minimizes reliance on external vendors, all contributing to more affordable space access.

In summary, these FAQs highlight the engineering principles, operational strategies, and technological advancements shaping the landscape of space exploration. Understanding these factors is crucial for appreciating the complexities and potential of ongoing endeavors.

The subsequent section will explore the regulatory environment governing space activities and the evolving landscape of space law.

Conclusion

This document has examined facets central to the ongoing evolution within the field of aerospace engineering as exemplified by the operational and technological strategies of SpaceX. Discussions have encompassed reusable rocket technology, innovative propulsion systems, cost reduction methodologies, rapid prototyping techniques, and objectives related to interplanetary travel. Each element contributes to a complex framework driving progress and redefining the possibilities of space access.

Continued diligence in research, development, and responsible implementation of these technologies remains paramount. The sustained advancement of the sector requires a commitment to rigorous engineering principles, ethical considerations, and collaborative endeavors that extend beyond individual entities. The future trajectory of space exploration and its impact on global society hinges on the collective actions and informed decisions of stakeholders across the engineering, scientific, and political landscapes.