This entity represents a significant player within the British aviation and defense industry. Operating as a limited company, it focuses on the design, manufacture, and support of aerospace systems and components. This type of organization contributes to both the national economy and defense capabilities through technological innovation and job creation.

Its presence is vital for maintaining a competitive edge in the global aerospace market. The company’s activities foster technological advancements, attract investment, and provide skilled employment opportunities. Historically, such enterprises have played a crucial role in driving industrial growth and shaping national security strategies.

The following sections will delve deeper into the specific contributions, operational aspects, and market position of similar organizations within the United Kingdom’s aerospace sector.

Strategic Guidance for Aerospace Manufacturers

The subsequent points offer insights applicable to entities operating within the aerospace manufacturing sector, focusing on optimization and sustained success.

Tip 1: Prioritize Technological Innovation: Sustained investment in research and development is paramount. This facilitates the creation of cutting-edge products and services, ensuring competitiveness in a rapidly evolving market. For instance, explore advanced materials, additive manufacturing, and autonomous systems.

Tip 2: Emphasize Supply Chain Resilience: Diversify supplier networks to mitigate potential disruptions. Conduct regular risk assessments and establish contingency plans to ensure continuity of operations. Maintaining strategic reserves of critical components can also prove beneficial.

Tip 3: Foster a Culture of Continuous Improvement: Implement lean manufacturing principles and Six Sigma methodologies to optimize processes, reduce waste, and enhance efficiency. Regular audits and employee training are crucial for driving continuous improvement initiatives.

Tip 4: Strengthen Cybersecurity Protocols: Given the sensitive nature of data involved, robust cybersecurity measures are essential. Implement multi-layered security systems, conduct regular penetration testing, and ensure compliance with relevant industry standards and regulations.

Tip 5: Cultivate Strategic Partnerships: Collaborate with universities, research institutions, and other industry players to access expertise, share resources, and accelerate innovation. Participating in industry consortia can also provide valuable networking opportunities.

Tip 6: Maintain Regulatory Compliance: Adherence to aviation regulations and quality standards is non-negotiable. Establish a dedicated compliance department and conduct regular audits to ensure ongoing conformity with all applicable legal and industry requirements.

Tip 7: Invest in Workforce Development: Address the skills gap by providing comprehensive training and development opportunities for employees. Partner with vocational schools and universities to cultivate a pipeline of qualified talent.

By focusing on these areas, manufacturers can enhance their operational efficiency, mitigate risks, and solidify their position within the competitive aerospace landscape.

The following section will present a conclusive summary of the key aspects discussed.

1. Manufacturing

The manufacturing arm of a UK aerospace entity represents the core operational function, directly translating designs and specifications into tangible products. This process encompasses a wide array of activities, from fabricating individual components to assembling complex systems such as aircraft structures, engines, or avionics. The efficiency and precision of these manufacturing operations directly influence product quality, delivery timelines, and overall cost-effectiveness. A robust manufacturing capability is, therefore, a fundamental component of competitiveness within the global aerospace market.

Consider the production of aircraft wings. This requires specialized machinery for milling aluminum alloys or laying up composite materials, alongside skilled technicians to operate these machines and ensure dimensional accuracy. Any inefficiency in this process, such as equipment downtime or material waste, can significantly impact the overall manufacturing cost and schedule. Furthermore, the integration of advanced manufacturing technologies, such as robotic automation and 3D printing, offers the potential to streamline production processes, reduce labor costs, and improve component performance. For instance, additive manufacturing allows for the creation of complex geometries that are difficult or impossible to produce using conventional methods.

In summary, manufacturing forms the bedrock upon which the success of a UK aerospace organization is built. Its efficiency, precision, and adoption of advanced technologies are critical determinants of product quality, cost-effectiveness, and competitiveness. By prioritizing manufacturing excellence, these entities can ensure their sustained growth and contribution to the broader aerospace sector.

2. Technology

Technology forms the very essence of any successful aerospace company, including a British entity. It is not merely an adjunct but rather an integral driver of design, manufacturing, operational efficiency, and strategic competitiveness. Technological advancements directly influence the capabilities of aerospace systems, ranging from improved fuel efficiency and enhanced safety features to more sophisticated navigation and communication systems. A commitment to technological innovation is, therefore, a prerequisite for survival and growth in this demanding sector. Consider, for example, the development of lighter and stronger composite materials. This technology allows for the creation of aircraft structures that are both more fuel-efficient and capable of withstanding extreme stress conditions, leading to both economic and performance benefits.

The application of advanced technologies extends beyond the design and manufacturing phases to encompass operational aspects as well. For instance, the implementation of sophisticated data analytics and predictive maintenance technologies can significantly reduce downtime and improve the reliability of aircraft systems. Real-time monitoring of engine performance, coupled with advanced diagnostic algorithms, allows for the early detection of potential problems, enabling proactive maintenance interventions. Similarly, the integration of digital twins virtual representations of physical assets allows for the simulation and optimization of system performance under a wide range of operating conditions. Moreover, technology is enabling enhanced cybersecurity protocols to protect sensitive data and systems from evolving threats, safeguarding critical infrastructure and intellectual property.

In conclusion, technology is not simply a component of aerospace operations but rather the catalyst for innovation and progress. British aerospace companies must prioritize investment in research and development, cultivate strategic partnerships with technology providers, and foster a culture of continuous learning to remain competitive. By embracing technological advancements, they can enhance their product offerings, improve operational efficiency, and contribute to the advancement of the global aerospace industry.

3. Innovation

Innovation is not merely a desirable attribute but a fundamental imperative for organizations operating within the aerospace sector, particularly for British entities. The relentless pursuit of advancements in technology, design, and manufacturing processes is essential for maintaining a competitive edge in the global market and ensuring long-term sustainability. These organizations are key drivers and beneficiaries of innovation.

- Materials Science Advancement

The development and application of novel materials, such as advanced composites, lightweight alloys, and nanomaterials, is crucial. For example, research into carbon fiber reinforced polymers (CFRP) has enabled the creation of lighter and stronger aircraft structures, leading to improved fuel efficiency and reduced emissions. This directly impacts operational costs and environmental sustainability. The incorporation of graphene into composite materials promises even greater strength-to-weight ratios, further driving innovation in airframe design.

- Digital Transformation of Manufacturing

The integration of digital technologies, including additive manufacturing (3D printing), automation, and artificial intelligence (AI), is transforming aerospace manufacturing processes. Additive manufacturing allows for the creation of complex geometries and customized parts, reducing lead times and material waste. For example, printing engine components with integrated cooling channels optimizes performance and reduces fuel consumption. AI-powered systems enable predictive maintenance, reducing downtime and improving operational efficiency.

- Autonomous Systems Development

Innovation in autonomous systems is driving the development of unmanned aerial vehicles (UAVs) and autonomous flight control systems. These technologies have applications ranging from surveillance and reconnaissance to cargo delivery and passenger transport. The development of robust and reliable autonomous flight control algorithms is essential for ensuring safety and regulatory compliance. For example, the use of AI-powered object recognition systems enables UAVs to navigate complex environments and avoid collisions.

- Sustainable Aviation Technologies

The aerospace sector is under increasing pressure to reduce its environmental impact. Innovation in sustainable aviation technologies, such as electric propulsion, hybrid-electric systems, and sustainable aviation fuels (SAF), is critical for achieving emissions reduction targets. The development of high-energy-density batteries and efficient electric motors is essential for enabling electric-powered aircraft. The production of SAF from renewable sources offers a pathway to reducing the carbon footprint of traditional jet engines. Organizations focused on aerospace innovation must consider both performance and environmental sustainability.

These examples demonstrate that innovation is a multifaceted and interconnected process that is essential for success in the aerospace sector. British organizations must embrace a culture of innovation and invest in research and development to maintain a competitive edge and contribute to the advancement of aerospace technology. Prioritizing innovation ensures long-term viability in a global market characterized by constant change and increasing technological demands. Investment into it helps boost the British economy and creates skilled jobs.

4. Regulation

The operational framework of an entity within the British aerospace sector is intrinsically linked to a comprehensive and stringent regulatory environment. These regulations, mandated by national and international bodies, govern every aspect of its activities, from design and manufacturing to maintenance and operation. Non-compliance carries significant consequences, including fines, operational restrictions, and reputational damage. For example, regulations dictate stringent testing protocols for aircraft components to ensure structural integrity and passenger safety. The European Union Aviation Safety Agency (EASA) sets many of these standards. After Brexit, the UK Civil Aviation Authority (CAA) adapts and enforces these regulations. This ensures continued airworthiness and safety within UK aerospace operations.

Adherence to regulatory standards is not merely a matter of compliance but a fundamental component of ensuring safety, maintaining public trust, and fostering international cooperation. UK entities involved in aerospace collaborate with regulatory bodies to develop and implement best practices. This collaborative approach promotes innovation while upholding the highest safety standards. For instance, the development of new aircraft technologies requires close coordination with regulatory authorities to ensure that the design meets all safety requirements. The regulatory framework supports innovation by setting clear performance standards and providing a predictable environment for investment. Failure to proactively engage with regulatory changes can stifle innovation and impede market access. An entity within the UK aerospace sector must see regulatory compliance as an opportunity for continuous improvement and a driver of innovation.

In summary, regulation provides the essential framework for sustainable and responsible growth within the British aerospace sector. By prioritizing regulatory compliance, entities within the UK demonstrate their commitment to safety, quality, and ethical business practices. The challenge lies in navigating the complexity of regulatory requirements while maintaining a competitive edge and driving innovation. Proactive engagement with regulatory bodies and a commitment to continuous improvement are key to unlocking the benefits of a robust regulatory environment.

5. Employment

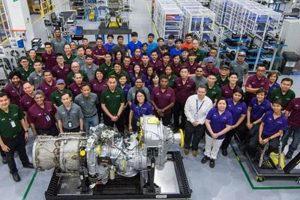

The aerospace sector, particularly entities operating within the United Kingdom, represents a significant source of high-skilled employment. These companies, which design, manufacture, and maintain aircraft and related systems, require a diverse workforce encompassing engineers, technicians, project managers, and specialized manufacturing personnel. The demand for these skilled professionals directly impacts employment rates and economic growth within the regions where these companies are located. For example, a large aerospace manufacturer often partners with local universities and vocational schools to create training programs tailored to its specific workforce needs, thereby ensuring a steady supply of qualified candidates.

The impact of the aerospace industry on employment extends beyond direct positions within the company itself. A robust supply chain supports these manufacturers, creating additional job opportunities within smaller businesses that provide components, materials, and specialized services. This multiplier effect demonstrates the broad economic significance of the aerospace sector. Further, the advanced nature of aerospace work contributes to a higher average wage compared to other manufacturing sectors, attracting talented individuals and boosting regional economies. However, challenges exist, including the need to constantly adapt to technological advancements. Continuous investment in training and upskilling programs is essential for ensuring that the workforce remains competitive.

In conclusion, the aerospace sector within the UK plays a crucial role in providing high-skilled employment opportunities. This positive impact requires ongoing commitment to education, training, and adaptation to emerging technologies. Ensuring a strong and capable workforce is essential for maintaining the global competitiveness of this industry and supporting sustained economic growth. The practical significance of understanding this connection lies in the ability to strategically invest in workforce development initiatives, fostering a mutually beneficial relationship between the aerospace sector and the broader community.

6. Exports

The export activities are critically important to the financial performance and overall success. These activities represent a substantial revenue stream, contribute to the nation’s trade balance, and enhance the reputation of the United Kingdom within the global aerospace market. The ability to successfully export aerospace products and services depends on factors like technological innovation, competitive pricing, and adherence to international standards. Effective export strategies are essential to long-term sustainability.

- Revenue Generation

Exporting aerospace products directly contributes to revenue growth. Sales of aircraft, components, and related services to international customers generate significant income, which can be reinvested in research and development, infrastructure improvements, and workforce training. For example, the sale of a fleet of commercial aircraft to an overseas airline generates substantial revenue that supports domestic manufacturing and employment.

- Balance of Trade Improvement

Aerospace exports play a vital role in improving the United Kingdom’s balance of trade. By exporting high-value products, the nation can offset imports and reduce its trade deficit. The value of aerospace exports significantly exceeds the value of aerospace imports, contributing positively to the national economy. The sector becomes a net exporter.

- Market Diversification

Exporting to multiple international markets reduces dependence on domestic demand and mitigates risks associated with economic downturns in specific regions. Diversification provides stability and resilience, ensuring continued revenue streams even during periods of domestic economic volatility. Pursuing opportunities in emerging markets with growing aviation sectors is often beneficial.

- Technological Advancement

Competing in the global export market necessitates continuous innovation and technological advancement. To meet the demands of international customers, manufacturers must invest in research and development to create cutting-edge products that offer superior performance and efficiency. The need to compete globally drives innovation and keeps the UK aerospace sector at the forefront of technological development.

The significance of exports to organizations within the UK aerospace sector cannot be overstated. Export activity is a driver of revenue growth and a vital component of the nation’s economic prosperity. Maintaining a strong export focus requires strategic investments in technological innovation, efficient manufacturing processes, and robust international marketing strategies. In this environment, proactive engagement with international customers and adherence to global standards are essential for sustaining export success.

7. Defense

The relationship between defense and a UK aerospace entity is fundamentally intertwined. The defense sector represents a significant customer for many aerospace companies. Organizations design, manufacture, and maintain military aircraft, weapon systems, and surveillance technologies. This close relationship dictates a focus on national security interests and the provision of technologically advanced solutions for defense applications. The performance of aerospace companies directly impacts the effectiveness and capabilities of the armed forces. As an illustrative example, an entity could develop and produce advanced radar systems for military aircraft, enhancing the nation’s air defense capabilities. The defense sector therefore acts as a powerful catalyst for innovation and technological advancement within the UK aerospace industry.

The economic impact of defense contracts on a UK aerospace organization extends beyond immediate revenue generation. These contracts often involve long-term commitments, providing financial stability and encouraging investment in research and development. Furthermore, defense contracts typically require adherence to rigorous quality standards and testing procedures, fostering excellence in manufacturing and engineering. The development of next-generation fighter aircraft provides a tangible example of this. The development requires considerable investment in cutting-edge technologies, contributing to the overall technological capabilities of the UK aerospace sector. Additionally, collaboration with defense agencies facilitates knowledge transfer and the development of dual-use technologies applicable to both military and civilian sectors.

The sustained success of a UK aerospace entity hinges on its ability to effectively serve the defense sector. Understanding the unique requirements and priorities of military customers is essential for developing tailored solutions. However, over-reliance on defense contracts also poses risks, as fluctuations in government spending or changes in defense priorities can significantly impact revenue. Therefore, diversification into civilian markets represents a strategic imperative for long-term stability. The connection to defense will continue to be vital, but aerospace organizations must manage the risks effectively and proactively position themselves for future growth.

Frequently Asked Questions

The following addresses common queries concerning the operations and implications of a British aerospace entity, providing a clear and objective understanding.

Question 1: What are the primary activities undertaken by a typical UK aerospace limited company?

The core activities generally encompass the design, manufacture, and maintenance of aircraft, components, and related systems. These organizations may also engage in research and development, contributing to technological advancements within the sector.

Question 2: How does this type of organization contribute to the UK economy?

Economic contributions are multifaceted, including revenue generation through exports, job creation across various skill levels, and investment in technological innovation. These organizations often serve as significant employers within their respective regions.

Question 3: What regulatory frameworks govern the operations of a British aerospace entity?

Regulatory oversight is provided by both national and international bodies, including the UK Civil Aviation Authority (CAA) and the European Union Aviation Safety Agency (EASA). These frameworks ensure safety, quality, and compliance with industry standards.

Question 4: How does the defense sector influence the activities of such an organization?

The defense sector often represents a substantial customer base for aerospace organizations, driving demand for military aircraft, weapon systems, and surveillance technologies. This relationship fosters innovation and technological advancement in support of national security interests.

Question 5: What skills and qualifications are typically required for employment within this sector?

Employment opportunities span a wide range of disciplines, including engineering, manufacturing, project management, and specialized technical roles. Relevant qualifications often include degrees in engineering, physics, or related fields, along with specialized certifications.

Question 6: What are the primary challenges and opportunities facing these organizations in the current market?

Challenges include adapting to technological advancements, navigating complex regulatory environments, and maintaining competitiveness in a global market. Opportunities lie in innovation, diversification into new markets, and collaboration with industry partners.

The insights provided offer a comprehensive overview of the key aspects related to such British aerospace businesses.

The following segment will offer a conclusive perspective.

Conclusion

This exploration has illuminated the significance of entities such as UK Aerospace Ltd within the British industrial landscape. It has demonstrated the multifaceted contributions across manufacturing, technological advancement, employment generation, and regulatory compliance. The organization’s engagement with both civilian and defense sectors, alongside its export activities, positions it as a critical component of the national economy. Understanding these key aspects provides a comprehensive perspective on the role and impact of such enterprises.

Sustained investment in innovation, a commitment to workforce development, and proactive engagement with global markets will be crucial for navigating future challenges. The continued success of British aerospace entities will not only benefit the national economy but also reinforce the United Kingdom’s position as a leader in aerospace technology and manufacturing. Focused strategic planning is, therefore, essential for ensuring long-term growth and continued contribution to the global aerospace sector.