This entity represents a collective of organizations involved in the design, development, manufacture, and support of aircraft and related systems. Such organizations contribute to both civilian and military sectors, providing essential transportation, defense, and technological advancements. Their activities encompass a wide range of disciplines, including aerodynamics, materials science, propulsion, and avionics.

The significance of these organizations lies in their contribution to economic growth, technological innovation, and national security. Historically, these have been instrumental in pioneering air travel, space exploration, and advanced defense systems. The resultant technologies often find applications beyond aerospace, benefitting various other industries. These contribute to high-skill employment and often drive research and development in related fields.

Further examination will explore specific contributions to aviation, advancements in material science, and impact on global transportation networks. This analysis will delve into the multifaceted roles these entities play within the broader technological and economic landscape.

Operational Guidance from Aerospace Manufacturers

The following guidance reflects best practices distilled from the operational experience within aerospace manufacturing. Adherence to these recommendations can enhance efficiency and ensure regulatory compliance.

Tip 1: Emphasize Rigorous Quality Control: Stringent quality assurance protocols are paramount. Implementing comprehensive testing procedures at each stage of the manufacturing process minimizes defects and ensures final product reliability.

Tip 2: Prioritize Advanced Materials Research: Investment in the research and development of advanced materials, such as composites and alloys, enhances aircraft performance and durability while reducing weight.

Tip 3: Implement Lean Manufacturing Principles: Streamlining production processes through lean manufacturing principles reduces waste, improves efficiency, and lowers overall production costs.

Tip 4: Foster a Culture of Continuous Improvement: Encouraging employee engagement in identifying and implementing process improvements contributes to increased efficiency and innovation.

Tip 5: Maintain Regulatory Compliance: Strict adherence to aviation regulations and industry standards is crucial for ensuring safety and avoiding legal repercussions. Stay informed about evolving regulatory requirements.

Tip 6: Optimize Supply Chain Management: Effective supply chain management ensures a reliable flow of components and materials, minimizing delays and disruptions in production.

Tip 7: Invest in Skilled Workforce Training: Continuous training and development of personnel are essential for maintaining a highly skilled workforce capable of adapting to evolving technologies and processes.

Implementing these guidelines can significantly improve operational efficiency, reduce costs, and enhance product quality within the aerospace manufacturing sector. Attention to these aspects is crucial for sustained success and competitiveness.

The concluding section will synthesize these operational considerations with broader industry trends and future challenges.

1. Innovation

Innovation constitutes a foundational pillar. It directly impacts the competitive advantage and long-term viability of the enterprise. The capacity to conceive, develop, and implement novel technologies and designs is the single most vital factor in this process. For example, the incorporation of advanced propulsion systems, such as electric or hybrid-electric configurations, represents a considerable innovation. This reduces fuel consumption and emissions footprints, aligning with stringent environmental regulations and market demands.

The integration of advanced materials and manufacturing processes embodies the innovative spirit. Composite materials, 3D printing, and automated assembly lines can significantly reduce aircraft weight, improve structural integrity, and lower production costs. Furthermore, innovative software and data analytics drive operational efficiency by optimizing flight paths, predictive maintenance, and supply chain management. For instance, the widespread adoption of fly-by-wire systems revolutionized aircraft control, improving safety and maneuverability.

Ultimately, sustained investment in research and development, coupled with a corporate culture that fosters creativity and experimentation, is essential for driving innovation. The ability to anticipate and adapt to evolving market needs and regulatory landscapes determines competitiveness and long-term viability. A failure to innovate results in technological obsolescence and loss of market share.

2. Manufacturing

Manufacturing is a critical component within the realm of aerospace, directly influencing operational efficiency, product quality, and overall market competitiveness. It encompasses a diverse set of processes, technologies, and strategies designed to transform raw materials and components into finished aircraft and related systems.

- Precision Engineering and Fabrication

Aerospace manufacturing demands exceptionally precise engineering and fabrication techniques. The complexity of aircraft design, coupled with stringent safety requirements, necessitates adherence to tight tolerances and meticulous quality control. For example, the production of turbine blades requires highly specialized machinery and skilled technicians to ensure optimal performance and durability.

- Advanced Materials Processing

The utilization of advanced materials, such as composites, alloys, and ceramics, necessitates specialized processing techniques. These materials often require unique manufacturing processes, including autoclaving, additive manufacturing, and advanced welding techniques. For instance, the fabrication of composite aircraft structures involves layering carbon fiber fabrics and resin, followed by curing in an autoclave to achieve desired strength and stiffness.

- Supply Chain Management

Efficient supply chain management is crucial for coordinating the flow of materials and components from numerous suppliers to the manufacturing facility. The aerospace industry relies on a complex network of suppliers, each specializing in specific components or materials. Effective supply chain management minimizes delays, reduces costs, and ensures the availability of critical parts. An example includes just-in-time delivery of avionics components directly to the assembly line, reducing inventory costs and minimizing the risk of obsolescence.

- Automation and Robotics

Automation and robotics are increasingly deployed to enhance efficiency, reduce costs, and improve quality in aerospace manufacturing. Robotic systems can perform tasks such as drilling, riveting, painting, and inspection with greater precision and speed than human workers. For instance, robotic arms can accurately position and fasten aircraft skin panels, reducing the risk of errors and improving assembly time.

The interplay of these facets highlights the multifaceted nature of manufacturing. Effective management of these elements contributes directly to a superior product, improved operational effectiveness, and a strengthened market position. Continuous investment in advanced manufacturing technologies and process optimization is essential for aerospace organizations seeking to maintain a competitive edge.

3. Regulation

Regulation serves as a cornerstone within the aerospace sector, dictating standards for safety, quality, and operational procedures. Its rigorous oversight directly influences product development, manufacturing processes, and airworthiness certification.

- Airworthiness Certification

Airworthiness certification, mandated by agencies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), ensures that aircraft designs meet stringent safety standards. Manufacturers must demonstrate compliance through rigorous testing and documentation. For example, new aircraft models undergo extensive flight testing to validate performance characteristics and system reliability before receiving certification for commercial operation.

- Manufacturing Standards and Compliance

Aerospace manufacturing is subject to stringent quality control standards, such as AS9100, which establishes requirements for quality management systems. Adherence to these standards ensures that components are manufactured to precise specifications and that production processes are consistently monitored. Manufacturers must implement robust quality control procedures and undergo regular audits to maintain compliance.

- Export Controls and Trade Regulations

The aerospace industry operates under strict export control regulations, such as the International Traffic in Arms Regulations (ITAR) in the United States, which govern the export of defense-related technologies and equipment. Compliance with these regulations requires manufacturers to obtain licenses and permits for exporting certain products and technologies. Violations can result in substantial penalties and restrictions on future export activities.

- Environmental Regulations

Increasingly stringent environmental regulations, such as those related to noise emissions and fuel efficiency, are driving innovation in aircraft design and technology. Manufacturers are investing in the development of quieter engines and more fuel-efficient aircraft to meet these requirements. For instance, the introduction of blended wing body designs and advanced composite materials aim to reduce fuel consumption and emissions without compromising performance.

These regulatory facets collectively shape the operational landscape. Compliance is not merely a legal obligation but a fundamental prerequisite for maintaining public trust and ensuring the safety of air travel. The ability to navigate and adapt to evolving regulatory requirements is a key differentiator for organizations seeking sustained success. Further discussion will examine the interplay between materials science and regulatory demands.

4. Materials

Materials constitute a pivotal element in the success and advancement of aerospace. The selection, processing, and application of materials directly impact aircraft performance, safety, and economic viability. The following explores key facets of material science within the aerospace industry.

- Advanced Composites

Advanced composites, such as carbon fiber reinforced polymers (CFRPs), offer high strength-to-weight ratios, enabling lighter and more fuel-efficient aircraft. These materials are increasingly used in aircraft structures, including wings and fuselages. The Boeing 787 Dreamliner, for instance, utilizes a significant amount of CFRP in its construction, resulting in improved fuel economy and reduced emissions. The cost-effective manufacturing and repair of these composites remain a critical focus.

- High-Temperature Alloys

High-temperature alloys, including nickel-based superalloys, are essential for components subjected to extreme heat, such as turbine blades in jet engines. These alloys maintain their strength and structural integrity at elevated temperatures, ensuring reliable engine performance. Modern jet engines incorporate advanced cooling systems and coatings to further enhance the temperature resistance of these alloys, contributing to improved engine efficiency and durability.

- Aluminum-Lithium Alloys

Aluminum-lithium alloys offer a combination of low density and high strength, making them attractive for airframe applications. These alloys provide weight savings compared to traditional aluminum alloys, contributing to improved aircraft performance. The Airbus A380, for example, utilizes aluminum-lithium alloys in its fuselage and wings, resulting in reduced structural weight and improved fuel efficiency. Their corrosion resistance and fatigue properties are continuously being researched.

- Coatings and Surface Treatments

Coatings and surface treatments protect aerospace materials from corrosion, wear, and environmental degradation. These treatments enhance the durability and lifespan of aircraft components, reducing maintenance costs and improving safety. Examples include protective coatings applied to aircraft exteriors to resist corrosion from exposure to salt water and de-icing fluids, extending the operational life of aircraft in harsh environments.

The selection of appropriate materials is intricately linked to design constraints, regulatory requirements, and economic considerations. Continuous research and development in material science are essential for pushing the boundaries of aerospace technology and ensuring the safety, efficiency, and sustainability of future aircraft.

5. Performance

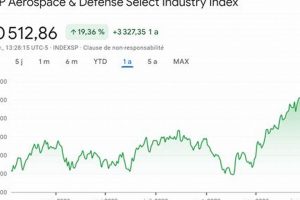

Aerospace organizations derive their fundamental purpose from achieving specific performance metrics, defining the operational capabilities and efficiency of aircraft systems. Performance, in this context, is multifaceted, encompassing speed, range, payload capacity, fuel efficiency, and operational lifespan. These characteristics are critical to the economic viability and competitive positioning of aircraft in the global market. For instance, an increase in fuel efficiency directly translates to reduced operating costs for airlines, improving profitability. Similarly, enhanced payload capacity enables the transport of more cargo or passengers, further contributing to revenue generation. The relentless pursuit of optimized performance drives innovation in aircraft design, materials science, and propulsion systems, directly shaping the evolution of this industry. This also relates to operational costs that affect sustainability of the organization.

Practical application of performance enhancements extends to various aspects. Improved aerodynamic designs, achieved through computational fluid dynamics (CFD) and wind tunnel testing, reduce drag and increase lift, resulting in greater speed and fuel efficiency. Implementation of advanced avionics systems improves navigation, flight control, and safety. Real-world examples of performance-driven design include the development of blended wing body aircraft, which promise significant reductions in fuel consumption compared to conventional aircraft designs. Furthermore, the adoption of lightweight composite materials reduces overall weight, enabling increased payload capacity or extended range. Operational performance can be measured by Return on Investment and other financial metrics.

In conclusion, performance is an essential element, driving technological advancements and influencing the economic viability of operations. Balancing performance objectives with safety regulations, environmental considerations, and economic constraints presents a continuous challenge. The sustained commitment to achieving superior performance, however, defines success within the sector, ensuring relevance in a rapidly evolving global marketplace. Continued investment in research, development, and strategic implementation remains crucial for entities seeking to maintain and enhance their market position.

6. Sustainability

Sustainability has emerged as a critical consideration within aerospace, driven by increasing environmental concerns and evolving regulatory landscapes. It necessitates a holistic approach, encompassing design, manufacturing, operations, and end-of-life management, impacting every facet of the industry.

- Sustainable Aviation Fuels (SAF)

The utilization of SAF represents a tangible pathway towards reducing the carbon footprint of air travel. SAFs are produced from renewable sources, such as biomass and waste products, offering a significant reduction in greenhouse gas emissions compared to conventional jet fuel. The adoption of SAFs requires investment in production infrastructure and collaboration across the supply chain to ensure availability and affordability. Organizations demonstrating a commitment to SAF adoption improve their environmental impact while potentially enhancing their public image.

- Lightweighting and Fuel Efficiency

The development and deployment of lightweight materials, such as composites and advanced alloys, reduce aircraft weight, leading to improved fuel efficiency and reduced emissions. Simultaneously, aerodynamic improvements in aircraft design minimize drag and optimize fuel consumption. Continuous investment in research and development is essential for advancing these technologies and maximizing their impact on sustainability. These material and design innovations are crucial to balancing regulatory compliance and market demands.

- Noise Reduction Technologies

Aircraft noise pollution represents a significant environmental concern, particularly for communities near airports. The development and implementation of noise reduction technologies, such as advanced engine designs and noise-dampening materials, mitigate the impact of aircraft noise on surrounding areas. Quiet engine technologies reduce noise emissions by modifying airflow and combustion processes. Noise-reducing flight procedures, like optimized approach and departure profiles, are also integral to noise management strategies. Effective noise mitigation strategies require collaboration among manufacturers, airlines, and airport operators.

- End-of-Life Management

The responsible management of aircraft at the end of their operational life cycle is an increasingly important aspect of sustainability. Decommissioned aircraft contain valuable materials that can be recycled or repurposed, reducing waste and conserving resources. Efficient dismantling processes and effective recycling technologies are crucial for maximizing the value recovery from end-of-life aircraft. Compliance with environmental regulations and responsible disposal practices are essential for minimizing the environmental impact of aircraft decommissioning.

These facets collectively illustrate the multifaceted nature of sustainability within aerospace. Integration of these considerations into core strategies is essential for long-term competitiveness. Continuous innovation, proactive regulatory engagement, and responsible resource management are critical for advancing sustainability goals and ensuring a responsible future for air travel.

Frequently Asked Questions

The following section addresses common inquiries regarding operations, scope, and impact within the specialized manufacturing sector.

Question 1: What core capabilities define operations?

Core capabilities encompass the design, manufacturing, and maintenance of aircraft and related components. These activities require specialized expertise in areas such as aerodynamics, materials science, and avionics.

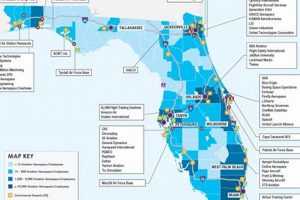

Question 2: How does this type of manufacturing contribute to economic growth?

Contributions to economic growth include the creation of high-skilled employment opportunities, the development of advanced technologies, and the generation of export revenues. The sector also stimulates related industries through supply chain relationships.

Question 3: What regulatory frameworks govern manufacturing processes?

Manufacturing processes are governed by stringent regulatory frameworks established by aviation authorities, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). These regulations ensure safety and quality standards.

Question 4: What are the primary challenges facing organizations within the sector?

Primary challenges include managing complex supply chains, adapting to evolving regulatory requirements, and investing in research and development to maintain a competitive advantage. Workforce development and skill shortages also pose significant concerns.

Question 5: How does this manufacturing contribute to advancements in material science?

Contribution to advancements in material science includes the development and application of lightweight composites, high-temperature alloys, and advanced coatings. These materials enhance aircraft performance and durability.

Question 6: What role does it play in promoting sustainability within the broader aviation industry?

A pivotal role is to promote sustainability through the development of fuel-efficient aircraft designs, the utilization of sustainable aviation fuels, and the implementation of environmentally responsible manufacturing processes. Collaboration across the industry is essential for achieving sustainability goals.

These FAQs provide a foundational understanding of critical facets. Continuous monitoring of industry trends and evolving technologies is recommended for staying informed.

The subsequent section will delve into case studies illustrating successful implementation of best practices.

Conclusion

This examination of utilicraft aerospace industries has underscored the complexity and critical importance of this sector. Key facets identified include the necessity for continuous innovation, rigorous manufacturing processes, stringent regulatory compliance, advanced materials utilization, optimized performance metrics, and a commitment to sustainable practices. The intersection of these elements determines the competitive advantage and long-term viability of organizations operating within this domain.

Moving forward, the ability to adapt to evolving technological landscapes and proactively address emerging challenges will define success. A sustained focus on research, development, and strategic partnerships is essential for maintaining relevance and driving future advancements. The continued pursuit of excellence within these core areas will ensure the ongoing contribution to economic growth, technological progress, and global connectivity.

![Israel Aerospace Industries North America: [Insights] Innovating the Future of Flight with Reliable Aviation Solutions Israel Aerospace Industries North America: [Insights] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-592-300x200.jpg)