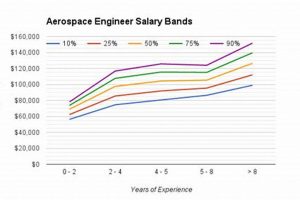

Compensation for entry-level positions within the aerospace industry represents the initial financial remuneration offered to individuals commencing their careers in this sector. This figure typically encompasses base pay and may include benefits packages, reflecting the skills, education, and demand for specific roles. As an example, a newly graduated engineer accepting a design position at an aerospace manufacturer might receive a sum constituting their initial earnings.

The initial compensation package offered to those entering the aerospace field is significant for several reasons. It provides a foundation for future earnings growth, impacts career choices, and influences the overall attractiveness of the industry to prospective talent. Historically, these entry-level figures have mirrored the cyclical nature of the aerospace market, responding to periods of growth, technological innovation, and fluctuations in government and private sector investment.

Given the multifaceted nature of this initial remuneration, the following discussion will delve into the factors that influence this figure, explore typical ranges across various job functions, and address strategies for prospective employees to maximize their earning potential upon entering the dynamic and technologically advanced world of aerospace.

Securing optimal initial earnings in the aerospace sector requires strategic planning and a thorough understanding of industry benchmarks. The following points offer guidance to prospective employees seeking to maximize their financial prospects at the outset of their aerospace careers.

Tip 1: Conduct Comprehensive Research: Prior to salary negotiations, thoroughly investigate the typical entry-level compensation for the specific role, geographic location, and company size. Utilize online resources, industry reports, and professional network connections to gather relevant data.

Tip 2: Emphasize Relevant Skills and Experience: Highlight academic achievements, internships, relevant projects, and technical skills that directly align with the job description. Quantify accomplishments whenever possible to demonstrate tangible contributions.

Tip 3: Negotiate Strategically: Understand the employer’s perspective while advocating for personal worth. Be prepared to justify salary expectations based on research and demonstrated value. Consider the total compensation package, including benefits, signing bonuses, and relocation assistance.

Tip 4: Consider Location and Cost of Living: Account for regional variations in cost of living when evaluating potential offers. A higher salary in one location may be offset by increased expenses, impacting overall financial well-being.

Tip 5: Obtain Relevant Certifications and Training: Enhance marketability and earning potential by acquiring industry-recognized certifications and pursuing specialized training in high-demand areas. This demonstrates a commitment to continuous professional development.

Tip 6: Network Actively: Build connections within the aerospace community through professional organizations, industry events, and online platforms. Networking can provide valuable insights into compensation trends and uncover unadvertised opportunities.

These strategic considerations can significantly impact an individual’s initial earnings and long-term career trajectory within the competitive aerospace landscape.

The subsequent sections will explore specific career paths within aerospace and their corresponding compensation ranges, providing further context for informed decision-making.

1. Education Level

Education level serves as a primary determinant of initial compensation in the aerospace industry. A direct correlation exists between the attainment of higher academic qualifications and the prospective earnings offered to entry-level candidates. This stems from the advanced knowledge, analytical skills, and problem-solving capabilities cultivated through rigorous academic programs. For example, a candidate possessing a Master’s degree in Aerospace Engineering is generally positioned to command a higher initial salary than a candidate with a Bachelor’s degree in the same field, assuming similar levels of practical experience. The advanced curriculum of the Master’s program often equips graduates with specialized skills that are directly applicable to complex aerospace challenges, making them more valuable to employers.

The impact of education extends beyond the initial degree. Specializations, relevant coursework, and research experience within a specific academic discipline further influence the earning potential. For instance, a Bachelor’s degree holder who completed a senior design project focused on computational fluid dynamics and has experience using industry-standard software could potentially negotiate a higher salary compared to a candidate with a more general aerospace engineering background. Similarly, doctorate degrees, indicative of significant research contributions and specialized expertise, typically lead to the highest starting salaries, particularly in research and development roles. Furthermore, ABET accreditation of an engineering program often signals quality and rigor, which can positively influence an employer’s perception and willingness to offer a competitive compensation package.

In conclusion, education level is a critical factor influencing the initial compensation offered in the aerospace sector. While experience and skills play important roles, a higher level of formal education often translates to a higher perceived value and a greater earning potential. Aspiring aerospace professionals should strategically consider advanced degrees and specialized coursework to enhance their marketability and maximize their compensation prospects. However, it is essential to note that the return on investment for advanced degrees should be carefully evaluated in light of tuition costs and potential salary increases.

2. Job Function

The specific role assumed within the aerospace industry exerts a significant influence on the initial compensation offered. Different job functions necessitate varying skill sets, levels of responsibility, and specialized knowledge, leading to disparities in entry-level remuneration.

- Aerospace Engineer

Aerospace engineers are involved in the design, development, and testing of aircraft, spacecraft, and related systems. Their responsibilities can range from aerodynamic analysis and structural design to propulsion system integration and flight control systems. Entry-level salaries for aerospace engineers typically reflect the high demand for their skills and the technical expertise required for these roles. For example, a design engineer focusing on aircraft wing structures may command a higher initial salary compared to a manufacturing engineer involved in production process optimization, due to the perceived complexity and specialized knowledge associated with the design role.

- Avionics Technician

Avionics technicians specialize in the maintenance, repair, and troubleshooting of electronic systems used in aircraft. This includes navigation systems, communication equipment, radar systems, and flight control systems. While requiring a strong technical aptitude, the initial compensation for avionics technicians may be lower compared to aerospace engineers, primarily due to the difference in formal education requirements and the perceived scope of responsibilities. However, experienced avionics technicians with specialized certifications can significantly increase their earning potential.

- Software Engineer (Aerospace)

Software engineers specializing in aerospace develop and maintain software for aircraft systems, mission control, and simulation environments. Their role involves programming, testing, and debugging software code, often requiring proficiency in multiple programming languages and software development methodologies. Due to the increasing reliance on software in aerospace applications, the demand for software engineers in this sector is high, leading to competitive entry-level salaries. For instance, a software engineer specializing in embedded systems for flight control may command a higher starting salary compared to a software engineer working on ground-based simulation software, reflecting the criticality of embedded systems in aircraft operation.

- Research Scientist (Aerospace)

Research scientists in the aerospace field conduct fundamental and applied research to advance aerospace technology. This may involve exploring new materials, developing innovative propulsion systems, or studying the effects of space environment on spacecraft components. The initial compensation for research scientists is often influenced by their educational attainment (Ph.D. preferred), research experience, and the specific area of research. A research scientist focusing on hypersonics may command a higher initial salary compared to a scientist working on more established areas of aerospace research, reflecting the specialized knowledge and demand for expertise in emerging fields.

In summary, the “Job Function” plays a crucial role in determining initial compensation within the aerospace sector. Roles requiring specialized knowledge, advanced technical skills, and greater responsibility tend to command higher entry-level salaries. Aspiring aerospace professionals should carefully consider their career interests and skill sets when selecting a job function, recognizing that the initial compensation can vary significantly across different roles. Furthermore, continuous professional development and the acquisition of specialized certifications can enhance earning potential within each job function.

3. Company Size

Company size represents a significant determinant in the compensation packages offered to entry-level aerospace professionals. The organizational structure, financial resources, and operational scale characteristic of different sized firms directly influence the remuneration provided to newly hired employees.

- Resource Allocation and Compensation Structures

Larger aerospace corporations often possess greater financial capacity, enabling them to offer more competitive salaries and comprehensive benefits packages compared to smaller enterprises. These larger companies typically have established compensation structures, including salary bands and performance-based bonuses, which are rigorously benchmarked against industry standards. Consequently, entry-level positions within these organizations frequently offer higher initial remuneration to attract top talent.

- Market Share and Revenue Generation

Company size is often correlated with market share and revenue generation. Larger aerospace companies, with established market presence and diversified revenue streams, can afford to invest more in talent acquisition and retention. This investment manifests in higher initial salaries, as well as opportunities for professional development and career advancement. Conversely, smaller firms may face budgetary constraints that limit their ability to offer compensation packages comparable to those of larger competitors.

- Risk Profile and Financial Stability

The perceived risk profile and financial stability of an aerospace company also influence entry-level compensation. Larger, publicly traded corporations are generally viewed as more stable employers, offering greater job security and long-term career prospects. This perceived stability can justify lower initial salaries, as candidates may prioritize long-term benefits over immediate financial gains. Smaller, privately held companies may offer higher initial salaries to compensate for the perceived risk associated with working for a less established organization.

- Operational Scope and Project Complexity

Company size often reflects the operational scope and project complexity undertaken. Larger aerospace companies typically engage in large-scale, complex projects requiring specialized expertise. These companies are therefore willing to pay a premium for entry-level talent with relevant skills and experience. Smaller firms may focus on niche markets or specialized services, requiring a different skill set and potentially offering lower initial salaries. For instance, a large aerospace manufacturer involved in commercial aircraft production may offer a higher initial salary to a structural engineer compared to a smaller firm specializing in drone technology.

In conclusion, company size serves as a crucial factor influencing initial compensation within the aerospace sector. The interplay between resource allocation, market position, risk profile, and operational scope determines the capacity and willingness of aerospace companies to offer competitive starting salaries. Aspiring aerospace professionals should carefully consider the size and financial stability of potential employers when evaluating job offers, recognizing that compensation packages can vary significantly based on organizational scale.

4. Geographic Location

Geographic location significantly impacts entry-level remuneration within the aerospace industry. Regional variations in cost of living, industry concentration, and government investment patterns contribute to the divergence in compensation packages offered to prospective employees.

- Cost of Living Adjustments

Metropolitan areas with higher costs of living, such as Los Angeles, California or Seattle, Washington, typically offer elevated entry-level salaries to offset increased expenses related to housing, transportation, and general living costs. Aerospace companies operating in these regions must adjust compensation to attract and retain talent in a competitive environment. Conversely, areas with lower costs of living may offer comparatively lower salaries, as the purchasing power of a given income is greater.

- Industry Hubs and Concentration of Aerospace Companies

Regions with a high concentration of aerospace companies, such as the “Aerospace Alley” in Southern California or the area surrounding Seattle, Washington, often experience heightened competition for skilled workers. This competition drives up entry-level salaries as companies vie for the best talent. Furthermore, the presence of established aerospace clusters fosters knowledge sharing and innovation, attracting skilled professionals and further contributing to regional salary inflation. Regions without such industry concentration often exhibit lower levels of compensation due to reduced demand and competition.

- Government Investment and Research Funding

Geographic regions that benefit from significant government investment in aerospace research and development, such as those with proximity to NASA centers or major military installations, often experience increased demand for aerospace professionals. This demand, fueled by government contracts and research grants, drives up entry-level salaries in these areas. Furthermore, government-funded research institutions and universities located in these regions often provide a pipeline of skilled graduates, further contributing to the regional aerospace talent pool and influencing compensation levels. The presence of these research centers directly translates to a higher demand for engineering and scientific personnel, impacting initial salaries.

- State and Local Tax Policies

State and local tax policies can also influence aerospace entry-level salaries. States with lower income tax rates may be more attractive to prospective employees, allowing companies to offer slightly lower gross salaries while still providing a competitive net income. Conversely, states with higher income tax rates may require companies to offer higher gross salaries to compensate for the increased tax burden. These tax policies can indirectly affect the overall compensation packages offered to entry-level aerospace professionals.

Therefore, geographic location represents a critical factor influencing entry-level compensation in the aerospace sector. Cost of living adjustments, industry concentration, government investment, and state tax policies collectively shape the salary landscape, creating regional disparities in remuneration. Aspiring aerospace professionals should carefully consider these factors when evaluating job offers and making career decisions.

5. Skills Demand

The prevailing demand for specific skill sets within the aerospace industry significantly influences the starting salary offered to entry-level professionals. The principles of supply and demand dictate that positions requiring rare or highly specialized expertise command higher compensation, reflecting the difficulty in sourcing qualified candidates.

- Specialized Engineering Disciplines

Certain engineering disciplines, such as propulsion engineering, avionics, and computational fluid dynamics, often face a greater demand than the available talent pool. This scarcity drives up initial salaries for entry-level engineers possessing these skills. For instance, an aerospace engineer specializing in hypersonic propulsion systems, a field experiencing renewed interest due to advancements in space exploration and defense, can expect a significantly higher starting salary compared to a general aerospace engineer without such specialized knowledge.

- Software Development and Cybersecurity

The increasing reliance on software-defined systems in aerospace necessitates a strong demand for software engineers with expertise in embedded systems, real-time operating systems, and cybersecurity. Entry-level software engineers proficient in programming languages like C++ and Ada, and possessing knowledge of secure coding practices, are highly sought after and command premium starting salaries. The growing threat of cyberattacks on aerospace systems further amplifies the need for cybersecurity specialists, leading to increased compensation for those with relevant skills.

- Data Analytics and Machine Learning

The aerospace industry generates vast amounts of data from flight operations, sensor readings, and simulations. Professionals with expertise in data analytics and machine learning are needed to extract insights from this data to improve aircraft performance, optimize maintenance schedules, and enhance safety. Entry-level data scientists proficient in statistical modeling, data visualization, and machine learning algorithms are in high demand, particularly those with domain knowledge of aerospace systems. This skills gap translates into competitive starting salaries for qualified candidates.

- Advanced Materials and Manufacturing

The development and application of advanced materials, such as composites and additive manufactured components, are critical for improving aircraft performance and reducing weight. Entry-level engineers and scientists with expertise in materials science, manufacturing processes, and non-destructive testing are highly sought after by aerospace companies. A materials engineer proficient in the characterization and testing of carbon fiber composites, for example, can expect a higher starting salary compared to an engineer with a more general materials science background. Furthermore, experience with advanced manufacturing techniques like 3D printing can further enhance earning potential.

In summary, the prevailing demand for specific skill sets profoundly impacts entry-level compensation within the aerospace sector. Positions requiring specialized engineering knowledge, software development expertise, data analytics capabilities, and advanced materials skills command higher starting salaries due to the limited supply of qualified candidates. Aspiring aerospace professionals should carefully consider the evolving skills landscape when pursuing their education and career development to maximize their earning potential.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding compensation for entry-level positions within the aerospace industry. These answers aim to provide clarity and inform decision-making for aspiring professionals.

Question 1: What factors predominantly influence the initial compensation for aerospace engineers?

The initial compensation for aerospace engineers is primarily influenced by educational attainment (degree level and relevant coursework), specialized skills (proficiency in specific software or technical domains), geographic location (cost of living and industry concentration), company size (large corporations versus smaller firms), and demand for specific expertise (e.g., propulsion systems, avionics, cybersecurity).

Question 2: How does the geographic location impact aerospace entry-level salaries?

Geographic location significantly impacts starting salaries due to variations in the cost of living and the concentration of aerospace industries. Metropolitan areas with higher costs of living and regions with a strong presence of aerospace companies typically offer higher entry-level compensation to attract and retain talent.

Question 3: Do advanced degrees substantially increase entry-level aerospace salaries?

Yes, advanced degrees, such as a Master’s or Ph.D., generally lead to higher starting salaries in the aerospace sector. This is attributable to the specialized knowledge, research experience, and analytical skills acquired through graduate-level studies.

Question 4: How important is company size in determining the entry-level pay?

Company size plays a significant role. Larger aerospace corporations, possessing greater financial resources, often offer more competitive starting salaries and comprehensive benefits packages compared to smaller companies.

Question 5: What are some effective strategies for negotiating a higher starting salary in aerospace?

Effective negotiation strategies include conducting thorough salary research, highlighting relevant skills and experience, quantifying accomplishments, understanding the employer’s perspective, and considering the entire compensation package, including benefits and relocation assistance.

Question 6: How does possessing in-demand skills influence an aerospace candidate’s starting salary?

Having in-demand skills, such as expertise in cybersecurity, data analytics, or advanced materials, significantly increases a candidate’s earning potential. Positions requiring such skills often command a premium starting salary due to the limited supply of qualified professionals.

In summary, entry-level compensation within the aerospace industry is a multifaceted issue influenced by education, skills, location, company size, and negotiation prowess. Prospective employees should carefully consider these factors when evaluating job offers and planning their career trajectory.

The following section will address resources for prospective employees.

Aerospace Starting Salary

The examination of aerospace starting salary reveals a complex interplay of factors influencing initial compensation for professionals entering this dynamic field. Education, specialized skills, geographic location, company size, and the prevailing demand for expertise all contribute to the final figure. A comprehensive understanding of these elements empowers prospective employees to make informed decisions and navigate the job market effectively.

The importance of diligent research and strategic self-presentation cannot be overstated. Aspirants are encouraged to meticulously assess their qualifications, thoroughly investigate prevailing industry standards, and proactively engage in professional development. Only through such concerted effort can individuals maximize their potential for achieving a competitive and rewarding start to their careers within the aerospace sector. The future of aerospace innovation hinges on attracting and retaining top talent, necessitating continued transparency and competitive compensation practices.

![BP Aerospace Salary Guide: What to Expect in [Year] Innovating the Future of Flight with Reliable Aviation Solutions BP Aerospace Salary Guide: What to Expect in [Year] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-148-300x200.jpg)