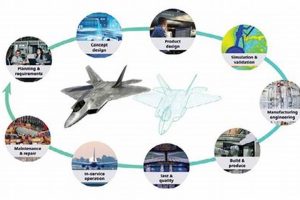

The advancement of capabilities within the sector encompassing aircraft, spacecraft, and related technologies involves a multifaceted process. This process integrates research and development, manufacturing, infrastructure establishment, and workforce training. The result is an enhanced capacity for producing goods and services associated with flight and space exploration, contributing to both economic growth and technological advancement.

Such expansion yields significant societal advantages. It fosters innovation, creating new products and services that can benefit other sectors. It generates high-skilled employment opportunities, stimulating economic prosperity within affected regions. Historically, strategic investment in these sectors has led to technological breakthroughs with widespread applications, from improved materials science to advanced communication systems.

This article will delve into the key aspects driving the subject, exploring specific technological innovations, examining current market trends, and analyzing the role of government policy in shaping its future trajectory. We will also consider the challenges and opportunities that lie ahead, including sustainability concerns and the increasing importance of international collaboration.

Effective and strategic deployment is crucial for organizations and governments involved in the sector. The following guidelines offer key considerations for fostering sustained progress.

Tip 1: Prioritize Investment in Fundamental Research: Success requires a sustained commitment to basic research across relevant scientific disciplines. Funding should target both established institutions and emerging research groups to encourage diverse perspectives and novel solutions.

Tip 2: Cultivate a Skilled Workforce: Establish comprehensive educational programs and vocational training initiatives to meet the evolving demands of the industry. These programs should emphasize both technical expertise and critical thinking skills.

Tip 3: Foster Public-Private Partnerships: Encourage collaboration between governmental entities, private sector companies, and academic institutions. Shared resources and expertise can accelerate innovation and reduce the risks associated with large-scale projects.

Tip 4: Streamline Regulatory Processes: Develop clear and efficient regulatory frameworks that promote safety and innovation without imposing unnecessary burdens. A transparent and predictable regulatory environment is essential for attracting investment.

Tip 5: Promote International Collaboration: Participate in international partnerships to share knowledge, access new markets, and address global challenges. Collaborative efforts can leverage diverse strengths and resources to achieve common goals.

Tip 6: Emphasize Sustainability and Environmental Responsibility: Integrate environmentally conscious practices into all aspects of the industry, from design and manufacturing to operations and disposal. This includes investing in sustainable materials and developing energy-efficient technologies.

Strategic adoption of these principles can greatly contribute to sustainable progress and sustained global competitiveness. Continuous evaluation and adaptation of these strategies are necessary to meet the dynamic demands of the evolving landscape.

The subsequent sections of this article will explore these areas in greater detail, providing specific examples and case studies to illustrate best practices and potential challenges.

1. Technological Advancement

Technological advancement serves as a primary catalyst for progression within the aerospace sector. Innovations in materials science, propulsion systems, avionics, and manufacturing techniques directly enable the development of more efficient, capable, and cost-effective aircraft and spacecraft. The adoption of composite materials, for example, reduces weight and increases fuel efficiency in aircraft, while advancements in rocket engine technology permit deeper space exploration. This interrelation suggests that the pace and scope of this development are significantly determined by the rate of technological progress.

The influence of technology manifests in various practical applications. The development of sophisticated sensor systems and data analytics has revolutionized air traffic management, enhancing safety and optimizing flight paths. Automation and robotics in manufacturing facilities have increased production efficiency and reduced labor costs. Furthermore, the integration of advanced communication systems allows for seamless connectivity between aircraft and ground stations, enabling real-time data exchange and improved operational control. Consider the advancements in unmanned aerial vehicles (UAVs), or drones, which showcase the ability to create new markets and applications, like aerial surveillance, package delivery, and infrastructure inspection, enabled by progress in areas like battery technology, autonomous flight control systems, and miniaturized sensors.

In conclusion, continued progress is inextricably linked to further scientific and engineering breakthroughs. Challenges include maintaining investment in long-term research and adapting to the ethical and societal implications of emerging technologies like artificial intelligence and autonomous systems. A robust approach to fundamental research, combined with a pragmatic approach to technology transfer, remains crucial for sustained growth and global competitiveness within the sector.

2. Skilled Workforce

A robust and technically proficient workforce is a fundamental prerequisite for sustained aerospace industrial development. The complexity and precision inherent in aircraft and spacecraft design, manufacturing, and operation necessitate a highly trained personnel pool across various disciplines.

- Engineering Expertise

Aerospace engineering encompasses a broad spectrum of specializations, including structural design, aerodynamics, propulsion, and control systems. A skilled workforce in these areas is vital for developing innovative and efficient aircraft and spacecraft. For instance, the design and testing of new engine technologies require engineers with expertise in thermodynamics, fluid dynamics, and materials science. Shortages in these areas can impede the progress of next-generation aircraft development.

- Advanced Manufacturing Skills

The manufacturing of aerospace components requires specialized skills in areas such as precision machining, composite fabrication, and electronics assembly. Skilled technicians and machinists are essential for producing high-quality parts that meet stringent safety and performance standards. For example, the fabrication of composite wings for modern aircraft requires technicians with expertise in layup techniques, curing processes, and non-destructive testing. A decline in advanced manufacturing skills can negatively impact production capacity and quality control.

- Maintenance and Operations Personnel

The maintenance and operation of aircraft and spacecraft require highly trained technicians and pilots. These individuals are responsible for ensuring the safety and reliability of aircraft throughout their service life. Airframe and powerplant (A&P) technicians, for instance, perform routine inspections, repairs, and overhauls of aircraft systems. A shortage of qualified maintenance personnel can lead to delays in aircraft maintenance and potentially compromise safety.

- Research and Development Scientists

Research and development (R&D) scientists are crucial for driving innovation in the aerospace sector. These individuals conduct basic and applied research in areas such as advanced materials, propulsion systems, and autonomous flight control. A strong base of R&D scientists is essential for maintaining technological leadership and developing disruptive technologies. For instance, research into new propulsion concepts, such as hypersonic engines, requires scientists with expertise in combustion, aerodynamics, and materials science.

In conclusion, a skilled workforce is not merely a supporting element but rather an integral component of aerospace industrial development. Targeted investments in education, training, and apprenticeship programs are necessary to ensure a sufficient supply of qualified personnel to meet the evolving demands of the industry. Failure to address workforce shortages can significantly hinder innovation, productivity, and competitiveness.

3. Infrastructure Investment

Adequate infrastructure is a fundamental enabler of aerospace industrial development, providing the physical and logistical support necessary for manufacturing, testing, and operating aircraft and spacecraft. Strategic investment in infrastructure reduces operational costs, enhances efficiency, and attracts further investment in the sector.

- Specialized Manufacturing Facilities

The production of aerospace components requires specialized manufacturing facilities equipped with advanced machinery, cleanrooms, and testing equipment. These facilities must be capable of handling large, complex parts and maintaining stringent quality control standards. For example, the manufacturing of aircraft wings often requires large autoclaves for curing composite materials. The availability of such specialized facilities is a critical factor in attracting aerospace manufacturers to a particular region.

- Airports and Airfields

Airports and airfields serve as the primary gateways for air transportation and play a vital role in supporting aerospace operations. Modern airports must have sufficient runway length, taxiway capacity, and terminal facilities to accommodate large aircraft. Additionally, they require sophisticated air traffic control systems and security measures. Investment in airport infrastructure is essential for supporting the growth of air travel and facilitating the efficient movement of goods and personnel. For example, airports are crucial for supporting flight testing activities and providing bases for aircraft maintenance and repair operations. Regional airports can also serve as hubs for aerospace component manufacturers, enabling efficient transportation of parts and materials.

- Testing and Research Facilities

The aerospace industry relies heavily on testing and research facilities to validate new designs and technologies. These facilities may include wind tunnels for aerodynamic testing, engine test stands for evaluating propulsion systems, and environmental testing chambers for simulating extreme conditions. Access to such facilities is essential for companies engaged in R&D and product development. For example, NASA’s wind tunnels have been instrumental in the development of numerous aircraft designs, including the Boeing 787 Dreamliner. University-based research facilities also play a critical role in training the next generation of aerospace engineers and scientists.

- Transportation Networks

Efficient transportation networks are essential for moving aerospace components and personnel between manufacturing facilities, airports, and other locations. This includes highways, railways, and waterways. Congestion and inadequate infrastructure can significantly increase transportation costs and delay production schedules. For example, the transport of large aircraft components, such as wings and fuselages, often requires specialized transportation equipment and careful planning. Investment in transportation infrastructure can improve supply chain efficiency and reduce the overall cost of manufacturing.

In summary, infrastructure investment is a vital catalyst for aerospace industrial development. By providing the necessary facilities and support systems, strategic investment in infrastructure reduces costs, enhances efficiency, and attracts further investment in the sector. This is a cornerstone of establishing and maintaining a competitive advantage in the global aerospace industry.

4. Policy Framework

A well-defined and effectively implemented policy framework is a cornerstone for fostering sustainable aerospace industrial development. Government policies influence investment decisions, technological innovation, workforce development, and international competitiveness within the sector.

- Regulatory Environment

A stable and transparent regulatory environment is crucial for attracting investment and promoting innovation. Regulations should be designed to ensure safety and environmental protection without imposing undue burdens on industry. For example, streamlined certification processes for new aircraft technologies can significantly reduce development costs and time-to-market. Conversely, excessive regulatory hurdles can stifle innovation and drive investment to more favorable jurisdictions. A balance is needed.

- Incentive Programs

Governments often use incentive programs, such as tax credits, grants, and subsidies, to encourage investment in specific areas of the aerospace industry. These programs can be targeted at promoting research and development, attracting foreign investment, or supporting workforce training. For example, tax incentives for companies that establish manufacturing facilities in underserved regions can stimulate economic growth and create jobs. The effectiveness of incentive programs depends on their design, implementation, and monitoring.

- Trade Policies

Trade policies, including tariffs, quotas, and trade agreements, can have a significant impact on the competitiveness of the aerospace industry. Free trade agreements can open up new markets for aerospace products and services, while protectionist measures can restrict access to foreign markets and increase costs. For example, bilateral air service agreements regulate the terms under which airlines from different countries can operate flights between their respective territories. These agreements can affect passenger flows, cargo volumes, and the overall competitiveness of the aviation industry.

- Defense Spending

Defense spending is a major driver of aerospace industrial development in many countries. Government procurement of military aircraft, spacecraft, and related technologies provides a significant source of revenue for aerospace companies. Defense spending can also stimulate innovation and technological advancements that have broader applications in the commercial sector. For example, the development of jet engine technology was heavily influenced by military research and development efforts during World War II. However, over-reliance on defense spending can make the aerospace industry vulnerable to fluctuations in government budgets and geopolitical tensions.

In conclusion, a comprehensive and well-coordinated policy framework is essential for creating a supportive environment for aerospace industrial development. By fostering innovation, attracting investment, and promoting competitiveness, government policies can help ensure the long-term growth and prosperity of the sector. Strategic alignment of these policy levers is critical to realizing the full potential of the aerospace industry.

5. Market expansion

Market expansion serves as a crucial determinant of aerospace industrial development, acting as both a catalyst for growth and a measure of its success. Increased demand for aerospace products and services directly incentivizes further investment in research and development, manufacturing capacity, and workforce training. The relationship is reciprocal; aerospace industrial development, characterized by technological advancements and increased efficiency, enhances the competitiveness of companies, thereby facilitating market expansion. A prime example is the expansion of the commercial aviation market in emerging economies. Increased air travel demand has spurred investment in new aircraft and airport infrastructure, simultaneously driving aerospace manufacturing and creating new markets for related services.

The dynamics extend beyond commercial aviation. The burgeoning space industry, driven by demand for satellite services, space tourism, and resource exploration, is generating significant opportunities for aerospace companies. As satellite technology advances and launch costs decrease, the market for satellite-based communications, Earth observation, and navigation services continues to expand. Furthermore, government investment in space exploration and defense further fuels this expansion, creating demand for advanced spacecraft, propulsion systems, and mission support services. The increasing focus on unmanned aerial vehicles (UAVs) and their applications, from agriculture to surveillance, presents another avenue for market growth, contingent upon regulatory frameworks that permit their widespread use.

Ultimately, market expansion is not merely a consequence of aerospace industrial development; it is an essential driver. The ability of aerospace companies to identify and capitalize on new market opportunities, coupled with supportive government policies, will determine the sector’s long-term growth and competitiveness. Challenges remain, including global economic uncertainties, geopolitical tensions, and the need for sustainable and environmentally responsible practices. Overcoming these challenges requires a strategic approach that prioritizes innovation, collaboration, and a commitment to meeting the evolving needs of the global marketplace.

6. Sustainability Integration

Sustainability integration represents a critical and increasingly essential facet of aerospace industrial development. The sector’s traditionally high environmental impact necessitates a shift towards sustainable practices to mitigate detrimental effects on the planet and ensure long-term viability. This integration encompasses multiple domains, including the design and manufacturing of aircraft and spacecraft, the operation of air transport systems, and the development of alternative fuels and propulsion technologies. The cause-and-effect relationship is evident: unsustainable practices lead to environmental degradation, resource depletion, and potential regulatory constraints, while sustainable approaches foster efficiency, reduce emissions, and enhance public perception.

The importance of sustainability integration is exemplified by the growing adoption of sustainable aviation fuels (SAF). Traditional jet fuel derived from petroleum contributes significantly to greenhouse gas emissions. SAF, produced from renewable sources such as algae, biomass, or waste products, offers a pathway to reduce carbon footprints. Airlines are progressively incorporating SAF into their fuel mix, and governments are providing incentives for its production and use. Another example is the development of lighter, more fuel-efficient aircraft designs utilizing composite materials and advanced aerodynamics. Such designs minimize fuel consumption and emissions during flight. Furthermore, electric and hybrid-electric propulsion systems are emerging as potential alternatives to conventional jet engines, particularly for regional and short-haul flights. These innovations demonstrate the practical significance of sustainability integration in transforming the aerospace industry.

In conclusion, sustainability integration is not merely an ethical imperative but also a strategic necessity for aerospace industrial development. The challenges involved are substantial, requiring sustained investment in research and development, supportive government policies, and collaboration across the industry. However, embracing sustainable practices will not only reduce the environmental impact of air travel and space exploration but also foster innovation, enhance competitiveness, and secure a more sustainable future for the sector. A comprehensive approach encompassing technological innovation, operational efficiency, and policy support is paramount to achieving meaningful progress.

Frequently Asked Questions Regarding Aerospace Industrial Development

The following section addresses common inquiries and misconceptions concerning the aerospace industrial landscape.

Question 1: What constitutes “aerospace industrial development” in its entirety?

Aerospace industrial development encompasses the coordinated growth and advancement of capabilities within the sector that designs, manufactures, and operates aircraft, spacecraft, and related technologies. It includes research and development, infrastructure construction, workforce training, and policy formulation aimed at enhancing productivity and competitiveness.

Question 2: What are the primary economic benefits derived from investing in aerospace industrial expansion?

Investment in the aerospace sector stimulates economic growth through job creation, technological innovation, and increased export revenue. It fosters the development of high-skilled employment opportunities, generates demand for related goods and services, and strengthens a nation’s technological base.

Question 3: What role does government policy play in fostering aerospace industrial growth?

Government policy establishes the regulatory framework, provides incentives for investment, supports research and development, and promotes international trade. Effective government policies create a stable and predictable environment that encourages innovation and attracts private sector participation.

Question 4: How does technological innovation contribute to aerospace industrial advancement?

Technological innovation drives improvements in aircraft and spacecraft performance, efficiency, and safety. It leads to the development of new materials, propulsion systems, avionics, and manufacturing processes that enhance the competitiveness of the aerospace industry. Consider the effect of advancements on the sector.

Question 5: What are the key challenges facing the aerospace sector in terms of sustainability?

The aerospace sector faces significant challenges in reducing its environmental impact, including greenhouse gas emissions, noise pollution, and resource consumption. Addressing these challenges requires the development and adoption of sustainable aviation fuels, more efficient aircraft designs, and alternative propulsion technologies. There are environmental and long term operation challenges for any sector including aerospace.

Question 6: How is international collaboration essential for aerospace industrial progress?

International collaboration enables the sharing of knowledge, resources, and expertise, accelerating the pace of technological innovation and reducing the cost of development. It facilitates access to new markets and promotes the standardization of regulations and procedures. Government support plays a vital role, as always.

In summary, aerospace industrial development is a complex and multifaceted process that requires coordinated efforts from government, industry, and academia. The benefits of investing in this sector are substantial, including economic growth, technological innovation, and enhanced national security.

The next section will explore specific case studies of successful aerospace industrial initiatives.

Concluding Remarks on Aerospace Industrial Development

This article has explored the multifaceted nature of aerospace industrial development, emphasizing the crucial interplay of technological advancement, a skilled workforce, strategic infrastructure investment, and a supportive policy framework. Sustained market expansion and the proactive integration of sustainability principles are also vital components for long-term success within this sector. Each of these elements contributes to a complex ecosystem where innovation and efficiency are paramount.

The future trajectory of aerospace industrial development hinges on continued commitment to these key areas. Stakeholders must recognize the strategic importance of fostering a competitive and sustainable industry to secure long-term economic benefits and maintain a position at the forefront of technological innovation. Vigilance and proactive adaptation to evolving global challenges are essential for continued progress in this domain.