The sector encompasses the design, development, manufacturing, and maintenance of aircraft, spacecraft, and related systems within the Federal Republic. This field involves a complex interplay of engineering disciplines, advanced materials, and stringent regulatory frameworks. Prominent examples include the production of commercial airliners, military aircraft components, and contributions to space exploration programs.

Its significance to the national economy is substantial, generating high-skilled employment, fostering technological innovation, and contributing significantly to export revenues. Historically, the region has been a key player in aviation advancements, experiencing periods of growth and adaptation shaped by global events and technological breakthroughs. The industry’s capabilities are crucial for maintaining a competitive edge in global markets and securing national strategic interests.

Subsequent discussion will focus on the key players, technological strengths, current challenges, and future outlook of this vital economic sector. Detailed analysis will be provided on specific areas of expertise and the collaborative networks that drive its success, along with the regulatory landscape that governs its operations.

Strategic Considerations for Engagement

This section provides essential guidance for entities seeking successful participation in the national aeronautical and astronautical engineering domain. Adherence to these points can enhance operational effectiveness and mitigate potential risks.

Tip 1: Establish a Strong Local Presence: Direct engagement through subsidiary establishment or strategic partnerships with established firms within the federal republic is crucial for navigating regulatory complexities and cultural nuances. This facilitates closer collaboration and improved market access.

Tip 2: Prioritize Technological Innovation: Investment in research and development, particularly in areas such as sustainable aviation technologies, advanced materials, and autonomous systems, is vital for maintaining a competitive advantage. Focus on technologies aligning with national strategic priorities.

Tip 3: Adhere to Stringent Regulatory Standards: Compliance with European Union Aviation Safety Agency (EASA) regulations and national aviation laws is non-negotiable. Proactive engagement with regulatory bodies and rigorous adherence to safety protocols are imperative.

Tip 4: Cultivate Collaborative Networks: Active participation in industry associations, research consortia, and collaborative projects facilitates knowledge sharing, resource pooling, and access to cutting-edge research. Collaborative efforts strengthen the overall ecosystem.

Tip 5: Focus on Specialized Expertise: Identify niche areas of specialization that align with national competencies and strategic initiatives. Focusing on specific areas, such as engine technology or composite materials, allows for the development of deep expertise and enhanced competitiveness.

Tip 6: Invest in Highly Skilled Workforce: Cultivate a highly skilled workforce through strategic partnerships with universities and vocational training institutions. Investing in continuous professional development is essential for maintaining technical proficiency.

Tip 7: Understand the National Industrial Strategy: Align business objectives with the national industrial strategy for the sector. This includes understanding government priorities, funding opportunities, and strategic initiatives aimed at strengthening the national competitive advantage.

Implementing these strategies allows for optimized integration and increased likelihood of success within the established national framework. These recommendations represent critical actions for maximizing operational efficiency and securing long-term viability.

The subsequent section will provide concluding remarks and outline potential future trajectories for sector development.

1. Engineering Excellence

Engineering excellence serves as a cornerstone of the national aeronautical and astronautical engineering sector. It manifests not merely as theoretical proficiency, but as a tangible commitment to precision, reliability, and innovation across all stages of design, development, and manufacturing. This commitment is directly linked to the industry’s global competitiveness and its ability to consistently meet stringent regulatory demands. For instance, the precision engineering involved in the production of jet engine components, requiring tolerances measured in microns, exemplifies this commitment. Failure to maintain such standards directly impacts engine performance, safety, and lifespan, underscoring the causal relationship between engineering prowess and successful operation within the field.

The importance of engineering excellence extends beyond component manufacturing to encompass systems integration and overall aircraft design. The advanced aerodynamics and structural integrity seen in aircraft produced by leading firms within the nation are direct results of sustained investment in engineering expertise. Furthermore, the ability to efficiently troubleshoot and resolve complex engineering challenges, such as adapting aircraft designs to meet evolving environmental regulations, showcases the practical application of this principle. This proficiency in complex problem-solving translates directly into cost savings, improved efficiency, and enhanced product quality, solidifying the nation’s reputation as a leader in aviation technology.

In conclusion, engineering excellence is not merely a desirable attribute, but a fundamental requirement for sustained success within the aerospace industry. The ability to consistently innovate, adhere to rigorous standards, and efficiently solve complex engineering problems is directly tied to the sector’s economic viability and global standing. While challenges remain, particularly in adapting to emerging technologies and maintaining a skilled workforce, the unwavering focus on engineering proficiency remains a critical factor in navigating these challenges and ensuring continued advancement.

2. Advanced Manufacturing

Advanced manufacturing constitutes a crucial pillar within the national aeronautical and astronautical engineering domain. Its implementation directly impacts production efficiency, product quality, and overall competitiveness on the global stage. The adoption of cutting-edge technologies, such as additive manufacturing (3D printing), robotic automation, and advanced materials processing, enables the production of lighter, stronger, and more complex components with greater precision and reduced waste. For example, the utilization of 3D printing in the manufacturing of turbine blades for aircraft engines allows for the creation of intricate geometries that enhance engine performance and fuel efficiency. This capability directly contributes to a reduction in operational costs and environmental impact.

The integration of advanced manufacturing techniques also facilitates greater flexibility and responsiveness to changing market demands. The ability to rapidly prototype and produce customized components enables national firms to cater to specific customer needs and adapt to evolving technological advancements. Furthermore, the implementation of digital manufacturing processes, such as data analytics and predictive maintenance, improves operational efficiency and reduces downtime. For instance, the deployment of sensors and data analytics in manufacturing facilities allows for the proactive identification and resolution of potential equipment failures, minimizing production disruptions and maximizing output. This predictive capability translates into cost savings and improved operational reliability.

In conclusion, advanced manufacturing is not merely a trend, but a necessity for sustained success within the aerospace sector. The continued investment in and implementation of cutting-edge manufacturing technologies is crucial for maintaining global competitiveness, driving innovation, and meeting the evolving demands of the market. While challenges remain, particularly in integrating new technologies and training a skilled workforce, the commitment to advanced manufacturing remains a critical factor in ensuring the long-term viability and prosperity of the national aerospace industry.

3. Research & Development

Research and development (R&D) forms a critical foundation for the aeronautical and astronautical engineering domain. Innovation propelled by systematic investigation drives technological advancement and strengthens the sector’s global competitiveness. The following facets illustrate the interplay between research endeavors and industry progress within the Federal Republic.

- Fundamental Research and Technological Breakthroughs

Fundamental research conducted at universities and research institutions provides the bedrock for technological breakthroughs. This includes investigations into advanced materials, aerodynamics, propulsion systems, and autonomous flight control. For instance, research into new composite materials that reduce aircraft weight and improve fuel efficiency directly benefits manufacturing processes and performance characteristics.

- Applied Research and Product Development

Applied research translates fundamental discoveries into practical applications. This involves prototyping, testing, and refining technologies for integration into aircraft and spacecraft. The development of new engine designs aimed at reducing emissions exemplifies this process, moving from theoretical concepts to tangible solutions for regulatory compliance and environmental sustainability.

- Government Funding and Strategic Initiatives

Government funding plays a crucial role in supporting R&D activities. Strategic initiatives, such as the LuFo (Luftfahrtforschung) program, provide financial resources for research projects focused on addressing national priorities, including sustainable aviation and enhanced security. These investments stimulate innovation and foster collaboration between industry, academia, and research institutions.

- Industry Collaboration and Knowledge Transfer

Collaboration between industry, research institutions, and universities facilitates knowledge transfer and accelerates the pace of innovation. Joint research projects and technology transfer programs enable companies to access cutting-edge research and integrate new technologies into their products. This collaborative ecosystem strengthens the sector’s overall capacity for innovation and enhances its global competitiveness.

These interconnected facets highlight the crucial role of R&D in driving progress. Sustained investment in these domains is essential for maintaining a competitive edge, addressing emerging challenges, and ensuring the continued prosperity of the national aerospace industry. Ongoing efforts to foster collaboration, incentivize innovation, and translate research findings into practical applications will be critical for realizing the sector’s full potential.

4. Global Collaboration

The interaction with international entities is integral to the success and advancement of aeronautical and astronautical engineering within the Federal Republic. This stems from the capital-intensive nature of the industry, the need for specialized expertise often distributed internationally, and the imperative to access global markets. The sector’s reliance on multinational partnerships is evident in joint ventures for aircraft development, collaborative research programs, and participation in international space missions. For instance, participation in the European Space Agency (ESA) allows national firms to contribute to and benefit from shared resources, technology, and expertise, leading to advancements in satellite technology and space exploration.

Global collaborative efforts also facilitate market access and risk sharing. By partnering with international aerospace companies, national firms can expand their reach into new markets and diversify their customer base. This is particularly crucial for smaller and medium-sized enterprises (SMEs) that may lack the resources to independently navigate complex international trade regulations and cultural nuances. Furthermore, collaborative projects enable the sharing of financial burdens and technological risks associated with large-scale development programs, enhancing the overall resilience of the sector. Airbus, as a prime example, demonstrates how multinational collaboration can lead to the development of commercially successful aircraft and the distribution of economic benefits across multiple countries.

In conclusion, global collaboration is not merely a supplementary aspect of the aerospace industry; it is a fundamental requirement for innovation, competitiveness, and sustained growth. National firms must actively pursue and cultivate international partnerships to access specialized expertise, expand market reach, and mitigate financial risks. Effective management of these collaborations, including addressing intellectual property concerns and ensuring equitable benefit sharing, is essential for maximizing their positive impact on the national economy and technological advancement.

5. Skilled Workforce

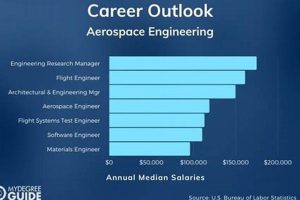

The proficiency and availability of a skilled workforce are intrinsically linked to the success and sustainability of the aeronautical and astronautical engineering sector within the Federal Republic. This is not simply a correlational relationship, but a causal one: the presence of highly trained engineers, technicians, and specialists directly enables innovation, efficient production, and adherence to rigorous safety standards. Without a readily available pool of qualified personnel, the sector’s ability to compete globally and maintain its technological leadership would be fundamentally compromised. The complex nature of aerospace engineering requires specialized expertise in areas ranging from aerodynamics and propulsion to avionics and advanced materials.

The national emphasis on vocational training and higher education in engineering disciplines plays a critical role in cultivating this skilled workforce. Dual education systems, combining practical on-the-job training with theoretical instruction, provide a steady stream of qualified technicians and engineers. Furthermore, close collaboration between universities and industry ensures that educational curricula are aligned with the evolving needs of the sector. For example, partnerships between leading aerospace firms and technical universities facilitate research collaborations, internships, and graduate programs, providing students with hands-on experience and exposure to cutting-edge technologies. This synergy between education and industry is essential for maintaining a competitive edge and addressing the challenges posed by emerging technologies such as artificial intelligence and advanced manufacturing.

In conclusion, the availability of a skilled workforce is not merely a desirable attribute, but a foundational requirement for the sustained growth and competitiveness of the aeronautical and astronautical engineering sector. The ongoing investment in education, vocational training, and industry-academia collaboration is crucial for ensuring a consistent supply of qualified personnel capable of driving innovation and maintaining the nation’s position as a global leader in aerospace technology. Challenges remain in attracting and retaining talent, particularly in the face of increasing competition from other industries, but the commitment to fostering a highly skilled workforce remains paramount.

6. Stringent Regulations

The aeronautical and astronautical engineering sector operates under a framework of stringent regulations. These guidelines, established by national and international bodies, govern all aspects of aircraft and spacecraft design, manufacturing, operation, and maintenance. Compliance is not optional but legally mandated, directly impacting every facet of the industry.

- Airworthiness Certification

Airworthiness certification is a cornerstone of aviation safety. Regulatory bodies, such as the European Union Aviation Safety Agency (EASA), oversee the process of evaluating and approving aircraft designs to ensure they meet stringent safety standards. This includes rigorous testing and documentation to demonstrate compliance with regulations pertaining to structural integrity, performance, and operational capabilities. The certification process directly impacts the design and manufacturing of aircraft, influencing material selection, engineering processes, and quality control measures.

- Environmental Regulations

Environmental regulations are increasingly shaping the industry’s development. Standards related to noise emissions, fuel efficiency, and greenhouse gas emissions require manufacturers to invest in research and development of more sustainable technologies. These regulations drive innovation in engine design, aerodynamics, and alternative fuels. Non-compliance can result in significant penalties, including fines and restrictions on aircraft operations.

- Safety Management Systems (SMS)

Safety Management Systems (SMS) are mandatory for all operators and manufacturers. SMS requires the implementation of a comprehensive framework for identifying and mitigating safety risks. This includes hazard reporting, risk assessments, and safety audits. Effective SMS implementation necessitates a strong safety culture within organizations and continuous monitoring of operational processes.

- Export Control Regulations

Export control regulations restrict the transfer of sensitive technologies and equipment to certain countries. Compliance with these regulations requires thorough due diligence and adherence to complex licensing requirements. Violations can result in severe penalties, including fines and imprisonment. The sector’s reliance on international collaboration necessitates a deep understanding of export control regulations and a robust compliance program.

Collectively, these examples illustrate the profound impact of stringent regulations on the aerospace industry. These governing principles directly affect operational processes, technological development, and business strategies, demanding constant vigilance and adaptation from national firms.

7. Economic Contribution

The presence of a robust aeronautical and astronautical engineering sector provides significant impetus to the national economy. This is not simply a matter of correlation; there exists a causal relationship wherein the industry’s activities directly generate employment, stimulate technological innovation, and contribute substantially to export revenues. The sector acts as a catalyst for related industries, creating a ripple effect that benefits suppliers, research institutions, and educational establishments. The importance of this contribution is reflected in government policies designed to support and promote aerospace activities.

Illustrative examples highlight the economic impact. The production of commercial aircraft, military equipment, and satellite technologies generates substantial export earnings, bolstering the national trade balance. Furthermore, the development of advanced materials and manufacturing processes within the industry spills over into other sectors, enhancing their competitiveness. The creation of high-skilled jobs, often requiring specialized training and expertise, elevates the overall skill level of the workforce and contributes to higher average wages. The industry’s investments in research and development drive technological progress, creating new opportunities for innovation and entrepreneurship. Direct contributions to national GDP are considerable, underscoring its strategic importance.

Understanding the economic contribution of the aeronautical and astronautical engineering domain is crucial for policymakers and business leaders. Informed decisions regarding investment, regulation, and workforce development can maximize the sector’s positive impact on national prosperity. However, this requires addressing challenges such as global competition, technological disruption, and the need for continuous innovation. Sustained commitment to supporting this sector is essential for realizing its full economic potential and ensuring long-term competitiveness.

Frequently Asked Questions

The following frequently asked questions address common inquiries regarding the national aeronautical and astronautical engineering sector. These answers aim to provide clarity on key aspects of the industry.

Question 1: What are the primary sectors encompassed within the national aeronautical and astronautical engineering landscape?

The domain includes commercial aviation, defense aerospace, space technology, and related support services. These areas encompass the design, development, manufacturing, and maintenance of aircraft, spacecraft, and associated systems.

Question 2: What are the key factors driving innovation within the national aerospace sector?

Innovation is primarily fueled by research and development (R&D) activities, government funding initiatives, collaboration between industry and academia, and the need to comply with stringent environmental regulations. Investment in advanced materials, sustainable aviation technologies, and autonomous systems also contributes significantly.

Question 3: What role does the European Union Aviation Safety Agency (EASA) play in regulating sector activities?

EASA is the primary regulatory body responsible for setting and enforcing safety standards for aviation within Europe. EASA’s regulations cover airworthiness certification, operational safety, and environmental protection. Compliance with EASA standards is mandatory for all operators and manufacturers within the national sector.

Question 4: What are the main challenges facing the national aeronautical and astronautical engineering arena?

Key challenges include increasing global competition, the need to adapt to emerging technologies, the shortage of skilled workers, and the pressure to reduce carbon emissions. Overcoming these challenges requires sustained investment in R&D, workforce development, and sustainable aviation technologies.

Question 5: How does the government support the national aerospace industry?

The government provides financial support through funding initiatives, such as the LuFo program, which supports research and development projects. The government also promotes international collaboration, fosters a favorable regulatory environment, and invests in education and training programs to develop a skilled workforce.

Question 6: What is the outlook for the national aeronautical and astronautical engineering field?

The outlook is generally positive, driven by increasing demand for air travel, the growth of the space industry, and the need for advanced defense technologies. However, the sector faces challenges related to sustainability, global competition, and technological disruption. Continued innovation and strategic investments will be crucial for ensuring long-term growth and competitiveness.

This FAQ provides a foundational understanding of key issues. The intricacies of the industry require constant analysis and awareness to ensure continued success.

The subsequent portion will delve into concluding remarks and future trajectory of the specific branch.

Concluding Remarks

The preceding analysis has explored various facets of the aerospace industry germany, highlighting its engineering excellence, advanced manufacturing capabilities, commitment to research and development, global collaborative networks, skilled workforce, stringent regulatory framework, and significant economic contribution. These elements collectively define a complex and dynamic sector that plays a crucial role in the nation’s economic prosperity and technological advancement. Understanding these core components is essential for stakeholders seeking to engage with and contribute to its sustained growth.

Sustained vigilance and strategic investment are imperative to address existing challenges and capitalize on future opportunities. The aerospace industry germany requires continued commitment to innovation, workforce development, and adaptation to evolving global market dynamics. Proactive measures are necessary to ensure the sector’s continued competitiveness and its ability to navigate the complexities of the 21st century. Its enduring significance necessitates informed decision-making and a steadfast focus on long-term sustainability.