This specific role bridges the gap between highly technical products and the clients who need them. Individuals in this position leverage engineering expertise to understand complex aerospace systems, components, or services and then effectively communicate their value proposition to potential customers. For example, an individual might be responsible for selling advanced propulsion systems to satellite manufacturers or composite materials to aircraft companies.

The importance of these positions stems from their ability to drive revenue growth within aerospace companies. Effective communication of complex technical specifications translates directly into increased sales and market share. Historically, these roles have evolved from purely technical positions to encompass sales acumen, reflecting the increasing need for technically sound individuals who can also foster strong client relationships. The benefits include contributing to the advancement of aerospace technology, directly impacting company profitability, and building a diverse skill set that blends engineering and business expertise.

The subsequent discussion will delve into the specific responsibilities, required qualifications, and career trajectory associated with this hybrid role, providing a detailed examination of the day-to-day tasks and professional development opportunities available.

This section offers practical guidance for individuals seeking success in positions related to the sale of aerospace engineering solutions. The advice focuses on key skills and strategies for excelling in this demanding field.

Tip 1: Develop a Strong Technical Foundation: A comprehensive understanding of aerospace engineering principles is paramount. Proficiency in areas such as aerodynamics, propulsion, materials science, and avionics enables effective communication with technical clients and informed product demonstrations.

Tip 2: Cultivate Exceptional Communication Skills: The ability to articulate complex technical information in a clear, concise, and compelling manner is crucial. This includes both verbal and written communication skills, as well as the ability to tailor presentations to different audiences.

Tip 3: Master Sales and Negotiation Techniques: Familiarity with sales methodologies, negotiation strategies, and customer relationship management (CRM) systems is essential for achieving sales targets and building long-term client partnerships. This involves understanding the sales cycle, identifying customer needs, and crafting persuasive proposals.

Tip 4: Network Strategically within the Aerospace Industry: Building a strong professional network is vital for generating leads, gaining industry insights, and identifying potential career opportunities. This includes attending industry conferences, joining professional organizations, and engaging with contacts on platforms such as LinkedIn.

Tip 5: Stay Abreast of Industry Trends and Technological Advancements: The aerospace industry is constantly evolving, so continuous learning and professional development are essential. This involves staying informed about new technologies, regulations, and market trends through industry publications, webinars, and training courses.

Tip 6: Emphasize Value Proposition: Demonstrating the tangible benefits of the product or service to the client is key. Quantify the return on investment (ROI) through metrics such as increased efficiency, reduced costs, or improved performance.

Tip 7: Understand the Competitive Landscape: Thoroughly analyze competitor products, pricing strategies, and market positioning. This knowledge will enable more effective differentiation and provide a compelling case for the superiority of your offering.

By implementing these tips, individuals can enhance their capabilities and increase their prospects within these specialized sales roles. A combination of technical expertise, communication proficiency, and strategic sales acumen is critical for success.

The following sections will explore relevant educational pathways and potential career progression within the field of aerospace sales engineering.

1. Technical Proficiency

Technical proficiency forms the bedrock upon which effective sales strategies are built within the aerospace engineering sector. Without a solid grasp of the underlying engineering principles, an individual is limited in their capacity to articulate the value proposition of complex products or services. For instance, a fundamental understanding of aerodynamics is essential when discussing the benefits of a novel wing design with an aircraft manufacturer. Similarly, a working knowledge of materials science is necessary to explain the advantages of advanced composites in reducing aircraft weight and improving fuel efficiency.

The correlation extends beyond basic product knowledge. Technical proficiency enables a professional to engage in meaningful conversations with engineers and technical decision-makers, addressing specific concerns and tailoring solutions to meet unique operational requirements. Consider the scenario where a sales engineer is promoting a new satellite communication system. A deep understanding of signal processing, antenna design, and orbital mechanics allows them to discuss system performance with potential clients in a way that builds trust and demonstrates credibility. The absence of this technical depth could lead to miscommunication, missed opportunities, and ultimately, lost sales.

In summary, technical proficiency is not merely an asset; it is a prerequisite for success in positions related to the sale of aerospace engineering solutions. It empowers professionals to effectively communicate value, build credibility with technical clients, and ultimately drive revenue growth within their organizations. Challenges arise when individuals attempt to compensate for a lack of technical knowledge with sales tactics alone. A sustained commitment to continuous learning and professional development in relevant engineering disciplines is crucial for long-term success and adaptability in this rapidly evolving field.

2. Communication Expertise

Communication expertise is a cornerstone of success within the field, fundamentally shaping the effectiveness of professionals engaged in bridging technical capabilities and client needs. The ability to articulate complex engineering concepts concisely and persuasively is not merely beneficial; it is essential for driving sales and fostering long-term client relationships.

- Clear and Concise Articulation of Technical Concepts

The translation of intricate engineering specifications into accessible language is critical. A sales engineer may, for example, need to explain the performance characteristics of a new radar system to a non-technical procurement manager. The ability to simplify complex data without sacrificing accuracy is paramount. Failure to do so can lead to misinterpretations, mistrust, and ultimately, lost sales opportunities.

- Active Listening and Needs Assessment

Effective communication is not solely about conveying information; it also involves actively listening to and understanding client needs. This requires probing questions, attentive observation, and the ability to synthesize information into a clear understanding of the client’s specific challenges and objectives. A successful sales engineer might identify a need for a more fuel-efficient engine by carefully listening to a client’s concerns about rising operational costs.

- Persuasive Presentation Skills

The ability to present technical information in a compelling and persuasive manner is crucial for securing sales. This involves crafting engaging presentations, using visual aids effectively, and tailoring the message to resonate with the audience. For instance, a sales engineer might demonstrate the benefits of a new composite material by showcasing its superior strength-to-weight ratio in a dynamic presentation that captures the client’s attention.

- Written Communication Proficiency

Clear and concise written communication is essential for creating effective proposals, reports, and email correspondence. The ability to convey technical information accurately and persuasively in writing is critical for building credibility and maintaining client relationships. A well-written proposal that clearly outlines the benefits of a specific aerospace solution can significantly increase the likelihood of securing a contract.

The multifaceted nature of communication expertise directly impacts the success of professionals in roles related to aerospace engineering solutions. By mastering these skills, individuals enhance their ability to connect with clients, understand their needs, and ultimately, drive revenue growth within their organizations. Communication is the linchpin between complex technical offerings and the practical needs of the aerospace industry.

3. Sales Acumen

Sales acumen, the capacity for keen insight into the sales process, is directly correlated with success in roles selling aerospace engineering solutions. Effective sales within this sector necessitate more than technical knowledge; they demand a strategic understanding of market dynamics, customer motivations, and competitive landscapes. For instance, a sales engineer with strong sales acumen recognizes when a potential client is primarily concerned with minimizing operational costs versus maximizing performance capabilities. This awareness allows for the tailoring of product presentations and proposals to address the client’s specific priorities, increasing the likelihood of a successful sale.

The importance of sales acumen is further underscored by the long sales cycles and high-value contracts characteristic of the aerospace industry. Securing a contract for the provision of aircraft components or satellite systems often requires navigating complex procurement processes and building long-term relationships with key decision-makers. A sales engineer with well-developed sales acumen understands the importance of consistent follow-up, strategic networking, and proactive problem-solving in navigating these challenges. This proactive approach is critical for building trust and credibility with clients, ultimately leading to increased sales and market share. Consider a scenario where a competitor offers a similar product at a lower price. A sales engineer with strong sales acumen might emphasize the long-term cost savings associated with their product’s superior reliability and performance, thereby justifying the higher initial investment.

In conclusion, sales acumen is not merely a complementary skill; it is an integral component of effective sales within the aerospace engineering sector. Its importance lies in the capacity to understand client needs, navigate complex sales processes, and differentiate product offerings in a competitive market. Without this strategic perspective, even the most technically proficient sales engineers may struggle to achieve consistent sales success. Continuous development of sales acumen, through training, mentorship, and practical experience, is therefore essential for professionals seeking to excel in these specialized sales roles.

4. Industry Knowledge

Possessing comprehensive industry knowledge is paramount for success in roles focused on selling aerospace engineering solutions. This knowledge base extends beyond familiarity with product specifications; it encompasses a deep understanding of market trends, regulatory landscapes, competitive dynamics, and emerging technologies within the aerospace sector. Its absence directly impairs a sales engineer’s ability to identify opportunities, effectively communicate value propositions, and build credible relationships with clients. For example, an understanding of evolving FAA regulations concerning aircraft emissions allows a sales engineer to position a more fuel-efficient engine solution as a strategic advantage for airlines seeking regulatory compliance and cost reduction. Conversely, a lack of awareness of these regulations would hinder the ability to articulate this specific benefit, potentially leading to a missed sales opportunity.

The practical application of industry knowledge also manifests in the ability to anticipate future trends and proactively address client needs. Consider a sales engineer responsible for selling advanced materials to aerospace manufacturers. A strong understanding of industry forecasts projecting increased demand for lightweight aircraft components would enable the individual to proactively engage with clients, highlighting the benefits of these materials in meeting future production requirements and improving aircraft performance. Furthermore, industry knowledge facilitates a deeper understanding of the competitive landscape, allowing sales engineers to effectively differentiate their offerings from those of competitors. This includes understanding competitors’ product strategies, pricing models, and market positioning, enabling the development of targeted sales strategies that emphasize unique strengths and advantages.

In summary, comprehensive industry knowledge is an indispensable asset for those in the “aerospace sales engineer jobs”. It empowers professionals to identify opportunities, communicate value propositions effectively, and build long-term relationships with clients. The challenges associated with navigating a rapidly evolving aerospace landscape necessitate a continuous commitment to learning and staying abreast of industry trends, regulations, and technological advancements. The absence of this commitment can lead to obsolescence and diminished sales effectiveness, underscoring the critical connection between industry knowledge and sustained success in this field.

5. Problem Solving

Problem-solving capabilities are integral to success in roles concerning aerospace engineering solutions. These roles frequently demand creative resolutions to complex client challenges, bridging technical specifications with practical applications. The efficacy of a sales engineer is often determined by the ability to diagnose needs, develop tailored solutions, and address concerns effectively.

- Technical Troubleshooting

Aerospace engineering solutions often involve intricate technologies that require skillful troubleshooting. A sales engineer must be capable of diagnosing technical issues that arise during product demonstrations or implementation. For example, if a new avionics system is not integrating seamlessly with a client’s existing infrastructure, the sales engineer must collaborate with the technical team to identify and rectify the issue promptly. A failure to address such technical problems can lead to client dissatisfaction and lost business opportunities.

- Customization and Adaptation

Aerospace clients frequently require customized solutions tailored to their specific operational needs. A sales engineer must be adept at understanding these unique requirements and working with engineering teams to adapt products or services accordingly. Consider a situation where a client requires a modified aircraft engine design to optimize performance for specific flight conditions. The sales engineer must facilitate the communication of these requirements to the engineering team and ensure that the final product meets the client’s expectations. The ability to navigate these customization processes is crucial for maintaining client satisfaction and securing repeat business.

- Navigating Regulatory Hurdles

The aerospace industry is subject to stringent regulatory requirements. Sales engineers must possess the ability to navigate these regulatory landscapes and assist clients in achieving compliance. For instance, if a new material is being proposed for use in aircraft construction, the sales engineer must understand the relevant certification processes and guide the client through the necessary steps to obtain approval. A failure to address regulatory concerns can significantly delay project timelines and jeopardize sales opportunities.

- Conflict Resolution

Disagreements or disputes may arise during the sales process or during the implementation of aerospace engineering solutions. A sales engineer must possess the ability to mediate conflicts and find mutually agreeable solutions. For instance, if a client is dissatisfied with the performance of a delivered product, the sales engineer must listen to their concerns, investigate the issue, and propose a resolution that addresses the client’s needs while protecting the interests of the company. Effective conflict resolution skills are essential for maintaining strong client relationships and preserving long-term business prospects.

These facets of problem-solving underscore its critical importance within roles focused on aerospace engineering solutions. The capacity to diagnose technical issues, customize solutions, navigate regulatory hurdles, and resolve conflicts effectively directly impacts the success of sales efforts and the maintenance of strong client relationships. The proactive identification and resolution of potential problems is a defining characteristic of successful professionals in this field.

6. Relationship Building

Relationship building is a cornerstone of success. The aerospace industry operates on trust and long-term collaboration, securing a sale requires cultivating and maintaining strong relationships with clients, often over extended periods. This proactive effort contributes directly to repeat business and sustained growth. A single transaction represents a limited engagement, whereas a strong relationship paves the way for future projects and opportunities. This focus shifts the dynamic from a transactional approach to a partnership paradigm.

The cultivation of these relationships often involves significant investment in time and resources. Regularly engaging with clients, understanding their evolving needs, and providing proactive support are essential elements. For example, a sales engineer may organize technical workshops or attend industry events to connect with clients and foster open communication. Furthermore, addressing client concerns promptly and effectively demonstrates a commitment to their success, solidifying the relationship. Consider a scenario where a client experiences a technical challenge with a delivered solution. A sales engineer who quickly mobilizes resources to resolve the issue not only mitigates the immediate problem but also strengthens the client’s trust and confidence in the company.

The challenges associated with relationship building stem from the inherent complexities of the aerospace industry and the diverse range of stakeholders involved. Navigating organizational hierarchies, understanding individual motivations, and effectively communicating technical information to non-technical audiences all require finesse and adaptability. However, the rewards of successful relationship building are substantial, leading to increased sales, enhanced brand reputation, and a competitive advantage in the market. The ability to forge lasting partnerships is therefore a critical skill for any professional.

Frequently Asked Questions

This section addresses common inquiries regarding roles focused on selling aerospace engineering solutions, providing clarity and insights into the responsibilities, qualifications, and career outlook.

Question 1: What specific educational background is most beneficial for securing employment in this field?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a related engineering discipline is generally considered essential. Advanced degrees, such as a master’s degree, can provide a competitive advantage, particularly for roles involving highly specialized technical products or services. Courses in business administration or sales management can supplement engineering knowledge, enhancing the individual’s overall skill set.

Question 2: How important is prior sales experience compared to technical expertise?

Both are valued, but technical expertise is often prioritized. While prior sales experience is advantageous, employers typically seek candidates with a strong technical foundation and the aptitude to develop sales skills through training and mentorship. A deep understanding of aerospace engineering principles enables more effective communication with technical clients and facilitates the development of tailored solutions.

Question 3: What are the typical day-to-day responsibilities?

Daily tasks often involve identifying potential clients, preparing technical presentations, conducting product demonstrations, responding to client inquiries, negotiating contracts, and collaborating with internal engineering teams to develop customized solutions. Furthermore, regular travel to client sites and industry events is often required. Maintaining accurate sales records and tracking key performance indicators (KPIs) are also essential responsibilities.

Question 4: What are some of the most challenging aspects of this profession?

Challenges include navigating complex sales cycles, managing demanding client expectations, staying abreast of rapidly evolving technologies, and differentiating product offerings in a competitive market. Effectively communicating the value proposition of highly technical products to diverse audiences also presents a significant challenge. Balancing sales targets with the need to provide comprehensive technical support requires a strategic approach.

Question 5: What is the typical career progression?

Individuals may start as associate sales engineers or technical sales representatives, gradually progressing to senior sales engineer roles or sales management positions. Opportunities may also exist to transition into product management or business development roles within aerospace companies. Continued professional development and a track record of sales success are critical for career advancement.

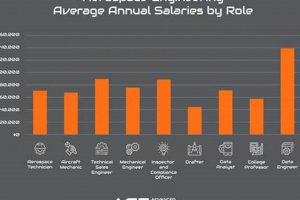

Question 6: What is the expected salary range?

Salary ranges vary depending on experience, education, location, and the specific employer. However, the field generally offers competitive compensation packages, including base salary, commission, and benefits. Performance-based incentives can significantly increase earning potential. Industry surveys and salary benchmarking tools can provide more specific estimates based on individual qualifications and market conditions.

These FAQs provide a foundational understanding of roles selling aerospace engineering solutions. The subsequent discussion will explore emerging trends and future prospects within this dynamic sector.

The next section provides insight on Aerospace Sales Engineer jobs.

Conclusion

This examination of aerospace sales engineer jobs has detailed the multifaceted nature of these positions, emphasizing the critical interplay between technical expertise, communication skills, and sales acumen. The analysis has underscored the importance of industry knowledge, problem-solving capabilities, and relationship-building prowess in navigating the complexities of the aerospace market. The discussed frequently asked questions have provided essential clarity regarding educational prerequisites, typical responsibilities, and career progression pathways.

The aerospace sectors continued reliance on specialized sales professionals underscores the strategic value of these roles. As technology evolves and market dynamics shift, individuals in aerospace sales engineer jobs must remain adaptive and committed to continuous professional development. The insights provided herein serve as a foundation for informed decision-making for both aspiring and established professionals seeking success in this demanding, yet rewarding, field. Continued diligence and strategic adaptation will be crucial for thriving in this evolving landscape.