Positions focused on designing, developing, testing, and maintaining aircraft, spacecraft, satellites, and related systems within the state of Texas constitute a significant segment of the engineering sector. These roles require a strong foundation in mathematics, physics, and engineering principles, often coupled with specialized knowledge in areas such as aerodynamics, propulsion, materials science, and control systems. For example, these engineers may work on designing new aircraft wings to improve fuel efficiency or developing guidance systems for space vehicles.

The availability of these specialized roles in Texas provides significant economic benefits, fostering innovation and technological advancement within the state. The presence of major aerospace companies, government facilities, and research institutions contributes to a robust ecosystem that supports career growth and advancement in this field. Historically, Texas has played a vital role in the aerospace industry, dating back to early aviation and the space race, solidifying its position as a key hub for related activities.

The following sections will provide a deeper examination of the types of organizations offering employment opportunities, the specific skills and qualifications sought by employers, the typical compensation packages available, and the overall outlook for individuals pursuing a career in this technologically advanced domain within the Texas market.

The pursuit of a successful career related to the design, development, and maintenance of aircraft and spacecraft in Texas requires strategic planning and a focused approach. The following recommendations are intended to guide aspiring and current professionals in maximizing their potential within this competitive field.

Tip 1: Develop Specialized Skills: Cultivate expertise in high-demand areas. Examples include proficiency in CAD/CAM software, finite element analysis, or specific aerospace materials like composites. Such specialization enhances marketability.

Tip 2: Prioritize Relevant Education: Secure advanced degrees or certifications aligned with career aspirations. A Master’s degree in Aerospace Engineering or a related field is often a prerequisite for advanced roles. Project management certifications can also be beneficial.

Tip 3: Network Strategically: Attend industry conferences, join professional organizations like the American Institute of Aeronautics and Astronautics (AIAA), and actively connect with professionals currently employed in the aerospace sector in Texas. Networking expands awareness of unadvertised opportunities.

Tip 4: Target Specific Companies: Research organizations with significant operations in Texas, such as Lockheed Martin, Boeing, or NASA’s Johnson Space Center. Tailor applications to align with the specific needs and priorities of these employers.

Tip 5: Gain Practical Experience: Pursue internships or co-op programs with aerospace companies. Practical experience significantly enhances a candidate’s qualifications and provides valuable industry exposure.

Tip 6: Highlight Technical Proficiency: Showcase relevant technical skills in resumes and cover letters. Quantify accomplishments whenever possible, such as improvements in efficiency or reductions in costs achieved through engineering efforts.

Tip 7: Prepare for Rigorous Interviews: Expect technical interviews that assess problem-solving abilities and in-depth knowledge of aerospace engineering principles. Practice answering common interview questions and be prepared to discuss specific projects or research experiences.

Adherence to these suggestions enhances the probability of securing and advancing a career in aerospace engineering within the Texas job market. Continuous learning and professional development are essential for long-term success in this dynamic and technically demanding industry.

The subsequent sections will delve into specific career paths, salary expectations, and long-term growth prospects for aerospace engineers in Texas, providing a comprehensive overview of the landscape.

1. Design and Development

The “Design and Development” phase within “aerospace engineer jobs in texas” represents a critical stage where theoretical concepts are translated into tangible products and systems. This phase encompasses activities ranging from initial concept generation to detailed engineering design, simulation, and prototyping. Successful “Design and Development” directly impacts the performance, reliability, and safety of aerospace vehicles and components.

Texas’s aerospace sector significantly relies on skilled engineers capable of executing complex design tasks. For example, engineers at Lockheed Martin’s Fort Worth facility are involved in the design and development of advanced fighter aircraft, demanding expertise in aerodynamics, structural analysis, and avionics systems integration. Similarly, engineers at NASA’s Johnson Space Center contribute to the design of spacecraft and related systems for human spaceflight missions. The state’s concentration of aerospace companies and government facilities fosters a continuous demand for engineers with expertise in areas such as computational fluid dynamics, materials science, and systems engineering.

The proficiency of engineers in “Design and Development” directly influences the competitiveness and innovation within the Texas aerospace industry. Challenges include managing complex project requirements, adhering to stringent regulatory standards, and incorporating advanced technologies to improve performance and reduce costs. The effective integration of simulation and modeling tools, combined with a thorough understanding of manufacturing processes, is crucial for ensuring successful product development and maintaining Texas’s prominent position within the global aerospace market.

2. Testing and Analysis

Within the context of roles focused on aircraft and spacecraft engineering in Texas, “Testing and Analysis” constitutes a vital process for validating designs, ensuring performance standards are met, and mitigating potential risks. It encompasses a wide array of methodologies designed to assess the integrity and functionality of aerospace components and systems under various operating conditions.

- Structural Testing

Structural testing involves subjecting aerospace components, such as wings or fuselages, to simulated flight loads and environmental conditions to evaluate their structural integrity and identify potential failure points. For instance, a wing component might be subjected to stress tests simulating the forces experienced during takeoff, flight, and landing. These tests are crucial for verifying that the component can withstand the operational stresses and ensuring the safety of the aircraft or spacecraft. In the context of these engineering roles in Texas, engineers are responsible for designing and executing these tests, analyzing the resulting data, and recommending design modifications as needed.

- Aerodynamic Analysis

Aerodynamic analysis focuses on evaluating the aerodynamic performance of aerospace vehicles and components. This involves conducting wind tunnel tests and computational fluid dynamics (CFD) simulations to assess lift, drag, stability, and control characteristics. For example, engineers might use wind tunnels to measure the aerodynamic forces acting on a scale model of an aircraft wing at different angles of attack. CFD simulations can provide detailed insights into the airflow patterns around the aircraft, helping to identify areas of potential drag or instability. Within these engineering roles in Texas, engineers utilize these analyses to optimize the aerodynamic design of aircraft and spacecraft, improving fuel efficiency and enhancing overall performance.

- Materials Testing

Materials testing involves assessing the properties of materials used in aerospace construction, such as aluminum alloys, composites, and titanium, under various conditions. This may include tensile testing, fatigue testing, and corrosion testing to determine the material’s strength, durability, and resistance to environmental degradation. For example, engineers might conduct tensile tests to measure the material’s ability to withstand pulling forces or fatigue tests to assess its resistance to repeated stress cycles. This testing ensures the selected materials meet the stringent performance requirements of aerospace applications. Within the context of these engineering positions in Texas, engineers apply the results of materials testing to select appropriate materials for specific applications and to ensure the long-term reliability of aerospace structures.

- Systems Integration Testing

Systems integration testing focuses on verifying the functionality and compatibility of various subsystems within an aerospace vehicle, such as avionics, propulsion, and control systems. This involves testing the integrated system under simulated operational conditions to identify potential issues with communication, control, or performance. For example, engineers might simulate a flight scenario to test the interaction between the autopilot system and the navigation system. This testing ensures that the various subsystems function seamlessly together and meet the overall performance requirements of the aircraft or spacecraft. Within the context of these engineering jobs in Texas, engineers design and execute systems integration tests, analyze the resulting data, and develop solutions to address any integration issues.

These facets of “Testing and Analysis” are fundamentally linked to the success and safety of aerospace projects in Texas. The ability of engineers to accurately and thoroughly conduct these tests is crucial for validating designs, identifying potential problems, and ensuring that aerospace vehicles and systems meet the stringent performance and safety standards required for operation. The demand for skilled engineers capable of performing and interpreting these tests remains consistently high within the Texas aerospace sector.

3. Research and Innovation

In the context of “aerospace engineer jobs in texas,” “Research and Innovation” represents a fundamental driver of advancement and a critical component of the state’s aerospace industry. This encompasses a spectrum of activities aimed at developing new technologies, improving existing systems, and exploring novel concepts that can shape the future of aerospace.

- Advanced Materials Development

This facet focuses on researching and developing new materials with enhanced properties, such as lighter weight, higher strength, and improved temperature resistance. Examples include the development of advanced composites for aircraft structures and high-temperature alloys for jet engine components. Aerospace engineering positions in Texas are directly involved in this research, contributing to the design, testing, and characterization of these materials, which ultimately enhance the performance and efficiency of aerospace vehicles.

- Autonomous Systems and Robotics

This area centers on the development of autonomous systems and robotic technologies for aerospace applications, such as unmanned aerial vehicles (UAVs), autonomous spacecraft, and robotic assembly systems. For example, research is underway to develop UAVs for surveillance, reconnaissance, and delivery missions, as well as robotic systems for in-space manufacturing and maintenance. Professionals in this field within Texas are responsible for designing, developing, and testing these autonomous systems, contributing to advancements in areas such as artificial intelligence, sensor technology, and control systems.

- Hypersonic Technologies

This facet focuses on the development of technologies for hypersonic flight, which involves traveling at speeds greater than five times the speed of sound. Research areas include hypersonic propulsion systems, thermal protection systems, and aerodynamic design. Aerospace engineer roles in Texas are engaged in developing and testing these technologies, contributing to the design of hypersonic vehicles for military, commercial, and space exploration applications.

- Sustainable Aviation Technologies

This area centers on developing technologies to reduce the environmental impact of aviation, such as alternative fuels, electric propulsion systems, and improved aircraft designs. For example, research is being conducted on biofuels, hydrogen-powered aircraft, and electric vertical takeoff and landing (eVTOL) vehicles. Aerospace engineers in Texas are working to develop and implement these technologies, contributing to efforts to make aviation more sustainable and environmentally friendly.

These facets of “Research and Innovation” are essential for maintaining Texas’s competitive edge in the global aerospace industry. The ability of aerospace engineers in Texas to contribute to these research areas is crucial for advancing technology, creating new opportunities, and ensuring the continued growth and success of the sector. These activities also drive demand for highly skilled professionals with expertise in various engineering disciplines, solidifying Texas’s position as a leading hub for aerospace innovation.

4. Manufacturing and Production

The “Manufacturing and Production” facet is inextricably linked to “aerospace engineer jobs in texas,” representing the practical realization of designs and innovations. This phase involves transforming raw materials and components into finished aerospace products, ranging from aircraft and spacecraft to satellites and related equipment. The efficiency and precision of manufacturing processes directly impact the cost, quality, and delivery timelines of these products, thereby influencing the competitiveness of Texas-based aerospace companies.

Aerospace engineers in Texas play a crucial role in optimizing manufacturing processes, ensuring adherence to stringent quality standards, and implementing advanced manufacturing techniques. For example, engineers at Bell Helicopter’s Amarillo facility are involved in the manufacturing of rotorcraft, requiring expertise in areas such as composite materials processing, precision machining, and assembly line optimization. Similarly, engineers at Lockheed Martin’s Dallas-area facilities oversee the production of missile defense systems, demanding expertise in areas such as electronics manufacturing, systems integration, and testing. The application of lean manufacturing principles, automation technologies, and digital manufacturing tools is essential for improving productivity and reducing waste in these processes.

The integration of advanced manufacturing technologies, such as additive manufacturing (3D printing) and robotics, is transforming the aerospace manufacturing landscape in Texas. These technologies enable the creation of complex geometries, the reduction of material waste, and the automation of repetitive tasks. Aerospace engineers are at the forefront of implementing these technologies, driving innovation in manufacturing processes and improving the overall efficiency of the aerospace sector. Continuous improvement in manufacturing and production techniques is vital for maintaining Texas’s position as a leading center for aerospace manufacturing and ensuring the long-term competitiveness of the state’s aerospace industry.

5. Quality Assurance

The facet of “Quality Assurance” within the scope of “aerospace engineer jobs in texas” is paramount, serving as a systematic process of ensuring that aerospace products and services meet specified requirements and standards. It encompasses a wide range of activities, including inspection, testing, documentation, and process control, designed to prevent defects and maintain the highest levels of reliability and safety in the aerospace industry.

- Inspection and Testing Protocols

Inspection and testing protocols are critical components of quality assurance, involving the systematic examination of aerospace components and systems to verify conformance to design specifications and regulatory requirements. Examples include non-destructive testing (NDT) methods like ultrasonic testing and radiography to detect internal flaws in materials, as well as functional testing of avionics systems and flight control surfaces. Aerospace engineers in Texas are responsible for developing and implementing these protocols, ensuring that all products undergo rigorous testing to identify potential defects and ensure compliance with industry standards. For instance, engineers at Lockheed Martin’s Fort Worth facility utilize advanced inspection techniques to verify the integrity of the F-35 fighter jet’s composite structure, ensuring its ability to withstand the stresses of flight.

- Documentation and Traceability Systems

Documentation and traceability systems play a vital role in quality assurance by providing a comprehensive record of all manufacturing processes, materials used, and inspections performed on aerospace components. These systems enable engineers to track the history of each part, from raw material to finished product, facilitating root cause analysis in the event of a failure. In Texas, aerospace engineers are responsible for maintaining detailed documentation of all manufacturing processes, including material certifications, inspection reports, and test results. This documentation is essential for demonstrating compliance with regulatory requirements and for ensuring the traceability of parts in the event of a recall. For example, Boeing’s San Antonio facility maintains extensive documentation of all aircraft modifications and repairs, ensuring that all work meets the stringent requirements of the Federal Aviation Administration (FAA).

- Process Control and Statistical Analysis

Process control and statistical analysis are used to monitor and improve manufacturing processes, reducing variability and preventing defects. Statistical process control (SPC) techniques, such as control charts and Pareto analysis, are used to identify and eliminate sources of variation in manufacturing processes. Aerospace engineers in Texas are responsible for implementing process control systems and using statistical analysis to monitor process performance, identify trends, and implement corrective actions. This helps to ensure that manufacturing processes are stable, capable, and consistently producing high-quality products. For instance, engineers at Triumph Aerostructures in Red Oak utilize SPC techniques to monitor the dimensional accuracy of aircraft components, reducing variability and improving the overall quality of the final product.

- Compliance with Regulatory Standards

Compliance with regulatory standards is a fundamental aspect of quality assurance, requiring aerospace engineers to adhere to strict guidelines and regulations set forth by government agencies and industry organizations. These standards, such as those promulgated by the FAA and the International Aerospace Quality Group (IAQG), cover all aspects of aerospace design, manufacturing, and maintenance. Aerospace engineers in Texas are responsible for ensuring that all products and processes comply with these standards, participating in audits and inspections, and implementing corrective actions to address any non-compliance issues. For example, engineers at L3Harris Technologies in Greenville are responsible for ensuring that all aircraft modifications and upgrades comply with FAA regulations, maintaining the airworthiness of the aircraft and ensuring the safety of passengers and crew.

These interconnected facets underscore the critical importance of quality assurance in the aerospace sector within Texas. The application of rigorous testing, meticulous documentation, stringent process control, and adherence to regulatory standards ensures the reliability, safety, and performance of aerospace products and systems. As such, expertise in quality assurance is a highly valued attribute for aerospace engineers seeking positions in Texas, contributing to the continued growth and success of the state’s aerospace industry.

6. Project Management

Project Management constitutes a critical function within the landscape of aerospace engineering roles in Texas, providing the structure and oversight necessary to execute complex projects efficiently and effectively. From design and development to manufacturing and testing, aerospace projects necessitate meticulous planning, coordination, and control to meet stringent technical requirements, budget constraints, and delivery timelines.

- Planning and Scheduling

Planning and scheduling are foundational elements of project management, involving the definition of project scope, the creation of detailed work breakdown structures, and the establishment of realistic schedules. Within the context of aerospace engineering roles in Texas, project managers utilize sophisticated tools and techniques, such as Gantt charts and critical path method (CPM), to plan and schedule project activities, allocate resources effectively, and track progress against established milestones. For example, in the development of a new satellite system, project managers must carefully plan and schedule the design, manufacturing, testing, and launch phases, ensuring that all activities are completed on time and within budget. Effective planning and scheduling are essential for minimizing delays, reducing costs, and maximizing project success.

- Risk Management

Risk management is a proactive process that involves identifying, assessing, and mitigating potential risks that could impact project outcomes. Aerospace projects are inherently complex and face a variety of risks, including technical challenges, budget overruns, schedule delays, and regulatory compliance issues. Project managers in Texas utilize risk management techniques, such as risk assessment matrices and Monte Carlo simulations, to identify potential risks, evaluate their likelihood and impact, and develop mitigation plans. For instance, in the development of a new aircraft engine, project managers must assess the risk of technical failures, material shortages, and regulatory delays, and develop contingency plans to address these potential issues. Effective risk management is crucial for minimizing the impact of unforeseen events and ensuring project objectives are achieved.

- Resource Allocation and Management

Resource allocation and management involve the effective distribution and utilization of project resources, including personnel, equipment, materials, and funding. Aerospace projects often require specialized skills and expertise, as well as access to expensive equipment and facilities. Project managers in Texas are responsible for allocating resources efficiently, ensuring that the right resources are available at the right time, and managing resource conflicts effectively. For example, in the construction of a new spacecraft, project managers must allocate skilled engineers, technicians, and manufacturing personnel to various tasks, ensuring that all resources are utilized effectively and that project milestones are met. Effective resource allocation and management are essential for optimizing project performance and minimizing costs.

- Stakeholder Communication and Management

Stakeholder communication and management involve establishing and maintaining effective communication channels with all project stakeholders, including project sponsors, team members, customers, and regulatory agencies. Aerospace projects typically involve multiple stakeholders with diverse interests and perspectives. Project managers in Texas are responsible for communicating project status, addressing stakeholder concerns, and managing stakeholder expectations effectively. For instance, in the development of a new launch vehicle, project managers must communicate regularly with government agencies, commercial customers, and internal stakeholders, ensuring that all parties are informed of project progress and potential issues. Effective stakeholder communication and management are crucial for building trust, fostering collaboration, and ensuring that project objectives are aligned with stakeholder needs and expectations.

The discussed facets of project management underscore its indispensable role in aerospace engineering endeavors in Texas. Effective project management practices are crucial for ensuring that aerospace projects are completed successfully, on time, within budget, and in accordance with stringent quality and safety standards. Expertise in project management is a highly valued attribute for aerospace engineers seeking positions in Texas, contributing to the efficient and innovative advancements within the state’s aerospace sector.

Frequently Asked Questions

This section addresses common inquiries concerning careers focused on the design, development, and maintenance of aircraft and spacecraft within the state of Texas. The following questions and answers aim to provide clarity and guidance for individuals considering or currently pursuing opportunities in this specialized field.

Question 1: What are the primary educational qualifications required for roles focused on aircraft and spacecraft engineering in Texas?

A bachelor’s degree in aerospace engineering, or a closely related field such as mechanical engineering or electrical engineering, is typically the minimum requirement. Many advanced positions necessitate a master’s degree or doctorate, particularly those involving research and development or specialized design.

Question 2: Which specific skills are most valuable for securing employment in this sector within Texas?

Proficiency in computer-aided design (CAD) software, computational fluid dynamics (CFD), finite element analysis (FEA), and systems engineering are highly valued. In addition, knowledge of aerospace materials, propulsion systems, and avionics is beneficial. Strong problem-solving, analytical, and communication skills are also essential.

Question 3: What types of organizations typically offer employment opportunities for aerospace engineers in Texas?

Major aerospace companies such as Lockheed Martin, Boeing, and Bell Textron, along with government agencies like NASA’s Johnson Space Center, provide significant employment opportunities. Additionally, smaller aerospace contractors, research institutions, and universities offer a range of positions.

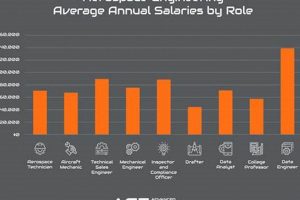

Question 4: What is the typical salary range for these specialized engineers in Texas?

Salaries vary based on experience, education, and specific job responsibilities. Entry-level positions may range from $70,000 to $90,000 annually, while experienced engineers and project managers can earn upwards of $150,000 or more. Compensation packages often include benefits such as health insurance, retirement plans, and paid time off.

Question 5: What are the potential career paths for individuals in this field within Texas?

Career paths can include design engineering, systems engineering, research and development, manufacturing engineering, project management, and quality assurance. Advancement opportunities may lead to roles in management, technical leadership, or specialized consulting.

Question 6: What is the current job market outlook for individuals in roles related to the design, development, and maintenance of aircraft and spacecraft in Texas?

The job market outlook is generally positive, driven by the continued growth of the aerospace industry in Texas and ongoing investments in space exploration and defense. However, competition for positions can be intense, particularly for highly specialized roles. Continuous professional development and skill enhancement are crucial for maintaining a competitive edge.

In summary, these specialized engineering positions in Texas offer rewarding career opportunities for individuals with the appropriate education, skills, and experience. The state’s robust aerospace industry and ongoing technological advancements contribute to a dynamic and challenging work environment.

The subsequent section will explore the impact of technological advancements on the future of aircraft and spacecraft engineering in Texas, providing insights into emerging trends and challenges.

Conclusion

This exposition has provided a comprehensive overview of aerospace engineer jobs in texas, encompassing the required qualifications, crucial skills, potential employers, typical compensation, and available career paths. Further detailed examinations of design, testing, research, manufacturing, quality assurance, and project management aspects, serve to illuminate the diverse functions encompassed within this field. It underscores the significant contributions these professionals make to the state’s economy and technological advancement.

As the aerospace industry continues to evolve, driven by innovation and increasing demand, the need for skilled engineers in Texas will remain strong. Aspiring professionals are encouraged to pursue advanced education, cultivate specialized skills, and actively engage with the aerospace community to maximize their potential in this dynamic and challenging field. Continued investment in research and development, coupled with strategic partnerships between industry, government, and academia, will be essential for sustaining Texas’s leadership in the aerospace sector.