The roles in question pertain to positions within the aeronautics and astronautics fields that focus on the design, development, testing, and maintenance of electrical systems. These systems are integral to the operation of aircraft, spacecraft, satellites, and related equipment. Examples include wiring harnesses, power distribution units, avionics systems, and control panels.

These occupations are vital to ensuring the safety, reliability, and performance of complex flying machines. They contribute directly to advancements in aviation technology, space exploration, and national defense. Historically, the need for specialized knowledge in this area has grown in tandem with increasing technological sophistication of flight vehicles.

The following sections will explore the qualifications, responsibilities, industry outlook, and career paths associated with this specialized field. A detailed examination of necessary skills and educational requirements will also be presented, providing a comprehensive overview for those interested in pursuing a career in this demanding yet rewarding area.

This section provides strategic advice for individuals seeking entry or advancement within the specialized sector of electrical engineering in aerospace. These tips focus on optimizing qualifications and career trajectory.

Tip 1: Emphasize Relevant Coursework: Academic programs should prominently feature coursework in electrical circuit design, power electronics, control systems, and electromagnetic compatibility. Certification in relevant software and hardware is highly advantageous.

Tip 2: Acquire Industry-Specific Certifications: Obtaining certifications such as those related to aviation maintenance, avionics systems, or electrical safety standards demonstrates a commitment to professional development and adherence to industry best practices.

Tip 3: Cultivate Strong Analytical and Problem-Solving Skills: These skills are essential for diagnosing and resolving complex electrical issues in aerospace systems. Proficiency in root cause analysis and troubleshooting techniques is crucial.

Tip 4: Gain Practical Experience Through Internships: Participating in internships with aerospace companies or research institutions provides invaluable hands-on experience and exposure to real-world challenges in the field.

Tip 5: Network Strategically Within the Industry: Attending industry conferences, joining professional organizations, and connecting with professionals on platforms like LinkedIn can open doors to opportunities and provide valuable insights.

Tip 6: Develop a Deep Understanding of Aerospace Standards and Regulations: Familiarity with standards set by organizations such as the FAA and NASA, as well as compliance requirements, is crucial for ensuring safety and regulatory adherence.

Tip 7: Focus on Continuous Learning: The aerospace industry is characterized by rapid technological advancements. Staying current with the latest developments in electrical engineering and aerospace technology is essential for long-term career success.

Adhering to these guidelines can significantly enhance the likelihood of securing and thriving in a rewarding career within the specialized sector of electrical roles related to flight.

The subsequent sections will delve into specific employers, salary expectations, and emerging trends within this dynamic professional arena, providing a comprehensive understanding of opportunities.

1. Design

Design, within the context of opportunities within the aeronautics and astronautics fields relating to electricity, is a fundamental and multifaceted undertaking. It represents the initial stage in the creation of electrical systems for aircraft, spacecraft, and related technologies. Effective design is paramount; flaws can propagate through subsequent stages, compromising system performance and safety. Design responsibilities include specifying system architecture, selecting appropriate components, creating schematics, and conducting simulations to ensure functionality under various operating conditions. Example: The design of a new power distribution system for a commercial airliner necessitates consideration of factors such as weight, power efficiency, fault tolerance, and electromagnetic compatibility.

The importance of robust electrical design in aerospace is underscored by the critical applications these systems support. Avionics, propulsion control, navigation, and communication all rely on intricate electrical networks. Errors in design can lead to catastrophic failures, emphasizing the need for rigorous verification and validation processes. For instance, the design of electrical wiring interconnect systems (EWIS) in aircraft requires adherence to stringent safety standards to mitigate the risk of fire hazards. Furthermore, increasingly complex electrical architectures and electrification trends in aerospace are driving innovation in design methodologies and tools.

In summary, electrical design constitutes a cornerstone of opportunities within the aeronautics and astronautics fields relating to electricity. Its impact extends to every aspect of aerospace vehicle operation, demanding expertise in electrical engineering principles, regulatory compliance, and systems-level thinking. The challenges inherent in aerospace electrical design, particularly concerning safety and reliability, necessitate a commitment to continuous improvement and adoption of advanced technologies. The future evolution of these jobs is inextricably linked to advancements in design methodologies and the ability to adapt to emerging requirements.

2. Maintenance

Maintenance is an indispensable function directly connected to electrical occupations in aeronautics and astronautics. It ensures the continued airworthiness, reliability, and safety of complex aerospace systems. Effective upkeep prevents failures and maximizes the operational lifespan of critical electrical components.

- Scheduled Inspections

Regular inspections are performed to detect signs of wear, corrosion, or damage to electrical wiring, connectors, and components. These inspections are mandated by regulatory authorities and manufacturers’ recommendations. An example is the periodic inspection of wiring harnesses in aircraft wings to identify potential chafing or degradation that could lead to short circuits.

- Troubleshooting and Repair

This involves diagnosing and resolving electrical faults or malfunctions. Technicians utilize specialized testing equipment, such as multimeters and oscilloscopes, to pinpoint the source of the problem. An example is tracing a fault in an aircraft’s navigation system back to a faulty circuit board or a broken wire.

- Component Replacement

When electrical components reach the end of their service life or fail, they are replaced with new or refurbished parts. This requires adherence to strict quality control standards and documentation procedures. For example, replacing a malfunctioning generator on an aircraft engine necessitates verifying the replacement part meets the original equipment manufacturer’s specifications.

- Preventative Maintenance

Proactive maintenance activities are conducted to prevent potential electrical failures before they occur. This may include cleaning and lubricating connectors, tightening loose connections, and applying protective coatings to prevent corrosion. An example is applying dielectric grease to electrical connectors in spacecraft to prevent arcing in the vacuum of space.

The facets of maintenance described are critical to the operational integrity of aerospace vehicles. The skills and expertise required for these tasks are essential for qualified personnel engaged in electrical jobs within this industry. Proper maintenance not only ensures safety but also reduces downtime and extends the operational lifespan of aerospace assets.

3. Testing

Testing is a critical component of electrical roles within the aeronautics and astronautics fields. It validates the functionality, reliability, and safety of electrical systems and components under simulated and real-world conditions, ensuring compliance with stringent aerospace standards.

- Functional Testing

Functional testing verifies that electrical systems operate as intended under normal and abnormal conditions. This includes assessing voltage levels, current flows, signal integrity, and response times. For instance, functional testing of an aircraft’s flight control system ensures that it responds correctly to pilot inputs and environmental changes, preventing potential hazards during flight.

- Environmental Testing

Environmental testing assesses the performance of electrical components and systems under extreme conditions such as temperature variations, vibration, altitude changes, and electromagnetic interference. These tests simulate the harsh environments encountered during flight or space missions. An example is subjecting a satellite’s power supply to thermal cycling to ensure it can withstand the temperature fluctuations in orbit.

- Electromagnetic Compatibility (EMC) Testing

EMC testing ensures that electrical systems do not interfere with each other or with external electromagnetic sources. This is crucial for preventing malfunctions and ensuring the reliable operation of sensitive avionics equipment. An example is testing an aircraft’s radar system to ensure that its electromagnetic emissions do not disrupt the operation of the navigation system.

- Safety Testing

Safety testing verifies that electrical systems are designed and built to prevent hazards such as electrical shock, fire, and explosion. This includes insulation resistance testing, ground continuity testing, and high-voltage testing. An example is testing the insulation of wiring harnesses in spacecraft to ensure that they can withstand the high voltages used in power distribution systems, preventing potentially catastrophic arcing.

These varied forms of testing collectively contribute to the robustness and dependability required of systems and components in electrical occupations within aeronautics and astronautics. Each test regime yields information vital for ensuring that designs conform to stringent standards. Continuous refinement of testing methodologies is critical to maintaining safety and performance levels, especially given evolving regulatory expectations.

4. Systems integration

Systems integration is a critical function within aerospace electrical engineering positions. It involves combining various electrical and electronic components into a unified, functional system. The efficacy of integration directly influences overall system performance and reliability. Improper integration can lead to malfunctions, inefficiencies, and potentially catastrophic failures. For instance, integrating a new navigation system into an existing aircraft requires careful consideration of power requirements, data interfaces, and electromagnetic compatibility to avoid disrupting other onboard systems. A successful integration ensures each component operates harmoniously within the larger system, meeting specified performance criteria and safety standards.

Electrical occupations often necessitate proficiency in systems integration methodologies and tools. Engineers must be able to design and implement interfaces between different electrical systems, troubleshoot integration issues, and validate system performance. This often involves working with a variety of hardware and software platforms, as well as adhering to industry-specific integration standards. Consider the integration of a satellite’s communication payload with its power and control systems. This requires careful management of power distribution, signal routing, and thermal management to ensure the payload operates reliably in the harsh environment of space.

In summary, systems integration is an indispensable element. It drives efficient operation and directly impacts safety in the field of aeronautics and astronautics relating to electricity. Personnel engaged in relevant electrical activities must possess robust integration skills and a systems-level understanding to ensure the successful deployment and operation of complex aerospace systems. Challenges arise from increasing system complexity and the need for interoperability across diverse platforms, highlighting the importance of standardization and modular design practices.

5. Troubleshooting

Troubleshooting is an inherent and critical aspect of electrical positions within the aeronautics and astronautics domain. The complex nature of electrical systems in aircraft, spacecraft, and related equipment necessitates the ability to diagnose and resolve malfunctions efficiently and effectively. Failures in these systems can have severe consequences, ranging from operational disruptions to catastrophic accidents. Therefore, skilled troubleshooting is essential for maintaining safety and operational readiness. Causes of electrical malfunctions can stem from component failures, wiring defects, environmental factors, or design flaws. An inability to resolve these issues promptly can lead to significant downtime and increased maintenance costs. For example, a malfunctioning sensor in an aircraft’s engine control system can lead to reduced engine performance or even engine failure, requiring immediate and accurate troubleshooting to identify and rectify the problem. The absence of effective troubleshooting can result in grounded aircraft, delayed space missions, and compromised national defense capabilities.

The importance of troubleshooting is further underscored by the increasing complexity of modern aerospace electrical systems. Advanced avionics, fly-by-wire controls, and sophisticated power distribution networks require specialized knowledge and diagnostic tools. Practical application of troubleshooting skills often involves using multimeters, oscilloscopes, and specialized software to trace electrical signals, identify faulty components, and verify repairs. Technicians and engineers must be adept at interpreting schematics, wiring diagrams, and technical manuals to pinpoint the source of a problem. A real-world instance is the diagnosis of intermittent faults in an aircraft’s communication system, requiring meticulous examination of wiring connections, circuit boards, and software configurations to isolate the root cause. Success in this area depends on a combination of theoretical knowledge, practical experience, and analytical reasoning.

In summary, troubleshooting constitutes a fundamental skill set. Its efficient execution directly impacts safety and operational continuity in activities relating to electrical components in flight vehicles. Challenges are continually introduced via advancements in electronics systems, necessitating constant training to maintain proficiency and adapt to evolving technologies. It is through rigorous analysis, diagnosis, and repair that those employed in relevant roles ensure the continuous operational integrity and safety of systems in both flight and terrestrial support.

6. Quality assurance

Quality assurance constitutes a critical function intrinsically linked to electrical roles within the aerospace industry. It encompasses a systematic approach to ensuring that electrical systems, components, and processes meet specified requirements and adhere to rigorous safety standards. The integrity of these systems is paramount, given their direct impact on flight safety and mission success.

- Compliance with Regulatory Standards

Compliance with aviation regulations is non-negotiable. Aerospace electrical engineers and technicians must demonstrate a thorough understanding of standards established by regulatory bodies such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). For example, adherence to FAA Part 25 regulations pertaining to aircraft electrical systems is essential to obtain type certification. This ensures that electrical designs and installations meet minimum safety requirements.

- Verification and Validation Processes

Rigorous verification and validation (V&V) processes are implemented to confirm that electrical systems perform as intended. Verification ensures that the design meets specified requirements, while validation confirms that the system meets the user’s needs and operates effectively in its intended environment. An example is conducting extensive testing of an aircraft’s electrical power system to verify that it can supply adequate power to all onboard systems under various flight conditions.

- Defect Prevention and Root Cause Analysis

Proactive defect prevention measures are crucial to minimizing the risk of electrical failures. This includes implementing robust design reviews, utilizing advanced simulation tools, and conducting thorough inspections. Root cause analysis is employed to investigate any electrical failures or anomalies that occur. An example is conducting a detailed investigation into an electrical short circuit on a spacecraft to identify the cause and implement corrective actions to prevent recurrence.

- Documentation and Traceability

Comprehensive documentation and traceability are essential for maintaining the integrity of aerospace electrical systems. All design changes, manufacturing processes, and testing results must be meticulously documented and traceable to specific requirements. This ensures that any issues can be quickly identified and resolved. An example is maintaining detailed records of all wiring harness installations on an aircraft, including wire gauge, connector types, and routing information.

These facets of quality assurance are fundamental to ensuring the reliability and safety of aerospace electrical systems. Aerospace electrical personnel must possess a strong commitment to quality and adherence to established standards. These comprehensive measures help mitigate risk and guarantee operational performance.

Frequently Asked Questions

This section addresses prevalent inquiries concerning career prospects within the aeronautics and astronautics sector focusing on electric systems.

Question 1: What educational qualifications are generally required?

A bachelor’s degree in electrical engineering, aerospace engineering, or a closely related field is typically the minimum requirement. Advanced degrees, such as a master’s or doctorate, may be preferred or required for research and development positions.

Question 2: What are the essential skills for success in this field?

Essential skills include a strong understanding of electrical circuit design, power electronics, control systems, electromagnetic compatibility, and aerospace standards. Proficiency in relevant software and hardware tools is also crucial. Analytical problem-solving skills are paramount.

Question 3: What types of tasks are commonly performed in related roles?

Common tasks include designing electrical systems, developing wiring harnesses, testing electrical components, troubleshooting electrical malfunctions, and ensuring compliance with safety regulations. System integration is also a key responsibility.

Question 4: What is the typical career path for someone entering this domain?

Entry-level positions often involve assisting senior engineers with design, testing, or maintenance tasks. With experience, individuals may progress to project management roles, technical leadership positions, or specialized engineering roles.

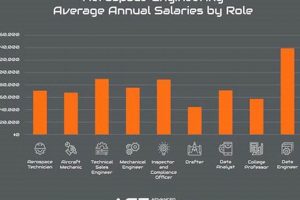

Question 5: What are the salary expectations in the field?

Salaries vary depending on experience, education, location, and employer. However, compensation is generally competitive, reflecting the specialized skills and knowledge required. Researching industry salary surveys can provide more specific details.

Question 6: What are some of the challenges specific to this job?

The field presents challenges such as adherence to stringent safety regulations, the need for continuous learning due to rapid technological advancements, and the demanding nature of aerospace environments. Troubleshooting complex systems under pressure is also a frequent requirement.

In summary, a career path in this sector requires specialized knowledge, commitment to continuous learning and adherence to rigorous quality requirements. Prospective employees are required to adapt to emerging tech

The next section will explore the impact of emerging technologies on this area.

Aerospace Electrical Roles

This discourse has provided a detailed exploration of positions that involve electricity in the aeronautics and astronautics industries. Key areas discussed included design, maintenance, testing, systems integration, troubleshooting, and quality assurance. These elements constitute the core responsibilities and challenges associated with these functions.

Given the increasing complexity and criticality of electrical systems in modern flight vehicles, continued investment in education, training, and technological advancement is essential. The future of aviation and space exploration depends, in part, on the expertise and dedication of individuals working in these exacting and demanding fields. Individuals seeking careers can have an impact on the future.