Positions within the aircraft and spacecraft industry located in the city of Spokane, Washington, constitute a specific employment sector. These roles encompass a range of technical, engineering, manufacturing, and administrative functions necessary for the design, production, and maintenance of aerospace components and systems. An example includes a mechanical engineer designing aircraft parts at a local manufacturing plant.

The availability of such opportunities provides significant economic benefits to the region. It fosters innovation, attracts skilled labor, and contributes to the overall growth of the local economy. Historically, the presence of aerospace-related businesses has stimulated technological advancement and created a skilled workforce prepared for future challenges in the field.

The following sections will delve into the specific types of roles available, the key companies operating in this sector within the Spokane area, the required qualifications and training for these positions, and resources available for individuals seeking to enter or advance within this industry.

The pursuit of employment in the aircraft and spacecraft industry within Spokane, Washington, requires a strategic approach. The following recommendations aim to optimize the search and application process.

Tip 1: Conduct Targeted Research: Identify companies with a significant presence in the Spokane area that are actively involved in aerospace activities. Investigate their specific areas of expertise, product lines, and recent projects. This will allow for a more tailored application.

Tip 2: Emphasize Relevant Skills: Highlight skills and experience that align directly with the requirements of the aerospace industry. This includes proficiency in CAD software, knowledge of materials science, understanding of quality control procedures, and experience with relevant manufacturing processes.

Tip 3: Network Strategically: Attend industry events, career fairs, and workshops to connect with professionals currently working in the Spokane aerospace sector. Networking can provide valuable insights into open positions and company cultures.

Tip 4: Tailor Resumes and Cover Letters: Customize each application to reflect the specific requirements outlined in the job description. Emphasize achievements and quantifiable results that demonstrate the applicant’s ability to contribute to the company’s success.

Tip 5: Obtain Relevant Certifications: Consider pursuing certifications that are highly valued within the aerospace industry, such as those related to quality assurance, project management, or specific manufacturing processes. Such certifications can enhance an applicant’s credibility and competitiveness.

Tip 6: Consider Internship Opportunities: Explore internship programs with aerospace companies in Spokane. Internships provide valuable hands-on experience and can often lead to full-time employment opportunities.

Tip 7: Monitor Industry News: Stay informed about developments in the aerospace industry, particularly within the Spokane region. This includes tracking company announcements, new projects, and expansions, which may indicate upcoming hiring needs.

By focusing on targeted research, skill alignment, strategic networking, tailored applications, relevant certifications, and staying informed about the industry, individuals can significantly increase their chances of securing positions within the growing aerospace field in Spokane.

These tips provide a foundation for a successful job search, which will be further enhanced by exploring resources and educational opportunities specific to the local aerospace ecosystem.

1. Engineering Design

Engineering design forms a foundational pillar within the aerospace sector, particularly impacting the scope and nature of available positions in Spokane, Washington. This discipline dictates the creation, analysis, and refinement of aircraft components and systems, thereby driving demand for specialized expertise.

- Conceptualization and Modeling

This phase involves the initial development of design concepts, often utilizing CAD (Computer-Aided Design) software. Engineers in this role are responsible for creating detailed 3D models and simulations to evaluate performance characteristics. Within the Spokane context, this might involve designing lightweight composite structures for aircraft interiors, requiring proficiency in materials science and structural analysis.

- Stress and Structural Analysis

Ensuring the structural integrity of aerospace components is paramount. Engineers specializing in stress and structural analysis employ finite element analysis (FEA) to simulate the effects of various loads and environmental conditions. For instance, they might analyze the impact of turbulence on an aircraft wing designed and manufactured in Spokane, ensuring it meets rigorous safety standards.

- Systems Integration

Aerospace systems are complex and require seamless integration of various components, including electrical, mechanical, and hydraulic systems. Engineers in this role are responsible for ensuring compatibility and optimal performance of these integrated systems. An example is the integration of advanced avionics systems into a regional jet manufactured with components from Spokane-based suppliers.

- Design Validation and Testing

Before components can be deployed, they undergo rigorous testing to validate their performance and reliability. Engineers involved in design validation and testing develop and execute test plans, analyze data, and identify areas for improvement. This might involve subjecting aerospace components manufactured in Spokane to extreme temperature variations or vibration tests to ensure they meet operational requirements.

These diverse facets of engineering design collectively contribute to the demand for highly skilled engineers within the Spokane aerospace industry. The ability to conceptualize, analyze, integrate, and validate aerospace designs directly influences the competitiveness and innovation of local companies, further solidifying the region’s position within the broader aerospace ecosystem. The engineering design field has an impact on manufacturing, making sure the component is suitable for production.

2. Manufacturing Roles

Manufacturing roles form a critical segment of employment opportunities within Spokane, Washington’s aerospace sector. These positions are directly responsible for the physical creation of aircraft components and systems, translating engineering designs into tangible products. The presence of robust manufacturing capabilities in Spokane directly impacts the availability and diversity of such roles, ranging from entry-level assembly positions to highly skilled machining and fabrication specialists. Without a capable manufacturing base, engineering designs would remain theoretical, and the Spokane area would lack a substantial portion of its aerospace workforce. For example, specialized CNC machinists producing precision parts for Boeing 737s within a Spokane facility represent a direct link between manufacturing expertise and the broader aerospace supply chain.

The types of manufacturing roles present in Spokane are diverse, reflecting the various stages of aerospace production. These include composite technicians responsible for fabricating lightweight structural components, welders specializing in aerospace-grade materials, quality control inspectors ensuring adherence to stringent industry standards, and assembly technicians integrating individual parts into larger sub-assemblies. Each of these roles requires specific skills and training, contributing to the demand for skilled labor in the region. The success of aerospace manufacturing in Spokane hinges on the efficient execution of these processes, demanding a workforce capable of meeting the high precision and quality requirements of the industry. The availability of training programs at local community colleges and vocational schools is therefore critical to maintaining a qualified talent pool.

In conclusion, manufacturing roles are an indispensable element of the aerospace jobs landscape in Spokane, WA. These positions are essential for transforming designs into reality and driving economic activity in the region. Ensuring a skilled workforce capable of meeting the stringent demands of aerospace manufacturing remains a key challenge, requiring continued investment in training and development programs. The interconnectedness of design, manufacturing, and quality control highlights the need for a holistic approach to workforce development and industry growth in Spokane’s aerospace sector, therefore, creating a growing demand for jobs.

3. Quality Assurance

Quality assurance (QA) occupies a central position within the aerospace sector in Spokane, WA. It directly influences the availability, nature, and requirements of positions across the industry. The stringent safety and performance demands of aerospace necessitate rigorous QA processes to ensure components, systems, and completed aircraft meet exacting specifications. This translates into a sustained demand for QA personnel with specialized skills and knowledge. The effectiveness of QA procedures is directly correlated with the safety and reliability of aircraft, impacting not only customer satisfaction but also the potential for liability and regulatory scrutiny. A defect in a critical component, undetected by QA, could lead to catastrophic consequences, highlighting the grave responsibility entrusted to QA professionals.

The specific activities undertaken by QA personnel within Spokane’s aerospace firms are diverse, encompassing inspection, testing, auditing, and documentation. Inspectors utilize precision measuring tools and techniques to verify dimensional accuracy and material properties. Testers subject components and systems to simulated operational conditions to identify potential weaknesses or failures. Auditors assess compliance with industry standards and regulatory requirements. All activities generate detailed documentation that provides a traceable record of quality control processes. For example, a QA technician at a Spokane-based composite manufacturer might perform ultrasonic inspections to detect voids or delaminations within a wing structure, ensuring its structural integrity. The successful completion of these QA tasks is vital for maintaining the competitiveness and reputation of Spokane’s aerospace industry.

In summary, quality assurance is not merely a functional area within the Spokane aerospace sector but rather a fundamental principle underpinning its success and sustainability. The demand for skilled QA professionals reflects the industry’s commitment to safety, reliability, and compliance. Challenges include keeping abreast of evolving industry standards, adapting to new materials and manufacturing processes, and ensuring consistent execution of QA procedures across all levels of the organization. A strong focus on quality assurance enhances the value of aerospace jobs in Spokane, WA, and contributes to its economic growth.

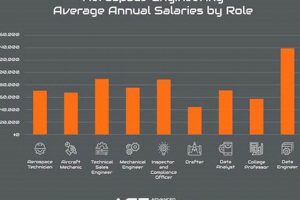

4. Skills Demand

The aerospace industry in Spokane, WA, exhibits a pronounced demand for specific skill sets that directly influence the availability and nature of employment opportunities. This demand is driven by technological advancements, stringent regulatory requirements, and the increasing complexity of aerospace systems. A thorough understanding of these skill requirements is crucial for individuals seeking to enter or advance within this sector. The skills are critical for maintaining the jobs market within Spokane, WA.

- Engineering Expertise (Mechanical, Aerospace, Electrical)

A strong foundation in engineering principles is essential for many roles within Spokane’s aerospace companies. Mechanical engineers are needed for designing and analyzing structural components. Aerospace engineers contribute to aerodynamic performance and flight control systems. Electrical engineers are critical for developing and maintaining avionics and electrical systems. For example, local companies often seek engineers proficient in CAD software, FEA (Finite Element Analysis), and systems integration to support design and manufacturing processes.

- Precision Manufacturing Skills

The manufacture of aerospace components demands a high degree of precision and adherence to strict quality standards. Skills in CNC machining, welding (especially with specialized aerospace alloys), composite materials fabrication, and quality inspection are highly sought after. A real-world example includes a machinist skilled in 5-axis CNC milling producing complex turbine blades for jet engines within a Spokane-based facility.

- Quality Assurance and Regulatory Compliance

The aerospace industry operates under stringent regulatory oversight. Consequently, skills in quality assurance, auditing, and compliance with standards such as AS9100 are highly valued. Professionals who can demonstrate expertise in implementing and maintaining quality management systems, conducting internal audits, and ensuring adherence to FAA regulations are in high demand. Companies must comply with rules to continue operations and meet contracts.

- Project Management and Lean Manufacturing

Effective project management and lean manufacturing principles are essential for optimizing production processes and reducing costs within the aerospace industry. Skills in project planning, risk management, supply chain management, and process improvement are highly valued. For example, a project manager overseeing the implementation of a new manufacturing line for aircraft components in Spokane would need to apply lean principles to minimize waste and maximize efficiency.

The pronounced demand for these specialized skill sets underscores the importance of targeted education, training, and professional development for individuals seeking to enter or advance within the Spokane aerospace sector. By acquiring and honing these skills, individuals can significantly enhance their competitiveness and contribute to the continued growth and innovation of this vital industry. Continued growth will need further skills being demanded from the industry.

5. Local Companies

The presence and activities of local companies are the primary drivers of available employment opportunities within Spokane, Washington’s aerospace sector. The types of businesses, their scale of operations, and their specific focuses directly shape the skills demanded, the job titles offered, and the overall economic impact of the industry in the region. Understanding the key players is therefore essential for comprehending the local aerospace job market.

- Manufacturing Facilities

These companies are engaged in the physical production of aerospace components and systems, ranging from precision-machined parts to composite structures. Their presence creates a demand for machinists, technicians, quality control inspectors, and production managers. Triumph Composite Systems, with its Spokane facility, exemplifies this, manufacturing composite parts for commercial and military aircraft. These companies need a constant amount of employees.

- Engineering Services Firms

Engineering firms provide design, analysis, and testing services to aerospace manufacturers. Their existence creates a demand for engineers with expertise in various disciplines, including mechanical, aerospace, and electrical engineering. These firms often serve as subcontractors to larger aerospace companies, offering specialized expertise in areas such as stress analysis, computational fluid dynamics, and systems integration. Jobs within engineering services firms can provide broad exposure to different aerospace projects and technologies.

- Maintenance, Repair, and Overhaul (MRO) Providers

MRO providers specialize in the maintenance, repair, and overhaul of aircraft and aircraft components. Their operations generate employment opportunities for aircraft mechanics, avionics technicians, and other skilled tradespeople. The presence of MRO facilities in Spokane reflects the region’s strategic location and its role as a transportation hub. An example might be a facility specializing in the overhaul of regional jet engines, requiring highly skilled technicians with specialized training and certifications.

- Supply Chain Companies

Companies that supply materials, components, and services to the aerospace industry are also integral to the local job market. These include distributors of aerospace-grade metals, providers of specialized coatings and finishes, and manufacturers of tooling and equipment. Their presence creates a demand for sales representatives, logistics specialists, and quality control personnel. Efficient supply chain operations are essential for supporting the manufacturing and MRO activities of other aerospace companies in the region.

In summary, the diversity and specialization of local aerospace companies directly shape the availability and nature of jobs in Spokane, WA. From manufacturing and engineering to MRO and supply chain activities, these companies collectively contribute to a dynamic and evolving job market. Understanding their specific operations and skill requirements is crucial for individuals seeking to enter or advance within the region’s aerospace sector. Furthermore, the local companies affect the economy growth.

6. Economic Impact

The presence of aerospace activities within Spokane, Washington, generates a substantial economic impact, significantly influencing the region’s prosperity. A direct correlation exists between the number and types of aerospace jobs in Spokane and the overall economic health of the city and surrounding areas. Aerospace jobs typically offer higher wages compared to other sectors, increasing disposable income within the community. This, in turn, stimulates local spending, supporting retail businesses, service providers, and the housing market. Furthermore, the aerospace sector attracts skilled labor to the region, contributing to a more educated and productive workforce. An example includes the expansion of Triumph Composite Systems in Spokane, which created numerous high-paying manufacturing jobs, resulting in increased tax revenues for the city and stimulating demand for housing and local services.

The economic impact extends beyond direct employment. The aerospace sector fosters a network of suppliers, contractors, and service providers, creating indirect employment opportunities. For instance, machine shops, metal suppliers, and engineering firms that support aerospace manufacturers also benefit from the industry’s growth. Moreover, the presence of a strong aerospace sector enhances the region’s reputation as a hub for innovation and technology, attracting further investment and fostering economic diversification. Local educational institutions benefit as well, adapting curricula to meet the evolving needs of the aerospace industry and ensuring a steady stream of qualified graduates. An increase in the number of aerospace companies choosing to locate or expand in Spokane would have a multiplying effect on the local economy, creating a positive feedback loop of growth and prosperity.

In conclusion, the aerospace sector serves as a significant driver of economic growth in Spokane, WA. The high-paying jobs it provides, coupled with the indirect employment and investment it attracts, contribute substantially to the region’s overall economic well-being. Challenges include maintaining a skilled workforce, attracting new aerospace companies, and adapting to technological advancements in the industry. Continued investment in education, infrastructure, and workforce development is essential for maximizing the economic benefits derived from aerospace activities in Spokane.

Frequently Asked Questions

This section addresses common inquiries regarding the aerospace job market in Spokane, Washington, providing factual information and clarifying prevalent misunderstandings.

Question 1: What types of aerospace companies operate in the Spokane area?

The aerospace sector in Spokane includes companies involved in manufacturing, engineering services, maintenance, repair, and overhaul (MRO), and supply chain activities. This diversity encompasses a range of technical and administrative roles.

Question 2: What are the most in-demand skills for aerospace jobs in Spokane?

Skills highly sought after include engineering expertise (mechanical, aerospace, electrical), precision manufacturing capabilities (CNC machining, welding), quality assurance knowledge, and project management proficiency. Certifications in relevant areas can enhance competitiveness.

Question 3: Where can individuals find information about available aerospace job openings in Spokane?

Job boards, company websites (particularly those of local aerospace firms), industry-specific networking events, and professional associations are valuable resources for identifying available positions. Local community colleges may also have career services departments with connections to aerospace employers.

Question 4: What level of education or training is typically required for aerospace jobs in Spokane?

Educational requirements vary depending on the specific role. Engineering positions generally necessitate a bachelor’s degree in a relevant field. Manufacturing roles may require vocational training, apprenticeships, or associate’s degrees. Advanced degrees may be beneficial for research and development positions.

Question 5: How does the aerospace industry contribute to the Spokane economy?

The aerospace sector provides high-paying jobs, stimulates local spending, attracts skilled labor, and fosters a network of suppliers and service providers, contributing significantly to the region’s economic well-being.

Question 6: What are the prospects for future growth in the aerospace sector in Spokane?

The future growth of the aerospace sector in Spokane is dependent upon continued investment in workforce development, infrastructure, and technological innovation. The region’s strategic location and access to skilled labor position it favorably for future expansion. The more the city invests in this sector, more opportunities for jobs will be available.

Key takeaways include the diversity of aerospace companies in Spokane, the importance of specific skill sets, and the sector’s significant contribution to the local economy. Continued investment and workforce development are crucial for future growth.

The following section will provide resources beneficial to those pursuing aerospace careers in the Spokane, WA region.

Aerospace Jobs in Spokane WA

This exploration has detailed the multifaceted nature of aerospace jobs in Spokane WA, from the crucial roles in engineering design and manufacturing to the imperative of quality assurance and the specific skill sets demanded by local companies. The significance of this sector to the regional economy has been underscored, demonstrating its contribution to employment, investment, and technological advancement.

The future vitality of aerospace jobs in Spokane WA hinges on strategic investments in workforce development, infrastructure enhancements, and the cultivation of a business-friendly environment. A sustained commitment to these areas will ensure that Spokane remains a competitive hub within the aerospace industry, attracting skilled professionals and driving economic prosperity for the region.