Opportunities in the aviation and defense sectors involve a range of positions related to aircraft maintenance, engineering, and support services. These roles often require specialized skills and certifications, contributing to the safe and efficient operation of aircraft. For example, a licensed aircraft maintenance engineer or avionics technician would fall under this category.

The significance of these positions lies in their contribution to the continued airworthiness and operational readiness of aircraft. They play a crucial role in ensuring safety standards are met and maintained, impacting both commercial aviation and defense capabilities. Historically, the demand for skilled professionals in these areas has remained consistent, driven by the ongoing need for aircraft maintenance and upgrades.

The following sections will explore specific roles within this sector, the skills and qualifications required, and potential career pathways for individuals seeking to enter or advance within this field.

Securing a position in the aircraft services sector requires strategic planning and a focused approach. The following tips offer guidance on maximizing opportunities and building a successful career in this demanding field.

Tip 1: Emphasize Relevant Qualifications: Highlight certifications and licenses applicable to aircraft maintenance, avionics, or engineering. Examples include EASA or FAA certifications, demonstrating compliance with industry standards.

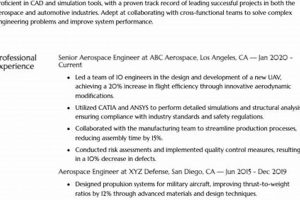

Tip 2: Tailor Applications to Specific Roles: Customize resumes and cover letters to match the requirements of each position. Demonstrate a clear understanding of the skills and experience sought by potential employers.

Tip 3: Network Within the Industry: Attend industry events, conferences, and workshops to connect with professionals and learn about potential openings. Building relationships can provide valuable insights and access to unpublished opportunities.

Tip 4: Demonstrate Problem-Solving Skills: Showcase the ability to diagnose and resolve technical issues efficiently and effectively. Provide specific examples of successful troubleshooting experiences in previous roles.

Tip 5: Prioritize Safety and Compliance: Emphasize a commitment to adhering to safety protocols and regulatory requirements. A strong understanding of aviation safety standards is crucial for success in this field.

Tip 6: Seek Continuous Professional Development: Stay updated with the latest advancements in aircraft technology and maintenance practices. Investing in ongoing training and education enhances career prospects.

A proactive approach, combined with relevant skills and a commitment to excellence, is essential for navigating opportunities within the aircraft services landscape. Focus on showcasing expertise and demonstrating a dedication to maintaining the highest standards of quality and safety.

The next section will provide insights into the future outlook of the industry and the emerging trends shaping career paths.

1. Maintenance Engineering Expertise

Maintenance engineering expertise forms a cornerstone of operations within specialized aviation companies. The availability of skilled maintenance engineers directly impacts the organization’s ability to provide airworthy aircraft, a fundamental requirement for continued operation. A deficiency in this area can lead to grounded aircraft, canceled flights, and significant financial losses. The cause-and-effect relationship is clear: robust maintenance engineering expertise ensures aircraft availability, while its absence precipitates operational disruptions. For instance, a failure to detect and rectify a fatigue crack in an aircraft’s wing structure during routine maintenance can result in catastrophic structural failure during flight. A specific instance could involve detecting corrosion on a Boeing 737’s fuselage, requiring immediate repair by certified maintenance engineers to prevent further degradation and potential structural compromise.

The importance of maintenance engineering expertise extends beyond immediate repairs. These engineers play a crucial role in developing and implementing preventative maintenance programs, ensuring the proactive identification and mitigation of potential issues. They also contribute to the ongoing improvement of maintenance procedures, incorporating lessons learned from past experiences and adapting to new technologies. As an example, the implementation of non-destructive testing (NDT) techniques, such as ultrasonic or radiographic inspections, requires specialized training and expertise. Properly conducted NDT can identify hidden flaws, preventing failures before they occur. The data gathered informs the development of more effective maintenance schedules and inspection criteria.

In summary, maintenance engineering expertise is not merely a desirable attribute but an indispensable component of a successful organization in this sector. Its presence guarantees airworthiness, enhances operational efficiency, and mitigates safety risks. Organizations must invest in the recruitment, training, and retention of qualified maintenance engineers to maintain a competitive edge and uphold the highest safety standards. The practical significance of this understanding lies in the realization that skilled maintenance engineers are not simply a cost center but a valuable asset that safeguards operations and ensures long-term sustainability.

2. Avionics System Integration

Avionics system integration is intrinsically linked to opportunities in aircraft-related services. Successful integration of avionics systemsnavigation, communication, flight control, and electronic warfare systemsdirectly impacts flight safety and operational effectiveness. Deficiencies in this area can lead to system malfunctions, navigation errors, and compromised aircraft performance. For example, improper integration of a new GPS system could result in inaccurate positioning data, leading to navigation errors and potential accidents. This highlights the critical role of skilled professionals in ensuring seamless functionality.

The importance of avionics system integration within the aerospace job market is further illustrated by the increasing complexity of modern aircraft. As aircraft become more technologically advanced, the demand for specialists capable of installing, configuring, and troubleshooting sophisticated avionics systems rises. Furthermore, regulatory compliance mandates rigorous testing and certification of integrated avionics systems. For instance, any modification to an aircraft’s avionics suite requires thorough validation to meet FAA or EASA standards. This validation process necessitates specialized knowledge and expertise in system integration principles. A specific example would be the integration of a new weather radar system. Professionals would not only install the hardware but also configure the system, test its performance against predefined metrics, and document the integration process for regulatory approval.

In conclusion, avionics system integration represents a vital aspect of maintaining modern aircraft. It generates numerous positions for qualified technicians, engineers, and specialists. The continual evolution of avionics technology ensures a consistent demand for individuals possessing the skills necessary to manage these complex systems. Organizations focused on aircraft-related services rely heavily on avionics integration capabilities to deliver safe and efficient operations. Therefore, a thorough understanding of avionics integration is essential for anyone seeking a career in this sector, particularly those specializing in specialized aerospace fields.

3. Aircraft Modification Programs

Aircraft modification programs represent a significant sector within the aviation industry, directly influencing the skill sets and expertise demanded from personnel within specialized aerospace roles. These programs encompass a range of activities, from minor interior upgrades to major structural alterations, all aimed at extending the lifespan, enhancing the performance, or adapting the functionality of existing aircraft. This creates a demand for specific expertise.

- Engineering Design and Analysis

Modification programs necessitate thorough engineering design and analysis to ensure structural integrity and aerodynamic performance. Professionals in this area conduct stress analysis, computational fluid dynamics simulations, and develop detailed engineering drawings for the modifications. For example, when converting a passenger aircraft into a cargo freighter, engineers must redesign the floor structure to support heavier loads and create a new cargo door. This requires expertise in structural mechanics, materials science, and aviation regulations. Opportunities arise for structural engineers, design engineers, and CAD/CAM specialists.

- Manufacturing and Fabrication

The physical implementation of aircraft modifications involves manufacturing and fabrication of new components and structures. This work requires skilled technicians and machinists capable of working with aviation-grade materials and adhering to strict tolerances. For instance, creating a new winglet design to improve fuel efficiency requires precise machining of aluminum or composite materials. Opportunities exist for machinists, sheet metal workers, composite technicians, and welders with specialized aviation certifications.

- Installation and Integration

Installation and integration are critical phases. Qualified mechanics, avionics technicians, and electrical engineers integrate new systems and components into the aircraft while ensuring compatibility with existing systems. For instance, installing a new In-Flight Entertainment (IFE) system requires careful routing of wiring harnesses, integration with the aircraft’s power system, and configuration of the software interface. This demands expertise in aircraft electrical systems, avionics troubleshooting, and system integration, generating demand for avionics technicians, aircraft mechanics, and electrical engineers.

- Certification and Regulatory Compliance

All aircraft modification programs must comply with stringent regulatory requirements, necessitating expertise in aviation law and certification procedures. Professionals in this area work with regulatory agencies (e.g., FAA, EASA) to obtain necessary approvals and ensure that the modified aircraft meets all applicable safety standards. This process may involve conducting flight tests, preparing detailed documentation, and demonstrating compliance with airworthiness directives. Job roles include certification engineers, compliance specialists, and aviation lawyers. The success of any aircraft modification hinges on their expertise.

In summary, aircraft modification programs are multifaceted and require a diverse range of skills and expertise. As a result, this sector directly fuels the demand for specialized aerospace roles. Individuals possessing the skills in engineering, manufacturing, installation, and certification are well-positioned to capitalize on these professional opportunities, highlighting the dynamic interplay between modification activities and career paths within the aircraft maintenance industry.

4. Regulatory Compliance Adherence

Regulatory compliance adherence is fundamentally linked to job roles within the aviation industry. Strict regulations govern aircraft maintenance, operations, and modifications, and adherence to these standards is non-negotiable. Therefore, individuals employed in these roles must possess a comprehensive understanding of applicable regulations and demonstrate a commitment to upholding them. Failure to comply with regulatory requirements can result in severe consequences, including aircraft grounding, financial penalties, and even criminal charges. For instance, an aircraft maintenance technician who fails to properly document a repair, violating FAA regulations, may face suspension of their license. The industry-wide effect is a heightened demand for compliance-focused roles.

The importance of regulatory compliance manifests across various facets of aviation employment. Quality assurance personnel meticulously audit maintenance procedures to ensure conformity with established standards. Engineers designing aircraft modifications must account for airworthiness directives and certification requirements. Flight operations personnel adhere to flight time limitations and operational procedures mandated by regulatory bodies. A practical example includes the implementation of Safety Management Systems (SMS) in aviation organizations. SMS requires dedicated personnel to monitor safety performance, identify hazards, and implement corrective actions, ensuring continuous improvement in regulatory compliance. Another example is adherence to Export Administration Regulations (EAR) and International Traffic in Arms Regulations (ITAR), crucial for companies involved in international aerospace transactions. Specialized roles are created to ensure compliance with these regulations, covering export licensing, technology control, and security protocols.

In summary, regulatory compliance adherence is not merely an ancillary function but a core component of aerospace operations. The aviation sector’s reliance on stringent regulations creates a sustained demand for professionals with expertise in this area. Understanding and adhering to aviation regulations is, therefore, crucial for securing and maintaining employment in this industry. The inherent challenge lies in the evolving nature of regulations, requiring continuous learning and adaptation from aerospace professionals to ensure ongoing compliance and maintain the industry’s commitment to safety and airworthiness.

5. Quality Assurance Standards

Quality Assurance (QA) standards are inextricably linked to opportunities within aerospace roles. The aerospace industry operates under stringent QA requirements to ensure the safety, reliability, and performance of aircraft and related systems. Compliance with these standards directly impacts the availability and nature of specialized aerospace jobs, influencing the skill sets and responsibilities of individuals in those positions. Failure to meet QA standards can result in catastrophic consequences, emphasizing the importance of qualified personnel who can uphold these stringent requirements. For example, a lack of adherence to AS9100 standards in the manufacturing of aircraft components can lead to defective parts, potentially causing system failures and jeopardizing flight safety. The employment of QA specialists is thus critical to mitigate these risks.

The practical application of QA standards within aerospace roles extends across various functional areas. Quality control inspectors meticulously examine manufactured parts, assemblies, and completed systems to identify defects and non-conformances. Quality engineers develop and implement QA processes, conduct audits, and analyze data to improve system performance and reduce errors. Compliance officers ensure that the organization adheres to all relevant regulations and industry standards. For example, Nadcap accreditation is a crucial element within aerospace manufacturing, requiring specialized auditors to verify compliance. This creates employment opportunities for qualified auditors and QA professionals with specific expertise in Nadcap processes. Another example is the implementation of Statistical Process Control (SPC) in manufacturing, where quality engineers apply statistical methods to monitor and control manufacturing processes, ensuring consistent product quality and reducing variability.

In summary, quality assurance standards are not merely a set of guidelines but a fundamental prerequisite for the aerospace sector. The industry’s reliance on stringent QA measures generates a sustained demand for skilled professionals. Organizations require personnel with in-depth knowledge of these standards and the ability to implement and maintain effective QA systems. Understanding the link between QA standards and aerospace roles is therefore critical for anyone seeking employment. The evolving nature of these standards necessitates continuous learning and professional development to ensure ongoing compliance and contribute to the industry’s commitment to safety and reliability.

6. Global Support Network

The existence of a global support network directly influences the scope and nature of opportunities within the aviation sector, specifically those related to aerospace organizations. A robust global support network enables companies to provide maintenance, repair, and overhaul (MRO) services, as well as technical assistance, to aircraft operators worldwide. This expanded reach directly translates to a larger workforce and more diverse roles requiring specialized expertise. The absence of a global network limits an organization’s service capabilities, thereby restricting its growth potential and corresponding employment opportunities. For example, a company specializing in engine maintenance with service centers located across multiple continents can support a wider range of clients and aircraft types than a company with a single, localized facility. This results in the need for more technicians, engineers, logistics personnel, and customer service representatives.

The presence of a global support network necessitates personnel capable of operating in diverse cultural and regulatory environments. This generates opportunities for individuals with multilingual skills, international experience, and a thorough understanding of aviation regulations in different regions. Furthermore, it creates demand for roles focused on supply chain management, logistics coordination, and international sales and marketing. A practical example involves a company that provides on-site aircraft maintenance services. The need to deploy teams of technicians to various locations around the world necessitates the expertise of logistics coordinators who can arrange transportation, accommodation, and visas for personnel, as well as manage the import and export of equipment and spare parts. These individuals must be adept at navigating customs regulations and cultural differences to ensure seamless operations. The ability to effectively support a global customer base translates into a significant competitive advantage, attracting more clients and further driving the demand for qualified personnel.

In summary, a global support network is an integral component of aerospace organizations, significantly influencing the availability and characteristics of various roles. The ability to provide worldwide services directly translates to a broader range of employment opportunities, requiring specialized skills, international experience, and a commitment to regulatory compliance. As the aviation industry continues to expand globally, the importance of global support networks will only increase, ensuring a consistent demand for qualified personnel who can contribute to their success. A key challenge lies in managing the complexity and logistical requirements of a global operation, requiring continuous improvement in communication, coordination, and cultural sensitivity to maintain operational efficiency and customer satisfaction.

7. Technical Training Provision

Technical training provision is inextricably linked to the availability and competency of personnel employed in specialized aerospace roles. The highly technical nature of aircraft maintenance, repair, and operations (MRO) necessitates specialized training programs designed to equip individuals with the knowledge and skills required to perform their duties safely and effectively. The absence of adequate technical training leads to reduced operational efficiency, increased safety risks, and potential regulatory violations. For example, improperly trained aircraft maintenance technicians may fail to identify critical structural defects, leading to component failures and potentially catastrophic accidents. This underscores the critical role of comprehensive technical training in ensuring airworthiness and operational safety within the aviation industry.

The practical significance of technical training is evident in the certification requirements for various aerospace roles. Aircraft Maintenance Engineers (AMEs) must complete approved training programs and pass rigorous examinations to obtain their licenses, demonstrating their competency in aircraft maintenance procedures. Similarly, avionics technicians require specialized training in electronic systems and troubleshooting techniques to maintain and repair sophisticated avionics equipment. Aircraft modification programs also demand personnel trained in specific processes such as composite repair or non-destructive testing. Continuing professional development (CPD) is similarly important to address the constant evolution of technologies in this industry. Thus, technical training isn’t just about an initial qualification. In reality, constant training is the only way to stay relevant in such positions. One example could be understanding the new requirements of the latest composite materials or the changes in aircraft.

In summary, technical training provision is not merely a supplementary function but a core component of maintaining a skilled and competent workforce within the aviation and defense sectors. Robust training programs, coupled with ongoing professional development, are essential for ensuring operational safety, regulatory compliance, and technological advancement. The dynamic nature of the aerospace industry necessitates a sustained investment in technical training to address emerging challenges and capitalize on new opportunities. The need for trained personnel is constant, but the skills required must evolve with technological improvements. A constant and dedicated investment in training is, therefore, required to maintain a top-quality workforce.

Frequently Asked Questions Regarding Specialized Aviation Careers

The following questions address common inquiries concerning career opportunities within specialized aircraft maintenance, modification, and support services. These responses aim to provide clarity and guidance for prospective applicants and industry stakeholders.

Question 1: What specific qualifications are typically required for aviation-related positions?

Positions generally necessitate industry-recognized certifications such as EASA or FAA licenses, specific aircraft type ratings, and relevant experience commensurate with the role’s responsibilities. The precise requirements are dependent on the specific job function, ranging from aircraft maintenance engineering to avionics system integration.

Question 2: How does the global nature of the aviation industry affect employment opportunities?

The global reach of aviation maintenance and support services creates opportunities for individuals with multilingual capabilities, international experience, and a willingness to work in diverse locations. Many organizations operate global support networks, requiring personnel capable of providing on-site maintenance and technical assistance worldwide.

Question 3: What is the importance of regulatory compliance in aviation career paths?

Strict adherence to aviation regulations is paramount. Individuals in all aviation-related roles must possess a thorough understanding of applicable regulations, such as those promulgated by the FAA or EASA, and demonstrate a commitment to upholding them. Compliance is essential for ensuring airworthiness and operational safety.

Question 4: How do aircraft modification programs impact job roles within this sector?

Aircraft modification programs create a demand for professionals with expertise in engineering design, manufacturing, installation, and certification. These programs involve a range of activities, from minor upgrades to major structural alterations, requiring a diverse skill set and adherence to stringent regulatory requirements.

Question 5: What role does technical training provision play in career advancement?

Continuous professional development and technical training are crucial for career advancement in this sector. The rapidly evolving nature of aircraft technology necessitates ongoing learning and adaptation to maintain competency and stay abreast of new developments. Investments in training enhance career prospects and ensure long-term employability.

Question 6: How significant are quality assurance standards in aerospace employment?

Quality assurance standards are of utmost importance. Adherence to standards such as AS9100 and Nadcap is essential. The maintenance of a QA system and QA checks at all stages of an aircraft check, repair or build are of high importance.

In summary, a career in this sector demands constant learning and improvement, global awareness and strict adherence to all regulations to maintain quality and safety. Only those with high levels of understanding and committment will thrive in such roles.

The subsequent sections will delve into the benefits of a successful approach for job searching.

Conclusion

This exploration has illuminated the diverse landscape of opportunities related to specific aviation service roles. The significance of expertise in areas such as maintenance engineering, avionics system integration, regulatory compliance, and technical training provision has been emphasized. A clear understanding of these elements is critical for individuals seeking to enter or advance within this demanding sector.

The aviation industry is a global entity, characterized by stringent regulatory requirements and rapid technological advancements. Success demands a commitment to continuous learning, adherence to rigorous quality standards, and a willingness to embrace new challenges. As the demand for skilled professionals continues to grow, those who possess the necessary qualifications and a dedication to excellence will find themselves well-positioned for a fulfilling and impactful career.