The field concerned with the design, development, testing, and production of aircraft and spacecraft, when considered within the context of a specific emirate, reflects the growing technological ambitions of the region. This specialized area encompasses diverse activities, from the development of advanced aviation systems to participation in space exploration initiatives. For example, it might involve designing more efficient aircraft for Emirates Airline or contributing to the UAE’s Mars mission, Hope.

The significance of expertise in this domain is multi-faceted. It fosters technological innovation, diversifies the economy beyond traditional sectors, and enhances national prestige. Its historical development in the region is closely linked to the growth of the aviation industry, driven by the strategic location of the emirate as a global transportation hub, and more recently to the nation’s ambitious space program. Investments in education, research, and development in this area are seen as crucial for long-term sustainable growth.

The following sections will delve into the specific opportunities and challenges within this industry locally, the educational institutions offering relevant training, the leading companies operating in the region, and the future outlook for this vital technological sector.

Essential Considerations for Pursuing a Career

This section offers practical advice for individuals interested in establishing a career within the specified technical field and geographic location. It emphasizes strategic preparation and professional development.

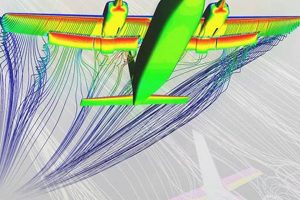

Tip 1: Emphasize Foundational Knowledge: A strong grounding in mathematics, physics, and computer science is paramount. These disciplines form the bedrock upon which advanced engineering concepts are built. For example, proficiency in computational fluid dynamics (CFD) is essential for aircraft design and optimization.

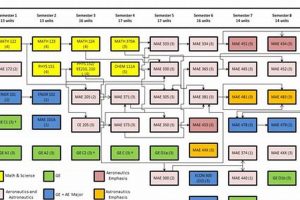

Tip 2: Seek Specialized Education: Pursue advanced degrees or specialized certifications from reputable institutions. Several universities in the emirate, as well as international programs, offer tailored curricula. Consider programs focused on specific areas such as propulsion systems, avionics, or spacecraft engineering.

Tip 3: Gain Practical Experience: Internships and research opportunities within the local aerospace sector are invaluable. Companies and research centers frequently offer programs that provide hands-on experience with real-world projects. This experience significantly enhances employability.

Tip 4: Develop Strong Communication Skills: Effective communication is crucial for collaborating with international teams and presenting technical information clearly. Hone both written and oral communication skills, including the ability to prepare technical reports and present findings to diverse audiences.

Tip 5: Understand Local Regulations and Standards: Familiarize oneself with the regulatory framework governing aviation and space activities in the UAE. Understanding these standards is essential for compliance and ethical practice. The General Civil Aviation Authority (GCAA) provides relevant information and guidelines.

Tip 6: Network Actively: Attend industry conferences, workshops, and networking events to connect with professionals and learn about emerging trends. Building a strong professional network can open doors to career opportunities and mentorship.

Tip 7: Stay Updated with Industry Trends: The aerospace sector is rapidly evolving. Continuously update knowledge of new technologies, materials, and engineering methodologies. Subscribing to industry publications and participating in professional development courses can facilitate this.

By focusing on fundamental knowledge, acquiring specialized skills, and actively engaging with the local aerospace community, individuals can position themselves for success in this dynamic and promising field.

The following sections will provide an overview of education, leading companies, and future prospects.

1. Emirati Space Program

The Emirati Space Program serves as a primary driver and significant component within the broader scope of aerospace engineering in Dubai. The Program’s ambitious goals, including satellite development, space exploration, and human spaceflight initiatives, necessitate a robust and highly skilled aerospace engineering workforce. The direct effect of these initiatives is a heightened demand for engineers specializing in areas such as spacecraft design, propulsion systems, mission control, and data analysis. For instance, the development and launch of the Hope probe to Mars required expertise in numerous aerospace engineering disciplines, fostering growth and specialization within local engineering teams. This Program’s existence validates and amplifies the need for a sophisticated understanding and expertise in related engineering fields.

Further, the Emirati Space Program acts as a catalyst for research and development activities within local universities and research institutions. Funding and collaborative opportunities linked to the program encourage innovation in materials science, robotics, and other areas crucial to aerospace advancement. The Mohammed bin Rashid Space Centre (MBRSC), a key entity within the Program, actively engages in technology transfer and knowledge sharing initiatives, promoting practical application of engineering principles. This engagement spans development projects like KhalifaSat and future missions, offering hands-on experience to local engineers and researchers, thereby solidifying the long-term foundation for the sector.

In summary, the Emirati Space Program is intrinsically linked to the development and expansion of aerospace engineering in Dubai. It provides a clear strategic direction, creates tangible opportunities for professional development, and stimulates innovation across various engineering disciplines. The program’s success is directly dependent on a skilled engineering workforce, making it a vital component of the emirate’s ambition to establish itself as a leading center for aerospace technology and innovation. Challenges remain in maintaining a sustainable pipeline of talent and fostering deeper collaboration between industry, academia, and government entities. The Program highlights the growing need for specialized aerospace engineering skills within the region.

2. Aviation Infrastructure Growth

Aviation infrastructure growth in Dubai and the encompassing engineering disciplines are intrinsically linked in a cause-and-effect relationship. The continuous expansion and modernization of airports, air traffic control systems, and maintenance facilities directly necessitate the expertise of highly skilled engineers. As Dubai International Airport (DXB) and Al Maktoum International Airport (DWC) undergo expansions to accommodate increasing passenger and cargo traffic, engineering professionals are essential for designing and implementing these infrastructural enhancements. These engineers are involved in planning terminal expansions, optimizing runway layouts, and integrating advanced technologies to improve operational efficiency and safety. The sustained growth of aviation infrastructure, therefore, is a significant driver for the demand for engineering specialists within Dubai’s aerospace sector.

Further demonstrating this connection is the crucial role that aerospace engineers play in the design and maintenance of aircraft themselves. As airlines operating in and out of Dubai, such as Emirates, expand their fleets and adopt newer, more technologically advanced aircraft, engineering professionals are required to maintain and service these aircraft, ensuring optimal performance and safety. Additionally, infrastructure projects related to aircraft maintenance, repair, and overhaul (MRO) facilities depend heavily on engineering expertise. These facilities require specialized knowledge of aircraft systems, structural integrity, and advanced materials to ensure that aircraft are maintained to the highest standards. The engineering community, therefore, serves as a critical pillar in ensuring the operational effectiveness and safety of the region’s aviation industry.

In conclusion, the continuous growth of aviation infrastructure in Dubai serves as a primary stimulus for the expansion and development of aerospace engineering capabilities. This relationship creates opportunities for engineers specializing in airport design, air traffic control, aircraft maintenance, and related fields. The ability to effectively plan, design, and manage aviation infrastructure is essential for Dubai to maintain its position as a leading global aviation hub, with sustained engineering expertise as a cornerstone for its continued success. However, this rapid growth also presents challenges, including the need to attract and retain skilled engineers, manage complex projects efficiently, and adapt to evolving technological advancements in the industry. These challenges require strategic investments in education, research, and development, as well as strong collaboration between government, industry, and academic institutions.

3. Educational Investment Ascendancy

Increased investment in educational institutions and programs directly supports the growth of aerospace engineering capabilities in Dubai. This strategic focus ensures the availability of a skilled workforce and fosters innovation within the sector.

- Curriculum Development and Specialization

Funding enables universities to develop specialized curricula tailored to the needs of the aerospace industry. This includes programs focused on aircraft design, propulsion systems, avionics, and space mission planning. The result is graduates with highly relevant skills who are better prepared to contribute to local aerospace projects. This specialized training is essential for handling the complexities of modern aerospace engineering.

- Research Infrastructure Enhancement

Investments in research infrastructure, such as advanced laboratories and simulation facilities, provide students and faculty with the resources to conduct cutting-edge research. This leads to innovation in areas like advanced materials, computational fluid dynamics, and artificial intelligence for aerospace applications. These advancements improve the competitiveness of the local aerospace industry.

- International Partnerships and Collaborations

Funding supports partnerships with leading international universities and research institutions. These collaborations facilitate the exchange of knowledge and expertise, providing local students and faculty with access to global best practices and research opportunities. International collaboration enhances the quality of education and research, ensuring that Dubai’s aerospace programs remain competitive on a global scale.

- Scholarships and Talent Development Programs

Scholarships and talent development programs encourage more students to pursue careers in aerospace engineering. By reducing the financial barriers to education, these programs broaden access to opportunities and ensure that the best and brightest students are able to contribute to the sector’s growth. These initiatives foster a diverse and highly skilled workforce, essential for the long-term sustainability of the aerospace industry.

The combined effect of these facets is a significant enhancement of aerospace engineering capabilities in Dubai. By strategically investing in education, the emirate is fostering a skilled workforce, driving innovation, and positioning itself as a regional hub for aerospace technology and expertise. This commitment to education is crucial for the long-term sustainability and success of the aerospace industry in Dubai.

4. Research & Development Focus

A sustained emphasis on research and development (R&D) is a critical catalyst for the advancement of aerospace engineering capabilities within Dubai. Strategic investments in R&D infrastructure and programs directly impact the technological capabilities and competitive advantage of the local aerospace sector.

- Advanced Materials Research

Research efforts concentrated on advanced materials, such as composites, alloys, and nanomaterials, are essential for enhancing the performance and efficiency of aircraft and spacecraft. Development of lighter, stronger, and more durable materials directly translates into improvements in fuel efficiency, payload capacity, and operational lifespan. For example, research into carbon fiber composites can lead to the development of lighter aircraft structures, reducing fuel consumption and emissions.

- Autonomous Systems Development

Investment in autonomous systems, including unmanned aerial vehicles (UAVs) and autonomous spacecraft, drives innovation and opens new possibilities in aerospace applications. Development of autonomous systems requires expertise in areas such as artificial intelligence, sensor technology, and robotics. These technologies can be applied to various areas, including surveillance, mapping, and transportation. For example, development of autonomous drones for infrastructure inspection can significantly reduce costs and improve safety.

- Propulsion System Innovation

Research into advanced propulsion systems, such as hybrid-electric engines and alternative fuels, is critical for reducing the environmental impact of aviation and enhancing aircraft performance. Development of more efficient and sustainable propulsion systems can help to meet growing demand for air travel while minimizing emissions. For example, research into biofuels and electric propulsion systems can lead to significant reductions in greenhouse gas emissions from aircraft.

- Space Technology Development

Investment in space technology, including satellite development, space exploration, and space-based communication systems, supports the growth of the UAE’s space program and fosters innovation in related fields. Development of advanced satellite technologies requires expertise in areas such as telecommunications, remote sensing, and navigation. These technologies can be applied to various sectors, including telecommunications, environmental monitoring, and disaster management. For example, development of advanced communication satellites can improve connectivity and provide access to information in remote areas.

These focused research initiatives collectively contribute to the advancement of aerospace engineering in Dubai by fostering innovation, developing new technologies, and enhancing the skills of the local workforce. A strategic emphasis on R&D is essential for ensuring the long-term competitiveness and sustainability of the emirate’s aerospace sector. This commitment to R&D drives growth and innovation in the broader technological landscape.

5. Regional Aerospace Hub

The ambition to establish Dubai as a leading regional aerospace hub is inextricably linked to the development and promotion of aerospace engineering capabilities within the emirate. This hub designation signifies a concentrated effort to attract investment, foster innovation, and create a thriving ecosystem for aerospace-related activities. The demand for skilled aerospace engineers is directly proportional to the scale and scope of activities associated with this hub status. The presence of maintenance, repair, and overhaul (MRO) facilities, aircraft manufacturing ventures, and space technology development projects all require a robust talent pool of engineers with specialized skills. The establishment of the Dubai Airshow, for example, showcases this hub ambition and simultaneously fuels the need for local expertise in engineering design, testing, and production to support the exhibited technologies and attract further investment.

Furthermore, the “Regional Aerospace Hub” designation necessitates a commitment to research and development, driving the need for engineers specializing in areas such as advanced materials, propulsion systems, and autonomous technologies. The success of attracting international aerospace companies and fostering local innovation depends heavily on the availability of engineers capable of conducting cutting-edge research and translating scientific discoveries into practical applications. Educational institutions within Dubai play a crucial role in supporting this hub ambition by offering specialized aerospace engineering programs and collaborating with industry partners to ensure that graduates possess the skills and knowledge required to contribute to the local aerospace sector. The practical application of this understanding is evident in the strategic partnerships forged between universities and aerospace companies to conduct joint research projects and offer internships to engineering students.

In summary, the pursuit of becoming a “Regional Aerospace Hub” serves as a powerful catalyst for the growth and development of “aerospace engineering dubai.” This strategic ambition creates a demand for skilled engineers, fosters innovation through research and development, and drives collaboration between industry, academia, and government. While challenges remain in attracting and retaining top talent, the emirate’s commitment to creating a thriving aerospace ecosystem positions it for long-term success as a leading hub in the region. This is not merely a designation but an active pursuit requiring continuous investment in human capital and technological advancements.

Frequently Asked Questions

This section addresses common inquiries regarding aerospace engineering opportunities, education, and career prospects within the Dubai context. The responses aim to provide clear and objective information based on current industry trends and available resources.

Question 1: What specific skills are most valued by aerospace engineering employers in Dubai?

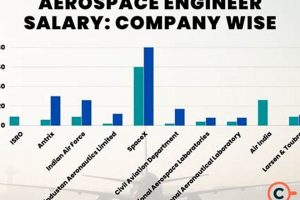

Employers frequently seek candidates proficient in areas such as computational fluid dynamics (CFD), finite element analysis (FEA), systems engineering, and project management. Experience with industry-standard software and familiarity with aviation regulations are also highly advantageous.

Question 2: What educational pathways are recommended for aspiring aerospace engineers in Dubai?

A bachelor’s degree in aerospace engineering or a related field (e.g., mechanical engineering, electrical engineering) is the foundational requirement. Advanced degrees (master’s or doctoral) are often beneficial for specialized roles and research positions. Programs accredited by recognized engineering bodies are preferred.

Question 3: Are there specific areas of aerospace engineering that are experiencing particularly strong growth in Dubai?

Due to the UAE Space Program and aviation sector expansion, notable growth exists in areas related to satellite technology, aircraft maintenance, repair, and overhaul (MRO), and autonomous systems. Expertise in these fields is generally in high demand.

Question 4: What role does the UAE Space Agency play in shaping aerospace engineering opportunities in Dubai?

The UAE Space Agency provides strategic direction, funding, and regulatory oversight for space-related activities. It fosters collaboration between academic institutions, industry partners, and government entities, creating opportunities for engineers in spacecraft design, mission planning, and space exploration.

Question 5: How competitive is the job market for aerospace engineers in Dubai?

The job market is generally competitive, particularly for entry-level positions. However, candidates with strong academic credentials, relevant experience, and specialized skills have significantly better prospects. Networking and proactive career development are essential.

Question 6: Are there specific professional certifications that can enhance career prospects for aerospace engineers in Dubai?

Professional certifications such as those offered by the American Institute of Aeronautics and Astronautics (AIAA) or equivalent organizations can demonstrate expertise and enhance credibility. Certifications related to project management, quality control, or specific engineering disciplines may also be valuable.

In summary, a successful career in aerospace engineering within Dubai requires a combination of strong technical skills, relevant education, practical experience, and professional development. Remaining informed about industry trends and actively networking are crucial for navigating the competitive job market.

The subsequent sections will delve into the potential challenges and opportunities that may arise in this field within the specific context of the UAE.

Aerospace Engineering Dubai

This exploration of aerospace engineering dubai has revealed its multifaceted nature, intertwined with the emirate’s strategic goals in aviation and space exploration. The industry’s growth is fueled by significant investments in education, research, and infrastructure, coupled with the ambitions of the UAE Space Program. This confluence of factors creates both opportunities and challenges for professionals seeking to contribute to this technologically advanced sector.

The future trajectory of aerospace engineering dubai hinges on continued collaboration between academic institutions, government entities, and industry partners. A sustained commitment to innovation, talent development, and the adoption of best practices is essential for realizing the full potential of this field and solidifying Dubai’s position as a leading aerospace hub in the region. This pursuit necessitates a strategic and focused approach to ensure sustained growth and competitiveness in a rapidly evolving global landscape.