The field encompasses the design, development, testing, and production of aircraft and spacecraft. Its scope extends from commercial airliners and military jets to satellites, rockets, and space probes. Practical applications of this discipline involve creating efficient and safe transportation systems within Earth’s atmosphere and enabling exploration beyond it. Examples include the creation of lightweight, fuel-efficient aircraft wings; the development of advanced propulsion systems for rockets; and the design of heat shields to protect spacecraft during atmospheric re-entry.

This area of engineering has driven significant technological advancements, leading to improved global connectivity, enhanced national security, and a greater understanding of the universe. Its impact is evident in the reduced travel times afforded by modern airliners, the precise navigation capabilities provided by satellite systems, and the scientific discoveries resulting from space exploration missions. Historically, innovation in this area has spurred advancements in materials science, computational modeling, and control systems, with implications extending far beyond the aviation and space industries.

The subsequent sections will delve deeper into specific areas within this domain, highlighting recent innovations and future challenges. Topics covered will include advancements in aerodynamics, the exploration of new propulsion technologies, and the ongoing efforts to develop more sustainable and environmentally friendly air and space transportation solutions.

The multifaceted nature demands a strategic approach for both aspiring professionals and seasoned practitioners. The following provides insights designed to optimize efforts within this demanding and ever-evolving field.

Tip 1: Emphasize Foundational Knowledge: A strong understanding of mathematics, physics, and computer science is critical. Proficiency in these areas forms the basis for comprehending advanced concepts in aerodynamics, propulsion, and structural mechanics. Example: A thorough grounding in fluid dynamics is necessary to optimize aircraft wing design for minimal drag.

Tip 2: Cultivate Interdisciplinary Skills: Success requires the ability to integrate knowledge from various engineering disciplines. This includes electrical engineering for avionics systems, mechanical engineering for propulsion systems, and materials science for selecting appropriate materials. Example: Designing a satellite requires collaboration between experts in power systems, thermal control, and communication systems.

Tip 3: Stay Abreast of Technological Advancements: Continuous learning is essential due to the rapid pace of innovation. This involves monitoring developments in areas such as additive manufacturing, advanced composites, and artificial intelligence. Example: Tracking the development of new battery technologies is crucial for designing electric aircraft.

Tip 4: Prioritize Systems Thinking: Focus on understanding how individual components interact within a larger system. A holistic perspective enables identification of potential problems and optimization of overall performance. Example: When designing a rocket engine, consider its integration with the vehicle’s control system and fuel supply.

Tip 5: Develop Strong Communication Skills: The ability to effectively communicate technical information is crucial for collaboration and project management. This includes writing clear and concise reports, delivering persuasive presentations, and participating effectively in team discussions. Example: Clearly documenting design specifications and test results is essential for ensuring project success.

Tip 6: Embrace Simulation and Modeling: Utilize computational tools to analyze and optimize designs. Simulation allows for exploring different design options and predicting performance before physical prototypes are built. Example: Using computational fluid dynamics (CFD) software to simulate airflow around an aircraft wing.

Tip 7: Seek Practical Experience: Internships, research projects, and industry collaborations provide valuable hands-on experience. Practical application of theoretical knowledge enhances understanding and develops problem-solving skills. Example: Participating in a student rocket project to gain experience in rocket design and testing.

These guidelines underscore the importance of a robust academic foundation, continuous learning, and practical experience in navigating the complexities. By focusing on these areas, individuals can enhance their contributions and thrive within this demanding, yet rewarding, industry.

The following sections will provide further insights into specific areas of innovation, current challenges, and future trends.

1. Aircraft Design

Aircraft design represents a foundational element. Its prominence stems from the fact that advancements in aviation directly reflect progress within the broader engineering field. The relationship is causal: theoretical breakthroughs in aerodynamics, propulsion, and materials science are implemented in aircraft design, directly impacting performance, safety, and efficiency. The continuous drive to optimize aircraft exemplifies the core principles. Consider the evolution from the Wright brothers’ first flight to modern commercial airliners. Each iteration embodies sophisticated engineering principles, demonstrating advancements in wing design, engine technology, and control systems. The development of composite materials, for instance, has enabled the creation of lighter and stronger aircraft, contributing to improved fuel efficiency and payload capacity. Understanding aircraft design is practically significant as it showcases the tangible outcomes of research and development, impacting not only the aviation industry but also other sectors through technological spillover.

Further analysis reveals that aircraft design is not a monolithic process. It incorporates numerous specializations, each requiring expertise in specific areas. Aerodynamicists focus on airflow and drag reduction, structural engineers ensure the integrity of the airframe, and propulsion engineers optimize engine performance. Each specialization contributes to the overall design, with trade-offs often necessary to achieve optimal performance characteristics. The design of the Boeing 787 Dreamliner serves as a prime example of this interdisciplinary approach, incorporating advancements in aerodynamics, composite materials, and engine technology to achieve unprecedented fuel efficiency. Military aircraft, such as the F-35 Lightning II, illustrate the complexity of modern design, requiring integration of stealth technology, advanced sensors, and sophisticated weapon systems.

In conclusion, aircraft design is inextricably linked. Its evolution serves as a tangible demonstration of the advancements. The design process exemplifies the application of core principles, resulting in safer, more efficient, and more capable aircraft. While challenges remain, such as reducing noise pollution and developing sustainable aviation fuels, the continued focus on innovation ensures the continued progression. This field will remain a critical component, driving advancements and shaping the future of air transportation.

2. Spacecraft Propulsion

Spacecraft propulsion is intrinsically linked to the broader scope. It represents a critical component enabling space exploration and utilization. The development and application of spacecraft propulsion systems demonstrate core principles, directly influencing mission feasibility, duration, and payload capacity. Without effective propulsion systems, space exploration beyond Earth’s immediate vicinity would be impossible. Consider the Apollo missions, which relied on powerful chemical rockets to achieve lunar orbit and landing. The success of these missions underscored the importance of reliable and efficient propulsion in achieving ambitious space exploration goals. Similarly, interplanetary missions, such as the Voyager probes, depend on propulsion systems for trajectory correction and long-duration operation.

Further analysis reveals the diversity of spacecraft propulsion technologies, each with its advantages and limitations. Chemical rockets, while providing high thrust, are limited by propellant mass. Electric propulsion systems, such as ion drives, offer higher efficiency but lower thrust, making them suitable for long-duration missions. Nuclear propulsion, while promising significant performance improvements, faces technological and political challenges. The selection of a specific propulsion system depends on mission requirements, considering factors such as delta-v, payload mass, and mission duration. For example, the Dawn mission utilized ion propulsion to reach and orbit the asteroids Vesta and Ceres, demonstrating the effectiveness of electric propulsion for interplanetary travel.

In conclusion, spacecraft propulsion is indispensable for achieving the goals. Its continued development is crucial for enabling more ambitious space exploration and utilization. The challenges remain in developing more efficient, reliable, and cost-effective propulsion systems. This area will drive innovation and shape the future of space travel. This focus ensures the continued progression and enabling humanity to explore farther and more efficiently in the vast region beyond.

3. Satellite Systems

Satellite systems represent a critical facet of aerospace engineering. Their importance stems from their multifaceted applications, ranging from communication and navigation to Earth observation and scientific research. These systems exemplify the integration of numerous aerospace engineering disciplines, including orbital mechanics, spacecraft design, communications engineering, and power systems engineering. The design, deployment, and operation of satellites necessitate a deep understanding of these disciplines, making satellite systems a comprehensive embodiment of aerospace principles. For instance, the Global Positioning System (GPS) relies on a constellation of satellites orbiting Earth, each precisely engineered and controlled to provide accurate location data. The existence and functionality of GPS directly result from advances and practical applications of aerospace principles.

Further analysis reveals the intricate interplay between various subsystems within a satellite. The communication subsystem ensures reliable data transmission, while the power subsystem provides energy for all onboard components. The attitude control system maintains the satellite’s orientation, and the thermal control system regulates temperature. The successful integration of these subsystems requires a systems-level understanding of aerospace engineering principles. The development of Earth observation satellites, such as those used for weather forecasting or environmental monitoring, necessitates advanced sensor technology and data processing techniques. These satellites exemplify the application of aerospace engineering in addressing critical global challenges. Moreover, the ongoing miniaturization of satellite components, driven by technological advancements, is leading to the development of smaller, more cost-effective satellites, expanding the accessibility and applications.

In conclusion, satellite systems are a testament to the broad scope and practical impact. These systems are a critical aspect and showcase the integration of knowledge. Continued innovation in satellite technology will undoubtedly shape the future, enabling new capabilities. Addressing challenges in space debris mitigation and ensuring sustainable space operations remains crucial for safeguarding satellite systems and the benefits they provide. This necessitates a comprehensive approach integrating technological advancements and international cooperation, securing the continued function of these important engineering achievements.

4. Avionics Development

Avionics development is an integral part of aerospace engineering, concerning the design, development, and implementation of electronic systems for aircraft and spacecraft. These systems manage crucial functions, ensuring safe and efficient operation. Its contribution to these systems showcases practical applications of electrical engineering, computer science, and aerospace engineering principles.

- Flight Control Systems

Flight control systems regulate aircraft attitude and trajectory. These systems employ sensors, actuators, and computer algorithms to translate pilot input into precise control surface movements. The fly-by-wire systems found in modern airliners, for example, represent a sophisticated application, where electronic signals replace mechanical linkages, improving maneuverability, stability, and fuel efficiency.

- Navigation Systems

Navigation systems determine an aircraft’s position and guide it along a pre-defined route. Inertial navigation systems (INS), GPS receivers, and radar altimeters provide position data, which is then processed by onboard computers to generate navigational instructions. Satellite-based navigation systems have revolutionized air travel, enabling more precise route planning and reducing reliance on ground-based navigation aids.

- Communication Systems

Communication systems facilitate voice and data exchange between the aircraft and ground stations. These systems utilize radio frequencies to transmit information related to air traffic control, weather updates, and passenger communications. Advanced communication systems, such as satellite communication links, enable long-range connectivity, facilitating real-time data transmission and improving operational efficiency.

- Electronic Warfare Systems

Electronic warfare systems play a role in military aircraft, providing capabilities for electronic surveillance, jamming, and countermeasures. These systems detect and analyze enemy radar signals, disrupt enemy communications, and protect the aircraft from incoming threats. The integration of electronic warfare systems significantly enhances the survivability and effectiveness of military aircraft in contested airspace.

These multifaceted aspects underpin the safe and effective performance. These systems, from flight control to electronic warfare, highlight the critical contributions of this field. It is the cornerstone for ensuring safety in both civilian and military operations. Continued advancements promise increased automation, connectivity, and resilience, shaping the future in flight.

5. Materials Innovation

Materials innovation is a cornerstone of advancements, driving progress across various domains. The development and implementation of new materials directly impact the performance, safety, and efficiency of aircraft and spacecraft. These innovations address critical challenges such as weight reduction, increased strength, and enhanced thermal resistance.

- Advanced Composites

The use of advanced composites, such as carbon fiber reinforced polymers, has revolutionized aircraft design. These materials offer a superior strength-to-weight ratio compared to traditional aluminum alloys, resulting in lighter aircraft that consume less fuel. Examples include the Boeing 787 Dreamliner, which utilizes a significant amount of composite materials in its airframe. The reduced weight translates to improved fuel efficiency and extended range.

- High-Temperature Alloys

Spacecraft and high-speed aircraft require materials capable of withstanding extreme temperatures. High-temperature alloys, such as nickel-based superalloys, are used in engine components and heat shields to protect against thermal stresses. These alloys maintain their strength and structural integrity at elevated temperatures, ensuring the reliability of critical systems. The development of these alloys has enabled the design of reusable spacecraft, such as the Space Shuttle, and hypersonic aircraft.

- Shape Memory Alloys

Shape memory alloys (SMAs) exhibit unique properties, allowing them to return to a pre-defined shape after deformation. SMAs are used in actuators, sensors, and deployable structures. Their application in aircraft wings allows for adaptive control surfaces, optimizing aerodynamic performance. In spacecraft, SMAs are used in deployable antennas and solar panels, simplifying deployment mechanisms and reducing weight.

- Ceramic Matrix Composites

Ceramic matrix composites (CMCs) offer excellent high-temperature resistance and low density, making them ideal for use in extreme environments. CMCs are used in rocket engine nozzles and hypersonic vehicle components, where they withstand intense heat and pressure. These materials enable higher engine operating temperatures, resulting in improved thrust and fuel efficiency.

These material advancements exemplify the synergistic relationship. The creation and use has been proven to enhance capabilities, paving the way for future exploration and technological progress. The continued pursuit of new and improved materials remains central to advancing the frontier.

6. Flight Simulation

Flight simulation constitutes a critical facet, providing a safe and cost-effective environment for pilot training, aircraft design validation, and the analysis of flight dynamics. Its application across these diverse areas highlights its significance.

- Pilot Training

Flight simulators offer a realistic representation of the flight environment, allowing pilots to practice maneuvers and emergency procedures without the risks associated with actual flight. Examples include full-motion simulators used by airlines to train pilots for routine and emergency situations. The ability to simulate adverse weather conditions, system failures, and other scenarios enhances pilot preparedness and improves aviation safety.

- Aircraft Design Validation

Flight simulators are used to evaluate and refine aircraft designs before physical prototypes are built. Engineers can use simulation software to model aircraft performance, stability, and control characteristics, identifying potential design flaws and optimizing aircraft configurations. Examples include the use of computational fluid dynamics (CFD) software to simulate airflow around aircraft wings, providing insights into aerodynamic performance.

- Accident Investigation

Flight simulation plays a role in accident investigations, allowing investigators to recreate the conditions leading to an accident and identify potential causes. By simulating the flight path, weather conditions, and aircraft systems, investigators can gain a better understanding of the sequence of events and determine contributing factors. The data acquired provides critical insights for preventing similar accidents in the future.

- Mission Rehearsal

Military and space agencies use flight simulation for mission rehearsal, allowing pilots and astronauts to practice complex maneuvers and procedures in a realistic environment. The simulation of specific mission scenarios enhances crew coordination, improves decision-making, and reduces the risk of errors during actual missions. An example includes mission-specific training for Space Shuttle astronauts.

These applications demonstrate the integration of core tenets, contributing to enhanced safety, efficiency, and performance in the aerospace sector. Its ongoing development ensures continual progress. The technology continues to evolve, driving advancements in pilot training, aircraft design, and flight operations.

7. Rocketry Advancements

Rocketry advancements serve as a critical catalyst within the broader context. Innovations in rocket technology directly translate into enhanced capabilities in space exploration, satellite deployment, and even high-speed terrestrial transport. The development of more efficient propulsion systems, for instance, enables missions to distant celestial bodies, increasing payload capacity and reducing mission duration. Consider the evolution from solid-fueled rockets to liquid-fueled and, more recently, reusable rocket systems. These advancements directly contribute to the feasibility of missions, reducing costs and increasing accessibility to space. The practical significance is evident in the expanding commercial space sector, where companies leverage improved technologies for satellite launches and space tourism.

Further examination reveals the interconnectedness of various aspects within rocket science. The development of new materials capable of withstanding extreme temperatures and pressures is essential for creating reliable and reusable rocket engines. Advancements in guidance and control systems improve the accuracy and stability of rockets during flight. The integration of these technologies, alongside improved manufacturing techniques, has led to significant reductions in launch costs. SpaceX’s Falcon 9 exemplifies this integration, demonstrating the effectiveness of reusable rocket technology in lowering the barrier to space access. This has resulted in increased launch frequency and a wider range of space-based applications, from scientific research to global communication networks. The integration also underscores the importance of interdisciplinary collaboration, requiring expertise from materials scientists, propulsion engineers, and control systems specialists.

In summary, rocketry advancements are inextricably linked and are of core significance. The relentless pursuit of improved propulsion, materials, and control systems continues to drive progress, enabling increasingly ambitious space exploration endeavors. While challenges remain in areas such as reducing launch costs and mitigating environmental impact, the ongoing investment in research and development ensures that rocketry will continue to be a vital component, shaping the future of humanity’s presence beyond Earth. This also necessitates a comprehensive approach, integrating technological innovation with responsible space practices, ensuring sustainable utilization of orbital resources.

Frequently Asked Questions

The following addresses prevalent queries regarding aerospace engineering. These questions aim to clarify common misconceptions and provide a more comprehensive understanding of the field.

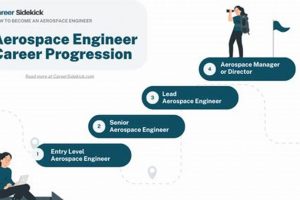

Question 1: What are examples of career paths one can pursue after completing a degree in aerospace engineering?

Career options include aircraft design engineer, propulsion engineer, satellite systems engineer, avionics engineer, and research scientist. Employment opportunities exist within government agencies such as NASA and the Department of Defense, as well as in private sector companies involved in aerospace manufacturing and research.

Question 2: How does aerospace engineering contribute to national defense?

The field plays a crucial role in developing advanced military aircraft, missile systems, and surveillance technologies. Innovations in these areas enhance national security capabilities and provide a strategic advantage.

Question 3: What are some of the current challenges facing aerospace engineers?

Challenges include developing sustainable aviation fuels, reducing aircraft noise pollution, mitigating space debris, and designing spacecraft capable of withstanding long-duration space missions.

Question 4: Is aerospace engineering only concerned with aircraft and spacecraft?

While aircraft and spacecraft are central, the principles and techniques are applicable to other areas, including wind energy, automotive design, and biomedical engineering. The skills developed in aerospace engineering are transferable to a variety of other sectors.

Question 5: What role does computer simulation play?

Computer simulation is used extensively in aircraft design, propulsion system analysis, and flight dynamics modeling. Simulation tools enable engineers to evaluate design concepts, optimize performance, and predict system behavior before physical prototypes are built.

Question 6: What are the key differences between aeronautical and astronautical engineering?

Aeronautical engineering primarily focuses on the design and development of aircraft that operate within Earth’s atmosphere. Astronautical engineering focuses on the design and development of spacecraft, satellites, and related technologies for operation in outer space.

These responses provide a concise overview of several important aspects. It is a diverse and impactful discipline contributing to national defense, innovation and many other sectors.

The next section will cover predictions.

Conclusion

The preceding exploration delineates the diverse manifestations. The design of aircraft, the development of spacecraft propulsion, the engineering of satellite systems, and advancements in avionics, materials, flight simulation, and rocketry collectively represent a multifaceted discipline. Each facet demonstrates the application of core engineering principles to address tangible challenges and advance technological capabilities.

Continued innovation remains crucial. The examples detailed in this article serve as a foundation for future development, driving progress in space exploration, air transportation, and national security. Sustained investment and collaborative endeavors are essential to unlock the full potential, thereby shaping the future.