This entity denotes a specific type of business organization specializing in the field of designing, developing, and manufacturing components, systems, or entire vehicles for flight, whether within Earth’s atmosphere or in outer space. As a “SL” (Sociedad Limitada), it is a limited liability company, indicating a specific legal structure common in certain countries, offering its owners protection from personal liability for the company’s debts. An example could be a company contracted to develop a new wing design for a commercial airliner or another focused on satellite propulsion systems.

Such an entity is crucial for advancements in aviation, space exploration, and defense technologies. It contributes to economic growth through job creation, technological innovation, and export opportunities. Its history is intertwined with the evolution of flight, from early aircraft development to the current era of sophisticated satellites and space vehicles. Benefits include specialized expertise, dedicated resources, and a focused approach to solving complex technical challenges within its domain.

The following sections will delve further into specific aspects related to the operation, impact, and future trends associated with organizations operating within the aerospace sector and adopting this specific legal structure.

Strategic Recommendations for Aerospace Engineering Groups Organized as Limited Liability Companies

The following recommendations aim to enhance operational efficiency, strategic planning, and overall competitiveness for aerospace engineering groups structured as limited liability companies.

Tip 1: Prioritize Rigorous Risk Management: Implement comprehensive risk assessment protocols addressing technical, financial, and legal liabilities specific to the aerospace industry. Example: Conduct regular Failure Mode and Effects Analyses (FMEAs) on critical project components.

Tip 2: Foster Robust Intellectual Property Protection: Secure patents and trademarks for proprietary technologies and designs. Actively monitor and enforce intellectual property rights to maintain a competitive advantage. Example: File patent applications for innovative engine designs or software algorithms.

Tip 3: Cultivate Strong Industry Partnerships: Establish collaborative relationships with research institutions, universities, and other aerospace companies to access advanced technologies and expertise. Example: Participate in joint research projects focusing on sustainable aviation fuels or advanced materials.

Tip 4: Maintain Strict Regulatory Compliance: Adhere to all applicable aviation regulations, quality standards, and environmental requirements imposed by relevant governing bodies. Example: Obtain and maintain AS9100 certification to demonstrate commitment to quality management systems.

Tip 5: Invest in Continuous Employee Training: Provide ongoing professional development opportunities for engineers and technical staff to enhance their skills and knowledge in emerging aerospace technologies. Example: Sponsor employee participation in industry conferences and workshops on advanced composites or artificial intelligence applications.

Tip 6: Optimize Supply Chain Management: Establish reliable relationships with qualified suppliers and implement efficient supply chain processes to ensure timely delivery of high-quality components and materials. Example: Implement a vendor rating system to evaluate supplier performance and identify potential risks.

These recommendations emphasize proactive planning, strategic alliances, and a commitment to quality and compliance, which are crucial for success in the competitive aerospace sector.

The next section provides a concluding overview of the key aspects discussed in this article.

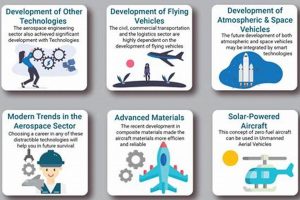

1. Innovation

Innovation is a cornerstone of any aerospace engineering group, particularly those structured as limited liability companies (“SL”). The dynamic nature of the aerospace sector necessitates continuous improvement and novel solutions to maintain competitiveness, meet evolving regulatory requirements, and address emerging market demands. For organizations operating as an SL, innovation provides the means to differentiate themselves, attract investment, and ensure long-term sustainability.

- Materials Science Advancement

This facet concerns the development and application of new materials exhibiting enhanced strength-to-weight ratios, temperature resistance, and durability. Examples include the use of carbon fiber composites in aircraft structures, high-temperature alloys in jet engines, and radiation-shielding materials in spacecraft. Implementation can decrease aircraft weight, increase payload capacity, and improve fuel efficiency. For an aerospace engineering SL, expertise in materials science directly translates to competitive advantages in designing next-generation aircraft and spacecraft.

- Propulsion System Enhancement

Enhancements in propulsion systems focus on improving fuel efficiency, reducing emissions, and increasing thrust-to-weight ratios. Examples encompass advanced engine designs, such as geared turbofans and hybrid-electric propulsion systems, as well as the development of alternative fuels. An aerospace engineering SL specializing in propulsion system design will prioritize this innovation to address environmental concerns and regulatory mandates, while also reducing operational costs for their clients.

- Autonomous Systems Development

This area involves the creation of autonomous systems for aircraft, spacecraft, and related applications. Examples include autonomous flight control systems, unmanned aerial vehicles (UAVs), and autonomous satellite navigation. Successful integration of autonomous systems allows for increased operational efficiency, reduced pilot workload, and the ability to perform missions in hazardous environments. An aerospace engineering SL may focus on developing specialized autonomous capabilities for military, commercial, or scientific purposes.

- Digitalization and Simulation

This facet involves leveraging digital technologies and advanced simulation techniques to optimize design, manufacturing, and operational processes. Examples include the use of computational fluid dynamics (CFD) for aerodynamic analysis, finite element analysis (FEA) for structural optimization, and digital twin technology for predictive maintenance. Adoption of these technologies allows an aerospace engineering SL to reduce development costs, shorten time-to-market, and improve product performance through virtual prototyping and testing.

The innovations listed above represent critical areas where aerospace engineering groups organized as SLs must invest to remain competitive. By prioritizing research and development in these fields, such entities can deliver innovative solutions to meet the challenges of the evolving aerospace landscape, thereby maximizing their value proposition and securing their long-term success.

2. Compliance

Adherence to regulatory requirements and industry standards is non-negotiable for any aerospace engineering group structured as a limited liability company (SL). The highly regulated nature of the aerospace sector necessitates a comprehensive compliance framework to ensure safety, quality, and operational integrity. Non-compliance can result in severe penalties, reputational damage, and even the revocation of operating licenses.

- Aviation Regulations and Certification

Aerospace engineering groups operating as SLs must comply with regulations set forth by aviation authorities such as the FAA (Federal Aviation Administration) in the United States and EASA (European Union Aviation Safety Agency) in Europe. Compliance encompasses aircraft design certification, production certification, and operational regulations. For example, a company designing a new aircraft component must demonstrate compliance with airworthiness directives and obtain necessary certifications before the component can be integrated into an aircraft. Failure to comply can lead to grounding of aircraft and legal repercussions.

- Quality Management Systems (QMS)

Implementation and maintenance of a robust QMS, such as AS9100, is critical for aerospace engineering SLs. These systems ensure that products and services meet stringent quality standards throughout the entire lifecycle, from design and manufacturing to maintenance and repair. For example, a company manufacturing aircraft engines must adhere to rigorous inspection and testing procedures to ensure each engine meets performance and safety requirements. Non-compliance can result in product defects, safety hazards, and loss of customer confidence.

- Environmental Regulations

Aerospace engineering groups must comply with environmental regulations aimed at reducing emissions, noise pollution, and waste generation. This includes adherence to standards set by organizations like the EPA (Environmental Protection Agency) and compliance with international agreements such as CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation). For example, a company developing new aircraft engines must invest in technologies to reduce fuel consumption and emissions. Failure to comply can result in fines, legal challenges, and damage to the company’s reputation.

- Export Control Regulations

Aerospace engineering SLs involved in the development or manufacturing of technologies with military applications must comply with export control regulations such as the EAR (Export Administration Regulations) in the United States and the ITAR (International Traffic in Arms Regulations). These regulations restrict the export of sensitive technologies to certain countries or entities. For example, a company developing advanced radar systems must obtain necessary licenses before exporting the technology to foreign customers. Non-compliance can result in severe penalties, including fines and imprisonment.

These facets illustrate the breadth and depth of compliance requirements for an aerospace engineering group structured as an SL. Adherence to these regulations is not merely a legal obligation but a fundamental aspect of responsible business practice, ensuring the safety, reliability, and sustainability of the aerospace industry. Implementing a comprehensive compliance program is essential for mitigating risks, maintaining stakeholder confidence, and achieving long-term success.

3. Risk Mitigation

For an aerospace engineering group organized as a Sociedad Limitada (“SL”), comprehensive risk mitigation is not merely a desirable attribute but a critical imperative for sustained operation and success. The aerospace sector is inherently characterized by high levels of technological complexity, significant financial investment, and stringent safety requirements. Therefore, the failure to adequately identify, assess, and mitigate potential risks can have catastrophic consequences, ranging from project delays and financial losses to, more gravely, loss of life and severe environmental damage. Effective risk mitigation within an aerospace engineering SL requires a structured approach encompassing technical, financial, operational, and strategic considerations. For example, during the development of a new aircraft engine, a risk mitigation strategy must account for potential design flaws, material failures, supply chain disruptions, and regulatory hurdles. Each identified risk necessitates a corresponding mitigation plan that may involve redundant systems, rigorous testing protocols, and proactive engagement with regulatory bodies. This methodical approach is not optional but essential for ensuring the viability of aerospace projects.

The importance of risk mitigation is further underscored by the unique legal and financial structure of the SL. As a limited liability company, the personal assets of the owners are generally protected from the company’s debts and liabilities. However, this protection does not absolve the company or its management from the responsibility of exercising due diligence in managing risks. A failure to implement adequate risk mitigation measures could expose the SL to lawsuits, fines, and reputational damage, potentially undermining its financial stability and long-term prospects. Consider, for instance, a scenario where an aerospace engineering SL is contracted to develop a critical component for a satellite. If the company fails to adequately assess and mitigate the risk of component failure in the harsh environment of space, the resulting satellite malfunction could lead to significant financial losses for the client and damage the SL’s reputation. Such a failure highlights the practical significance of robust risk management, demonstrating how a seemingly technical issue can have far-reaching legal and financial implications for the SL.

In summary, risk mitigation is an indispensable element of an aerospace engineering group operating as an SL. Its effective implementation is not simply a matter of best practice but a fundamental requirement for ensuring project success, maintaining financial stability, and upholding ethical and legal responsibilities. The challenges inherent in the aerospace sector demand a proactive and comprehensive approach to risk management, one that anticipates potential problems and implements robust mitigation strategies to minimize their impact. Understanding this connection is paramount for any stakeholder involved in the operation or oversight of an aerospace engineering SL, enabling them to make informed decisions and contribute to the long-term sustainability of the organization and the broader aerospace industry.

4. Collaboration

Effective collaboration is a cornerstone of success for any “aerospace engineering group sl”. The complexity inherent in aerospace projects necessitates a multidisciplinary approach, integrating expertise from diverse fields such as aerodynamics, propulsion, materials science, and software engineering. A solitary entity seldom possesses the complete spectrum of knowledge and resources required to navigate the intricacies of aircraft or spacecraft development. Therefore, strategic partnerships and collaborative ventures are indispensable for sharing expertise, mitigating risks, and accelerating innovation. For example, the development of a new commercial airliner typically involves collaboration between airframe manufacturers, engine suppliers, avionics providers, and various research institutions. The “aerospace engineering group sl” may specialize in one or more of these areas, contributing its expertise to the overall project while benefiting from the knowledge and resources of its partners.

Furthermore, the global nature of the aerospace industry often requires international collaboration to access specialized technologies, navigate regulatory landscapes, and penetrate new markets. An “aerospace engineering group sl” may collaborate with foreign companies or research organizations to jointly develop a new product or service, leveraging the unique strengths and capabilities of each partner. For instance, European aerospace companies often collaborate with their counterparts in North America and Asia to develop advanced propulsion systems or satellite technologies. Such collaborations not only facilitate technological advancements but also promote economic growth and foster international cooperation. The importance of collaboration extends beyond external partnerships to encompass internal team dynamics within the “aerospace engineering group sl”. Effective communication, knowledge sharing, and cross-functional teamwork are essential for ensuring that projects are completed efficiently and effectively. By fostering a collaborative work environment, the “aerospace engineering group sl” can maximize the collective intelligence of its employees and drive innovation from within.

In conclusion, collaboration is not merely a desirable characteristic but a fundamental requirement for “aerospace engineering group sl” to thrive in the competitive aerospace sector. It enables access to diverse expertise, promotes innovation, facilitates international market penetration, and enhances internal team performance. While challenges such as intellectual property protection and cultural differences may arise in collaborative ventures, the benefits of collaboration far outweigh the risks. A commitment to fostering effective partnerships and collaborative work environments is essential for any “aerospace engineering group sl” seeking to achieve long-term success and contribute to the advancement of the aerospace industry.

5. Sustainability

Sustainability has become a critical focus for aerospace engineering groups structured as limited liability companies (“SL”). The industry’s significant environmental impact necessitates proactive strategies to reduce emissions, minimize waste, and conserve resources. An integrated sustainability approach is not only ethically responsible but also economically prudent, fostering innovation, enhancing brand reputation, and ensuring long-term viability.

- Sustainable Aviation Fuels (SAF)

The development and adoption of SAF represent a key strategy for reducing the carbon footprint of air travel. SAF are produced from renewable sources such as algae, biomass, and waste streams, offering a substantial reduction in greenhouse gas emissions compared to conventional jet fuel. Aerospace engineering SLs play a crucial role in researching and developing SAF-compatible engine technologies and optimizing aircraft designs to maximize fuel efficiency. For example, companies are developing advanced combustion systems that can efficiently burn SAF without compromising performance. The widespread adoption of SAF could significantly reduce the environmental impact of air travel, making it a more sustainable mode of transportation. In particular, such groups are working with existing aircrafts’ engine to make it compatible with SAF use.

- Lightweight Materials and Design

The use of lightweight materials such as carbon fiber composites and advanced alloys is essential for reducing aircraft weight and improving fuel efficiency. Aerospace engineering SLs are investing in research and development to create lighter and stronger materials that can withstand the stresses of flight while minimizing fuel consumption. For example, companies are developing advanced composite structures for aircraft wings and fuselages, reducing weight and improving aerodynamic performance. Optimized aerodynamic designs, such as blended wing body aircraft, further contribute to fuel efficiency and reduced emissions. A lighter aircraft with better aerodynamic design is one that consumes less fuel and thus, less emission to the environment.

- Electric and Hybrid-Electric Propulsion Systems

The development of electric and hybrid-electric propulsion systems offers a promising pathway to reduce emissions and noise pollution in aviation. Electric aircraft can be powered by batteries or fuel cells, producing zero emissions during flight. Hybrid-electric aircraft combine electric propulsion with traditional combustion engines, offering a more immediate solution for reducing emissions on shorter routes. Aerospace engineering SLs are actively researching and developing electric motors, battery technologies, and hybrid-electric architectures for aircraft applications. For example, companies are developing electric vertical takeoff and landing (eVTOL) aircraft for urban air mobility, providing a sustainable alternative to traditional helicopters. The future is heading toward using more electric in aviation.

- Circular Economy Principles

Adopting circular economy principles in aerospace manufacturing and operations can minimize waste, conserve resources, and reduce environmental impact. This involves designing products for disassembly and reuse, recycling materials, and implementing closed-loop manufacturing processes. Aerospace engineering SLs can promote circularity by designing aircraft components that can be easily disassembled and recycled at the end of their service life. For example, companies are developing recycling technologies for composite materials, enabling the reuse of carbon fibers in new aerospace applications. Companies that are in aircraft maintenance sector are encouraged to follow circular economy so that it will become more sustainable.

- Waste Management and Recycling

Airlines and airports generate significant amounts of waste, including food packaging, single-use plastics, and maintenance materials. Implementing effective waste management and recycling programs can reduce landfill waste and promote resource conservation. Aerospace engineering SLs can contribute by developing innovative recycling technologies for aircraft components and promoting the use of sustainable materials in cabin interiors. For example, companies are developing recycling programs for aircraft tires and batteries, preventing them from ending up in landfills. Recycling also means reducing the use of new materials.

These sustainability initiatives are becoming increasingly integral to the business strategies of aerospace engineering SLs. By embracing sustainability, these companies can not only reduce their environmental impact but also enhance their competitiveness, attract environmentally conscious customers, and contribute to a more sustainable future for the aerospace industry.

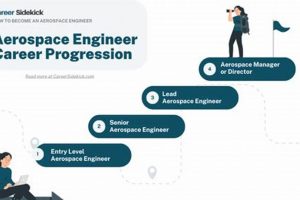

6. Talent Acquisition

For an “aerospace engineering group sl”, talent acquisition is not merely a human resources function but a strategic imperative directly influencing innovation, competitiveness, and long-term viability. The aerospace sector demands highly specialized skills in areas such as aerodynamics, propulsion, avionics, and materials science. Securing individuals with the requisite expertise is paramount for an “aerospace engineering group sl” to undertake complex projects, develop cutting-edge technologies, and maintain a competitive edge. For example, a company specializing in satellite propulsion systems requires engineers with advanced knowledge of rocket engine design, fluid dynamics, and combustion processes. Failure to attract and retain such talent can severely limit the company’s ability to innovate and execute projects effectively. This in turn affects the bottom line and the ability to grow and expand the business.

The effectiveness of talent acquisition strategies directly impacts the ability of the “aerospace engineering group sl” to meet increasingly stringent regulatory requirements and navigate the complexities of global markets. Skilled engineers and technicians are essential for ensuring compliance with aviation safety standards, environmental regulations, and export control laws. Furthermore, the “aerospace engineering group sl” must cultivate a culture of continuous learning and professional development to retain top talent in a rapidly evolving technological landscape. Companies can offer specialized training programs, mentorship opportunities, and opportunities to participate in cutting-edge research projects. These tactics are essential for employee retention and can also be used as a talent acquisition incentive.

In summary, talent acquisition represents a critical component of an “aerospace engineering group sl’s” overall strategic framework. The ability to attract, develop, and retain highly skilled individuals directly impacts the company’s capacity for innovation, competitiveness, and long-term success. Challenges in talent acquisition, such as skills shortages and competition from larger organizations, necessitate proactive and creative recruitment strategies. By prioritizing talent acquisition and investing in employee development, an “aerospace engineering group sl” can establish a sustainable competitive advantage and contribute to the advancement of the aerospace industry.

7. Financial Stability

Financial stability is paramount for any enterprise, but it assumes particular significance for an aerospace engineering group structured as a Sociedad Limitada (“SL”). The capital-intensive nature of aerospace projects, long development cycles, and inherent technological risks necessitate a robust financial foundation to ensure operational continuity, attract investment, and sustain competitiveness.

- Revenue Diversification

Reliance on a single revenue stream, such as a major government contract, exposes an aerospace engineering SL to significant financial risk. Diversifying revenue sources through multiple contracts, product offerings, or service lines enhances financial resilience. For example, a company specializing in aircraft component manufacturing could expand its services to include maintenance, repair, and overhaul (MRO) operations, providing a more stable income stream. The implications of revenue diversification include reduced vulnerability to market fluctuations and increased capacity to weather economic downturns.

- Cost Management and Efficiency

Effective cost management is crucial for maintaining profitability and financial stability in the highly competitive aerospace sector. Implementing efficient manufacturing processes, optimizing supply chain management, and controlling overhead expenses are essential for maximizing profit margins. For instance, an aerospace engineering SL could invest in automation technologies to reduce labor costs and improve production efficiency. Efficient cost management allows the company to allocate resources more effectively, invest in research and development, and maintain a competitive pricing strategy.

- Access to Capital and Investment

Aerospace projects often require substantial upfront investment, making access to capital a critical determinant of financial stability. An aerospace engineering SL must maintain strong relationships with banks, investors, and other financial institutions to secure funding for new projects and expansion initiatives. For example, a company developing a new electric aircraft might seek venture capital funding to finance prototype development and testing. Adequate access to capital allows the company to pursue innovative projects, expand its operations, and capitalize on market opportunities.

- Risk Management and Insurance

The aerospace industry is characterized by inherent technological, operational, and financial risks. Implementing a comprehensive risk management program, including insurance coverage for product liability, property damage, and business interruption, is essential for protecting the financial interests of the aerospace engineering SL. For example, a company manufacturing aircraft engines might purchase product liability insurance to cover potential damages resulting from engine failure. Effective risk management minimizes potential financial losses and enhances the company’s ability to withstand unforeseen events.

These facets underscore the critical importance of financial stability for an aerospace engineering group structured as an SL. Proactive financial planning, diversification of revenue streams, efficient cost management, access to capital, and robust risk management are essential for ensuring the long-term sustainability and success of the organization.

Frequently Asked Questions Regarding Aerospace Engineering Group SL Operations

The following addresses common inquiries concerning the structure, operation, and strategic considerations for aerospace engineering groups organized as limited liability companies (Sociedad Limitada).

Question 1: What advantages does the Sociedad Limitada (SL) structure offer an aerospace engineering group compared to other business entities?

The SL structure, common in specific legal jurisdictions, provides limited liability protection to its owners, shielding personal assets from business debts and lawsuits. This is particularly advantageous in the aerospace sector, where projects carry inherent risks and potential for significant financial exposure. Further benefits include a relatively simple formation process and flexible management structure.

Question 2: What are the primary compliance obligations for an aerospace engineering group SL?

Compliance obligations encompass adherence to aviation regulations set by authorities such as the FAA and EASA, implementation of quality management systems like AS9100, adherence to environmental regulations regarding emissions and noise, and compliance with export control regulations for technologies with military applications.

Question 3: How can an aerospace engineering group SL effectively manage intellectual property rights?

Effective management of intellectual property involves securing patents and trademarks for proprietary technologies and designs, implementing robust internal procedures to protect trade secrets, actively monitoring and enforcing intellectual property rights, and conducting thorough due diligence before entering into collaborative agreements.

Question 4: What strategies can an aerospace engineering group SL employ to mitigate financial risks?

Financial risk mitigation strategies include revenue diversification through multiple contracts and service offerings, efficient cost management to maximize profit margins, maintaining access to capital through strong relationships with financial institutions, and implementing a comprehensive risk management program with appropriate insurance coverage.

Question 5: How important is collaboration for an aerospace engineering group SL, and what types of collaborations are most beneficial?

Collaboration is critical for accessing specialized expertise, sharing resources, and mitigating risks. Beneficial collaborations include partnerships with research institutions, universities, other aerospace companies, and international organizations to leverage diverse capabilities and navigate global markets.

Question 6: How can an aerospace engineering group SL contribute to sustainability in the aerospace industry?

Contributions to sustainability include investing in the development and adoption of sustainable aviation fuels, utilizing lightweight materials and design principles, exploring electric and hybrid-electric propulsion systems, and implementing circular economy principles to minimize waste and conserve resources.

These answers provide a general overview of key considerations for aerospace engineering groups structured as SLs. Specific circumstances may require consultation with legal, financial, and technical experts.

The following section will delve into future trends and opportunities for aerospace engineering groups.

Conclusion

This exploration of the “aerospace engineering group sl” construct has illuminated the complex interplay of technological innovation, stringent regulatory compliance, strategic risk mitigation, collaborative engagement, and enduring financial stability that defines these specialized entities. The sustained success of such organizations hinges upon a deep commitment to quality, safety, and sustainability, intertwined with a proactive approach to intellectual property protection and talent acquisition. The legal structure itself, the Sociedad Limitada, offers specific advantages in terms of liability and management flexibility, while simultaneously requiring diligent adherence to corporate governance principles.

As the aerospace sector confronts evolving technological landscapes and increasing environmental awareness, it becomes ever more critical for aerospace engineering groups of this type to prioritize adaptability, continuous learning, and responsible corporate citizenship. Investments in cutting-edge research and development, coupled with adherence to the highest ethical standards, will prove essential to not just the survival of individual companies but also the continued advancement and responsible evolution of the global aerospace industry.