The transition from mechanical engineering to aerospace engineering represents a common career path. Mechanical engineering provides a robust foundation in areas such as thermodynamics, fluid mechanics, structural analysis, and materials science. These fundamental principles are highly relevant and applicable to the design, analysis, and manufacturing of aerospace vehicles and related systems. For instance, a mechanical engineer specializing in finite element analysis could readily apply their skills to analyze the structural integrity of an aircraft wing.

This career transition is facilitated by the inherent overlap in the core competencies of both disciplines. Many mechanical engineers possess the foundational knowledge necessary to succeed in aerospace roles. Moreover, gaining specialized aerospace knowledge and skills often involves targeted professional development, such as advanced coursework, certifications, or on-the-job training. The historical context reveals numerous examples of individuals with mechanical engineering backgrounds making significant contributions to the aerospace industry, highlighting the value of a versatile engineering skillset.

The subsequent discussion will elaborate on specific strategies and resources available to facilitate this career shift, including relevant areas of specialization within aerospace, key skills to acquire, and pathways for professional development to effectively leverage a mechanical engineering background in an aerospace engineering context. This includes examining the specific skills and knowledge beyond the core curriculum that are needed to function effectively in the aerospace sector.

Tips for Transitioning from Mechanical to Aerospace Engineering

Achieving a successful transition from mechanical engineering to aerospace engineering requires strategic planning and focused effort. These tips offer guidance for navigating this career shift effectively.

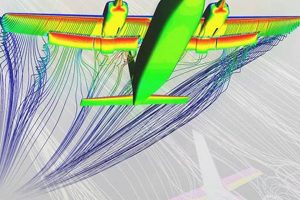

Tip 1: Enhance Knowledge in Aerodynamics: Aerodynamics is fundamental in aerospace engineering. Pursue coursework or online resources focusing on compressible flow, airfoil design, and computational fluid dynamics (CFD) to build a strong foundation. A mechanical engineer might, for instance, use CFD software to analyze airflow over a turbine blade; this skill can be adapted to analyze airflow over an aircraft wing.

Tip 2: Develop Expertise in Aerospace Materials: Aerospace structures often utilize advanced materials like composites, titanium alloys, and aluminum alloys. Gain familiarity with their properties, manufacturing processes, and applications. This might involve understanding how carbon fiber reinforced polymers (CFRPs) contribute to weight reduction in aircraft structures, enhancing fuel efficiency.

Tip 3: Acquire Systems Engineering Skills: Aerospace projects often involve complex systems integration. Understanding systems engineering principles, including requirements management, verification, and validation, is essential. This could entail learning how to manage the interfaces and interactions between different aircraft subsystems, such as avionics, hydraulics, and propulsion.

Tip 4: Seek Relevant Project Experience: Participate in projects related to aerospace, either through academic research, internships, or personal projects. Designing a small-scale drone, analyzing the performance of a rocket engine nozzle, or contributing to a university-led aerospace competition can provide valuable practical experience.

Tip 5: Obtain Industry-Specific Certifications: Consider pursuing certifications relevant to aerospace, such as those related to aircraft maintenance, quality assurance, or specialized software tools. This demonstrates a commitment to professional development and enhances credibility within the field.

Tip 6: Network with Aerospace Professionals: Attend industry conferences, join professional organizations like the American Institute of Aeronautics and Astronautics (AIAA), and connect with aerospace engineers on professional networking platforms. Building relationships with professionals can provide valuable insights, mentorship, and potential job opportunities.

Tip 7: Master Simulation and Analysis Tools: Proficiency in software used for aerospace analysis and design, such as MATLAB, ANSYS, or Nastran, is crucial. Becoming adept at using these tools for structural analysis, thermal analysis, and flight dynamics simulation can significantly improve career prospects.

These strategies emphasize proactive skill development and industry engagement. By focusing on these areas, a mechanical engineer can effectively bridge the knowledge gap and establish a successful career in aerospace engineering.

The subsequent section will address common challenges encountered during this career transition and offer guidance on overcoming them.

1. Adaptable foundational knowledge

Adaptable foundational knowledge, acquired through a mechanical engineering curriculum, directly influences the feasibility of transitioning into aerospace engineering. The core coursework within mechanical engineering provides a robust understanding of physical principles, mathematical modeling, and engineering design methodologies. This knowledge base, encompassing thermodynamics, fluid mechanics, heat transfer, and structural analysis, serves as a critical prerequisite for comprehending the complexities of aerospace systems. For example, a mechanical engineer’s understanding of fluid dynamics is directly applicable to analyzing airflow over aircraft wings, while knowledge of heat transfer is vital for designing thermal management systems for satellites. This inherent transferability allows mechanical engineers to rapidly assimilate specialized aerospace concepts.

The ability to adapt this foundational knowledge to aerospace challenges is pivotal. Aerospace engineering often demands the application of established mechanical engineering principles within extreme conditions or specialized contexts. Understanding material behavior at high speeds or in vacuum environments, for instance, requires an extrapolation of knowledge gained in traditional mechanical engineering materials science. Similarly, applying principles of vibration analysis to prevent structural failure in spacecraft necessitates a refined understanding of dynamic systems. The practical significance lies in the minimized learning curve and accelerated ability of mechanical engineers to contribute meaningfully to aerospace projects.

In summary, adaptable foundational knowledge acts as a catalyst, enabling mechanical engineers to pursue careers in aerospace. This adaptability stems from the broad scientific and engineering principles imparted during mechanical engineering education, allowing a seamless integration into the aerospace domain. The resulting synergy fosters innovation and contributes to advancements in aerospace technology. However, it is important to note that while adaptable foundational knowledge provides a strong base, it must be supplemented with focused training and experience in specialized aerospace areas to ensure competence and expertise.

2. Specialized skill acquisition

Specialized skill acquisition represents a critical factor determining whether a mechanical engineer can effectively transition to aerospace engineering. While a mechanical engineering background provides a solid foundation, success in aerospace necessitates the development of specific skills tailored to the unique challenges and demands of the aerospace sector.

- Computational Fluid Dynamics (CFD) Expertise

Aerospace applications often require intricate aerodynamic analyses. Proficiency in CFD software allows engineers to model and simulate airflow around aircraft, rockets, and other aerospace vehicles. This expertise is essential for optimizing aerodynamic performance, reducing drag, and ensuring stable flight. For example, CFD simulations can inform the design of airfoil shapes to maximize lift and minimize fuel consumption. Without this specialized skill, a mechanical engineer would be limited in their ability to contribute to aerodynamic design and analysis within the aerospace field.

- Aerospace Materials and Structures Knowledge

The aerospace industry utilizes specialized materials like composites, titanium alloys, and high-strength aluminum alloys due to their unique properties, such as high strength-to-weight ratios and resistance to extreme temperatures. Acquiring knowledge of these materials, their manufacturing processes, and their behavior under stress is crucial. A mechanical engineer working in aerospace must understand how to design structures using these materials to meet stringent weight and performance requirements. This includes expertise in finite element analysis (FEA) for structural simulations and understanding failure modes specific to aerospace materials.

- Guidance, Navigation, and Control (GNC) Systems Design

Aerospace vehicles require sophisticated GNC systems to maintain stability, navigate accurately, and achieve mission objectives. Developing expertise in this area involves understanding sensor technologies (e.g., accelerometers, gyroscopes, GPS), control algorithms, and feedback systems. Mechanical engineers transitioning to aerospace may need to learn how to design and implement control systems for spacecraft attitude control or aircraft flight control. This specialized skill set is vital for ensuring the safe and reliable operation of aerospace vehicles.

- Propulsion Systems Analysis and Design

Aerospace propulsion systems, including jet engines, rocket engines, and electric propulsion systems, present unique engineering challenges. Acquiring specialized knowledge in thermodynamics, combustion, and fluid dynamics is essential for analyzing and designing these systems. Mechanical engineers working on propulsion systems must understand how to optimize engine performance, minimize fuel consumption, and ensure safe and reliable operation. This expertise may involve using specialized software for engine simulation and conducting experimental testing to validate designs.

These examples illustrate the importance of specialized skill acquisition for mechanical engineers seeking to transition to aerospace engineering. While the foundational knowledge gained in mechanical engineering is valuable, success in aerospace requires a focused effort to develop expertise in these and other specialized areas. The acquisition of these skills enhances a mechanical engineer’s employability and enables them to contribute meaningfully to the design, analysis, and development of aerospace systems. These capabilities serve as a bridge, connecting the broader mechanical engineering domain to the more focused specialization of aerospace, facilitating a more seamless and effective career transition.

3. Industry-specific expertise

Industry-specific expertise is a pivotal determinant in the career transition from mechanical to aerospace engineering. While mechanical engineering provides a strong theoretical foundation, practical application and domain-specific knowledge are essential for success in the aerospace sector. Understanding industry standards, regulatory requirements, and specialized processes distinguishes a mechanical engineer prepared for aerospace work from one without such knowledge.

- Regulatory Compliance and Certification

The aerospace industry operates under stringent regulatory frameworks imposed by organizations such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). Expertise in these regulations is crucial. This includes understanding airworthiness standards, certification processes, and safety protocols governing aircraft design, manufacturing, and operation. For example, a mechanical engineer transitioning to aerospace must be familiar with the requirements for structural integrity testing, materials certification, and quality control procedures mandated by these agencies. Failure to comply with these regulations can result in significant financial penalties and jeopardize public safety.

- Specialized Design Software and Tools

Aerospace engineering relies heavily on specialized software tools for design, analysis, and simulation. Proficiency in software such as CATIA, ANSYS, NASTRAN, and MATLAB is often a prerequisite for aerospace engineering roles. These tools enable engineers to model complex aerospace systems, conduct finite element analysis, simulate flight dynamics, and optimize designs for performance and reliability. For instance, CATIA is widely used for 3D modeling of aircraft components, while ANSYS is employed for structural analysis and thermal simulations. Mastering these tools requires targeted training and practical experience, demonstrating a commitment to industry-specific practices.

- Aerospace Materials and Manufacturing Processes

The aerospace industry utilizes advanced materials such as composites, titanium alloys, and high-strength aluminum alloys due to their exceptional strength-to-weight ratios and resistance to extreme environments. Expertise in these materials, their properties, and their manufacturing processes is essential. This includes understanding composite layup techniques, welding procedures for titanium alloys, and heat treatment processes for aluminum alloys. A mechanical engineer working in aerospace must be knowledgeable about the specific challenges associated with manufacturing aerospace components, such as maintaining tight tolerances and ensuring quality control throughout the production process.

- Systems Engineering Principles in Aerospace

Aerospace projects are inherently complex and involve the integration of numerous subsystems. A strong understanding of systems engineering principles is essential for managing this complexity. This includes expertise in requirements management, system architecture design, interface control, verification and validation, and risk management. For example, a mechanical engineer working on an aircraft project must understand how different subsystems, such as avionics, propulsion, and hydraulics, interact and how to ensure that they function seamlessly together. Effective systems engineering practices are critical for ensuring project success, meeting performance requirements, and mitigating potential risks.

The facets of industry-specific expertise, including regulatory compliance, specialized software proficiency, materials knowledge, and systems engineering understanding, collectively determine the effectiveness of a mechanical engineer’s transition into aerospace. Without this expertise, a mechanical engineer may lack the practical skills and knowledge necessary to contribute meaningfully to aerospace projects. Developing this expertise requires targeted training, industry experience, and a commitment to continuous learning, effectively bridging the gap between the broader mechanical engineering domain and the specific demands of the aerospace sector.

4. Interdisciplinary project experience

Interdisciplinary project experience is a significant factor influencing the transition of mechanical engineers into aerospace engineering roles. This experience demonstrates an ability to collaborate across different engineering domains, a necessity in complex aerospace projects.

- Systems Integration Exposure

Interdisciplinary projects provide exposure to the intricacies of systems integration. Aerospace projects inherently require the seamless integration of mechanical, electrical, software, and other engineering systems. A mechanical engineer involved in a project that requires close collaboration with electrical engineers on sensor integration, or software engineers on control system development, gains valuable experience in understanding system-level interactions. For example, designing a robotic arm for spacecraft maintenance necessitates coordination between mechanical components, electrical actuators, and software control algorithms. This experience translates directly to aerospace roles, where systems-level thinking is critical.

- Cross-Domain Communication Skills

Participating in interdisciplinary projects necessitates the development of effective communication skills across diverse technical backgrounds. Mechanical engineers must be able to clearly articulate their design considerations and constraints to engineers from other disciplines and understand their perspectives in return. For instance, a project involving the development of a hybrid propulsion system requires mechanical engineers to communicate with chemical engineers regarding fuel properties and combustion processes. This skill in cross-domain communication is vital for navigating the collaborative environment inherent in aerospace projects, facilitating efficient problem-solving and knowledge sharing.

- Adaptability to Varied Technical Challenges

Interdisciplinary projects expose engineers to a broader range of technical challenges, fostering adaptability and problem-solving skills. Mechanical engineers may encounter challenges outside their traditional expertise, such as understanding communication protocols for data transmission or troubleshooting electronic control systems. For example, designing a remotely operated underwater vehicle (ROV) requires addressing challenges related to hydrodynamics, power management, and remote control, forcing mechanical engineers to expand their knowledge base and develop innovative solutions. This adaptability proves invaluable in the aerospace sector, where engineers often face novel and complex challenges requiring a multi-faceted approach.

- Exposure to Diverse Design Philosophies

Working alongside engineers from different disciplines exposes mechanical engineers to diverse design philosophies and methodologies. Electrical engineers may emphasize signal integrity and power efficiency, while software engineers prioritize code reliability and maintainability. Understanding these different perspectives broadens a mechanical engineer’s approach to design and encourages the adoption of best practices from other fields. For instance, a project involving the design of a medical device might expose mechanical engineers to human factors engineering principles, which can inform the design of user-friendly aerospace interfaces. This exposure to diverse design philosophies enhances a mechanical engineer’s ability to contribute effectively to multidisciplinary aerospace projects.

These aspects of interdisciplinary project experience, encompassing systems integration, communication skills, adaptability, and exposure to diverse design philosophies, contribute significantly to a mechanical engineer’s preparedness for a career in aerospace engineering. The ability to effectively collaborate, communicate, and adapt to diverse technical challenges is highly valued in the aerospace sector, making interdisciplinary project experience a valuable asset for mechanical engineers seeking to transition into this field.

5. Professional network engagement

Professional network engagement serves as a crucial catalyst for mechanical engineers aspiring to transition into aerospace engineering. Active participation in professional networks facilitates access to information, mentorship, and career opportunities otherwise unavailable through conventional channels. Engagement with organizations like the American Institute of Aeronautics and Astronautics (AIAA) or attendance at industry conferences provides direct interaction with aerospace professionals, fostering knowledge exchange and industry insights. For instance, a mechanical engineer seeking guidance on applying finite element analysis to spacecraft structures might find invaluable mentorship through connections established at an AIAA event. This access to specialized expertise directly impacts the feasibility and success of a career transition.

The effect of professional network engagement extends beyond acquiring technical knowledge. Networking cultivates awareness of emerging trends, skill demands, and hiring practices within the aerospace sector. Participation in industry-specific workshops and seminars allows mechanical engineers to tailor their skill development to align with the needs of aerospace employers. Furthermore, these networks often act as a conduit for accessing unadvertised job openings or gaining referrals from established professionals. The Society of Women Engineers (SWE), for example, can provide targeted support and networking opportunities for female mechanical engineers interested in aerospace, addressing unique challenges they may face in a historically male-dominated field. Such focused engagement significantly enhances career prospects.

In summary, professional network engagement is not merely a supplemental activity but an integral component of a successful transition from mechanical to aerospace engineering. It provides access to specialized knowledge, mentorship opportunities, and career pathways that accelerate skill development and increase employability. Challenges in initiating and maintaining network engagement, such as time constraints or geographic limitations, can be addressed through online platforms and virtual events, ensuring broader accessibility. Ultimately, proactive engagement with professional networks equips mechanical engineers with the resources and connections necessary to navigate the complexities of the aerospace industry and achieve their career aspirations.

Frequently Asked Questions

This section addresses common inquiries regarding the transition from mechanical engineering to aerospace engineering, providing clarity on the requirements, challenges, and opportunities involved.

Question 1: Is a mechanical engineering degree sufficient to work as an aerospace engineer?

A mechanical engineering degree provides a strong foundation for aerospace engineering. However, specialized knowledge in areas such as aerodynamics, aerospace materials, and flight control systems is typically required for effective performance in aerospace-specific roles.

Question 2: What are the most valuable skills for a mechanical engineer to acquire for a transition to aerospace?

Key skills include proficiency in computational fluid dynamics (CFD), finite element analysis (FEA), knowledge of aerospace materials (e.g., composites, titanium alloys), and familiarity with aerospace design software (e.g., CATIA, ANSYS).

Question 3: Are there specific areas within aerospace engineering where mechanical engineers are particularly well-suited?

Mechanical engineers often find opportunities in areas such as structural analysis, thermal management, propulsion systems (e.g., engine design, rocket nozzles), and mechanical systems design within aircraft and spacecraft.

Question 4: How can a mechanical engineer gain relevant experience in aerospace if their current role is unrelated?

Options include pursuing advanced coursework in aerospace engineering, participating in relevant online courses and certifications, contributing to open-source aerospace projects, seeking internships at aerospace companies, and joining aerospace-related professional organizations.

Question 5: Is a graduate degree in aerospace engineering necessary for mechanical engineers seeking to enter the field?

While not always mandatory, a graduate degree in aerospace engineering can significantly enhance career prospects and provide more in-depth knowledge of specialized aerospace topics. However, relevant experience and demonstrated skills can often compensate for the lack of a graduate degree.

Question 6: What are some common challenges faced by mechanical engineers transitioning to aerospace engineering?

Challenges may include a lack of familiarity with aerospace-specific regulations and standards, a need for specialized software training, competition from aerospace engineering graduates, and the necessity to bridge knowledge gaps in areas like orbital mechanics or avionics.

In summary, the transition from mechanical to aerospace engineering requires dedication, targeted skill development, and a proactive approach to acquiring industry-specific knowledge. With the right preparation, a mechanical engineer can successfully pursue a rewarding career in the aerospace sector.

The subsequent section will provide case studies of mechanical engineers who have made successful transitions into aerospace roles, highlighting their strategies and experiences.

Can a Mechanical Engineer Be an Aerospace Engineer

The preceding discussion comprehensively addressed the query of whether a mechanical engineer can effectively transition into aerospace engineering. The analysis confirms the feasibility of such a transition, contingent upon strategic skill acquisition, industry-specific knowledge development, and active professional network engagement. While a mechanical engineering curriculum provides a robust foundation in fundamental engineering principles, targeted efforts are essential to bridge the gap between the broader mechanical domain and the specialized requirements of the aerospace sector. Successful transitions involve focused training in areas like aerodynamics, aerospace materials, and flight control systems, as well as proficiency in relevant software tools and a thorough understanding of regulatory compliance.

The demonstrated adaptability of mechanical engineers, combined with the structured acquisition of aerospace-specific expertise, underscores the potential for significant contributions to the aerospace industry. Aspiring engineers should proactively pursue opportunities for interdisciplinary project experience and network with aerospace professionals to maximize their chances of success. The future of aerospace engineering will likely demand individuals with versatile skill sets and the capacity for continuous learning. Therefore, mechanical engineers who embrace these challenges and actively pursue professional development will find ample opportunities to thrive in this dynamic and technologically advanced field.

![Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-647-300x200.jpg)