Organized endeavors within the field focusing on the design, development, testing, and implementation of aircraft, spacecraft, and related technologies represent a cornerstone of aerospace advancement. These undertakings range from conceptual studies to tangible hardware creation, often requiring multidisciplinary teams and significant resource allocation. Examples include the development of novel propulsion systems, the design of unmanned aerial vehicles (UAVs), and the construction of satellites for communication or Earth observation.

These organized endeavors play a crucial role in advancing scientific knowledge, enhancing national security, and driving economic growth. Historically, such undertakings have led to breakthroughs in materials science, aerodynamics, and computer technology, impacting numerous other sectors. The successful execution of them fosters innovation, cultivates expertise, and provides significant benefits to society through improved transportation, communication, and exploration capabilities.

A further investigation into specific types of these organized endeavors, the required skill sets, and the future trends shaping the field will be examined.

Effective management and execution are paramount for successful outcomes within this technically demanding domain. The following guidance provides a framework for minimizing risks and maximizing the potential for innovation and advancement.

Tip 1: Define Clear Objectives: Prior to initiation, establish specific, measurable, achievable, relevant, and time-bound (SMART) goals. A well-defined scope prevents scope creep and ensures alignment among stakeholders.

Tip 2: Foster Interdisciplinary Collaboration: Given the multifaceted nature of the field, promote effective communication and knowledge sharing between diverse teams of engineers, scientists, and technicians. Siloed work practices can lead to inefficiencies and suboptimal solutions.

Tip 3: Implement Rigorous Testing and Validation: Comprehensive testing protocols are essential to identify and mitigate potential flaws in designs and systems. This should include simulations, hardware-in-the-loop testing, and flight tests where applicable.

Tip 4: Manage Risks Proactively: Identify potential risks early in the planning phase and develop mitigation strategies to address them. This includes technical, financial, and schedule-related risks.

Tip 5: Adhere to Industry Standards and Regulations: Strict adherence to established aerospace standards and regulatory requirements is critical to ensure safety, reliability, and compliance.

Tip 6: Leverage Advanced Simulation Tools: Computational fluid dynamics (CFD), finite element analysis (FEA), and other simulation tools can significantly reduce development time and costs by enabling virtual prototyping and optimization.

Tip 7: Prioritize Documentation and Knowledge Retention: Maintain thorough documentation throughout the life cycle, from initial design concepts to final test results. This facilitates knowledge transfer and enables future improvements.

Adherence to these guidelines can significantly enhance the likelihood of success in endeavors within this field, fostering innovation and contributing to advancement in aerospace technology.

Moving forward, a focus on specific examples and case studies will further illustrate the application of these principles.

1. Conceptualization

Conceptualization forms the foundational stage, the initial spark that ignites the process of translating abstract ideas into tangible aerospace systems. It is the rigorous examination of needs, opportunities, and constraints that defines the trajectory of subsequent design, development, and deployment efforts. It sets the boundaries and establishes the potential impact within the aerospace sector.

- Mission Definition

This aspect involves identifying the specific purpose of the proposed undertaking. This includes determining the target environment, desired performance metrics, and operational lifespan. For example, defining the mission of a new Earth observation satellite includes its orbital parameters, the types of sensors it will carry, and the resolution of the data it will collect. A poorly defined mission can lead to wasted resources and a final product that fails to meet user needs.

- Feasibility Analysis

A comprehensive assessment of technical, economic, and logistical viability is crucial. This involves evaluating available technologies, estimating development costs, and identifying potential risks. For instance, the feasibility analysis for a hypersonic transport aircraft would consider the maturity of high-temperature materials, the projected fuel consumption, and the impact on existing air traffic infrastructure. An inadequate feasibility analysis can result in projects that are technically unachievable or economically unsustainable.

- Requirements Elicitation

This involves gathering and documenting the specific needs and expectations of stakeholders. This includes engineers, scientists, customers, and regulatory agencies. For example, the requirements elicitation process for a new commercial aircraft would involve gathering input from airlines, pilots, passengers, and airworthiness authorities. A failure to accurately capture and document these requirements can lead to designs that do not meet the needs of the end users or that fail to comply with safety regulations.

- Concept Generation and Selection

This phase involves brainstorming and evaluating various potential solutions to meet the identified needs and requirements. This can include developing alternative designs, exploring different technologies, and assessing their relative merits. For example, the concept generation phase for a new lunar lander might involve considering different propulsion systems, landing gear configurations, and crew accommodation arrangements. A rigorous concept generation and selection process increases the likelihood of identifying the most promising and effective solution.

The thorough execution of conceptualization, encompassing mission definition, feasibility analysis, requirements elicitation, and concept generation, significantly influences the subsequent phases. Its emphasis on rigorous analysis and stakeholder alignment ensures the most viable and impactful are brought to fruition within the dynamic realm of aerospace engineering.

2. Design

Design represents a critical stage within undertakings focused on aerospace systems. It encompasses the translation of conceptual requirements into detailed specifications and blueprints for physical realization. Without meticulous design, the envisioned functionality and performance of aircraft, spacecraft, and associated technologies remain unrealized.

- Aerodynamic Configuration Design

This facet centers on shaping the external form of an aircraft or spacecraft to optimize lift, minimize drag, and ensure stability. Computational fluid dynamics (CFD) simulations are frequently employed to evaluate and refine aerodynamic performance. The design of a wing profile, for example, directly impacts fuel efficiency and flight characteristics. Inefficient designs can result in increased fuel consumption and compromised maneuverability.

- Structural Design and Analysis

Ensuring the structural integrity and load-bearing capacity of aerospace vehicles is paramount. This involves selecting appropriate materials, designing structural components, and performing stress analysis to withstand operational loads. Finite element analysis (FEA) is commonly used to simulate structural behavior under various conditions. Failure to adequately address structural design can lead to catastrophic failures and loss of life.

- Systems Engineering Design

This aspect focuses on the integration and coordination of various subsystems within an aerospace vehicle, such as propulsion, avionics, and environmental control. It involves defining interfaces, allocating resources, and managing complexity. Proper systems engineering design ensures that all subsystems function harmoniously to achieve overall mission objectives. Poor systems integration can result in performance degradation and operational inefficiencies.

- Control Systems Design

Developing control systems that enable stable and precise operation of aerospace vehicles is essential. This involves designing algorithms, selecting sensors and actuators, and implementing feedback control loops. Control systems design is crucial for maintaining stability during flight, guiding spacecraft to their destinations, and automating critical tasks. Inadequate control system design can lead to instability, loss of control, and mission failure.

These design facets are interdependent and iterative, requiring a holistic approach to ensure optimal performance and reliability in aerospace applications. The effectiveness of design directly influences the success of aerospace engineering endeavors, determining their ability to meet performance requirements, safety standards, and mission objectives.

3. Manufacturing

Manufacturing constitutes a critical phase in the execution of endeavors within aerospace engineering. It encompasses the transformation of detailed designs into physical components and functional systems. The precision and quality of manufacturing processes directly influence the performance, reliability, and safety of aerospace vehicles and associated technologies.

- Material Selection and Processing

The selection of appropriate materials and their subsequent processing are paramount in aerospace manufacturing. Materials must possess specific properties, such as high strength-to-weight ratio, corrosion resistance, and thermal stability. Processing techniques include advanced machining, composite layup, and additive manufacturing. For example, titanium alloys are frequently used in aircraft engine components due to their high strength and heat resistance. Improper material selection or processing can lead to structural failures and performance degradation.

- Precision Machining and Fabrication

Aerospace components often require extremely tight tolerances and intricate geometries. Precision machining techniques, such as computer numerical control (CNC) milling and turning, are employed to achieve the necessary accuracy. Skilled machinists and fabricators are essential to ensure that parts meet stringent specifications. The manufacture of turbine blades, for instance, demands exceptional precision to ensure efficient operation and prevent premature failure. Deviations from specified tolerances can result in performance losses and reduced lifespan.

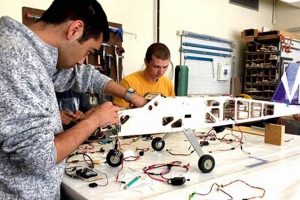

- Assembly and Integration

The assembly and integration of individual components into larger subsystems and complete aerospace vehicles require meticulous planning and execution. Processes such as riveting, welding, and bonding are used to join parts together. Proper alignment, fastening, and sealing are critical to ensure structural integrity and functional performance. The assembly of an aircraft fuselage, for example, requires precise alignment of numerous structural elements. Errors during assembly can lead to stress concentrations and compromised structural strength.

- Quality Control and Inspection

Rigorous quality control and inspection procedures are implemented throughout the manufacturing process to identify and correct defects. Non-destructive testing (NDT) methods, such as ultrasonic inspection and radiography, are used to detect internal flaws without damaging the parts. Dimensional measurements and visual inspections are performed to verify compliance with specifications. The inspection of a welded joint, for example, ensures that it meets strength and integrity requirements. Inadequate quality control can result in undetected defects that lead to catastrophic failures during operation.

The multifaceted nature of manufacturing necessitates a comprehensive and integrated approach to ensure the successful realization of endeavors within the aerospace field. Careful attention to material selection, precision machining, assembly techniques, and quality control is essential to achieve the performance, reliability, and safety standards required for aerospace applications.

4. Testing

Verification and validation are paramount stages within endeavors focused on aerospace technologies. This phase rigorously assesses components, systems, and integrated platforms against defined requirements and performance criteria. Without thorough evaluation, the successful operation and safety of aerospace assets cannot be assured.

- Component Testing

Individual components, such as sensors, actuators, and electronic modules, undergo rigorous testing to verify their functionality, reliability, and environmental tolerance. Environmental testing simulates extreme conditions, including temperature variations, vibration, and electromagnetic interference, to ensure robust performance in demanding aerospace environments. An accelerometer, for example, must maintain accuracy and stability across a wide temperature range to provide reliable data for flight control systems. Inadequate component testing can lead to premature failures and compromised system performance.

- System Integration Testing

Once individual components have been validated, they are integrated into larger subsystems and subjected to system-level evaluation. This phase focuses on verifying the interoperability and functionality of integrated systems, such as propulsion systems, avionics suites, and communication networks. Hardware-in-the-loop (HIL) simulations are frequently used to emulate real-world scenarios and assess system performance under dynamic conditions. The interaction between a flight control computer and an autopilot system, for instance, is rigorously tested to ensure seamless coordination and stable flight characteristics. Deficiencies identified during system integration testing can reveal design flaws or integration issues that would otherwise compromise overall system performance.

- Full-Scale Vehicle Testing

Complete aerospace vehicles, including aircraft, spacecraft, and missiles, undergo comprehensive testing to validate their overall performance, stability, and safety. Flight testing is conducted to evaluate aerodynamic characteristics, control system behavior, and structural integrity under realistic flight conditions. Ground-based testing, such as static fire tests for rocket engines, assesses propulsion system performance and structural durability. A new aircraft design, for example, undergoes extensive flight testing to verify its handling qualities, fuel efficiency, and stall characteristics. Failure to adequately test full-scale vehicles can result in catastrophic failures and loss of life.

- Non-Destructive Testing (NDT)

Non-destructive testing methods are employed to detect internal flaws and structural weaknesses in aerospace components and vehicles without causing damage. Techniques such as ultrasonic inspection, radiography, and eddy current testing are used to identify cracks, voids, and other defects that could compromise structural integrity. The inspection of welded joints in an aircraft fuselage, for example, ensures that they meet required strength and quality standards. NDT plays a crucial role in maintaining the safety and reliability of aerospace assets throughout their operational lifespan.

The multifaceted nature of verification and validation underscores its importance in the execution of undertakings. The careful implementation of components, systems, and full-scale vehicle evaluations is essential to achieving the performance, reliability, and safety standards required for aerospace applications.

5. Integration

Within the context of organized endeavors focused on aerospace systems, integration represents a pivotal stage that directly impacts project success. It signifies the process of seamlessly combining disparate components, subsystems, and software elements into a cohesive and functional whole. The efficacy of integration efforts directly determines whether a design concept can be translated into a reliable and high-performing aerospace system. Poor integration can lead to system malfunctions, performance degradation, and even catastrophic failures. Consider, for example, the challenges inherent in integrating a newly developed radar system into an existing aircraft avionics suite. The radar must communicate effectively with other onboard systems, such as the flight management system and the display units in the cockpit. Compatibility issues, timing conflicts, or software bugs can prevent the radar from functioning correctly, potentially compromising flight safety.

The significance of integration extends beyond mere physical connections. It encompasses the harmonization of diverse engineering disciplines, including electrical engineering, mechanical engineering, and software engineering. Successful undertakings require robust communication and collaboration among these disciplines to ensure that each component functions optimally within the larger system. For instance, the development of a satellite involves integrating numerous subsystems, such as the power system, the communication system, and the attitude control system. Each of these subsystems is designed and built by different teams of engineers, often working in separate locations. The integration process brings these subsystems together, requiring careful coordination and testing to ensure that they operate seamlessly in the harsh environment of space. The James Webb Space Telescope provides a notable example, where the integration of its complex optical system and scientific instruments presented significant challenges, ultimately overcome through meticulous planning and execution.

In summary, integration is not merely a technical task but a holistic process that requires careful planning, rigorous testing, and effective communication. It is a critical determinant of project success within the realm of organized efforts within the aerospace domain. Addressing integration challenges proactively and investing in robust integration processes are essential for ensuring the reliability, performance, and safety of aerospace systems. Looking forward, advanced modeling and simulation techniques, coupled with automated integration tools, are expected to play an increasingly important role in streamlining integration efforts and mitigating potential risks.

6. Deployment

Deployment represents the culmination of organized endeavors within the aerospace engineering field, signifying the transition of a developed system from its design and testing phases into operational use. It is the point where the tangible benefits of engineering efforts are realized, and the system begins to fulfill its intended purpose.

- Mission Activation

Mission activation refers to the initial operational phase following a deployment. In the context of satellite endeavors, this entails initiating onboard systems, establishing communication links, and maneuvering the satellite into its designated orbit. For aircraft undertakings, it involves commencing flight operations, establishing maintenance protocols, and training personnel. Incorrect execution can lead to mission failure or compromised system performance. For example, a flawed orbit insertion maneuver for a communication satellite could render it unusable.

- Infrastructure Implementation

The establishment of supporting infrastructure is integral to deployment. This encompasses ground stations for satellite control, launch facilities for space missions, and maintenance depots for aircraft fleets. A robust infrastructure ensures continuous operation and facilitates necessary maintenance and repairs. The absence of adequate infrastructure can severely limit the operational effectiveness of deployed systems. The lack of strategically located airfields, for example, can constrain the operational range of military aircraft.

- System Integration with Existing Operations

Deployment often necessitates the integration of newly developed systems with pre-existing operational frameworks. This requires careful coordination to ensure compatibility and avoid disruptions to ongoing activities. Integrating a new air traffic control system, for example, requires meticulous planning and phased implementation to minimize interference with existing air traffic operations. Poor integration can lead to inefficiencies, safety hazards, and operational disruptions.

- Performance Monitoring and Optimization

Post-deployment, continuous monitoring of system performance is essential to identify potential issues and optimize operational parameters. This involves collecting and analyzing data on system behavior, tracking key performance indicators, and implementing necessary adjustments. Regular monitoring of aircraft engine performance, for example, can detect early signs of wear and tear, allowing for proactive maintenance. A failure to monitor and optimize performance can result in decreased efficiency, increased maintenance costs, and reduced system lifespan.

These facets of deployment underscore its significance within the lifecycle of such endeavors. Successful transition to operational use relies on meticulous planning, robust infrastructure, effective integration, and continuous monitoring. Furthermore, deployment represents a critical feedback loop, providing valuable data for informing future design and development efforts within the aerospace engineering domain.

Frequently Asked Questions

This section addresses common inquiries concerning organized efforts undertaken within the aerospace engineering domain, providing factual and unbiased information.

Question 1: What constitutes a typical undertaking in this field?

A typical organized effort encompasses a structured set of activities aimed at designing, developing, testing, or deploying aerospace-related technologies or systems. Examples include the design and construction of unmanned aerial vehicles, the development of advanced propulsion systems, or the creation of satellite-based communication networks. These endeavors generally involve multidisciplinary teams, significant resource allocation, and adherence to stringent performance and safety requirements.

Question 2: What are the key phases involved in such an endeavor?

The lifecycle typically involves distinct phases, including conceptualization, design, manufacturing, testing, integration, and deployment. Conceptualization involves defining project goals and feasibility. Design translates concepts into detailed plans. Manufacturing focuses on fabrication and assembly. Testing validates designs and components. Integration combines various elements into a functional system. Deployment puts the system into operation.

Question 3: What skill sets are essential for success in these organized efforts?

Success demands a blend of technical expertise and project management proficiency. Core technical skills include knowledge of aerodynamics, propulsion systems, structural analysis, control systems, and materials science. Project management skills encompass planning, resource allocation, risk management, and team coordination.

Question 4: How are risks managed in these undertakings?

Risk management is a critical aspect, involving identification, assessment, and mitigation of potential hazards. Risk mitigation strategies often include redundancy in system design, rigorous testing protocols, and contingency planning to address unforeseen events.

Question 5: What are some common challenges encountered?

Common challenges include managing complex technical requirements, adhering to strict regulatory standards, controlling costs, and maintaining project schedules. Effective communication and collaboration among team members are crucial for overcoming these challenges.

Question 6: How do such endeavors contribute to societal advancement?

These endeavors contribute to societal advancement through technological innovation, economic growth, and enhanced national security. Advances in aerospace technology have led to improvements in air transportation, satellite communications, weather forecasting, and space exploration, providing tangible benefits to society.

The information provided aims to clarify commonly asked questions and provide a foundational understanding of the topic.

Continuing onward, key insights into potential future advancements will be discussed.

Conclusion

The preceding discussion has detailed essential facets of organized endeavors within the aerospace engineering field, encompassing conceptualization through deployment. These undertakings, characterized by their complexity and interdisciplinary nature, are pivotal in driving advancements across diverse sectors, including transportation, communication, and national security.

Continued innovation and rigorous execution of organized efforts remain critical to addressing emerging challenges and capitalizing on future opportunities in this dynamic domain. Sustained investment in research, development, and skilled workforce training will be essential to maintaining leadership and ensuring the sustained societal benefits derived from aerospace technology.