The distinction between engineering fields focusing on flight is primarily one of scope. One concentrates on aircraft operating within Earth’s atmosphere, while the other encompasses vehicles and systems designed for operation both inside and outside it. This delineation marks a fundamental difference in the technologies, challenges, and environments engineers in each field address. As an example, designing a commercial airliner falls under the purview of one discipline, while developing a satellite would be the domain of the other.

Understanding this differentiation is crucial for students selecting an engineering specialization, as career paths, required skill sets, and project types differ significantly. This knowledge also aids organizations in recruiting personnel with the precise expertise necessary for their specific projects. Historically, the expansion of flight beyond the atmosphere led to the emergence of a broader field, building upon the foundational principles established by its predecessor.

The following sections will delve further into the specific areas of study, project types, and career opportunities available within each engineering branch, illustrating their unique contributions to the advancement of flight and space exploration.

Clarifying the Disciplines

This section offers guidance in differentiating between these related engineering fields to aid in academic and career planning.

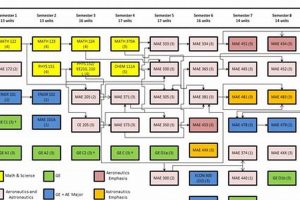

Tip 1: Examine Course Curricula: Aeronautical programs typically emphasize aerodynamics, propulsion systems for atmospheric flight, and aircraft structural design. Aerospace programs broaden this scope to include spacecraft design, orbital mechanics, and satellite communication systems.

Tip 2: Review Faculty Expertise: Faculty profiles often indicate research interests and specializations. A concentration of professors specializing in jet engine design likely points to an aeronautical focus, while expertise in satellite systems suggests an aerospace emphasis.

Tip 3: Consider Project Opportunities: Look for hands-on projects within the curriculum. Designing an aircraft wing is characteristic of aeronautical engineering, whereas developing a spacecraft guidance system aligns with aerospace engineering.

Tip 4: Research Career Trajectories: Investigate potential career paths for graduates. Aeronautical engineers often find roles in aircraft manufacturing or airline operations, while aerospace engineers may work for space agencies or satellite companies.

Tip 5: Assess Industry Connections: University partnerships with aerospace companies or government agencies may signal a stronger emphasis on a particular discipline. These connections can provide valuable internship or research opportunities.

Tip 6: Analyze Program Descriptions Carefully: Pay close attention to the wording used in program descriptions. Terms like “atmospheric flight” or “aircraft performance” typically indicate an aeronautical focus, while “space exploration” or “orbital dynamics” suggest an aerospace orientation.

By carefully evaluating program curricula, faculty expertise, project opportunities, career trajectories, industry connections, and program descriptions, prospective students can make informed decisions about which engineering discipline best suits their interests and goals.

The following sections will offer information about the job opportunities in each field.

1. Atmospheric flight

Atmospheric flight serves as a defining characteristic in differentiating between aeronautical and aerospace engineering. Its presence as the sole operational environment signifies the core domain of aeronautical engineering. Aeronautical engineers are principally concerned with designing, developing, and testing aircraft that operate exclusively within Earth’s atmosphere. This focus necessitates a deep understanding of aerodynamics, propulsion systems optimized for atmospheric conditions (e.g., jet engines, propellers), and structural considerations tailored to the stresses and strains experienced during flight within the atmosphere. Consider the development of a new generation of fuel-efficient commercial airliners; this undertaking falls squarely within the realm of aeronautical engineering, requiring expertise in minimizing drag, optimizing engine performance at varying altitudes, and ensuring structural integrity against atmospheric pressures and turbulence.

In contrast, while aerospace engineering principles also apply to atmospheric flight, its scope extends beyond this limitation. Aerospace engineers are equipped to address challenges associated with vehicles and systems designed to operate in both atmospheric and extra-atmospheric environments. This requires knowledge of orbital mechanics, spacecraft propulsion (e.g., rocket engines, ion thrusters), radiation shielding, and thermal management in the vacuum of space. A project involving the design of a reusable spacecraft, like the Space Shuttle, demands the application of aerospace engineering principles, addressing both the aerodynamic requirements of atmospheric reentry and the operational requirements of orbital flight and space-based activities. The design must account for extreme temperature variations and the absence of atmospheric pressure.

Therefore, atmospheric flight represents a critical demarcation. It highlights the specialization within aeronautical engineering while simultaneously underscoring the broader, more versatile skill set associated with aerospace engineering. Understanding this difference is essential for aspiring engineers when choosing a specialization, as it directly impacts the types of projects they will undertake and the environments in which they will work. Failure to appreciate this distinction can lead to misaligned career expectations and suboptimal utilization of engineering expertise.

2. Spacecraft design

Spacecraft design directly elucidates the distinction between aerospace and aeronautical engineering. It stands as a primary domain of aerospace engineering, diverging significantly from the atmospheric focus of aeronautical engineering. The design and development of spacecraft necessitate expertise beyond traditional aerodynamics, delving into areas like orbital mechanics, propulsion systems for vacuum environments, radiation shielding, and thermal control in the absence of atmospheric convection. A satellite, for example, requires systems for attitude control, power generation (typically solar), and communication with ground stations. The development and implementation of these systems are core responsibilities of aerospace engineers, representing capabilities largely absent from aeronautical engineering applications.

The practical implications of this distinction are substantial. Consider the International Space Station (ISS). Its design, construction, and ongoing operation rely heavily on aerospace engineering expertise. Engineers involved in this project address challenges such as maintaining the ISS’s orbit, managing its power supply, ensuring the survival of astronauts in the vacuum of space, and conducting scientific research in a microgravity environment. These activities are fundamentally different from the design and maintenance of commercial aircraft, which represents a core domain of aeronautical engineering. The contrasting demands associated with atmospheric versus space-based operations mandate specialized knowledge and training.

In summary, spacecraft design epitomizes the expanded scope of aerospace engineering compared to aeronautical engineering. While both fields share foundational principles, the unique challenges presented by space environments and spacecraft functionality firmly establish spacecraft design as a defining element differentiating these two disciplines. Understanding this distinction is crucial for aspiring engineers seeking to specialize in either atmospheric or extra-atmospheric flight and related technologies.

3. Orbital mechanics

Orbital mechanics, the study of the motion of artificial satellites and natural celestial bodies under the influence of gravity, constitutes a critical differentiating factor. It is fundamentally relevant to aerospace engineering but largely absent from the core curriculum of aeronautical engineering. Because aeronautical engineering focuses on flight within Earth’s atmosphere, the principles governing trajectories in space are typically beyond its scope. Aerospace engineers, conversely, must possess a comprehensive understanding of orbital mechanics to design missions, predict satellite behavior, and optimize spacecraft trajectories.

The design of a satellite constellation exemplifies the practical application of orbital mechanics within aerospace engineering. Precise calculations are required to determine the optimal altitude, inclination, and phasing of each satellite to achieve desired coverage and minimize interference. Furthermore, understanding orbital perturbations, such as atmospheric drag and gravitational anomalies, is essential for maintaining the constellation’s integrity over its operational lifespan. The Global Positioning System (GPS), a satellite constellation enabling positioning and timing services, demonstrates the significance of accounting for relativistic effects predicted by general relativity to maintain accuracy. These factors necessitate specialized knowledge beyond the traditional focus of aeronautical engineering.

In conclusion, orbital mechanics represents a key area of divergence between the two fields. Its essential role in spacecraft mission design and satellite operations underscores the expanded scope of aerospace engineering, while its relative absence in aeronautical curricula highlights the latter’s concentration on atmospheric flight. Comprehending this distinction is crucial for individuals seeking to specialize in either aeronautics or astronautics and for organizations recruiting talent for projects involving space-based activities.

4. Aerodynamics Focus

Aerodynamics, the study of air in motion and its interaction with solid objects, occupies a central role in both aeronautical and aerospace engineering. However, the scope and application of aerodynamic principles differ considerably, contributing significantly to the differentiation between these disciplines. While both fields require a strong foundation in aerodynamics, the specific areas of emphasis and the challenges addressed vary based on the operational environment.

- Aircraft Design and Performance

In aeronautical engineering, aerodynamics is paramount for optimizing aircraft design and performance within the Earth’s atmosphere. This involves minimizing drag, maximizing lift, and ensuring stability and control across a range of flight conditions, from takeoff and landing to cruise altitude. The design of wings, fuselages, and control surfaces is heavily influenced by aerodynamic considerations. For example, the development of high-lift devices, such as flaps and slats, directly addresses the need for increased lift during low-speed maneuvers. These considerations, while important in certain phases of aerospace vehicle flight, are fundamentally central to the entire operation of an aircraft.

- High-Speed Aerodynamics and Compressibility Effects

As aircraft speeds approach and exceed the speed of sound, compressibility effects become significant. Aeronautical engineers must account for these effects in the design of high-performance aircraft, such as fighter jets and supersonic transports. Shock waves, sonic booms, and changes in airflow properties necessitate advanced aerodynamic modeling and testing techniques. The development of swept wings, for instance, mitigates the effects of compressibility at high speeds. While aerospace vehicles may encounter similar conditions during atmospheric reentry, the duration and specific challenges differ substantially from sustained high-speed flight within the atmosphere.

- Re-entry Aerodynamics and Thermal Management

For aerospace engineering, particularly in the context of spacecraft design, re-entry aerodynamics presents unique challenges. As a spacecraft re-enters the Earth’s atmosphere, it experiences extreme heat due to air friction. The design of heat shields and the selection of appropriate materials are critical for protecting the spacecraft and its occupants. Aerodynamic shaping also plays a role in controlling the spacecraft’s trajectory and minimizing the peak heating rate. For example, the Space Shuttle utilized a ceramic tile heat shield to withstand the intense temperatures generated during re-entry. This aspect of aerodynamics is less prevalent in traditional aeronautical engineering applications.

- Extraterrestrial Aerodynamics (Hypothetical)

Looking towards the future of aerospace, consideration is given to other planets with atmosphere like mars, there still is need to calculate the atmospheric flight. this hypothetical cases, the conditions and calculations differ based on the atmosphere of planet. for example, the mars helicopter used different types of blades to fly in the less dense atmosphere of mars.

In summary, while aerodynamics is a core element of both aeronautical and aerospace engineering, its specific applications and the challenges it addresses vary considerably. Aeronautical engineering emphasizes aerodynamic optimization for sustained atmospheric flight, while aerospace engineering expands this focus to encompass the extreme conditions and unique requirements associated with spaceflight and atmospheric re-entry. This difference in aerodynamic focus is a key factor in differentiating between these two important engineering disciplines.

5. Propulsion systems

Propulsion systems serve as a critical point of divergence between aeronautical and aerospace engineering. The design, implementation, and operational characteristics of these systems reflect the distinct environments in which aircraft and spacecraft function, directly impacting the skill sets and knowledge required for engineers in each field.

- Atmospheric Engines: Air-Breathing Propulsion

Aeronautical engineering emphasizes propulsion systems designed for operation within Earth’s atmosphere. These “air-breathing” engines, such as turbojets, turbofans, and propellers, rely on atmospheric air for combustion. Optimization focuses on fuel efficiency, thrust-to-weight ratio, and performance characteristics within a specific range of altitudes and airspeeds. The design of a modern turbofan engine, for example, necessitates intricate aerodynamic analysis of compressor and turbine blades to maximize efficiency and minimize noise. The operational envelope remains confined to atmospheric conditions.

- Spacecraft Engines: Vacuum-Optimized Propulsion

Aerospace engineering encompasses propulsion systems designed for operation in the vacuum of space. These systems, often utilizing rockets or ion thrusters, carry both fuel and oxidizer. Design considerations prioritize specific impulse (a measure of fuel efficiency), thrust vector control, and reliability in the harsh space environment. The development of a liquid-fueled rocket engine, such as those used in the Saturn V or Space Shuttle, requires advanced knowledge of combustion chemistry, thermodynamics, and materials science to withstand extreme temperatures and pressures. The operational realm extends beyond atmospheric limitations.

- Hybrid Systems: Bridging the Gap

Some advanced projects require propulsion systems capable of operating both within and outside the atmosphere. These hybrid systems, often a focus of aerospace engineering, demand a deep understanding of both air-breathing and rocket propulsion principles. Single-stage-to-orbit (SSTO) vehicles, for example, propose the use of combined-cycle engines that transition from air-breathing mode in the atmosphere to rocket mode in space. The complexity of designing and controlling such systems highlights the advanced capabilities required of aerospace engineers.

- Future technologies

Future technologies may include new types of propulsion systems that can be operated on earth and in space like ramjet, scramjet, pulse detonation engine, and more. all of this technologies needs a deep analysis and focus in design in order to operate.

In summary, the distinct requirements of atmospheric and spaceflight necessitate different approaches to propulsion system design. Aeronautical engineering concentrates on optimizing air-breathing engines for efficient and reliable operation within the atmosphere, while aerospace engineering expands the scope to include rocket and other advanced propulsion systems capable of functioning in the vacuum of space. The selection and integration of appropriate propulsion systems is a defining characteristic in what divides these two disciplines.

6. Materials science

Materials science plays a pivotal role in differentiating aerospace and aeronautical engineering due to the disparate operational environments and performance demands placed on vehicles in each domain. The selection, development, and application of materials are critical considerations in both disciplines, yet the specific challenges and priorities differ substantially.

- Atmospheric Flight Material Considerations

In aeronautical engineering, material selection prioritizes strength-to-weight ratio, fatigue resistance, and corrosion resistance within atmospheric conditions. Aircraft components, such as wings and fuselages, require materials that can withstand aerodynamic loads, fluctuating temperatures, and potential exposure to moisture and corrosive agents. Aluminum alloys, composites, and high-strength steels are commonly employed. The development of new aluminum-lithium alloys, for example, directly addresses the need for lighter, more fuel-efficient aircraft, reflecting the specific material challenges within aeronautical engineering.

- Space Environment Material Challenges

Aerospace engineering confronts the additional challenges of extreme temperatures, vacuum conditions, and radiation exposure. Spacecraft materials must maintain structural integrity and functionality across a broad temperature range, withstand the damaging effects of radiation, and resist outgassing in a vacuum environment. Materials commonly used in spacecraft construction include titanium alloys, specialized polymers, and composite materials with enhanced thermal and radiation resistance. The development of ceramic matrix composites for heat shields demonstrates the specific material advancements driven by the demands of aerospace engineering.

- Thermal Management Materials

Thermal management constitutes a significant concern in both disciplines but with different emphasis. Aeronautical applications focus on dissipating heat generated by engines and aerodynamic friction, while aerospace engineering grapples with the extreme temperature variations experienced in space and during atmospheric re-entry. Heat-resistant alloys, thermal insulators, and heat pipes are utilized to maintain critical component temperatures within acceptable limits. The selection and application of these materials are tailored to the specific thermal environment encountered in each domain.

- Materials for Propulsion Systems

Both aero and aerospace engineering require the use of high temp materials. these high temp materials have to endure high pressure, high velocity and high temp. the different between both is aero materials will be focus on the atmosphere environment on the other hand, space need to also considered vacuum and radiation, with the new engine technology for both environments, the material science of the engines also need to be considered, this is to ensure the new propulsion systems operate efficiently.

In summary, the stringent material requirements imposed by the disparate operating environments of aircraft and spacecraft underscore a key distinction between aeronautical and aerospace engineering. While both disciplines share a foundation in materials science, the specific materials employed, the challenges addressed, and the performance criteria prioritized reflect the unique demands of atmospheric versus spaceflight. Consequently, expertise in specialized materials and their application is a defining characteristic that distinguishes engineers in these respective fields.

7. Control systems

Control systems engineering provides a crucial point of differentiation between aerospace and aeronautical engineering. While both disciplines require sophisticated control systems for stable and efficient operation, the complexity and scope of these systems differ significantly due to the operational environments. Aircraft control systems primarily address atmospheric flight dynamics, focusing on stability augmentation, autopilot functionalities, and flight management systems. These systems ensure safe and precise navigation within the atmosphere, compensating for turbulence, wind shear, and other atmospheric disturbances. Consider an autopilot system on a commercial airliner; it integrates sensor data (airspeed, altitude, attitude) to maintain a pre-programmed flight path, freeing the pilot to focus on other critical tasks. The system is designed specifically for atmospheric flight and its inherent challenges.

In contrast, aerospace control systems must address the complexities of both atmospheric and spaceflight. Spacecraft attitude control systems, for example, maintain the desired orientation of a satellite or spacecraft in the vacuum of space, counteracting external torques from solar radiation pressure or gravitational gradients. These systems often employ reaction wheels, thrusters, or magnetic torquers to achieve precise pointing accuracy. Furthermore, aerospace control systems are integral to orbital maneuvers, guiding spacecraft through complex trajectory changes using propulsion systems and gravitational assists. The control system for the James Webb Space Telescope, for instance, must maintain its precise orientation to ensure accurate observations, a task far beyond the scope of typical aeronautical control systems. Atmospheric control considerations are also factored into re-entry procedures, managing the craft during high velocity descent.

In summary, control systems are vital to both aeronautical and aerospace engineering; however, the increased complexity and operational requirements of spaceflight demand a broader and more sophisticated approach to control system design within the aerospace field. From atmospheric turbulence to orbital mechanics and spacecraft attitude control, the challenges addressed by aerospace control systems far exceed those typically encountered in aeronautical applications. This difference in scope and complexity underscores the distinct expertise required in each engineering discipline.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding the distinction between aerospace and aeronautical engineering. The answers aim to provide clarity and inform potential career paths.

Question 1: Is an aerospace engineer qualified to design aircraft?

An aerospace engineer possesses a foundational knowledge of aircraft design. However, specialization within aeronautical engineering provides a more in-depth understanding of atmospheric flight principles and optimization techniques specific to aircraft. An aerospace engineer might require further training or experience to become proficient in all aspects of aircraft design.

Question 2: Can an aeronautical engineer work on spacecraft projects?

An aeronautical engineer’s expertise is primarily focused on atmospheric flight. While possessing a strong foundation in aerodynamics and propulsion, the specialized knowledge required for spacecraft design, orbital mechanics, and space environment considerations is generally outside their core skill set. Additional education or training would be necessary.

Question 3: Which field offers broader career opportunities?

Aerospace engineering typically offers a wider range of career opportunities due to its broader scope, encompassing both atmospheric and space-related projects. Aeronautical engineering careers are primarily concentrated in the aviation industry.

Question 4: Is one field “better” than the other?

Neither field is inherently superior. The “better” choice depends entirely on an individual’s interests and career goals. Those passionate about atmospheric flight and aircraft design may find aeronautical engineering more fulfilling, while those drawn to space exploration and spacecraft development may prefer aerospace engineering.

Question 5: Do both fields require strong math and physics skills?

Yes, both aerospace and aeronautical engineering demand a strong foundation in mathematics and physics. These disciplines rely heavily on quantitative analysis and modeling to solve complex engineering problems.

Question 6: How have the names changed historically?

Historically, aeronautical engineering was the original field, focusing solely on flight within Earth’s atmosphere. The emergence of spaceflight led to the creation of aerospace engineering to encompass the broader scope of atmospheric and space-based activities.

In summary, the selection between aerospace and aeronautical engineering should be based on individual career aspirations and interests. Both fields offer challenging and rewarding opportunities for individuals with a strong aptitude for mathematics, physics, and engineering principles.

The next section will explore relevant career prospects.

Conclusion

This exploration has illuminated the fundamental distinctions between aerospace and aeronautical engineering. While both disciplines share common roots in flight mechanics and engineering principles, their divergence lies in the operational environment and scope of application. Aeronautical engineering concentrates on vehicles operating within Earth’s atmosphere, addressing challenges related to aerodynamics, propulsion, and structural integrity within those constraints. Aerospace engineering expands this scope to encompass vehicles and systems operating both within and beyond the atmosphere, incorporating orbital mechanics, spacecraft design, and the unique challenges of the space environment. Material selection, control systems, and system design are all impacted by this fundamental difference.

Understanding what’s the difference between aerospace engineering and aeronautical engineering is essential for aspiring engineers charting their career paths. Whether focusing on the skies above or the cosmos beyond, these fields drive innovation and progress in flight and space exploration, shaping the future of transportation, communication, and scientific discovery. Continued advancement in both areas will require dedicated, highly skilled engineers capable of pushing the boundaries of what is currently possible. The choice between them is a pivotal career decision that should be made with all of these factors in mind.

![Top Ivy League Aerospace Engineering Programs [Year] Innovating the Future of Flight with Reliable Aviation Solutions Top Ivy League Aerospace Engineering Programs [Year] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-123-300x200.jpg)