The discipline involving the design, development, testing, and production of aircraft and spacecraft is crucial to modern technological advancement. This field integrates principles from various engineering branches, including aerodynamics, propulsion, materials science, and structural analysis, to create efficient and safe systems. For instance, the design of a commercial airliner necessitates a thorough understanding of these principles to optimize fuel consumption and passenger comfort.

The importance of this area lies in its contribution to transportation, communication, and national defense. Advancements in aircraft technology have significantly reduced travel times and connected distant regions. Spacecraft development enables satellite communications, weather forecasting, and scientific exploration, yielding invaluable data and insights. Furthermore, innovations in aerospace often translate into improvements in other industries, such as automotive engineering and materials science. Historically, this discipline has driven significant technological leaps, from the first powered flight to the exploration of the solar system.

The core elements of this broad field will be explored further, including the two primary branches focused on flight within the Earth’s atmosphere, and outside of it, delving into specific aspects of design, materials used, and career opportunities available.

Guidance in Aerospace Engineering

Success in this demanding field requires dedication, a strong foundation in mathematics and physics, and a continuous commitment to learning. The following guidance highlights key areas to focus on for aspiring professionals.

Tip 1: Cultivate a Strong Mathematical Foundation: A comprehensive understanding of calculus, differential equations, and linear algebra is essential. These mathematical tools underpin many aerospace engineering principles, from aerodynamics to orbital mechanics. Practice applying these concepts to real-world problems.

Tip 2: Develop Proficiency in Physics: Physics provides the basis for understanding the physical laws governing flight and space travel. Focus on mechanics, thermodynamics, and electromagnetism. A thorough grasp of these principles is vital for analyzing and designing aerospace systems.

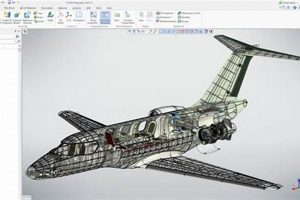

Tip 3: Master Computer-Aided Design (CAD) Software: Proficiency in CAD software is indispensable for designing and modeling aircraft and spacecraft components. Familiarize yourself with industry-standard software packages and practice creating detailed and accurate models.

Tip 4: Gain Practical Experience: Seek internships, research opportunities, or cooperative education programs to gain hands-on experience. Practical experience provides valuable insights into the challenges and rewards of aerospace engineering.

Tip 5: Develop Strong Communication Skills: Effective communication is crucial for collaborating with engineers, scientists, and other stakeholders. Practice writing clear and concise reports, giving presentations, and participating in technical discussions.

Tip 6: Stay Current with Technological Advancements: The aerospace industry is constantly evolving. Remain informed about the latest technologies, materials, and design techniques by reading industry publications, attending conferences, and engaging in continuing education.

Tip 7: Specialization is Key: Within the broad field, focus your studies and career on a specific area like propulsion, aerodynamics, or control systems. Depth of knowledge in one area often leads to greater expertise and career advancement.

By focusing on a strong academic foundation, practical skills, and continuous learning, individuals can significantly increase their chances of success in this dynamic and rewarding field.

These guidelines serve as a practical roadmap for those embarking on a career path within the demanding yet exciting world that involves aircraft and spacecraft. The following sections will expand upon specific applications of these principles.

1. Aerodynamics

Aerodynamics, the study of air in motion and its interaction with solid objects, is a cornerstone of the aerospace engineering field. Its principles dictate the performance characteristics of aircraft and spacecraft. The shape of an aircraft wing, for example, is carefully designed to generate lift, allowing it to overcome gravity. Simultaneously, it must minimize drag, the force that opposes motion through the air. Aerodynamic analysis provides the critical data needed to make these essential design decisions.

The importance of aerodynamics extends beyond the wing. The entire aircraft or spacecraft design, from its fuselage to its control surfaces, is shaped to optimize airflow. Computational Fluid Dynamics (CFD) simulations are commonly employed to model airflow patterns and predict aerodynamic forces. These simulations allow engineers to test and refine designs virtually, reducing the need for expensive and time-consuming wind tunnel experiments. Supersonic aircraft, such as the Concorde, presented unique aerodynamic challenges related to shock wave formation and drag reduction. The Concorde’s delta wing was a direct result of aerodynamic considerations necessary for sustained supersonic flight.

Understanding aerodynamic principles is crucial for aerospace engineers to design efficient, stable, and controllable aircraft and spacecraft. Advanced aerodynamic research is continually pushing the boundaries of what is possible, leading to innovative designs that improve fuel efficiency, reduce noise pollution, and enhance overall performance. The ongoing development of advanced airfoils and flow control technologies further demonstrates the central role aerodynamics plays in the progress of the discipline.

2. Propulsion Systems

Propulsion systems represent a critical facet within aerospace engineering, enabling flight and space travel. These systems generate the necessary thrust to overcome drag and gravity, powering aircraft and spacecraft from takeoff to orbit. Effective propulsion is paramount for achieving mission objectives and overall performance.

- Jet Engines

Jet engines, commonly used in commercial and military aircraft, operate by intaking air, compressing it, mixing it with fuel, igniting the mixture, and expelling the hot exhaust gases to generate thrust. Different types of jet engines, such as turbofans and turbojets, are designed for varying speed regimes and efficiency requirements. The development of high-bypass turbofans has significantly improved fuel efficiency in modern airliners, impacting the economics and environmental footprint of air travel. In the context of aerospace engineering, jet engine design demands expertise in thermodynamics, fluid mechanics, and materials science to optimize performance and reliability.

- Rocket Engines

Rocket engines are essential for spacecraft propulsion, operating on the principle of expelling mass at high velocity. Unlike jet engines, rockets carry their own oxidizer, allowing them to function in the vacuum of space. Rocket engines can utilize liquid or solid propellants, each offering advantages in terms of specific impulse and storage. The development of reusable rocket engines, such as those used by SpaceX, represents a significant advancement in reducing the cost of space access. Aerospace engineers working on rocket propulsion focus on combustion stability, nozzle design, and propellant management to maximize thrust and efficiency.

- Electric Propulsion

Electric propulsion systems offer an alternative to chemical rockets, utilizing electrical energy to accelerate propellant ions. These systems provide significantly higher specific impulse compared to chemical rockets, enabling longer-duration missions and greater payload capacity. Electric propulsion is commonly used for satellite station-keeping and interplanetary travel. Types of electric propulsion include ion thrusters and Hall-effect thrusters. Aerospace engineers working on electric propulsion address challenges related to power generation, ion source design, and system integration.

- Propellers and Turboprops

Propellers and turboprops are used for aircraft operating at lower speeds and altitudes. Propellers generate thrust by creating a pressure difference between the front and back of the rotating blades. Turboprop engines combine a gas turbine engine with a propeller, offering improved fuel efficiency compared to jet engines at lower speeds. These systems are commonly found in regional airliners and cargo aircraft. Aerospace engineering considerations for propellers and turboprops include blade aerodynamics, noise reduction, and structural integrity.

In summary, the design and operation of propulsion systems are central to achieving the goals and the safety within this field. From jet engines powering commercial airliners to rocket engines enabling space exploration, these systems represent a vital area of focus for aerospace engineers. Ongoing advancements in propulsion technology continue to drive innovation and expand the possibilities of flight and space travel.

3. Materials Science

Materials Science plays a fundamental role in aerospace engineering, dictating the performance, safety, and longevity of aircraft and spacecraft. The selection and application of appropriate materials are crucial for withstanding extreme conditions, minimizing weight, and optimizing structural integrity. Understanding material properties is thus indispensable for engineers in this field.

- High-Strength Alloys

Aerospace applications demand alloys capable of withstanding high stresses and temperatures. Aluminum alloys, titanium alloys, and nickel-based superalloys are frequently employed due to their strength-to-weight ratios and resistance to corrosion. For example, the fuselage of many commercial airliners is constructed from aluminum alloys, balancing strength with weight to improve fuel efficiency. The use of high-strength alloys enables aircraft to operate safely under demanding conditions, while minimizing the overall weight of the structure.

- Composite Materials

Composite materials, such as carbon fiber reinforced polymers (CFRP), offer exceptional strength-to-weight ratios and design flexibility. CFRP is extensively used in aircraft wings, fuselages, and control surfaces, allowing for complex aerodynamic shapes and reduced structural weight. The Boeing 787 Dreamliner, for example, incorporates a significant amount of CFRP in its structure, resulting in improved fuel efficiency and reduced maintenance costs. Composite materials also provide resistance to corrosion and fatigue, enhancing the lifespan of aerospace components.

- Thermal Protection Systems

Spacecraft re-entering the Earth’s atmosphere experience extreme temperatures due to aerodynamic heating. Thermal protection systems (TPS) are essential for shielding spacecraft from this intense heat. Materials such as ceramic tiles, ablative materials, and high-temperature alloys are used in TPS to dissipate heat and protect the underlying structure. The Space Shuttle, for example, utilized a TPS composed of ceramic tiles to withstand re-entry temperatures of up to 1,650 degrees Celsius. The selection and design of TPS materials are critical for ensuring the safe return of spacecraft and astronauts.

- Smart Materials

Smart materials, such as shape memory alloys and piezoelectric materials, offer the potential for innovative aerospace applications. Shape memory alloys can change shape in response to temperature variations, enabling adaptive structures and control surfaces. Piezoelectric materials can generate electricity when subjected to mechanical stress, offering opportunities for energy harvesting and structural health monitoring. These materials are being explored for use in morphing aircraft wings, vibration damping systems, and self-sensing structures, leading to improved performance and efficiency.

The selection and application of materials in aerospace engineering require a deep understanding of material properties, manufacturing processes, and structural design principles. Ongoing research and development efforts are focused on creating new materials with enhanced performance characteristics, enabling the design of lighter, stronger, and more efficient aircraft and spacecraft. As technology evolves, the role of materials science will remain central to advancing the boundaries of this dynamic field.

4. Structural Design

Structural design, a core discipline within aerospace engineering, ensures the integrity, safety, and performance of flight vehicles. It involves analyzing and designing the physical structure of aircraft and spacecraft to withstand various loads and environmental conditions encountered during operation. This is essential to ensuring flight safety and mission success.

- Load Analysis

Load analysis is the process of determining the forces and stresses acting on an aerospace structure. This includes aerodynamic loads, inertial loads, and thermal loads. Understanding the magnitude and distribution of these loads is crucial for designing structures that can withstand them without failure. For example, an aircraft wing must be designed to withstand the bending and torsional loads generated during flight, while a spacecraft must be designed to withstand the extreme thermal loads experienced during re-entry. Accurate load analysis relies on advanced computational methods and experimental testing.

- Material Selection and Sizing

Selecting appropriate materials and determining their dimensions are critical aspects of structural design. Materials must be chosen based on their strength, stiffness, weight, and resistance to environmental factors such as corrosion and temperature. Structural sizing involves calculating the required thickness and dimensions of structural components to ensure they can withstand the applied loads with an adequate margin of safety. The use of lightweight materials, such as composites, and optimized structural sizing can significantly improve the performance and fuel efficiency of aircraft.

- Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a powerful computational tool used to simulate the behavior of aerospace structures under load. FEA involves dividing a structure into a large number of small elements and then solving a system of equations to determine the stresses and deformations in each element. FEA allows engineers to identify potential weak points in a design and optimize the structure for maximum strength and minimum weight. FEA is used extensively in the design of aircraft wings, fuselages, and engine components.

- Structural Testing and Validation

Structural testing is performed to validate the design and analysis of aerospace structures. Testing involves subjecting prototype structures to simulated flight loads and environmental conditions to verify that they meet performance requirements. Structural testing can range from small-scale component tests to full-scale airframe tests. Data from structural testing is used to refine FEA models and improve design methodologies. Successful structural testing is essential for ensuring the safety and reliability of aerospace vehicles.

The integration of load analysis, materials considerations, FEA, and validation techniques collectively contributes to robust structural design, crucial for the overall success of aerospace endeavors. Structural design remains a critical area of focus for aerospace engineers, driving advancements in performance, safety, and efficiency in flight and space applications.

5. Control Systems

Control systems are integral to aerospace engineering, governing the stability, maneuverability, and overall performance of aircraft and spacecraft. These systems manage various aspects of flight, from maintaining altitude and heading to executing complex maneuvers and orbital adjustments. The effectiveness of these systems directly impacts the safety and efficiency of aerospace vehicles.

A critical function of control systems is to counteract disturbances and maintain desired flight parameters. In aircraft, autopilot systems use sensors and actuators to automatically adjust control surfaces, such as ailerons and elevators, to compensate for wind gusts and other external factors. Similarly, spacecraft utilize reaction control systems (RCS) or control moment gyros (CMGs) to maintain attitude and execute orbital maneuvers. The Apollo missions, for example, relied heavily on RCS thrusters for precise control during lunar landings and rendezvous. Furthermore, fly-by-wire systems, now common in modern aircraft, employ electronic interfaces and computer control to enhance pilot control and safety by providing stability augmentation and envelope protection.

The design and implementation of control systems in aerospace engineering present numerous challenges, including dealing with nonlinear dynamics, uncertainties in system parameters, and stringent reliability requirements. Advanced control techniques, such as adaptive control and model predictive control, are often employed to address these challenges. In summary, control systems are crucial in managing the stability in flight, demonstrating their indispensable position. Continued advancements in control system technologies will be essential for enabling future innovations in flight and space exploration.

6. Orbital Mechanics

Orbital mechanics, a specialized area within aerospace engineering, governs the motion of spacecraft and other celestial bodies. It applies principles of physics, particularly Newton’s laws of motion and gravitation, to predict and control the trajectories of objects in space. This discipline is fundamental to mission planning, satellite deployment, and interplanetary travel. Without a thorough understanding of orbital mechanics, these activities would be impossible. A direct example is the calculation of transfer orbits, like the Hohmann transfer, which allow spacecraft to efficiently move between different orbits around a central body. Such calculations are essential for missions aiming to reach other planets or establish geostationary orbits for communication satellites.

The successful design and execution of space missions heavily relies on accurately predicting and accounting for various perturbations that affect orbital trajectories. These perturbations include atmospheric drag, the gravitational influence of other celestial bodies, and solar radiation pressure. Aerospace engineers employ sophisticated mathematical models and computer simulations to account for these factors and ensure that spacecraft remain on their intended paths. Failure to accurately model these perturbations can lead to significant deviations from the planned trajectory, potentially jeopardizing the mission. The International Space Station (ISS), for instance, requires periodic orbit adjustments to counteract atmospheric drag and maintain its operational altitude, a task that depends on precise knowledge of orbital mechanics.

In conclusion, orbital mechanics is an indispensable component of aerospace engineering, providing the theoretical foundation and practical tools necessary for navigating the space environment. Its significance extends beyond mission planning to include areas such as satellite navigation, space debris management, and the exploration of distant planets. As space activities continue to expand, the importance of orbital mechanics will only increase, driving further advancements in this crucial discipline.

Frequently Asked Questions Regarding Aerospace Engineering

The following addresses prevalent inquiries concerning the field involving the design, development, and production of aircraft and spacecraft. The information provided aims to clarify common misunderstandings and provide a concise overview of essential aspects.

Question 1: What distinguishes aeronautical engineering from astronautical engineering?

Aeronautical engineering pertains to the design and development of aircraft that operate within Earth’s atmosphere. Astronautical engineering, on the other hand, focuses on spacecraft and related technologies designed for operation in outer space.

Question 2: What educational background is required to pursue a career in this discipline?

A bachelor’s degree in aerospace engineering or a closely related field, such as mechanical engineering, is typically required. Advanced positions may necessitate a master’s degree or doctorate. A strong foundation in mathematics, physics, and computer science is essential.

Question 3: What are some typical career paths for graduates with degrees in the discipline?

Graduates may find employment in various sectors, including aircraft manufacturing, space agencies, defense contractors, and research institutions. Common roles include design engineer, test engineer, research scientist, and project manager.

Question 4: What are the primary skills needed to succeed in this area?

Critical skills include a strong understanding of aerodynamics, propulsion, structural analysis, and control systems. Proficiency in computer-aided design (CAD) software and numerical simulation tools is also essential. Strong analytical and problem-solving abilities are necessary.

Question 5: What are some of the current challenges facing aerospace engineers?

Significant challenges include developing more fuel-efficient aircraft, reducing noise pollution, creating sustainable propulsion systems, and designing spacecraft capable of withstanding long-duration space missions. Managing space debris and ensuring the safety of space travel are also critical concerns.

Question 6: How does the field contribute to broader technological advancements?

Innovations in aerospace engineering often have far-reaching applications in other industries, such as automotive engineering, materials science, and medical technology. Advancements in aerodynamics, propulsion, and materials, driven by aerospace research, frequently find applications in diverse fields.

This section provides key information regarding common questions surrounding this technological field. The subsequent section will present conclusions.

Conclusion

The preceding exploration of aerospace engineering has elucidated the discipline’s multifaceted nature, encompassing areas from aerodynamics and propulsion to materials science and orbital mechanics. These interconnected fields are critical for the design, development, and operation of both aircraft and spacecraft, addressing challenges in atmospheric flight and space exploration.

Aerospace engineering remains a pivotal driver of technological innovation, pushing boundaries in transportation, communication, and scientific discovery. Continued investment in research, development, and education within this field is essential to addressing future global challenges and sustaining advancements in air and space technology.