The convergence of chemical engineering principles with the demands of flight and space exploration yields a specialized field focused on developing materials, processes, and systems optimized for extreme environments. This discipline addresses challenges such as designing lightweight, high-strength composites for aircraft structures, formulating rocket propellants with enhanced performance, and creating life support systems for extended space missions. Examples include the development of heat shields that can withstand extreme temperatures during atmospheric reentry and the design of fuel cells that provide efficient and sustainable power for spacecraft.

The application of chemical engineering expertise to aerospace endeavors offers significant advantages. It enables the creation of lighter, stronger, and more durable components, leading to improved fuel efficiency and increased payload capacity for aircraft and spacecraft. Moreover, the development of advanced propulsion systems and life support technologies is essential for expanding the scope of space exploration and ensuring the safety and well-being of astronauts. Historically, advancements in materials science and chemical processes have been critical to every major milestone in aviation and space travel, from the first powered flight to the ongoing exploration of Mars.

The subsequent sections will delve into specific areas where this interdisciplinary approach is making a significant impact. Topics covered will include the synthesis of novel polymers for aerospace applications, the optimization of combustion processes for rocket engines, and the development of sustainable methods for resource utilization in space.

Guidance for Advancement

The following points offer strategic insights relevant to professionals and researchers in the convergence of chemical engineering and aerospace technologies. Careful consideration of these guidelines can facilitate success in this demanding field.

Tip 1: Prioritize Materials Science Expertise. A comprehensive understanding of polymer chemistry, composite materials, and nanomaterials is essential. This knowledge base is crucial for developing lightweight, high-strength components that meet the stringent performance requirements of aerospace applications. Example: Research into carbon nanotube-reinforced polymers can yield materials with exceptional strength-to-weight ratios.

Tip 2: Emphasize Process Optimization. The ability to design and optimize chemical processes for the production of aerospace-grade materials is highly valuable. This includes process modeling, simulation, and control to ensure consistent product quality and minimize waste. Example: Implementing statistical process control (SPC) in the manufacturing of composite aircraft parts can reduce defects and improve reliability.

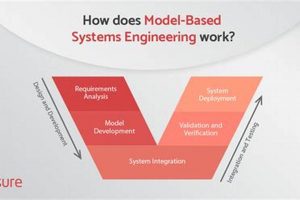

Tip 3: Cultivate Systems Thinking. Aerospace projects are inherently complex and interdisciplinary. Professionals must possess the ability to understand how individual components and processes interact within a larger system. Example: Designing a closed-loop life support system for a spacecraft requires a holistic understanding of air purification, water recycling, and waste management.

Tip 4: Master Thermodynamics and Transport Phenomena. These fundamental principles are essential for designing efficient propulsion systems, heat management systems, and environmental control systems. Example: Accurate modeling of heat transfer in a rocket nozzle is crucial for preventing thermal failure.

Tip 5: Embrace Computational Modeling. Computational fluid dynamics (CFD) and finite element analysis (FEA) are indispensable tools for simulating and optimizing the performance of aerospace components and systems. Example: CFD simulations can be used to predict the aerodynamic forces acting on an aircraft wing.

Tip 6: Maintain Regulatory Awareness. Aerospace is a highly regulated industry. Professionals must be familiar with relevant standards, regulations, and certification processes. Example: Adhering to FAA regulations for aircraft materials and manufacturing processes is essential for ensuring safety and compliance.

Tip 7: Seek Interdisciplinary Collaboration. The most innovative solutions often arise from collaborative efforts between chemical engineers, aerospace engineers, materials scientists, and other experts. Example: Working with electrical engineers to develop advanced sensor technologies for aircraft monitoring.

These guidelines underscore the importance of a robust technical foundation, a systems-level perspective, and a commitment to continuous learning. Adherence to these principles can significantly enhance the prospects for success in this demanding and rewarding field.

The concluding section will offer a summary of the key concepts and insights discussed, followed by a broader perspective on the future of this synergy.

1. Material Synthesis

Material synthesis forms a cornerstone of advancement within the aerospace domain. Its connection is inextricably linked to performance, safety, and mission capability. The ability to create novel materials with specific properties directly affects the design and functionality of aircraft, spacecraft, and related equipment. For example, the development of carbon-fiber reinforced polymers (CFRPs) represented a significant advancement, allowing for lighter yet stronger aircraft structures, leading to improved fuel efficiency and increased payload capacity. Without sophisticated material synthesis techniques, realizing these performance gains would be impossible. Therefore, improved performance in aerospace engineering arises as the result of advances in material synthesis.

The relationship also extends to specialized applications like thermal protection systems for spacecraft during atmospheric reentry. Here, material synthesis focuses on creating materials capable of withstanding extreme temperatures and thermal shock. Examples include ceramic composites and ablative materials specifically engineered to dissipate heat and protect the underlying structure. Further, the development of high-temperature alloys for jet engine turbines depends heavily on precise control of chemical composition and processing, which directly impacts engine efficiency and durability. Similarly, synthesizing high-performance polymers for seals and adhesives in aerospace applications must meet stringent requirements for temperature resistance, chemical inertness, and mechanical strength. The synthesis process must be highly controlled to ensure the final product meets these exact specifications, highlighting its crucial role in maintaining the functionality and reliability of aerospace systems.

In summary, material synthesis provides the foundational building blocks for aerospace innovation. Its impact is evident in every facet of aerospace engineering, from structural components to propulsion systems and thermal protection. Ongoing research focuses on developing even more advanced materials with tailored properties to meet the ever-increasing demands of future aerospace missions. Challenges remain in scaling up production of these advanced materials and reducing costs, but the pursuit of novel materials and their associated synthetic pathways remains a critical endeavor for the continued progress of the field.

2. Propulsion Efficiency

Propulsion efficiency, a critical metric in aerospace engineering, quantifies the effectiveness with which a propulsion system converts energy into thrust. Within the realm of chemical engineering aerospace, optimizing this efficiency involves a multifaceted approach encompassing fuel composition, combustion processes, and nozzle design. The subsequent discussion will explore specific facets contributing to propulsion efficiency.

- Fuel Formulation and Optimization

The chemical composition of rocket propellants significantly influences propulsion efficiency. Chemical engineers formulate fuels to maximize energy density and minimize molecular weight of exhaust gases, thereby increasing specific impulse. Examples include the development of hypergolic propellants, which ignite spontaneously upon mixing, and the ongoing research into advanced solid propellants with enhanced burning rates. The selection of additives and catalysts further refines combustion characteristics to improve overall performance.

- Combustion Chamber Design and Process Control

Efficient combustion within the engine is paramount for maximizing thrust. Chemical engineering principles are applied to design combustion chambers that promote complete and stable combustion of the fuel-oxidizer mixture. Factors such as chamber geometry, injector design, and ignition systems are carefully optimized to minimize energy losses due to incomplete combustion or heat transfer to the chamber walls. Precise control of fuel-oxidizer ratio and chamber pressure is essential for maintaining optimal combustion conditions.

- Nozzle Design and Expansion Ratio

The nozzle plays a crucial role in converting the thermal energy of the exhaust gases into kinetic energy, generating thrust. Chemical engineers collaborate with aerospace engineers to design nozzles with optimal geometry for expanding the exhaust gases to the ambient pressure at the nozzle exit. The expansion ratio, defined as the ratio of the nozzle exit area to the throat area, is carefully selected to maximize thrust while minimizing losses due to over- or underexpansion. Computational fluid dynamics (CFD) simulations are extensively used to optimize nozzle designs.

- Advanced Propulsion Concepts

Beyond conventional chemical rockets, chemical engineering contributes to the development of advanced propulsion concepts. These include ion propulsion, which uses electric fields to accelerate ionized gases, and nuclear thermal propulsion, which uses a nuclear reactor to heat a propellant. Chemical engineers play a role in developing the materials and processes required for these advanced systems, such as high-temperature materials for reactor components and efficient ionization methods.

The interdisciplinary nature of achieving enhanced propulsion efficiency underscores the significance of the chemical engineering aerospace field. By integrating chemical engineering principles into the design and optimization of propulsion systems, it becomes possible to achieve greater thrust, improved fuel economy, and extended mission capabilities for both atmospheric and space-based vehicles.

3. Life Support Systems

Life support systems constitute an indispensable element of long-duration space missions, representing a critical interface between human physiology and the hostile environment of space. Within the context of chemical engineering aerospace, these systems demand innovative solutions for air revitalization, water purification, waste management, and food production.

- Air Revitalization

This facet focuses on removing carbon dioxide and other contaminants from the spacecraft atmosphere while replenishing oxygen. Chemical engineers design and optimize processes such as carbon dioxide adsorption using solid sorbents, the Sabatier reaction to convert carbon dioxide into methane and water, and electrolysis to produce oxygen from water. The International Space Station utilizes such systems. Efficiency and reliability are paramount, as any failure can have life-threatening consequences.

- Water Purification and Recycling

Water is a precious resource in space. Chemical engineering principles are applied to develop systems that purify and recycle water from various sources, including urine, condensate, and wash water. Technologies employed include membrane filtration, distillation, and adsorption. These systems minimize the need to transport water from Earth, reducing mission costs and increasing mission duration. The design considerations include minimizing energy consumption and ensuring the purity of the recycled water meets stringent health standards.

- Waste Management

Efficient waste management is crucial for maintaining a hygienic environment within a spacecraft and minimizing the risk of microbial contamination. Chemical engineers develop processes for treating and disposing of solid and liquid waste, including incineration, composting, and chemical stabilization. Volume reduction and resource recovery are key objectives. For example, research is underway on systems that can convert waste into useful products, such as methane for fuel or nutrients for plant growth.

- Food Production

For long-duration missions, in-situ food production becomes increasingly important. Chemical engineering contributes to the design of controlled-environment agriculture systems that can grow crops in space. This involves optimizing nutrient delivery, lighting, and environmental conditions to maximize plant growth and minimize resource consumption. Hydroponics and aeroponics are commonly used techniques. The integration of food production with waste management systems, where waste is converted into fertilizer, represents a closed-loop approach to life support.

The integrated design of life support systems requires a holistic approach, considering the interactions between individual components and the overall system performance. Chemical engineering aerospace plays a pivotal role in developing these technologies, ensuring the safety and sustainability of human space exploration. Future advances will focus on creating more compact, efficient, and reliable systems that can operate autonomously for extended periods with minimal maintenance. These advanced, self-sustaining systems will be required for long-term missions to Mars and beyond, making this domain indispensable to further expansion of human presence in space.

4. Thermal Management

Thermal management is an indispensable component of chemical engineering aerospace, addressing the critical need to regulate temperature within spacecraft, aircraft, and associated systems. Extreme temperature fluctuations, generated by solar radiation, aerodynamic heating, and internal heat dissipation from electronic equipment, can compromise performance and structural integrity. Effective thermal management strategies are essential for ensuring operational reliability and crew safety. The correlation between chemical engineering and thermal management stems from the design, development, and implementation of materials and processes capable of withstanding and mitigating these thermal challenges. For instance, the Space Shuttle relied on a thermal protection system (TPS) comprised of ceramic tiles and reinforced carbon-carbon composites to shield against reentry temperatures exceeding 1,600 degrees Celsius. Chemical engineers played a central role in developing and optimizing the composition and manufacturing processes of these materials, ensuring their effectiveness in dissipating heat and preventing structural damage.

Further practical application exists in the design of cooling systems for high-power electronic components within satellites. Chemical engineers contribute to the development of heat pipes, pumped fluid loops, and phase-change materials used to transfer heat away from sensitive electronics and maintain optimal operating temperatures. These systems often incorporate specialized fluids with high thermal conductivity and heat capacity, formulated by chemical engineers to maximize heat transfer efficiency. In aircraft, thermal management solutions are integral to maintaining the integrity of engine components, controlling cabin temperature, and preventing ice formation on critical surfaces. Anti-icing fluids, developed by chemical engineers, prevent ice accumulation on wings and control surfaces, enhancing safety during flight in icing conditions. The development of high-temperature alloys for jet engine turbines exemplifies the intersection of materials science and thermal management, enabling engines to operate at higher temperatures and achieve greater efficiency.

In summary, thermal management represents a critical area of overlap between chemical engineering and aerospace. The design and implementation of effective thermal control strategies necessitate a deep understanding of heat transfer phenomena, materials science, and chemical processes. Continued advancements in this field are crucial for enabling future aerospace missions, improving the performance and reliability of aircraft, and ensuring the safety of space travelers. Challenges remain in developing lightweight, high-performance thermal management solutions that can operate reliably in extreme environments, driving ongoing research and innovation in this critical domain.

5. Corrosion Resistance

Corrosion resistance constitutes a critical design parameter within chemical engineering aerospace, directly impacting the longevity, safety, and performance of aerospace vehicles and infrastructure. The operational environments of aircraft and spacecraft expose materials to a complex interplay of factors, including extreme temperatures, high stresses, ultraviolet radiation, atomic oxygen (in low Earth orbit), and corrosive substances like de-icing fluids and salt spray. The presence of these elements accelerates degradation processes, potentially leading to structural failure and operational impairment. The design, material selection, and manufacturing processes are therefore strategically crafted to mitigate corrosion effects. For example, aircraft fuselages are frequently constructed from aluminum alloys treated with conversion coatings and organic paints to provide a barrier against moisture and corrosive agents. Similarly, critical components within rocket engines and spacecraft propulsion systems are often fabricated from stainless steel or nickel-based alloys, possessing inherent resistance to high-temperature oxidation and chemical attack from propellants.

Furthermore, the understanding and control of corrosion mechanisms are essential for predictive maintenance and life-cycle management of aerospace assets. Non-destructive evaluation (NDE) techniques, such as ultrasonic testing and eddy current inspection, are employed to detect early signs of corrosion before they compromise structural integrity. Chemical engineers play a key role in developing and refining these NDE methods, as well as in formulating corrosion inhibitors and protective coatings that can be applied during maintenance procedures to extend the service life of aerospace components. The selection of appropriate materials and coatings is guided by a thorough understanding of electrochemical principles and corrosion kinetics, as well as by considerations of weight, cost, and environmental impact. An example is the use of chromate conversion coatings on aluminum, while effective, are now being replaced with more environmentally friendly alternatives due to chromium’s toxicity. These alternatives must provide comparable corrosion protection while adhering to stricter environmental regulations.

In conclusion, corrosion resistance is not merely a desirable attribute but an essential requirement in chemical engineering aerospace. The proactive management of corrosion through careful material selection, protective coatings, and robust inspection protocols is paramount for ensuring the safe and reliable operation of aircraft, spacecraft, and related infrastructure. Continued research and development efforts are focused on creating novel corrosion-resistant materials, developing advanced inspection techniques, and formulating environmentally sustainable corrosion mitigation strategies. These efforts are essential for pushing the boundaries of aerospace exploration and ensuring the long-term viability of aerospace assets.

6. Resource Utilization

The concept of resource utilization, particularly in the context of chemical engineering aerospace, addresses the imperative to maximize the efficiency and sustainability of aerospace operations. This encompasses the recovery, processing, and application of materials and energy sources in both terrestrial and extraterrestrial environments, with a focus on minimizing waste and reducing dependence on Earth-based resources.

- In-Situ Resource Utilization (ISRU)

ISRU constitutes a central tenet of resource utilization in space exploration. It involves leveraging resources available on other celestial bodies, such as the Moon or Mars, to produce essential consumables like water, oxygen, propellant, and construction materials. Chemical engineering plays a critical role in developing the processes and technologies required for ISRU, including extraction methods, chemical reactors for synthesizing propellants, and techniques for purifying water and extracting valuable minerals. A prime example is the proposed extraction of water ice from lunar polar regions, followed by electrolysis to produce hydrogen and oxygen for rocket propellant. This capability would dramatically reduce the cost and complexity of long-duration missions, enabling sustainable exploration and eventual colonization.

- Closed-Loop Life Support Systems

As previously discussed, closed-loop life support systems represent a crucial aspect of resource utilization within spacecraft. These systems aim to recycle and regenerate essential resources such as air and water, minimizing the need for resupply from Earth. Chemical engineering contributes to the development of technologies for air revitalization, water purification, and waste processing, enabling astronauts to survive and thrive in confined environments for extended periods. Advanced systems may even incorporate the cultivation of plants to provide food and oxygen, creating a self-sustaining ecosystem within the spacecraft. This reduces the mass and cost of consumables required for extended missions.

- Recycling and Waste Management in Aerospace Manufacturing

Resource utilization extends beyond space operations to encompass sustainable practices within the aerospace manufacturing industry. Chemical engineering principles are applied to develop processes for recycling and reusing materials used in aircraft and spacecraft construction, such as aluminum, titanium, and composite materials. Effective waste management strategies are also essential for minimizing the environmental impact of aerospace manufacturing, including the treatment and disposal of hazardous chemicals and the recovery of valuable metals from electronic waste. This minimizes the consumption of virgin resources and reduces pollution.

- Advanced Materials and Lightweighting Strategies

The development of advanced materials with enhanced strength-to-weight ratios is a key aspect of resource utilization in aerospace engineering. Lighter aircraft and spacecraft require less fuel to operate, reducing greenhouse gas emissions and minimizing the consumption of fossil fuels. Chemical engineering contributes to the synthesis of novel polymers, composites, and nanomaterials that enable lightweighting strategies without compromising structural integrity or performance. These materials often incorporate recycled or bio-based components, further reducing their environmental footprint and dependency on scarce resources.

These interrelated facets highlight the vital role of chemical engineering aerospace in promoting sustainable practices and enabling long-term space exploration. By developing innovative technologies for resource extraction, recycling, and efficient material usage, this field contributes to the creation of a more environmentally responsible and economically viable aerospace sector. Future progress will likely focus on developing fully integrated systems that can operate autonomously and adapt to changing conditions, further enhancing the efficiency and resilience of aerospace operations.

7. Process Optimization

Process optimization, a fundamental tenet of chemical engineering, holds significant importance within the context of aerospace applications. The rigorous demands of aerospace require materials and systems engineered with extreme precision and reliability. Consequently, the optimization of chemical processes involved in their creation is not merely beneficial, but essential for ensuring safety, efficiency, and performance. This involves a systematic approach to identify and refine process parameters to achieve desired outcomes, such as maximizing yield, minimizing waste, reducing energy consumption, and enhancing product quality. This optimization is directly associated with the success of a variety of aerospace endeavors.A primary example lies in the manufacture of composite materials used extensively in modern aircraft. These composites, offering high strength-to-weight ratios, are created through complex chemical processes involving resin impregnation and curing. Optimizing these processes, specifically parameters like temperature, pressure, and curing time, is vital for achieving the desired material properties and minimizing defects. Deviations from optimal conditions can lead to structural weaknesses, compromising the aircraft’s integrity. Similarly, rocket propellant production relies on carefully controlled chemical reactions to synthesize high-energy compounds. Process optimization in this domain focuses on maximizing propellant yield, ensuring consistent composition, and minimizing the formation of impurities that could degrade performance or stability.Furthermore, life support systems for space missions depend on efficient chemical processes for air revitalization, water purification, and waste management. Optimizing these processes is crucial for minimizing resource consumption, ensuring the health and safety of astronauts, and enabling long-duration space travel. Process optimization also contributes to the development of advanced propulsion systems, such as ion thrusters, where precise control of ionization and acceleration processes is essential for maximizing thrust and minimizing energy consumption.The understanding of process optimization techniques therefore empowers chemical engineers working in the aerospace sector to address complex challenges and develop innovative solutions. This might involve the application of statistical process control (SPC) to monitor and control manufacturing processes, the use of computational modeling to simulate and optimize chemical reactions, or the implementation of advanced control strategies to maintain stable operation under varying conditions.

Frequently Asked Questions

This section addresses common inquiries regarding the intersection of chemical engineering and aerospace, providing clear and concise answers to enhance understanding of this specialized field.

Question 1: What fundamental skills are required to succeed in chemical engineering aerospace?

A strong foundation in chemical engineering principles, including thermodynamics, transport phenomena, reaction kinetics, and materials science, is essential. Additionally, familiarity with aerospace engineering concepts, such as aerodynamics, propulsion, and structural analysis, is highly beneficial. Proficiency in computational modeling and simulation tools is also crucial.

Question 2: How does chemical engineering contribute to the development of advanced aerospace materials?

Chemical engineers play a key role in synthesizing and processing materials with enhanced properties, such as high strength-to-weight ratios, temperature resistance, and corrosion resistance. This includes the development of novel polymers, composites, ceramics, and metals tailored for specific aerospace applications, ranging from aircraft structures to rocket engine components.

Question 3: What role does chemical engineering play in optimizing rocket propulsion systems?

Chemical engineers contribute to the formulation and production of rocket propellants with high energy density and optimal combustion characteristics. They also design and optimize combustion chambers and nozzles to maximize thrust and minimize fuel consumption. Additionally, they explore advanced propulsion concepts, such as electric propulsion and hybrid rocket engines.

Question 4: How are chemical engineering principles applied in designing life support systems for space missions?

Chemical engineers develop and optimize processes for air revitalization, water purification, waste management, and food production within spacecraft. These systems aim to recycle and regenerate essential resources, minimizing the need for resupply from Earth and enabling long-duration space missions. Examples include carbon dioxide removal technologies and water recovery systems.

Question 5: What are the major challenges facing chemical engineers working in the aerospace industry?

Key challenges include developing materials that can withstand extreme temperatures and pressures, designing efficient and reliable propulsion systems, creating closed-loop life support systems for long-duration space travel, and minimizing the environmental impact of aerospace activities. Meeting stringent safety requirements and regulatory standards is also a constant concern.

Question 6: What are the career opportunities available in chemical engineering aerospace?

Career paths include roles in research and development, materials engineering, propulsion systems design, life support system engineering, and process optimization within aerospace companies, government agencies, and research institutions. Specific job titles might include materials scientist, propulsion engineer, or environmental control systems engineer.

In summary, a comprehension of the fundamental principles, an awareness of ongoing challenges, and an understanding of the available opportunities are essential to navigate the intersection of chemical engineering and aerospace successfully.

The following section will delve into emerging trends shaping the future of this dynamic field.

Conclusion

The preceding discussion has illuminated the multifaceted role of chemical engineering aerospace in advancing the capabilities of flight and space exploration. From the synthesis of high-performance materials to the optimization of propulsion systems and the development of sustainable life support technologies, this interdisciplinary field provides essential solutions to the challenges inherent in operating within extreme environments. The principles of chemical engineering, when applied to aerospace endeavors, enable the creation of safer, more efficient, and more reliable systems.

Continued innovation within chemical engineering aerospace is paramount for realizing ambitious future goals, including long-duration space missions, the establishment of extraterrestrial settlements, and the development of more sustainable aviation practices. Sustained investment in research, development, and education within this critical field will unlock new possibilities and drive progress in aerospace technology for decades to come.