The discipline concerned with the design, development, testing, and production of aircraft and spacecraft represents a critical sector of modern technological advancement. It encompasses a wide range of specializations, including aerodynamics, propulsion systems, materials science, and structural analysis. The application of scientific and mathematical principles is fundamental to creating efficient and reliable vehicles that operate within and beyond Earth’s atmosphere.

This field is vital for national security, global transportation, and space exploration. Innovation in this area drives economic growth and leads to advancements in other sectors, such as telecommunications and weather forecasting. Its historical roots can be traced back to early experiments in flight, evolving into the complex and sophisticated systems seen today, constantly pushing the boundaries of what is achievable.

The following discussion will delve into the various aspects of this field, exploring key challenges, emerging technologies, and future trends shaping the evolution of air and space vehicles. This exploration will highlight specific design considerations, material advancements, and the integration of novel technologies influencing the future of flight.

Essential Considerations in Aircraft and Spacecraft Development

The successful creation of air and space vehicles requires a rigorous adherence to established principles and a commitment to continuous improvement. The following recommendations offer guidance for professionals within this complex domain.

Tip 1: Prioritize System Integration: Effective coordination between subsystems is paramount. Thoroughly evaluate the interaction of propulsion, avionics, and structural components to avoid unforeseen complications during operation.

Tip 2: Emphasize Material Selection: The choice of materials directly impacts performance and safety. Employ rigorous testing protocols to validate the suitability of novel alloys, composites, and other advanced materials in extreme environments.

Tip 3: Implement Robust Testing Procedures: Comprehensive testing is crucial to identifying potential weaknesses. Utilize wind tunnels, flight simulators, and structural test rigs to subject designs to realistic operational conditions.

Tip 4: Adhere to Stringent Safety Standards: Safety must be a primary consideration throughout the entire development lifecycle. Implement redundant systems and fail-safe mechanisms to mitigate the risk of catastrophic failures.

Tip 5: Optimize Aerodynamic Efficiency: Minimizing drag and maximizing lift are essential for fuel efficiency and performance. Conduct computational fluid dynamics (CFD) analyses to refine airfoil designs and optimize vehicle shapes.

Tip 6: Embrace Automation and Robotics: Employing automated manufacturing processes and robotic assembly techniques can improve precision, reduce costs, and enhance overall production efficiency.

Tip 7: Foster Interdisciplinary Collaboration: Promote effective communication and knowledge sharing between engineering disciplines. Encouraging cross-functional teams facilitates innovative solutions and addresses complex challenges more effectively.

These guidelines emphasize the importance of a holistic approach to the design, development, and production of aircraft and spacecraft. Adhering to these principles enhances the reliability, safety, and performance of these critical vehicles.

The subsequent sections will explore specific technological advancements and future trends influencing the trajectory of this ever-evolving field.

1. Aerodynamics Optimization

Aerodynamics optimization represents a cornerstone of modern aerospace engineering, directly influencing the performance, efficiency, and safety of air and space vehicles. Achieving superior aerodynamic characteristics is essential for minimizing drag, maximizing lift, and ensuring stable flight across a range of operating conditions. This process involves sophisticated computational modeling, wind tunnel testing, and iterative design refinement.

- Drag Reduction

Minimizing aerodynamic drag directly translates to increased fuel efficiency and reduced operating costs for aircraft. For spacecraft, drag reduction during atmospheric entry or orbital maneuvers is critical for precise trajectory control and minimizing thermal loads. Techniques employed include streamlining the vehicle shape, implementing laminar flow control technologies, and optimizing surface finish.

- Lift Augmentation

Generating sufficient lift is fundamental for sustained flight. Aerodynamic optimization focuses on maximizing lift-to-drag ratio through airfoil design, high-lift devices such as flaps and slats, and boundary layer control. This is particularly crucial for aircraft operating at low speeds or high altitudes, and for spacecraft during atmospheric flight.

- Stability and Control

Ensuring stable and controllable flight characteristics is paramount for safety. Aerodynamic optimization involves careful consideration of vehicle geometry, control surface design, and the interaction between aerodynamic forces and flight control systems. This includes mitigating adverse yaw, preventing stall, and maintaining stability across a range of flight regimes.

- Computational Fluid Dynamics (CFD) Integration

CFD plays a vital role in aerodynamics optimization by providing detailed simulations of airflow around air and space vehicles. These simulations allow engineers to predict aerodynamic forces, identify areas of flow separation, and evaluate the effectiveness of design modifications. CFD results are often validated through wind tunnel testing, providing a powerful tool for iterative design refinement.

These interconnected facets of aerodynamics optimization are indispensable for advancements in aerospace engineering. Efficient and stable designs, resulting from this optimization, are crucial for everything from commercial aviation and military aircraft to space exploration and satellite technology, demonstrating its foundational importance in achieving future milestones in air and space travel.

2. Propulsion Systems

Propulsion systems are fundamental to the field, providing the necessary thrust to overcome gravity and atmospheric drag, enabling aircraft and spacecraft to operate within and beyond Earth’s atmosphere. The efficacy and design of propulsion systems directly influence the range, speed, payload capacity, and overall mission capabilities of aerospace vehicles. The selection of a specific propulsion system is dictated by factors such as the operational environment, performance requirements, and economic considerations. For example, commercial airliners typically employ turbofan engines optimized for fuel efficiency at subsonic speeds, whereas military aircraft may utilize turbofan or turbojet engines with afterburners to achieve supersonic flight. Spacecraft, on the other hand, require rocket engines, often employing chemical propellants, for orbital maneuvers and deep-space missions.

The development and integration of propulsion systems within the aerospace context necessitates a multidisciplinary approach, encompassing thermodynamics, fluid mechanics, combustion, materials science, and control systems. Advancements in propulsion technology, such as high-bypass-ratio turbofans, pulse detonation engines, and electric propulsion systems, have consistently expanded the boundaries of aerospace capabilities. The Boeing 787 Dreamliner, for example, incorporates advanced turbofan engines that contribute significantly to its improved fuel efficiency and reduced emissions. Similarly, ion propulsion systems, though offering lower thrust compared to chemical rockets, enable extended-duration missions for deep-space probes due to their high specific impulse. The design and implementation of these systems involves intricate engineering trade-offs and rigorous testing to ensure reliability and performance across the operational envelope.

In conclusion, propulsion systems are an indispensable element of aerospace engineering. The ongoing research and development efforts aimed at enhancing propulsion system efficiency, thrust-to-weight ratio, and environmental compatibility are crucial for addressing the evolving demands of air transportation, space exploration, and national security. Future advancements, such as hypersonic propulsion and advanced rocket engine designs, hold the potential to revolutionize air and space travel, enabling faster, more efficient, and more sustainable aerospace operations. The understanding of propulsion systems is therefore not merely a component of the field, but a prerequisite for its continued progress.

3. Materials Science

The intersection of materials science and aerospace engineering is a critical determinant of performance, safety, and longevity in aircraft and spacecraft design. The selection and application of materials within this domain directly impact structural integrity, weight, resistance to extreme environments, and overall vehicle efficiency. Advancements in aerospace capabilities are often predicated on breakthroughs in materials science, enabling the development of components that withstand the stresses of high-speed flight, exposure to vacuum and radiation in space, and the corrosive effects of atmospheric conditions. For instance, the development of high-temperature nickel-based superalloys facilitated the creation of more efficient jet engines capable of operating at higher turbine inlet temperatures, directly translating to improved fuel economy and thrust.

The cause-and-effect relationship between materials science and aerospace engineering is evident in numerous applications. The use of lightweight composite materials, such as carbon fiber reinforced polymers (CFRP), in aircraft structures reduces weight, thereby improving fuel efficiency and payload capacity. However, the implementation of CFRP requires careful consideration of factors such as impact resistance, thermal expansion, and susceptibility to moisture absorption. Similarly, the development of thermal protection systems (TPS) for spacecraft re-entering Earth’s atmosphere relies on advanced ceramic materials capable of withstanding extremely high temperatures generated by aerodynamic heating. The Space Shuttle, for example, utilized a TPS comprised of thousands of individual ceramic tiles to protect the vehicle from the intense heat of re-entry. The materials are not simply components; they dictate the operational parameters of the vehicles.

In summary, the understanding and application of materials science principles are indispensable for successful aerospace engineering endeavors. The ongoing pursuit of novel materials with enhanced properties, coupled with advanced manufacturing techniques, is essential for pushing the boundaries of air and space travel. Challenges remain in addressing issues such as cost, scalability, and long-term durability, but overcoming these hurdles will unlock new possibilities for innovative aerospace designs and mission capabilities. The synergy between materials science and aerospace engineering represents a continuous cycle of innovation, driving progress in both fields and shaping the future of flight.

4. Structural Integrity

Structural integrity is a paramount consideration within the field of aerospace engineering, directly influencing the safety, reliability, and operational lifespan of aircraft and spacecraft. It encompasses the ability of an aerospace vehicle to withstand applied loads, environmental stresses, and material degradation without experiencing catastrophic failure. Maintaining structural integrity requires a comprehensive approach, integrating rigorous design principles, advanced materials selection, meticulous manufacturing processes, and thorough inspection and maintenance procedures. Any compromise in structural integrity can have severe consequences, potentially leading to loss of life, mission failure, and significant financial losses. The Comet airliner disasters of the 1950s, attributed to metal fatigue around the square windows, serve as a stark reminder of the critical importance of structural integrity in aircraft design and the severe implications of neglecting this aspect.

The design of aerospace structures involves detailed stress analysis, fatigue analysis, and fracture mechanics assessments to ensure that components can withstand the expected operational loads throughout their service life. Finite element analysis (FEA) is extensively used to simulate stress distributions within complex structures, allowing engineers to identify areas of high stress concentration and optimize designs to minimize the risk of failure. Furthermore, non-destructive testing (NDT) methods, such as ultrasonic testing, radiographic inspection, and eddy current testing, are employed to detect internal flaws and cracks in materials and components without causing damage. The widespread use of composite materials in modern aircraft structures, such as the Boeing 787 Dreamliner and the Airbus A350 XWB, necessitates sophisticated damage tolerance analysis to ensure that structures can withstand damage from impact events or manufacturing defects without compromising overall structural integrity.

In conclusion, structural integrity is an indispensable element of aerospace engineering. The ability to design, manufacture, and maintain aerospace vehicles that can reliably withstand the stresses of flight and the harsh environments of space is essential for ensuring safety, mission success, and long-term operational viability. Continued research and development in areas such as advanced materials, structural health monitoring, and predictive maintenance are crucial for enhancing structural integrity and pushing the boundaries of aerospace capabilities. The pursuit of enhanced structural integrity remains a constant driving force within the field, shaping the future of air and space travel.

5. Avionics Integration

Within the broader scope of aerospace engineering, avionics integration represents the critical process of combining electronic systems to control, monitor, and manage aircraft and spacecraft functions. The seamless operation of these integrated systems is essential for safe, efficient, and reliable flight, both within and beyond Earth’s atmosphere. Avionics are no longer isolated components, but rather interconnected networks that dictate a vehicle’s capabilities.

- Flight Control Systems

These systems manage aircraft or spacecraft trajectory, attitude, and stability. Modern fly-by-wire systems, replacing mechanical linkages with electronic signals, enhance responsiveness and allow for advanced control laws. The integration of sensors, actuators, and computers enables precise control, even in turbulent conditions or during automated maneuvers. Commercial airliners and military aircraft rely heavily on these integrated flight control systems.

- Navigation Systems

Accurate navigation is crucial for determining position, velocity, and heading. Avionics integration combines GPS, inertial navigation systems (INS), and other sensors to provide precise location data. This data is then used for route planning, guidance, and automated landing systems. Spacecraft navigation, relying on star trackers and deep-space network communication, demands highly precise and robust integration.

- Communication Systems

Maintaining reliable communication links is vital for coordinating air traffic, transmitting data, and relaying critical information. Avionics integration incorporates various communication systems, including VHF radios, satellite communication links, and data links. Secure and encrypted communication is particularly important for military aircraft and unmanned aerial vehicles (UAVs).

- Sensor Systems

A variety of sensors provide crucial data about the aircraft or spacecraft’s environment and performance. These include radar systems, weather sensors, engine monitoring systems, and structural health monitoring systems. Integrating these sensors allows pilots or ground control to make informed decisions and detect potential problems early. Military reconnaissance aircraft and weather satellites rely extensively on sophisticated sensor integration.

These facets of avionics integration exemplify the complexity and importance of electronics within the broader discipline of aerospace engineering. The development and seamless operation of these integrated systems directly determine the capabilities and safety of modern air and space vehicles. Continued advancements in microelectronics, software engineering, and data processing will further enhance the capabilities of avionics systems, driving innovation and expanding the possibilities within the field.

Frequently Asked Questions Regarding the Discipline

This section addresses common inquiries concerning the principles, scope, and career pathways associated with this multifaceted engineering domain. It is intended to provide clear and concise answers to prevalent questions.

Question 1: What are the fundamental areas of specialization within this engineering discipline?

The field encompasses a broad range of specializations, including aerodynamics, propulsion, structures, materials science, avionics, and control systems. Each area focuses on specific aspects of aircraft and spacecraft design, development, and operation.

Question 2: What educational qualifications are typically required to pursue a career in this field?

A bachelor’s degree in aerospace engineering or a closely related field, such as mechanical or electrical engineering, is generally the minimum requirement. Advanced degrees, such as master’s or doctoral degrees, may be necessary for research-oriented positions or specialized roles.

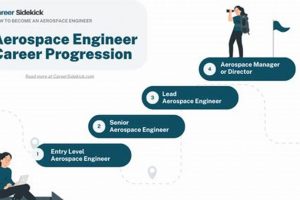

Question 3: What are some common career paths for graduates in this discipline?

Graduates can pursue careers in a variety of sectors, including aerospace manufacturing, government research agencies, defense contractors, and airlines. Potential roles include design engineer, research scientist, test engineer, and project manager.

Question 4: What are the key challenges currently facing the aerospace industry?

Significant challenges include developing more fuel-efficient aircraft, reducing aircraft noise and emissions, improving air traffic management systems, and enabling safe and affordable space travel.

Question 5: How does materials science contribute to advancements in aerospace engineering?

Materials science plays a critical role in developing lightweight, high-strength materials that can withstand extreme temperatures and pressures. These materials are essential for improving aircraft performance, reducing weight, and enhancing structural integrity.

Question 6: What is the role of avionics in modern aircraft and spacecraft?

Avionics systems are responsible for controlling, monitoring, and managing various functions, including flight control, navigation, communication, and sensor data. They are integral to ensuring safe and efficient operation of modern aircraft and spacecraft.

The above responses aim to clarify some of the frequently asked questions related to this field. A thorough understanding of these topics is crucial for navigating the complexities of this dynamic and demanding engineering domain.

The subsequent section will explore emerging trends and future directions shaping the trajectory of aerospace technology and innovation.

Conclusion

This exploration has traversed the multifaceted landscape of engineering aerospace, emphasizing its fundamental principles, critical areas of specialization, and the inherent challenges that define the field. From aerodynamics optimization and propulsion systems to materials science, structural integrity, and avionics integration, each element contributes to the advancement and success of air and space vehicles. The continued pursuit of innovation in these domains remains paramount.

The future trajectory of engineering aerospace hinges on addressing current limitations and embracing emerging technologies. Sustained dedication to research, development, and rigorous application of engineering principles is essential to unlock the next generation of air and space capabilities. The ongoing commitment to safety, efficiency, and sustainability will shape the future of flight and space exploration for decades to come.