Opportunities within KF Aerospace encompass a range of positions, from aircraft maintenance engineers and avionics technicians to logistics specialists and administrative roles. These positions are found across the company’s various locations and divisions, supporting both civilian and military aviation activities. As an example, one might find advertised roles for licensed aircraft maintenance engineers certified to work on specific aircraft types, or openings for project managers overseeing large-scale maintenance contracts.

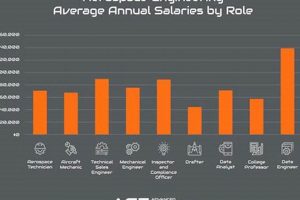

Securing employment with this organization offers access to a stable career path within the growing aerospace sector. Benefits often include competitive salaries, comprehensive health insurance, and opportunities for professional development and advancement. The historical context of the company reveals a long-standing commitment to the aviation industry, contributing to the overall growth and maintenance of vital aerospace infrastructure.

The subsequent sections will delve into specific career paths available, the required qualifications and training, and the overall impact of working within this sector of the aviation industry.

This section offers guidance for individuals seeking positions within KF Aerospace. The following tips are designed to improve the likelihood of successful application and integration into the company.

Tip 1: Research Company Values. Familiarity with KF Aerospace’s mission, values, and operational areas is crucial. Understanding the company’s commitment to safety, quality, and innovation demonstrates genuine interest and alignment during the application process. For example, referencing specific company initiatives during an interview can highlight a proactive approach.

Tip 2: Tailor Application Materials. Generic resumes and cover letters are often overlooked. Customizing these documents to reflect the specific requirements outlined in the job description is essential. Emphasize relevant skills and experience, directly addressing how they contribute to the position’s objectives. A maintenance engineer applying for a specific aircraft type position should highlight their experience with that model.

Tip 3: Highlight Relevant Certifications. The aerospace industry requires specialized certifications and licenses. Ensure that all relevant credentials, such as Transport Canada or EASA certifications, are prominently displayed on the resume. Verification of these credentials should be readily available upon request.

Tip 4: Network Strategically. Attending industry events and connecting with KF Aerospace employees on professional networking platforms can provide valuable insights and potential opportunities. Direct engagement with company personnel can reveal unadvertised openings and provide firsthand knowledge of the work environment.

Tip 5: Prepare for Technical Assessments. Many positions require technical proficiency testing. Review fundamental aerospace principles, relevant regulations, and specific aircraft systems related to the applied position. Thorough preparation demonstrates competence and commitment to the field.

Tip 6: Demonstrate Problem-Solving Abilities. Aerospace roles often involve complex challenges. Articulating past experiences where problem-solving skills were utilized to overcome obstacles is vital. Provide specific examples outlining the situation, the actions taken, and the resulting outcome.

Adhering to these recommendations can significantly enhance an individual’s prospect of securing a position within KF Aerospace. Emphasis on preparation, customization, and industry knowledge provides a distinct advantage in the competitive job market.

The subsequent section will address the long-term career progression opportunities within KF Aerospace and the benefits of contributing to this dynamic sector.

1. Aircraft Maintenance

Aircraft maintenance constitutes a significant portion of operational activities and therefore, a notable segment of opportunities at KF Aerospace. Effective maintenance is a direct cause of continued airworthiness and operational efficiency. KF Aerospace’s commitment to aircraft maintenance creates demand for skilled technicians, engineers, and support personnel. For instance, a contract to maintain a fleet of aircraft necessitates hiring licensed aircraft maintenance engineers, avionics technicians, and quality assurance inspectors. The absence of robust maintenance capabilities would directly impede the ability to fulfill contractual obligations, affecting KF Aerospace’s reputation and financial stability.

The practical significance lies in the direct impact on flight safety and regulatory compliance. The organization adheres to stringent maintenance schedules and protocols mandated by aviation authorities. Personnel involved in aircraft maintenance roles are responsible for performing inspections, repairs, and overhauls in accordance with these regulations. An example of this is the detailed inspection of engine components, followed by precise reassembly and testing, ensuring optimal performance and minimizing the risk of in-flight failures. This meticulous approach emphasizes KF Aerospace’s dedication to upholding the highest standards of safety.

In conclusion, aircraft maintenance is not merely a component of KF Aerospace’s job functions but a fundamental pillar supporting its core operations. Challenges arise from the evolving complexity of aircraft systems and the need for continuous training and certification. Understanding the critical role of aircraft maintenance within KF Aerospace provides valuable insight for prospective employees, emphasizing the importance of technical proficiency, adherence to regulations, and a commitment to safety.

2. Avionics Expertise

Avionics expertise forms a critical component of numerous KF Aerospace job functions. The effective operation and maintenance of modern aircraft rely heavily on sophisticated electronic systems, including navigation, communication, flight control, and surveillance equipment. Therefore, KF Aerospace’s ability to provide comprehensive aerospace services is directly dependent on the availability of highly skilled avionics technicians, engineers, and specialists. As an example, a large-scale aircraft maintenance contract necessitates personnel capable of diagnosing and rectifying complex avionics issues, upgrading existing systems, and ensuring compliance with aviation regulations. The absence of qualified avionics personnel would directly impede the ability to fulfill contractual obligations.

The practical significance of avionics expertise within KF Aerospace is evident in its impact on flight safety, operational efficiency, and regulatory compliance. Avionics technicians are responsible for troubleshooting and repairing malfunctions, conducting routine inspections, and installing new avionics equipment. Examples range from diagnosing intermittent radar system failures to upgrading flight management systems to meet evolving air traffic control standards. The ramifications of inadequate avionics maintenance can range from flight delays to safety compromises. As a real-world example, consider that a malfunctioning navigation system can create hazardous conditions for aircraft, resulting in potential safety risks during takeoff, landing, and in-flight maneuvers.

In summary, avionics expertise is not merely a supporting function within KF Aerospace but rather a central element that underpins the organization’s operational capabilities and commitment to airworthiness. Challenges arise from the ever-increasing complexity of avionics systems and the demand for ongoing training and certification to keep pace with technological advancements. Understanding the vital role of avionics expertise within KF Aerospace provides insight for prospective employees, emphasizing the importance of technical proficiency, problem-solving skills, and a dedication to maintaining the highest standards of aviation safety.

3. Logistics Coordination

Logistics coordination within KF Aerospace is a critical function encompassing the management and flow of resources, materials, and information necessary to support its aviation maintenance, repair, and overhaul (MRO) operations. Its importance is directly linked to the efficient execution of contracts, adherence to timelines, and overall operational efficacy, significantly impacting various KF Aerospace job roles.

- Supply Chain Management

Effective supply chain management ensures the timely procurement of aircraft parts, components, and materials required for maintenance activities. This involves sourcing materials from approved vendors, negotiating contracts, and managing inventory levels. The ramifications of supply chain disruptions include delays in aircraft maintenance, increased costs, and potential breaches of contractual obligations. KF Aerospace jobs related to supply chain management involve roles such as procurement specialists, inventory managers, and logistics analysts, all contributing to a seamless flow of materials.

- Transportation and Distribution

Transportation and distribution are vital for moving parts and equipment to various KF Aerospace facilities and customer locations. This includes coordinating transportation logistics, managing customs clearance, and ensuring adherence to safety regulations. Delays in transportation can result in extended aircraft downtime and increased operational costs. Job roles directly involved encompass transportation coordinators, warehouse personnel, and international logistics specialists, all contributing to the efficient movement of resources.

- Inventory Control

Efficient inventory control is essential for managing the storage and tracking of aircraft parts and materials within KF Aerospace warehouses. This involves implementing inventory management systems, conducting regular audits, and minimizing obsolescence. Inadequate inventory control can lead to shortages of critical parts, increased holding costs, and potential losses due to damage or theft. KF Aerospace roles related to inventory control include warehouse managers, inventory specialists, and material handlers, all working to maintain accurate and readily available supplies.

- Maintenance Planning and Scheduling

Logistics coordination is integral to maintenance planning and scheduling, ensuring that the right parts and resources are available at the right time for scheduled maintenance events. This involves coordinating with maintenance teams, forecasting material requirements, and scheduling deliveries. Inefficient coordination can result in delays in maintenance activities, increased labor costs, and reduced aircraft availability. KF Aerospace jobs involved in this facet include maintenance planners, schedulers, and logistics coordinators, all focused on synchronizing resources for optimal efficiency.

These facets of logistics coordination demonstrate their direct relevance to various KF Aerospace jobs, highlighting their essential role in supporting the organization’s operational efficiency, regulatory compliance, and ability to meet customer demands. Effective logistics coordination ensures the smooth flow of resources, optimizing maintenance schedules, reducing downtime, and ultimately contributing to the success of KF Aerospace.

4. Engineering Design

Engineering design is a fundamental component of KF Aerospace’s operations, directly influencing its capacity to offer innovative and comprehensive aerospace solutions. Opportunities in this domain range from conceptual design to detailed implementation, affecting various KF Aerospace job roles and project outcomes. Engineering Design underpins efficiency and safety.

- Aircraft Modification and Upgrades

Aircraft modification involves altering existing aircraft to enhance performance, extend lifespan, or adapt to new operational requirements. This includes designing structural modifications, integrating new avionics systems, and improving passenger amenities. The role of engineering design is crucial in ensuring that these modifications comply with regulatory standards and maintain the aircraft’s structural integrity. KF Aerospace jobs related to aircraft modification include design engineers, structural analysts, and certification specialists, all working to deliver safe and effective aircraft enhancements. A real-world example would be the design and integration of a new surveillance system into an existing aircraft, necessitating detailed engineering analysis and testing.

- New System Integration

Integrating new systems into aircraft requires careful design to ensure compatibility with existing infrastructure. This involves designing interfaces, developing control systems, and conducting extensive testing to validate performance. Engineering design is essential for optimizing system performance and minimizing integration challenges. Opportunities related to new system integration include systems engineers, avionics engineers, and software developers, all collaborating to implement cutting-edge technologies within aircraft. For example, the integration of a new satellite communication system requires designing the antenna placement, wiring interfaces, and control software.

- Structural Analysis and Testing

Structural analysis is critical for ensuring the integrity and safety of aircraft structures. This involves performing stress analysis, fatigue analysis, and finite element modeling to identify potential weaknesses and optimize designs. Testing, in design engineering, validates structural integrity and verifies compliance with safety standards. KF Aerospace jobs focused on structural analysis and testing include structural engineers, stress analysts, and materials engineers, all working to ensure the structural soundness of aircraft. An example would be the analysis of wing structures to withstand aerodynamic loads during flight.

- Design for Manufacturing

Engineering design considers manufacturability to streamline production processes and reduce costs. This involves designing components and assemblies that are easy to manufacture, assemble, and maintain. Effective design for manufacturing requires collaboration between design engineers, manufacturing engineers, and production teams. Roles related to design for manufacturing include design engineers with manufacturing expertise, process engineers, and industrial designers, all contributing to efficient production processes. An example is designing a modular aircraft component that can be easily assembled on the production line.

These examples illustrate the critical role of engineering design in shaping KF Aerospace’s capabilities and influencing its success. The integration of these facets contributes to KF Aerospace’s ability to provide innovative and reliable aerospace solutions, directly enhancing its competitiveness in the industry. By considering manufacturability early in the design process, KF Aerospace optimizes production efficiency and ensures that its products are cost-effective. Such considerations are vital for KF Aerospace’s continued success and growth in the aviation sector.

5. Project Management

Project management constitutes a crucial element within the scope of KF Aerospace’s operational framework. Effective project management directly impacts the company’s ability to execute complex aerospace projects, maintain timelines, adhere to budgetary constraints, and meet client expectations. The ramifications of deficient project management practices can manifest as project delays, cost overruns, compromised quality, and ultimately, damage to the company’s reputation. Consequently, project management expertise is consistently sought in various KF Aerospace job roles, underscoring its integral nature. For instance, a project involving the refurbishment of an aircraft fleet necessitates meticulous planning, resource allocation, risk mitigation, and stakeholder communication, all orchestrated by skilled project managers.

The practical application of project management principles within KF Aerospace extends across various domains. In aircraft maintenance, project managers oversee scheduled maintenance events, ensuring the timely availability of parts, personnel, and facilities. In aircraft modification programs, project managers coordinate engineering design, manufacturing, and installation activities, adhering to strict regulatory standards and client specifications. In technology integration projects, project managers facilitate the deployment of new avionics systems, managing software development, hardware installation, and pilot training initiatives. An absence of effective project management would impair these activities, leading to inefficiency, increased costs, and potential safety compromises. A real-world example of this is a scenario in which the integration of a new avionics system into an existing aircraft requires careful coordination between engineering, maintenance, and flight operations teams. The project manager would oversee this integration, ensuring that all stakeholders are aligned and that the project is completed on time and within budget.

In summation, project management is not merely an ancillary function at KF Aerospace but rather a critical competency that underpins its ability to deliver aerospace solutions effectively. While challenges persist in managing complex projects in a highly regulated environment, the integration of robust project management methodologies ensures efficient resource utilization, risk mitigation, and adherence to stringent quality standards. Understanding the integral role of project management within KF Aerospace is essential for prospective employees, highlighting the importance of leadership skills, organizational abilities, and a commitment to achieving project objectives. This ultimately strengthens KF Aerospace’s position in the competitive aerospace market.

6. Quality Assurance

Quality Assurance (QA) is integral to KF Aerospace operations, influencing all KF Aerospace jobs. QA ensures that all services and products meet rigorous industry standards, regulatory requirements, and customer expectations, impacting efficiency, safety, and operational effectiveness. Its implementation mitigates risks and reinforces the company’s market position, contributing directly to the organizations stability.

- Regulatory Compliance

QA ensures KF Aerospace adheres to aviation regulations mandated by bodies like Transport Canada and the FAA. Compliance is critical for maintaining operational licenses and certifications. KF Aerospace jobs within QA focus on implementing and monitoring processes to meet these regulatory standards. For example, quality control inspectors verify adherence to maintenance procedures and documentation protocols, thus upholding legal and safety mandates. Non-compliance leads to operational shutdowns and legal repercussions.

- Process Standardization

QA promotes standardized processes across all KF Aerospace operations to minimize variability and enhance efficiency. Process standardization ensures consistent execution, adherence to best practices, and effective use of resources. Roles in process improvement, auditing, and training contribute to standardization. Implementing standardized inspection checklists ensures uniform maintenance procedures across all aircraft types. Inconsistent processes introduce operational inefficiencies, errors, and safety compromises.

- Defect Prevention

Defect prevention is a proactive aspect of QA, aimed at identifying and addressing potential issues before they escalate into significant problems. Preventative measures include rigorous testing, inspections, and root cause analysis. KF Aerospace jobs in this area involve data analysis, risk assessment, and implementation of corrective actions. Regular inspection of aircraft components during maintenance, for example, is a defect prevention measure. Reactive approaches to defect management result in higher costs, increased downtime, and potential safety hazards.

- Continuous Improvement

QA fosters a culture of continuous improvement within KF Aerospace, driving innovation and operational enhancements. This involves ongoing monitoring of processes, identification of areas for improvement, and implementation of corrective actions. Continuous improvement roles include quality managers, data analysts, and process engineers. Analyzing customer feedback to improve maintenance procedures and reduce turnaround times, for example, illustrates continuous improvement. Stagnant QA programs hinder progress and reduce competitiveness.

In conclusion, QA is not merely a procedural formality within KF Aerospace, but rather a foundational element impacting all KF Aerospace jobs. Emphasizing compliance, standardization, defect prevention, and continuous improvement bolsters the organizations capacity to deliver superior aerospace solutions, ensuring safety, efficiency, and customer satisfaction. Its central role reinforces KF Aerospaces competitiveness and reputation within the aviation sector.

KF Aerospace Jobs

This section addresses common inquiries regarding employment opportunities with KF Aerospace. The information provided aims to clarify the application process, expectations, and career prospects within the organization.

Question 1: What types of positions are commonly available within KF Aerospace?

KF Aerospace offers a diverse range of roles, encompassing aircraft maintenance engineers, avionics technicians, logistics specialists, project managers, and administrative personnel. Openings vary depending on the specific needs of the company and its contractual obligations.

Question 2: What qualifications are typically required for aircraft maintenance roles?

Aircraft maintenance roles generally necessitate a valid Aircraft Maintenance Engineer (AME) license or equivalent certification, issued by a recognized aviation authority (e.g., Transport Canada, EASA). Specific aircraft type ratings may also be required depending on the position.

Question 3: How does KF Aerospace support employee professional development?

KF Aerospace invests in employee professional development through training programs, tuition reimbursement, and opportunities for skill enhancement. The company recognizes the importance of continuous learning in the rapidly evolving aerospace industry.

Question 4: What is the application process for KF Aerospace positions?

The application process typically involves submitting a resume and cover letter through the company’s online portal. Shortlisted candidates may then be invited for interviews, technical assessments, and reference checks.

Question 5: Does KF Aerospace offer opportunities for recent graduates or apprentices?

KF Aerospace often provides entry-level positions and apprenticeship programs for recent graduates and individuals seeking to enter the aerospace industry. These programs offer valuable on-the-job training and mentorship opportunities.

Question 6: What are the core values that KF Aerospace seeks in its employees?

KF Aerospace values safety, quality, integrity, teamwork, and customer satisfaction. Employees are expected to uphold these values in their daily work and interactions.

These frequently asked questions provide a foundational understanding of employment opportunities at KF Aerospace. Prospective applicants are encouraged to consult the company’s official website for the most up-to-date information and job postings.

The subsequent section will offer contact details for KF Aerospace’s Human Resources department, allowing potential applicants to seek clarification and/or further information.

KF Aerospace Jobs

This exploration of KF Aerospace jobs has highlighted the diversity of opportunities within the organization, spanning roles in aircraft maintenance, avionics, logistics, engineering design, project management, and quality assurance. Key aspects discussed include the necessary qualifications, the importance of aligning with company values, and the emphasis on continuous professional development.

The aerospace industry remains a dynamic sector, and KF Aerospace’s commitment to innovation and excellence positions it as a significant employer. Interested individuals are encouraged to visit the official KF Aerospace website for the latest job postings and application guidelines. Successful applicants will contribute to maintaining the highest standards of airworthiness and operational efficiency.

![Future Aerospace Engineer Job Outlook: [YEAR] Guide Innovating the Future of Flight with Reliable Aviation Solutions Future Aerospace Engineer Job Outlook: [YEAR] Guide | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-379-300x200.jpg)