Visual representations central to the field depict aircraft, spacecraft, satellites, and related technologies. These illustrations encompass a wide range, from conceptual sketches and detailed technical drawings to simulations and photographs of actual flight vehicles. For example, an engineer might use a computer-generated image to analyze airflow around a wing, or a photograph of a rocket launch to assess engine performance.

The employment of visual elements aids in communication, design, and analysis. They facilitate understanding of complex systems and contribute significantly to the iterative design process, enabling engineers to identify potential issues and optimize performance characteristics. Historically, hand-drawn schematics were crucial. Now, digital renderings and simulations provide unprecedented levels of detail and accuracy, accelerating development cycles and improving safety.

Subsequent discussion will delve into specific applications of these visuals in various phases of design and testing, and examine the tools and techniques utilized in their creation. Further examination of image analysis for performance evaluation, and the role of visualization in conveying complex information to stakeholders will follow.

Guidance on Visual Application in Aerospace Engineering

Effective utilization of visuals is paramount for conveying intricate concepts and data within the aerospace engineering domain. The following guidelines aim to enhance clarity and precision in their employment.

Tip 1: Clarity in Technical Drawings: Ensure all technical drawings adhere to industry standards and contain comprehensive annotations. For example, dimensional tolerances and material specifications should be clearly indicated on component schematics.

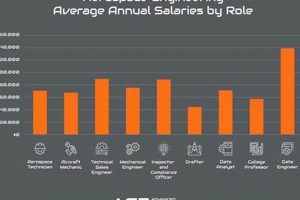

Tip 2: Data Visualization Integrity: Data representations, such as graphs and charts, must accurately reflect the underlying information. Axis labels, units, and scales require precise definition to avoid misinterpretation of aerodynamic performance data.

Tip 3: Effective Simulation Rendering: Employ realistic rendering techniques in simulations to provide accurate visual representations of physical phenomena. For instance, fluid dynamics simulations should demonstrate laminar and turbulent flow characteristics with fidelity.

Tip 4: Strategic Use of Color: Utilize color palettes judiciously to highlight critical features or convey quantitative information. Color-coding stress concentrations in finite element analysis can facilitate rapid identification of potential failure points.

Tip 5: Proper Scaling and Perspective: Maintain accurate scaling and perspective in illustrations of aircraft and spacecraft. This enables stakeholders to appreciate the relative size and spatial arrangement of components and systems.

Tip 6: Consistent Labeling and Nomenclature: Enforce consistent labeling and nomenclature across all visuals to prevent ambiguity. Designate components using standardized terms and abbreviations recognized within the aerospace engineering community.

Effective application of these guidelines will ensure that visuals serve as potent tools for communication, analysis, and design optimization within aerospace engineering projects. Clarity, accuracy, and consistency are paramount.

Subsequent sections will explore advanced techniques for generating and analyzing these visualizations, further enhancing their value in aerospace engineering applications.

1. Conceptual Visualizations

Conceptual visualizations serve as the initial bridge between abstract ideas and tangible designs in aerospace engineering. These are early-stage images, ranging from hand-drawn sketches to rudimentary computer-generated models, which represent proposed aircraft, spacecraft, or systems. The effect of these visualizations on subsequent development is significant. They facilitate early-stage problem identification, enable preliminary assessment of feasibility, and serve as crucial communication tools among engineering teams. Consider, for example, early sketches of the Wright Flyer. While rudimentary, these visuals codified the brothers’ understanding of aerodynamics and control surfaces, enabling them to build and test increasingly refined prototypes.

The importance of conceptual visualizations as a fundamental component is underscored by their role in fostering innovation and mitigating risks. Without visual representation, the complexities of aerospace systems would be exceedingly difficult to grasp, and critical design flaws might go unnoticed until later, more costly stages. For example, early visualizations of satellite deployment mechanisms can reveal potential interference issues before manufacturing begins, preventing costly redesigns. Furthermore, visual renderings of hypersonic aircraft designs enable aerodynamicists to evaluate potential heating issues and optimize shapes for minimizing drag.

In summary, conceptual visualizations are indispensable because they transform abstract ideas into tangible, analysable forms, ultimately streamlining the design process and reducing the likelihood of costly errors. While these early images might lack the precision of final blueprints, they provide essential frameworks for the complex engineering work that follows. Understanding this relationship allows for more efficient and successful implementation of aerospace projects. The ongoing challenge is to continue to develop tools and techniques that enhance the speed and accuracy with which these initial concepts can be visualized and assessed.

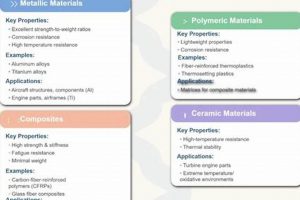

2. Technical Schematics

Technical schematics constitute a vital subset of aerospace engineering images. These detailed diagrams provide precise representations of aerospace systems, components, and circuits, detailing interconnections and functional relationships. The accuracy of these schematics directly impacts manufacturing, assembly, maintenance, and troubleshooting procedures. A clear and unambiguous schematic of an aircraft’s hydraulic system, for instance, is essential for technicians to diagnose and repair malfunctions. The consequence of errors in such schematics can range from costly delays to catastrophic system failures during operation.

The transition from conceptual designs to functional hardware relies heavily on the availability of accurate technical schematics. These documents serve as the blueprint for translating theoretical designs into tangible components, specifying dimensions, materials, and manufacturing processes. For example, a detailed schematic of a satellite’s power distribution network dictates the routing of electrical wiring, the placement of circuit breakers, and the integration of solar panels. Moreover, revisions to schematics following testing or operational feedback are essential for maintaining configuration control and ensuring the integrity of the engineering design. The impact of imprecise schematics can be seen in historical cases of manufacturing errors leading to structural weaknesses in aircraft.

In conclusion, technical schematics are indispensable elements within the broader landscape of aerospace engineering images. Their accuracy and clarity are paramount for the successful development, operation, and maintenance of aerospace systems. Challenges remain in ensuring consistent application of standards and effective dissemination of updates to schematics across geographically dispersed teams. A comprehensive understanding of this connection promotes safer and more efficient aerospace operations. This knowledge is critical for both seasoned engineers and those entering the field, influencing their work’s integrity and the safety of aerospace endeavors.

3. Simulation Renderings

Simulation renderings form a critical component within the spectrum of aerospace engineering images, providing visual representations of complex physical phenomena that are otherwise impossible or impractical to observe directly. These renderings are generated using computational models and algorithms to simulate aerodynamic behavior, structural responses, thermal characteristics, and other critical aspects of aerospace vehicles and systems.

- Aerodynamic Flow Visualization

Simulation renderings visualize airflow around aircraft and spacecraft, illustrating phenomena such as boundary layer separation, shock wave formation, and vortex shedding. These images allow engineers to assess aerodynamic performance, identify areas of high drag, and optimize vehicle shapes for improved efficiency. For example, computational fluid dynamics (CFD) simulations can generate visualizations of airflow around a wing, revealing regions of turbulent flow that can be addressed through design modifications.

- Structural Stress Analysis

Simulation renderings generated from finite element analysis (FEA) depict stress distributions within aerospace structures under various loading conditions. These images help engineers identify areas of high stress concentration, predict potential failure points, and optimize structural designs for increased strength and reduced weight. Examples include visualizing stress patterns in a landing gear assembly during touchdown or analyzing the structural integrity of a satellite antenna under thermal and vibrational loads.

- Thermal Management Visualization

Simulation renderings illustrate heat transfer processes within aerospace systems, showcasing temperature distributions and identifying potential overheating issues. These images are critical for designing effective thermal management systems, such as heat shields for re-entry vehicles or cooling systems for electronic components. For instance, simulations can generate renderings showing temperature gradients in a spacecraft’s electronics bay, guiding the placement of heat sinks and cooling channels.

- Combustion Simulation Visualization

Simulation renderings visualize the complex chemical reactions and fluid dynamics within combustion chambers of rocket engines and gas turbines. These images allow engineers to analyze combustion efficiency, optimize fuel-air mixing, and minimize pollutant formation. An example includes simulating the combustion process within a rocket engine nozzle to visualize flame propagation and identify areas of incomplete combustion.

These facets of simulation renderings collectively contribute to informed decision-making in aerospace engineering, enabling designers and analysts to virtually test and optimize systems before physical prototyping, thereby reducing costs and accelerating development cycles. These visuals serve not only as analytical tools but also as powerful communication aids, facilitating collaboration and understanding among engineers, stakeholders, and decision-makers.

4. Photographic Documentation

Photographic documentation serves as a critical component of aerospace engineering, capturing visual records of processes, experiments, and hardware at various stages of development and deployment. These images offer verifiable evidence, provide historical context, and facilitate communication across teams and stakeholders. Their relevance is underscored by the need for precise record-keeping in a field where safety and reliability are paramount.

- Testing and Experimentation Records

Photographs of wind tunnel tests, material stress tests, and engine performance evaluations provide empirical evidence supporting design decisions. For example, capturing images of a wing undergoing stress testing can reveal structural weaknesses or validate simulation models. Such documentation is invaluable for regulatory compliance and subsequent analysis.

- Manufacturing and Assembly Processes

Visual records of manufacturing steps, assembly procedures, and quality control inspections document the construction of aerospace components and systems. These images aid in identifying potential defects, tracking assembly sequences, and ensuring adherence to specifications. For instance, documenting the assembly of a satellite’s solar panels provides a visual audit trail that can be referenced during troubleshooting.

- In-Flight Performance Monitoring

Photographic and video recordings during flight tests and operational missions capture vehicle behavior and environmental conditions. This documentation assists in assessing aerodynamic performance, monitoring system health, and investigating anomalies. Capturing imagery of a rocket launch, for example, enables analysis of trajectory, engine performance, and potential structural issues.

- Accident and Failure Analysis

Photographic documentation of accident sites and component failures provides critical evidence for investigations aimed at determining root causes and preventing future incidents. Detailed images of wreckage, failed parts, and environmental conditions assist engineers in reconstructing events and identifying contributing factors. Such documentation is essential for improving safety standards and design practices.

The integration of photographic documentation into aerospace engineering workflows enhances transparency, accountability, and continuous improvement. These visual records serve as indispensable resources for validating designs, optimizing processes, and learning from past experiences. Their careful management and accessibility are crucial for maintaining the integrity and advancement of the field.

5. Data Visualization

Data visualization plays a crucial role in aerospace engineering, transforming raw numerical information into readily understandable visual formats. This process is not merely aesthetic; it directly impacts the ability to analyze trends, identify anomalies, and communicate complex findings effectively.

- Performance Trend Identification

Visualizing flight performance data, such as altitude, speed, and fuel consumption, allows engineers to identify trends and anomalies that might indicate system inefficiencies or potential failures. Graphical representations of these metrics over time offer insights that would be difficult to discern from raw data tables. For instance, a sudden drop in fuel efficiency depicted on a graph might signal a problem with engine performance.

- Simulation Output Analysis

Aerospace simulations generate vast datasets representing aerodynamic forces, thermal distributions, and structural stresses. Data visualization techniques, such as contour plots and heatmaps, enable engineers to analyze simulation results effectively, identifying areas of concern and optimizing designs. A heatmap showing stress concentrations on an aircraft wing, for example, can guide reinforcement efforts.

- Operational Status Monitoring

Real-time data visualization is essential for monitoring the operational status of aircraft and spacecraft. Graphical displays of sensor data, system parameters, and environmental conditions provide operators with a comprehensive overview of vehicle health and performance. An example is a cockpit display showing engine temperatures, oil pressure, and other critical parameters, allowing pilots to respond promptly to any anomalies.

- Communication of Complex Findings

Data visualization facilitates the communication of complex findings to diverse audiences, including engineers, managers, and stakeholders. Clear and concise charts, graphs, and diagrams can convey key insights more effectively than lengthy reports or technical jargon. For instance, a well-designed infographic summarizing the results of a flight test can communicate its findings to a broader audience.

These facets collectively demonstrate the indispensable connection between data visualization and aerospace engineering. By transforming raw data into meaningful visual representations, engineers can gain insights, make informed decisions, and communicate complex findings effectively, ultimately advancing the field.

6. Analysis Tools

Analysis tools are integral for extracting quantitative and qualitative information from aerospace engineering images. These tools range from basic image processing software to sophisticated simulation and analysis platforms, each contributing to a deeper understanding of visual data. Their effective utilization is critical for validating designs, troubleshooting failures, and optimizing performance.

- Image Processing Software

Image processing software enhances and manipulates aerospace engineering images to reveal subtle details or extract specific measurements. This includes tasks such as contrast adjustment, noise reduction, and edge detection. For example, analyzing a satellite image of a deployed antenna might involve enhancing the contrast to better visualize its shape or using edge detection to measure its dimensions. Such measurements can then be compared against design specifications.

- Computational Fluid Dynamics (CFD) Post-Processors

CFD post-processors visualize the results of aerodynamic simulations, generating images of airflow patterns, pressure distributions, and temperature gradients. These visual representations allow engineers to analyze the aerodynamic performance of aircraft and spacecraft, identify areas of concern, and optimize designs for improved efficiency. For instance, a CFD simulation of airflow around a wing can be visualized to identify regions of turbulence or boundary layer separation, guiding design modifications.

- Finite Element Analysis (FEA) Visualizers

FEA visualizers generate images of stress distributions, deformation patterns, and thermal behavior within aerospace structures. These images enable engineers to assess structural integrity, predict potential failure points, and optimize designs for increased strength and reduced weight. For example, FEA can be used to visualize the stress distribution within a rocket engine nozzle, identifying areas of high stress concentration that require reinforcement.

- Photogrammetry Software

Photogrammetry software reconstructs 3D models from overlapping photographs of aerospace components or structures. This technique allows engineers to obtain accurate measurements of dimensions, shapes, and surface features. For example, photogrammetry can be used to create a 3D model of an aircraft wing from a series of photographs, enabling precise measurement of its airfoil shape and surface roughness.

In summation, analysis tools are indispensable for extracting meaningful information from aerospace engineering images, enabling engineers to validate designs, optimize performance, and ensure the reliability of aerospace systems. The choice of analysis tool depends on the specific application and the type of information required, but their collective impact on aerospace engineering is undeniable.

Frequently Asked Questions

The following addresses common queries regarding the role and application of images within the aerospace engineering field. These answers provide clarity on their use, importance, and limitations.

Question 1: What constitutes an acceptable level of detail in technical schematics for aerospace component manufacturing?

Technical schematics must adhere to industry standards (e.g., ANSI, ISO) and include all critical dimensions, tolerances, material specifications, surface finish requirements, and manufacturing processes. The level of detail should be sufficient to enable unambiguous interpretation by manufacturing personnel, ensuring accurate replication of the designed component.

Question 2: How are simulation renderings validated for accuracy in predicting real-world aerodynamic behavior?

Validation involves comparing simulation results with experimental data obtained from wind tunnel tests or flight tests. Discrepancies between simulation and experimental results are analyzed, and the simulation models are refined to improve accuracy. This iterative process ensures that simulation renderings provide a reliable representation of aerodynamic phenomena.

Question 3: What protocols are in place to ensure the integrity and security of photographic documentation in aerospace engineering projects?

Photographic documentation should be stored securely, with access restricted to authorized personnel. A robust version control system should be implemented to track changes to images and prevent unauthorized modifications. Metadata, including date, time, location, and photographer information, should be embedded in the images to maintain provenance.

Question 4: How can data visualization be used to identify potential safety hazards in aircraft operational data?

Data visualization techniques, such as scatter plots, time-series graphs, and heatmaps, can reveal patterns and anomalies in operational data that might indicate potential safety hazards. For example, visualizing engine performance parameters over time can help identify trends that precede engine failures. These insights allow for proactive maintenance and mitigation of safety risks.

Question 5: What are the limitations of using image processing software to analyze satellite imagery for environmental monitoring?

Image processing software is susceptible to errors caused by atmospheric conditions, sensor limitations, and image distortions. The accuracy of environmental monitoring data derived from satellite imagery depends on the quality of the imagery and the effectiveness of the image processing techniques employed. Careful calibration and validation are essential to minimize these limitations.

Question 6: How do analysis tools contribute to the design of more fuel-efficient aircraft?

Analysis tools, such as CFD software and FEA visualizers, enable engineers to simulate and analyze the aerodynamic and structural performance of aircraft designs. By optimizing the shape of wings, fuselage, and other components, engineers can minimize drag, reduce weight, and improve fuel efficiency. These tools facilitate iterative design improvements and the development of more sustainable aerospace technologies.

In summary, visual representations in aerospace engineering necessitate rigorous validation, secure handling, and appropriate interpretation to ensure accuracy and reliability. Understanding the limitations of these representations is as important as appreciating their benefits.

The subsequent section will focus on emerging trends in aerospace image analysis and visualization.

Conclusion

The preceding discussion has underscored the pervasive importance of visual representations throughout aerospace engineering. From initial concept sketches to complex simulation renderings and meticulous photographic documentation, these visuals are not mere illustrations but critical instruments for analysis, design, and communication. Key aspects, including conceptual visualizations, technical schematics, simulation renderings, photographic documentation, data visualization, and the crucial analysis tools, each play an indispensable role in ensuring the safety, efficiency, and advancement of aerospace technologies.

Continued development and refinement of these imaging techniques, alongside rigorous validation and secure management, remain essential. Aerospace engineering images serve as a foundational language, demanding precision and clarity to facilitate innovation and progress in this complex domain. Their proper use will drive the next generation of aerospace achievements, ensuring a safer and more efficient future for flight and space exploration.