The field encompasses the design, development, testing, and production of aircraft and spacecraft. It integrates principles from various disciplines including aerodynamics, propulsion, materials science, structural analysis, and control systems to create vehicles that operate within and beyond Earth’s atmosphere. A foundational understanding of these interconnected elements is vital for any aspiring or practicing professional in the aerospace sector.

The systematic examination of its core competencies provides numerous advantages. It enables a clearer understanding of complex systems, facilitates efficient problem-solving, and promotes informed decision-making in the development of cutting-edge technologies. Historically, focused studies have been instrumental in driving innovation, from the earliest days of flight to the exploration of distant planets.

Therefore, this discussion will delve into the key disciplines involved, examining typical project workflows, exploring current trends, and highlighting potential career paths within this dynamic and vital sector. A breakdown of these elements provides a robust perspective of the modern industry.

The following points provide focused guidance for individuals seeking to understand or engage with the complexities inherent within the realm of flight and space vehicle engineering.

Tip 1: Prioritize Foundational Knowledge: A strong base in mathematics, physics, and computer science is essential. Aerodynamics, propulsion, and structural analysis rely heavily on these principles. Consistent effort in these core subjects will greatly aid comprehension of advanced topics.

Tip 2: Embrace Interdisciplinary Learning: This is inherently a multidisciplinary field. Understanding the connections between aerodynamics, materials science, control systems, and other areas is crucial for effective design and problem-solving. Seek opportunities to broaden your knowledge beyond a single specialization.

Tip 3: Develop Strong Analytical Skills: The ability to analyze complex systems, identify critical parameters, and predict performance is vital. Practice using analytical tools and techniques to solve engineering problems. Familiarity with simulation software and data analysis methods is highly valuable.

Tip 4: Gain Practical Experience: Seek internships, research opportunities, or hands-on projects related to aircraft or spacecraft. Practical experience complements theoretical knowledge and provides valuable insights into real-world engineering challenges. Working on a team can also help refine collaboration skills.

Tip 5: Stay Current with Technological Advancements: The aerospace sector is constantly evolving. Stay informed about emerging technologies, such as advanced materials, additive manufacturing, and autonomous systems. Continuously update your knowledge and skills to remain competitive.

Tip 6: Cultivate Effective Communication Skills: The ability to clearly communicate technical information is essential for collaborating with engineers, scientists, and other stakeholders. Practice writing technical reports, giving presentations, and engaging in constructive discussions.

A focused, informed approach, coupled with a commitment to continuous learning, will greatly enhance one’s understanding and capabilities within this demanding field.

These considerations serve as a valuable framework for navigating the diverse aspects within this engineering discipline.

1. Aerodynamics

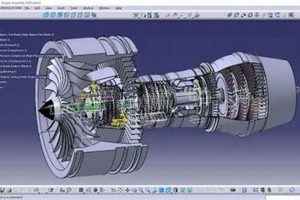

Aerodynamics, the study of air in motion and its interaction with solid objects, is a cornerstone of. Without a thorough comprehension of aerodynamic principles, the design and operation of aircraft and spacecraft would be impossible. Cause-and-effect relationships are evident; for instance, airfoil shape directly impacts lift and drag, determining flight efficiency and stability. The importance is paramount, as aerodynamic forces dictate flight characteristics and are crucial for achieving desired performance metrics. Consider the design of a commercial airliner’s wing; optimized airfoil profiles minimize drag, leading to reduced fuel consumption and increased range. Similarly, the aerodynamic shaping of a spacecraft’s heat shield is vital for dissipating extreme temperatures during atmospheric reentry.

Further analysis reveals that aerodynamic considerations extend beyond basic lift and drag. Understanding boundary layer effects, turbulence, and compressibility is essential for designing high-speed aircraft and spacecraft. Computational Fluid Dynamics (CFD) simulations are routinely employed to model airflow around complex geometries and predict aerodynamic performance. For example, CFD simulations are used to optimize the design of jet engine intakes to minimize flow distortion and maximize engine efficiency. Wind tunnel testing complements CFD simulations, providing empirical data to validate theoretical models and refine designs. The application of advanced control surfaces, such as flaps and slats, allows for dynamic manipulation of aerodynamic forces to enhance aircraft maneuverability and control.

In summary, aerodynamics is an indispensable element. Its impact on performance, safety, and efficiency is undeniable. Challenges in this field involve accurately modeling complex flow phenomena and developing innovative aerodynamic designs to meet increasingly stringent performance requirements. Recognizing the significance of aerodynamics is fundamental to understanding the broader objectives and advancements within the aerospace industry.

2. Propulsion Systems

Propulsion systems are integral to the design and functionality of any aircraft or spacecraft. These systems provide the thrust necessary to overcome drag and gravitational forces, enabling sustained flight and space travel. Understanding the principles and technologies behind various propulsion methods is paramount for professionals within the field.

- Jet Engines

Jet engines, predominantly used in commercial and military aircraft, operate by compressing air, mixing it with fuel, igniting the mixture, and expelling the hot exhaust gases to generate thrust. Different types of jet engines, such as turbojets, turbofans, and turboprops, offer varying levels of efficiency and performance characteristics. For instance, turbofans are favored for their fuel efficiency at subsonic speeds, making them ideal for long-haul commercial flights. Their design directly impacts aircraft range, payload capacity, and overall operational costs.

- Rocket Engines

Rocket engines are essential for space exploration and satellite launch. Unlike jet engines, rocket engines carry both fuel and oxidizer, enabling them to operate in the vacuum of space. Chemical rocket engines, such as those using liquid hydrogen and liquid oxygen, produce high thrust but have relatively low specific impulse (a measure of fuel efficiency). Advanced rocket engine technologies, like ion propulsion, offer significantly higher specific impulse but generate much lower thrust. The selection of a rocket engine depends heavily on the mission requirements, including payload mass, desired trajectory, and mission duration.

- Propellers

Propellers, commonly found on smaller aircraft and some larger cargo planes, generate thrust by accelerating a large volume of air. Propeller efficiency is influenced by factors such as blade design, rotational speed, and airspeed. While propellers are generally more efficient at lower speeds compared to jet engines, they become less effective at higher Mach numbers due to compressibility effects. The implementation dictates operational parameters such as cruise speed, take off distance, and fuel consumption.

- Electric Propulsion

Electric propulsion systems, which utilize electric power to accelerate a propellant, are gaining prominence for in-space propulsion and satellite station-keeping. These systems offer high specific impulse, enabling long-duration missions with reduced propellant requirements. Types of electric propulsion include ion thrusters, Hall-effect thrusters, and electrospray thrusters. Solar-electric propulsion, which uses solar panels to generate electricity, allows for continuous thrust generation over extended periods, proving invaluable for deep-space exploration.

The selection and integration of a specific propulsion system is a critical design consideration within the broader field. Factors such as mission objectives, performance requirements, and cost constraints heavily influence the choice of propulsion technology. Advancements in propulsion technology continue to drive innovation, enabling more efficient and ambitious aerospace endeavors.

3. Materials Science

Materials Science is fundamentally linked to aerospace engineering, impacting design, performance, and safety. Material selection dictates the feasibility and efficiency of aircraft and spacecraft. Understanding material properties, behaviors, and limitations is essential for innovation in this domain.

- High Strength-to-Weight Ratio

Aerospace structures necessitate materials possessing high strength-to-weight ratios to minimize structural mass without compromising integrity. Aluminum alloys, titanium alloys, and composite materials like carbon fiber reinforced polymers (CFRP) are commonly employed. For example, the Boeing 787 Dreamliner utilizes a significant proportion of CFRP in its fuselage and wings, reducing weight and improving fuel efficiency. The specific alloy used dictates the acceptable stress load.

- Thermal Resistance

Aircraft and spacecraft experience extreme temperature variations, from the frigid vacuum of space to the intense heat generated during atmospheric reentry. Materials must maintain structural integrity and resist thermal degradation under these conditions. High-temperature alloys, ceramics, and thermal protection systems (TPS) are employed to shield critical components. The Space Shuttle, for instance, relied on ceramic tiles as a TPS to withstand reentry temperatures exceeding 1,600 degrees Celsius. It is important to note that new high temperature alloys are being developed.

- Corrosion Resistance

Exposure to atmospheric conditions, including humidity, salt spray, and pollutants, can lead to corrosion of aerospace materials. Corrosion can weaken structural components and compromise safety. Protective coatings, corrosion-resistant alloys, and regular inspections are essential for mitigating corrosion risks. Stainless steel and anodized aluminum are frequently used in aircraft construction to enhance corrosion resistance. Without these measures, the components would fail.

- Fatigue Resistance

Aerospace structures are subjected to cyclic loading and vibration, which can lead to fatigue failure over time. Materials must exhibit high fatigue resistance to ensure long-term durability. Fatigue testing and analysis are crucial for predicting component lifespan and establishing maintenance schedules. Titanium alloys and advanced composite materials are often selected for their superior fatigue properties. In this area, new material testing is an area of active research.

These material characteristics are crucial in the field. The advancements drive innovation. Future progress hinges on the development and implementation of materials with enhanced performance capabilities.

4. Structural Analysis

Structural analysis is an indispensable component of the field, ensuring the integrity and safety of aircraft and spacecraft. It involves determining the effects of loads and stresses on physical structures and their components. A direct cause-and-effect relationship exists; applied forces lead to internal stresses and deformations within the structure. Understanding this relationship allows engineers to design structures capable of withstanding operational loads and environmental conditions. The importance of structural analysis stems from its direct influence on safety and performance. Without rigorous analysis, structures could fail under stress, leading to catastrophic consequences. For example, finite element analysis (FEA) is used extensively to simulate stress distributions in aircraft wings during flight. These simulations predict areas of high stress concentration, allowing engineers to reinforce those areas and prevent structural failure. Similarly, structural analysis is vital for designing spacecraft hulls to withstand the pressures of launch and the extreme temperatures of space.

The practical applications extend across multiple stages. During the design phase, structural analysis guides the selection of materials, the determination of component dimensions, and the optimization of structural layouts. Simulation software allows engineers to model complex structures and apply various load scenarios, such as aerodynamic forces, engine thrust, and landing impacts. Furthermore, structural analysis is crucial for assessing the effects of fatigue, corrosion, and other forms of degradation on structural integrity. Non-destructive testing methods, such as ultrasonic inspection and radiographic imaging, are used to detect flaws and monitor structural health. The data obtained is then used to validate analytical models and predict remaining service life. For instance, aircraft maintenance programs rely on structural analysis to identify critical areas prone to fatigue cracking and to schedule inspections and repairs accordingly.

In summary, structural analysis is a foundational pillar of aerospace design and engineering. It provides the means to predict structural behavior, optimize designs for strength and weight, and ensure safety and reliability. Challenges involve accurately modeling complex material behaviors, accounting for uncertainties in loading conditions, and developing efficient computational methods for analyzing large-scale structures. Ongoing research focuses on developing advanced simulation techniques and incorporating new materials to push the boundaries of structural performance in the aerospace industry.

5. Control Systems

Control systems are an essential and integrated element of aerospace engineering, directly influencing the stability, maneuverability, and overall performance of aircraft and spacecraft. Effective control is not merely a desirable feature; it is a fundamental requirement for safe and efficient operation. A malfunction or inadequacy can have catastrophic consequences, underscoring the gravity of design and implementation. The underlying relationship is that the control system directly regulates the vehicle’s response to external disturbances and pilot or operator commands. An illustrative example is the autopilot system in commercial airliners, which maintains a predetermined course, altitude, and airspeed, reducing pilot workload and improving fuel efficiency. The development of flight control systems with increasing autonomy is also crucial for unmanned aerial vehicles (UAVs), enabling them to perform complex tasks in dynamic environments.

The practical application of control systems within this field encompasses a broad spectrum of functions. These include flight control (stabilization, navigation, trajectory tracking), engine control (fuel management, thrust regulation), and attitude control (orientation, pointing accuracy). Sophisticated algorithms, such as proportional-integral-derivative (PID) control, model predictive control (MPC), and adaptive control, are employed to achieve desired performance characteristics. Real-time feedback from sensors, such as gyroscopes, accelerometers, and GPS receivers, provides the control system with information about the vehicle’s state. Control surfaces, such as ailerons, elevators, and rudders, are actuated to generate the necessary forces and moments to correct deviations from the desired trajectory or attitude. For instance, spacecraft utilize reaction wheels and thrusters for attitude control, ensuring precise pointing of instruments and antennas.

In summary, control systems are a critical and multifaceted element in the design and operation of aircraft and spacecraft. They dictate the vehicle’s response to external factors and ensure safety and efficiency. Challenges in this domain involve developing robust and reliable control algorithms that can handle uncertainties, disturbances, and system failures. Future advancements focus on incorporating artificial intelligence and machine learning techniques to create autonomous control systems capable of adapting to evolving environments and mission requirements. The continued development of control systems remains central to progress within the sector.

6. Regulations

Regulations form a critical framework within the field, guiding design, manufacturing, operation, and maintenance practices. These are not arbitrary constraints but rather derive from established safety principles and operational necessities. The cause-and-effect relationship is direct: adherence to regulations ensures airworthiness, mitigates risk, and maintains public safety. Consider, for example, Federal Aviation Regulations (FARs) in the United States or European Aviation Safety Agency (EASA) regulations in Europe. These bodies set standards for aircraft design, pilot training, and maintenance procedures. Failure to comply can result in significant penalties, grounding of aircraft, and, most critically, loss of life. Understanding and adhering to these regulations is, therefore, not merely a procedural requirement but a core responsibility within the domain.

The practical application of regulations is pervasive. During aircraft design, engineers must demonstrate compliance with airworthiness standards related to structural integrity, system redundancy, and emergency procedures. Certification processes, such as type certification for new aircraft models, require rigorous testing and documentation to prove compliance. In manufacturing, quality control processes are heavily influenced by regulatory requirements, ensuring that each aircraft component meets specified standards. Operational aspects, including pilot training, air traffic control, and aircraft maintenance, are also heavily regulated to minimize the risk of accidents and incidents. Regular audits and inspections are conducted by regulatory agencies to verify compliance and identify potential safety hazards.

In summary, regulations provide a structured and enforceable framework that underpins all aspects of design, engineering, and operation. They exist to mitigate risks and ensure safety. Challenges in the regulatory landscape include adapting to technological advancements, harmonizing international standards, and maintaining vigilance against emerging threats. A comprehensive understanding of regulations is therefore essential for success and ethical practice within the aerospace sector.

Frequently Asked Questions

This section addresses common inquiries regarding the scope, requirements, and career paths within the field, providing clarity on its multifaceted nature.

Question 1: What are the fundamental disciplines encompassed by aerospace engineering?

It encompasses a broad range of disciplines, including aerodynamics, propulsion, materials science, structural analysis, control systems, and avionics. A comprehensive understanding of these interconnected areas is crucial for successful design and development of aircraft and spacecraft.

Question 2: What educational qualifications are typically required to pursue a career in the field?

A bachelor’s degree in aerospace engineering or a closely related field (e.g., mechanical engineering, physics) is generally the minimum requirement. Advanced positions often require a master’s degree or doctorate, allowing for specialization and in-depth research.

Question 3: What are the primary responsibilities of an aerospace engineer?

Responsibilities vary depending on the specific role and area of specialization. They may include designing aircraft and spacecraft components, conducting performance analyses, overseeing manufacturing processes, testing prototypes, and ensuring compliance with regulatory standards.

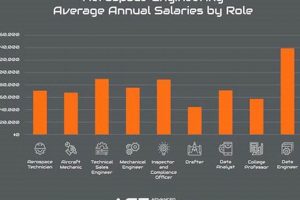

Question 4: What are some typical career paths available to graduates with an aerospace engineering degree?

Career paths are diverse, ranging from design and development to research and testing. Specific roles may include aircraft designer, propulsion engineer, structural analyst, flight test engineer, and systems engineer. Opportunities exist in both the public and private sectors, including aerospace companies, government agencies, and research institutions.

Question 5: How does the field contribute to technological advancements beyond aviation and space exploration?

Contributions extend to various sectors. Advancements in materials science, aerodynamics, and control systems developed for aerospace applications often find applications in other fields, such as automotive engineering, renewable energy, and medical technology. The pursuit of high performance and efficiency in aerospace drives innovation with broader societal benefits.

Question 6: What are the key challenges currently facing the aerospace engineering community?

Challenges include reducing the environmental impact of air travel, developing sustainable propulsion systems, improving air traffic management, and ensuring the safety and reliability of autonomous aircraft and spacecraft. Addressing these challenges requires interdisciplinary collaboration and continuous innovation.

This overview offers a glimpse into the vast landscape of aerospace engineering. A clear understanding of its intricacies empowers individuals to navigate this dynamic field effectively.

Having explored common queries, the next section will provide a detailed analysis of emerging trends and future directions within the domain.

Conclusion

This exploration of aerospace engineering overview has elucidated its multi-faceted nature, encompassing critical disciplines from aerodynamics and propulsion to materials science, structural analysis, control systems, and regulatory compliance. The interdependencies between these areas were highlighted, demonstrating the necessity for a holistic understanding to ensure the safe, efficient, and effective design and operation of aircraft and spacecraft. Furthermore, the examination of career paths and emerging trends showcased the dynamic and ever-evolving landscape of this sector.

As the aerospace industry continues to advance, addressing challenges related to sustainability, autonomy, and the exploration of new frontiers, a commitment to continuous learning and innovation remains paramount. Further investigation into specific areas of interest within aerospace engineering is encouraged, fostering deeper expertise and contributing to the future of flight and space exploration.