An entity operating within the aviation and defense sectors, it focuses on the development, manufacturing, and maintenance of aircraft and related systems. Its activities encompass a wide range of engineering and technological applications, often involving collaboration with international partners and serving both domestic and international markets. Example activities include producing aircraft components, providing maintenance services, and engaging in research and development for new aerospace technologies.

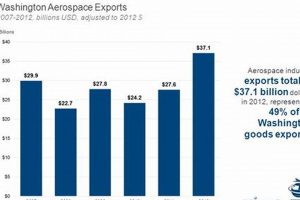

The enterprise plays a significant role in bolstering a nation’s technological capabilities and fostering economic growth. Investment in these types of industries creates high-skilled jobs, promotes innovation, and strengthens national security. Furthermore, its activities contribute to the advancement of scientific knowledge and have a cascading effect on other sectors, such as education and telecommunications. Historically, the establishment of such entities has been strategically important for nations seeking to reduce reliance on foreign suppliers and establish a competitive advantage in the global market.

The following analysis will explore aspects of its operational strategies, technological advancements, and contributions to the broader economic landscape. Further discussion will focus on its competitive position, future growth potential, and the challenges it faces in a rapidly evolving global environment.

Strategic Recommendations for Aerospace Advancement

The following recommendations offer insights for organizations seeking to achieve sustainable growth and competitive advantage in the aerospace sector. These tips emphasize strategic investments, operational efficiency, and technological leadership.

Tip 1: Prioritize Investment in Research and Development: Sustained investment in R&D is crucial for developing cutting-edge technologies and maintaining a competitive edge. Example: Allocate a significant portion of revenue to explore advancements in materials science, propulsion systems, and autonomous flight technologies.

Tip 2: Foster Strategic Partnerships: Collaboration with international partners, research institutions, and other industry players can enhance capabilities and access to new markets. Example: Establish joint ventures with specialized technology firms to accelerate the development and integration of advanced avionics systems.

Tip 3: Implement Robust Quality Control Measures: Maintaining rigorous quality control standards is essential for ensuring the safety and reliability of aerospace products and services. Example: Employ advanced inspection techniques and implement comprehensive quality management systems to minimize defects and ensure compliance with regulatory requirements.

Tip 4: Focus on Skills Development and Training: Investing in the training and development of a highly skilled workforce is critical for driving innovation and maintaining operational excellence. Example: Establish specialized training programs to equip engineers and technicians with the latest knowledge and skills in areas such as composite materials and digital manufacturing.

Tip 5: Streamline Supply Chain Management: Optimizing the supply chain can reduce costs, improve efficiency, and enhance responsiveness to changing market demands. Example: Implement advanced supply chain management systems to improve visibility, optimize inventory levels, and reduce lead times.

Tip 6: Embrace Digital Transformation: Adopting digital technologies can enhance productivity, improve decision-making, and enable new business models. Example: Implement cloud-based platforms for data analytics, predictive maintenance, and simulation-based design.

Tip 7: Enhance Cybersecurity Measures: Protecting critical infrastructure and data from cyber threats is paramount. Example: Implement robust cybersecurity protocols and conduct regular vulnerability assessments to safeguard sensitive information and prevent disruptions to operations.

These recommendations highlight the importance of strategic planning, technological innovation, and operational excellence in achieving long-term success. By focusing on these areas, organizations can enhance their competitive advantage and contribute to the continued advancement of the aerospace sector.

The subsequent sections of this analysis will further elaborate on specific strategies for navigating the challenges and opportunities in the evolving aerospace landscape.

1. Manufacturing

Manufacturing constitutes a foundational element. It represents the tangible realization of engineering designs and technological innovation into functional aerospace components and complete aircraft. This capability encompasses a broad spectrum of processes, from precision machining of critical engine parts to the assembly of airframes and the integration of complex avionics systems. The efficacy of manufacturing processes directly impacts the performance, reliability, and safety of the final product. A real-world example is the fabrication of composite wing structures, where precise control over material layering and curing processes is essential for achieving the required strength-to-weight ratio. A failure in manufacturing can have catastrophic consequences, underscoring the critical nature of this function.

The importance lies not only in producing hardware, but also in the economic and technological advancements that result. Investment in advanced manufacturing techniques, such as additive manufacturing (3D printing) and robotic automation, enhances production efficiency, reduces waste, and improves the overall quality of the product. This often leads to the creation of high-skilled jobs, the transfer of knowledge, and the stimulation of innovation within the local economy. Furthermore, domestically controlled manufacturing capabilities reduce reliance on foreign suppliers, strengthening national security and promoting economic independence. For example, investment in local manufacturing can provide critical support for military aviation programs and allow for rapid response to evolving defense needs.

In summary, the manufacturing aspect is not simply a production process, but an integral component of the entire operation, impacting product performance, economic development, and national security. Challenges include maintaining stringent quality control standards, adapting to rapidly changing technological landscapes, and managing complex supply chains. Addressing these challenges effectively is crucial for ensuring the long-term sustainability and competitiveness of any enterprise operating within this sector.

2. Maintenance

Maintenance is a critical and inseparable element. It directly affects operational readiness, safety, and the lifecycle cost of aircraft and associated systems. Robust maintenance programs ensure airworthiness, prevent component failures, and extend the service life of costly assets. Without comprehensive maintenance strategies, even the most technologically advanced aircraft become liabilities. The effects of inadequate maintenance can range from minor operational delays to catastrophic accidents, underscoring its importance. As an example, adherence to strict maintenance schedules, including regular inspections and component replacements, is paramount for both commercial airlines and military aviation fleets to mitigate risks associated with wear and tear, corrosion, and fatigue.

This component entails a wide range of activities, from routine inspections and repairs to major overhauls and upgrades. Specialized technicians, engineers, and support personnel are required to perform these tasks, demanding high levels of skill and training. The integration of advanced diagnostic tools and predictive maintenance technologies is becoming increasingly essential for optimizing maintenance schedules and minimizing downtime. Furthermore, maintenance activities frequently involve the procurement of spare parts and components, creating a substantial demand for suppliers and logistical support. Consider the complex logistical challenges involved in providing maintenance support for military aircraft deployed in remote locations, requiring the timely delivery of specialized parts and equipment.

In summary, maintenance is not merely a support function but a vital component, ensuring the ongoing reliability and performance of aircraft. Effective maintenance programs enhance safety, reduce operational costs, and extend the service life of assets. Challenges include managing complex maintenance schedules, adapting to evolving regulatory requirements, and integrating new technologies to improve efficiency and effectiveness. Overcoming these challenges is essential for maintaining a competitive advantage and ensuring the long-term success of aerospace operations.

3. Technology

Technological advancement is an indispensable driver within aerospace industries. It dictates the boundaries of what is achievable in flight performance, efficiency, safety, and defense capabilities. The integration of novel technologies enables the creation of more capable, reliable, and cost-effective aircraft, thereby influencing competitiveness and market positioning.

- Advanced Materials

The development and implementation of novel materials, such as carbon fiber composites, titanium alloys, and ceramic matrix composites, are crucial for enhancing aircraft performance. These materials offer improved strength-to-weight ratios, corrosion resistance, and high-temperature stability. Example: The use of carbon fiber composites in the Boeing 787 Dreamliner’s fuselage reduces weight, leading to improved fuel efficiency and reduced emissions. These advancements enable the construction of lighter, more durable aircraft capable of withstanding extreme conditions.

- Avionics and Control Systems

Modern avionics systems provide pilots with enhanced situational awareness, improved navigation capabilities, and automated flight control functions. These systems incorporate advanced sensors, displays, and processing capabilities, enabling safer and more efficient flight operations. Example: The integration of fly-by-wire technology in Airbus aircraft enhances flight stability and reduces pilot workload. Furthermore, the development of autonomous flight control systems is paving the way for unmanned aerial vehicles (UAVs) and future air mobility solutions.

- Propulsion Systems

Ongoing advancements in propulsion technology are essential for improving fuel efficiency, reducing emissions, and increasing aircraft speed and range. This includes the development of more efficient turbofan engines, hybrid-electric propulsion systems, and potentially even hypersonic propulsion technologies. Example: The development of geared turbofan engines by Pratt & Whitney has significantly improved fuel efficiency in narrow-body aircraft. These advancements are crucial for reducing the environmental impact of air travel and enabling longer-range flights.

- Digital Engineering and Manufacturing

The adoption of digital engineering tools and advanced manufacturing techniques is transforming the aerospace industry. This includes the use of computer-aided design (CAD), computer-aided manufacturing (CAM), and simulation tools for designing and optimizing aircraft components. Example: The use of additive manufacturing (3D printing) for producing complex engine parts allows for greater design freedom and reduced manufacturing lead times. These technologies streamline the development process, reduce costs, and improve product quality.

The integration of these technological advancements is not merely about improving existing capabilities; it’s about fundamentally transforming the industry. By embracing innovation and investing in research and development, it can achieve a competitive edge and contribute to advancements in global aviation and defense capabilities.

4. Collaboration

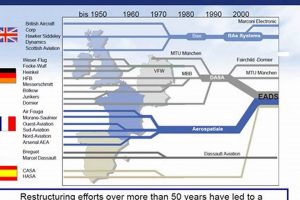

Collaboration is a critical enabler within aerospace industries, fostering innovation, risk mitigation, and market expansion. Aerospace projects are inherently complex and require specialized expertise that often resides across multiple organizations. Collaboration facilitates the pooling of resources, knowledge, and technologies, accelerating the development and deployment of advanced aerospace solutions. A cause-and-effect relationship exists whereby collaboration leads to increased innovation, reduced development time, and improved product quality. Without effective collaboration, aerospace firms risk duplication of effort, technological stagnation, and loss of competitiveness. A prime example is the collaborative development of the Airbus A380, which involved multiple European nations and suppliers, each contributing specialized components and expertise. The success of such large-scale projects hinges on seamless collaboration across organizational boundaries.

The benefits of collaboration extend beyond product development. Strategic alliances and joint ventures enable access to new markets, distribution channels, and technological capabilities. For instance, partnerships between established aerospace firms and emerging technology companies are becoming increasingly common. These partnerships facilitate the integration of disruptive technologies, such as artificial intelligence and advanced sensors, into existing aerospace platforms. Moreover, international collaborations are crucial for navigating complex regulatory environments and securing government contracts. Many defense projects require multinational cooperation to share development costs and ensure interoperability of systems. This understanding is practically significant as it highlights the need for fostering strong relationships with partners and establishing effective communication and coordination mechanisms.

In summary, collaboration is not merely a desirable attribute but a fundamental requirement for success within this sector. It fosters innovation, mitigates risks, and expands market reach. Challenges include managing intellectual property rights, aligning strategic objectives, and overcoming cultural barriers. However, the potential rewards of successful collaboration far outweigh the challenges, making it an essential component of any comprehensive aerospace strategy. Effective collaborative practices can lead to the development of cutting-edge technologies, the creation of economic opportunities, and the enhancement of national security.

5. Defense

Defense capabilities are intrinsically linked to the capacities within this industrial sector. The ability to design, manufacture, and maintain advanced aerospace systems directly contributes to a nation’s security and strategic autonomy. A robust defense industry fosters technological innovation, reduces reliance on foreign suppliers, and enhances operational effectiveness.

- Military Aircraft Production

The production of military aircraft, including fighter jets, transport planes, and surveillance aircraft, constitutes a core component. This involves the integration of advanced technologies, such as radar systems, electronic warfare suites, and precision-guided munitions. As an example, the production of advanced fighter jets equips a nation’s air force with the capability to defend its airspace and project power. These activities also stimulate economic growth by creating high-skilled jobs and generating export revenue.

- Unmanned Aerial Systems (UAS) Development

The development and deployment of UAS, commonly known as drones, is increasingly critical for modern defense operations. UAS provide valuable intelligence, surveillance, and reconnaissance (ISR) capabilities, as well as the ability to conduct targeted strikes. For example, UAS can be used to monitor borders, track enemy movements, and conduct search and rescue missions. The development of UAS also drives innovation in areas such as autonomous flight control, sensor technology, and data analytics.

- Maintenance, Repair, and Overhaul (MRO) Services

The provision of MRO services is essential for maintaining the operational readiness of military aircraft. This includes routine inspections, repairs, and overhauls, as well as upgrades to extend the service life of existing platforms. For instance, the MRO of military transport planes ensures their ability to deliver troops and supplies to remote locations. These services require specialized expertise and infrastructure, creating opportunities for skilled technicians and engineers.

- Development of Missile Systems

The design and manufacturing of missile systems, including air-to-air, surface-to-air, and ballistic missiles, contributes significantly to a nation’s defense capabilities. These systems provide a deterrent against potential adversaries and the ability to respond to threats. An illustration is the development of anti-ship missiles, which can protect naval vessels from attack. The creation and maintenance of these missile systems require expertise in propulsion, guidance, and warhead technology.

These various facets underscore the critical role in supporting national defense objectives. Investment in this sector enhances security, stimulates economic growth, and promotes technological innovation. The ability to indigenously develop and maintain advanced aerospace systems provides a strategic advantage, reduces reliance on foreign sources, and strengthens overall national resilience.

6. Innovation

Innovation serves as a cornerstone for advancement within aerospace, fundamentally influencing capabilities and competitiveness. It drives the development of novel technologies, processes, and business models that enable progress across all facets of the industry. For enterprises operating in this domain, a commitment to innovation is not merely an option but a strategic imperative for long-term sustainability and market leadership.

- Advanced Materials Research

The pursuit of new materials with enhanced properties, such as lighter weight, greater strength, and improved heat resistance, is a critical area of innovation. This involves research into composites, alloys, and nanomaterials that can improve aircraft performance, reduce fuel consumption, and increase durability. An example includes the development of ceramic matrix composites for high-temperature engine components, enabling greater efficiency and reduced emissions. The adoption of these advanced materials has significant implications for the design, manufacturing, and operational capabilities within aerospace, influencing both commercial and defense applications.

- Autonomy and Artificial Intelligence Integration

The incorporation of autonomy and AI into aerospace systems is transforming flight operations, maintenance practices, and decision-making processes. This includes the development of autonomous flight control systems, predictive maintenance algorithms, and AI-powered mission planning tools. An illustration is the use of AI to optimize flight routes and reduce fuel consumption, resulting in cost savings and environmental benefits. The integration of these technologies has far-reaching implications for the future of aviation, potentially leading to unmanned aerial vehicles (UAVs), autonomous air taxis, and more efficient air traffic management systems.

- Digital Manufacturing Technologies

The application of digital manufacturing technologies, such as 3D printing, robotic automation, and virtual reality, is revolutionizing aerospace production processes. These technologies enable the creation of complex parts with greater precision, reduced waste, and shorter lead times. One case is the 3D printing of lightweight engine components, allowing for more intricate designs and improved performance. Digital manufacturing not only reduces costs and improves efficiency but also enables the development of customized solutions tailored to specific customer needs.

- Sustainable Aviation Solutions

The pursuit of sustainable aviation solutions is driving innovation across the industry, including the development of alternative fuels, electric propulsion systems, and more efficient aircraft designs. This involves research into biofuels, hydrogen fuel cells, and hybrid-electric engines that can reduce emissions and mitigate the environmental impact of air travel. A real-world example involves the development of blended wing body aircraft, which offer improved aerodynamic efficiency and reduced fuel consumption. The shift towards sustainable aviation has significant implications for the industry, requiring collaboration between manufacturers, airlines, and policymakers to achieve ambitious environmental goals.

These innovative facets are interconnected, collectively contributing to advancements in performance, safety, and sustainability. Continuous investment in these areas is essential for enterprises aiming to maintain a competitive edge and contribute to the evolution of the aerospace sector. The implications extend beyond technological advancements, influencing economic growth, job creation, and national security. By embracing a culture of innovation and fostering collaboration across disciplines, enterprises can unlock new possibilities and shape the future of flight.

Frequently Asked Questions

The following addresses commonly encountered queries regarding operations within this industrial segment. It provides concise and factual responses intended to clarify ambiguities and enhance overall understanding.

Question 1: What constitutes the core business activities?

Core business activities encompass the design, manufacturing, and maintenance of aircraft, spacecraft, and related systems. These activities extend to research and development of new technologies, integration of advanced avionics, and the provision of engineering services to both commercial and defense clients.

Question 2: How does investment contribute to national security?

Investment strengthens national security by fostering technological independence, reducing reliance on foreign suppliers, and enabling the development of advanced defense systems. A robust presence within this sector ensures a nation’s ability to maintain its aerospace capabilities and respond effectively to emerging threats.

Question 3: What are the key technological trends impacting the industry?

Key technological trends include the adoption of advanced materials, such as composites and alloys; the integration of artificial intelligence and autonomous systems; the development of sustainable aviation technologies; and the implementation of digital manufacturing processes.

Question 4: How are quality control and safety ensured?

Quality control and safety are ensured through rigorous adherence to industry standards, comprehensive testing and inspection procedures, and the implementation of robust quality management systems. Independent audits and regulatory oversight further contribute to maintaining the highest levels of safety and reliability.

Question 5: What types of career opportunities are available?

Career opportunities span a wide range of disciplines, including engineering, manufacturing, research and development, project management, and logistics. The sector requires skilled professionals with expertise in areas such as aerodynamics, propulsion, avionics, and materials science.

Question 6: What are the challenges currently faced?

Current challenges include navigating complex regulatory environments, managing supply chain disruptions, addressing cybersecurity threats, and attracting and retaining skilled talent. Additionally, adapting to evolving customer demands and maintaining competitiveness in a global marketplace presents ongoing challenges.

In summary, understanding these key aspects is essential for appreciating the significance and complexities within this sector. Ongoing advancements and evolving challenges necessitate continuous adaptation and strategic planning.

The next section will explore case studies illustrating successful strategies and highlighting lessons learned.

Concluding Remarks

The preceding analysis has explored the multifaceted nature of Sharq Aerospace Industries. It has examined its role in manufacturing, maintenance, technological advancement, collaboration, defense capabilities, and innovation. Understanding these elements is essential for comprehending its contribution to both economic development and national security. The discussion has illuminated the complexities involved in operating within this highly specialized sector, emphasizing the importance of strategic planning, technological adaptation, and collaborative partnerships.

Continued progress hinges on sustained investment in research and development, a commitment to quality and safety, and the cultivation of a highly skilled workforce. The sector faces significant challenges, including navigating regulatory landscapes and adapting to rapid technological change. Overcoming these challenges will be crucial for ensuring its long-term viability and maximizing its potential to shape the future of aviation and defense. Further investigation and continued commitment to excellence are necessary to unlock the full potential and contribution of Sharq Aerospace Industries in the global landscape.