An enterprise operating within the Upstate South Carolina region specializes in providing services and products to the aerospace and defense sectors. The organization is located in Greenville and focuses on technological solutions and support for related industries. Its activities encompass a range of services, including maintenance, repair, and overhaul (MRO) operations, systems integration, and engineering support.

The presence of such a company in Greenville contributes to the regional economy by creating skilled jobs and attracting related businesses. It also enhances the area’s reputation as a hub for advanced manufacturing and technological innovation. The organization’s work supports national defense initiatives and strengthens the domestic aerospace supply chain. Historically, companies in this sector have played a vital role in technological advancements and national security.

This introduction sets the stage for a more in-depth exploration of specific capabilities, operational details, and contributions made by organizations like this one to the aerospace and defense landscape. Further discussion will cover areas such as technological capabilities, economic impact, and strategic importance within the broader industry.

Operational Best Practices

The following principles are derived from organizational models similar to that of entities that serve the aerospace and defense sectors in locations such as Greenville, SC. These best practices aim to improve efficiency, ensure compliance, and drive innovation.

Tip 1: Emphasize Rigorous Quality Control: Implementing stringent quality control measures throughout all stages of operation is crucial. This includes adhering to industry standards such as AS9100 and conducting regular audits to identify and rectify potential issues.

Tip 2: Invest in Employee Training and Development: A highly skilled workforce is essential. Continuous training programs focusing on technical expertise, safety protocols, and emerging technologies are vital for maintaining a competitive edge and ensuring operational excellence.

Tip 3: Prioritize Cybersecurity: Protecting sensitive data and intellectual property is paramount. Robust cybersecurity measures, including regular vulnerability assessments, penetration testing, and employee training on data protection, are necessary to mitigate risks.

Tip 4: Streamline Supply Chain Management: Efficient supply chain management is crucial for minimizing disruptions and optimizing costs. This includes establishing strong relationships with reliable suppliers, implementing inventory management systems, and diversifying sourcing options.

Tip 5: Foster a Culture of Innovation: Encouraging employees to explore new technologies and innovative solutions is essential for staying ahead in the competitive aerospace and defense landscape. This can be achieved through research and development initiatives, employee suggestion programs, and partnerships with academic institutions.

Tip 6: Maintain Compliance with Regulatory Requirements: Adhering to all applicable regulations, including those related to environmental protection, safety, and export control, is critical. Regular audits and legal counsel should be utilized to ensure ongoing compliance.

These operational best practices are essential for organizations aiming to achieve sustainable success in the demanding aerospace and defense industries. Adherence to these principles can result in improved efficiency, reduced costs, and enhanced customer satisfaction.

The next phase involves summarizing the core concepts presented and contextualizing them within the broader framework of achieving strategic objectives in the aerospace and defense market.

1. Engineering

Engineering forms the bedrock of operations for organizations like the one in Greenville, SC, that support the aerospace and defense sectors. It is the foundational element driving design, development, and maintenance of critical systems and components. Without robust engineering capabilities, the organization cannot effectively meet the complex demands of its clientele. The cause-and-effect relationship is straightforward: sophisticated engineering talent and processes directly result in superior product and service offerings. For example, precise engineering is necessary for the MRO (Maintenance, Repair, and Overhaul) services provided, ensuring aircraft components meet exacting safety and performance standards. Furthermore, it’s vital for integrating new technologies into existing platforms and creating innovative solutions tailored to specific client needs. The practical significance lies in maintaining operational readiness, enhancing performance, and ensuring the longevity of aerospace and defense assets.

Engineering within this context extends beyond basic design and maintenance. It encompasses systems engineering, materials science, electrical engineering, and software engineering. Each discipline plays a crucial role in delivering integrated solutions. Consider the development of advanced sensor systems, a common need in the defense sector. This necessitates a multi-disciplinary engineering approach, combining expertise in optics, signal processing, and embedded systems. Successful implementation requires rigorous testing and validation, often involving simulations and field trials. These engineering-driven processes directly contribute to improved accuracy, reliability, and overall performance of the systems. Further applications include developing lightweight and durable materials for aircraft structures, designing efficient power systems, and creating advanced control algorithms for unmanned aerial vehicles (UAVs).

In summary, engineering is an indispensable element for the success and viability of aerospace and defense organizations. The presence of a strong engineering base allows the organization to provide high-quality services, develop innovative solutions, and maintain a competitive edge. Challenges in this area include attracting and retaining top engineering talent, keeping pace with rapidly evolving technologies, and managing complex regulatory requirements. The ability to overcome these challenges will determine the long-term success and contribution of organizations in Greenville, SC, and similar locations within the broader aerospace and defense industry.

2. Manufacturing

Manufacturing forms a critical pillar within the operations of entities similar to those found near Greenville, SC, supporting the aerospace and defense sectors. It directly impacts product quality, production efficiency, and overall competitiveness, linking technical design to tangible output.

- Precision Component Fabrication

The aerospace and defense industries demand extremely precise components, often requiring tolerances measured in microns. Manufacturing processes such as CNC machining, additive manufacturing (3D printing), and specialized welding techniques are employed to meet these exacting standards. Failure to achieve the required precision can compromise system performance, safety, and reliability. For example, turbine blades in jet engines must be manufactured to incredibly tight specifications to withstand extreme temperatures and rotational speeds. Entities involved in supporting such systems must possess advanced manufacturing capabilities.

- Materials Engineering and Processing

Aerospace and defense applications frequently utilize advanced materials like titanium alloys, composites, and high-strength steels. These materials require specialized processing techniques, including heat treatment, surface coating, and non-destructive testing to ensure structural integrity and resistance to environmental factors. Proper material selection and processing are crucial for meeting stringent performance requirements and extending the lifespan of components. Companies involved in supporting these industries must have expertise in material science and processing methods to maintain and repair existing systems.

- Assembly and Integration

The assembly and integration of complex aerospace and defense systems require meticulous planning, skilled labor, and rigorous quality control procedures. Components from various sources must be seamlessly integrated to function as a cohesive unit. This often involves intricate wiring harnesses, hydraulic systems, and electronic control systems. For instance, the assembly of aircraft wings requires precise alignment and fastening techniques to ensure structural integrity and aerodynamic performance. Organizations involved in manufacturing these systems must possess the expertise and infrastructure to manage complex assembly processes and maintain stringent quality standards.

- Quality Assurance and Testing

Robust quality assurance and testing procedures are essential to verify that manufactured components and systems meet specified requirements and performance standards. This includes dimensional inspection, non-destructive testing (NDT), functional testing, and environmental testing. Any deviation from the prescribed standards must be identified and rectified before the component or system is deployed. Companies that contribute to the manufacturing aspects of these systems must be equipped with advanced testing equipment and expertise to ensure compliance with industry regulations and customer specifications.

These manufacturing facets directly influence the performance and reliability of aerospace and defense systems. The capacity to execute precision manufacturing is key for any firm to compete in the aerospace and defense arena. Investment in equipment, expertise, and streamlined processes related to manufacturing impacts overall success and supports industry activities.

3. Compliance

Adherence to regulatory standards and industry best practices constitutes a critical function for any organization operating within the aerospace and defense sectors, particularly for entities situated in locations like Greenville, SC. Compliance dictates how the organization conducts its operations, manages risk, and ensures the safety and reliability of its products and services. Failure to maintain stringent compliance protocols can result in severe penalties, reputational damage, and legal liabilities.

- Federal Aviation Administration (FAA) Regulations

The FAA establishes comprehensive regulations governing the design, production, maintenance, and operation of aircraft and aviation-related systems. Organizations providing MRO services or manufacturing aircraft components must demonstrate adherence to these standards. For instance, compliance with FAA Part 145 regulations is essential for MRO facilities to maintain their certification and legally perform maintenance on aircraft registered in the United States. Non-compliance can lead to revocation of certifications, grounding of aircraft, and significant financial penalties.

- International Traffic in Arms Regulations (ITAR)

ITAR controls the export and import of defense-related articles and services. Any entity involved in the design, manufacture, or export of items listed on the United States Munitions List (USML) must comply with ITAR. This includes obtaining necessary licenses and adhering to stringent security protocols to prevent unauthorized access or transfer of controlled technology. Violations of ITAR can result in substantial fines, imprisonment, and debarment from future government contracts.

- Export Administration Regulations (EAR)

EAR governs the export and re-export of dual-use items, meaning items that have both commercial and military applications. Compliance with EAR requires classifying products correctly, obtaining export licenses when necessary, and adhering to restrictions on exports to certain countries or end-users. Failure to comply with EAR can lead to civil and criminal penalties, including fines and imprisonment.

- AS9100 Quality Management System

AS9100 is a widely recognized quality management standard specific to the aerospace industry. Certification to AS9100 demonstrates an organization’s commitment to quality, safety, and reliability. Compliance with AS9100 involves implementing a robust quality management system, conducting regular audits, and continuously improving processes to meet customer requirements and regulatory expectations. Maintaining AS9100 certification is often a prerequisite for contracting with major aerospace and defense companies.

These compliance factors underscore the regulatory intensity surrounding aerospace and defense operations. Organizations servicing this market, as one would find in Greenville, SC, must dedicate resources and expertise to ensuring adherence to these multifaceted requirements. Regulatory compliance supports safe operations and contributes to maintaining reliability in the industries.

4. Innovation

Innovation is a fundamental driver for organizations in the aerospace and defense sectors, particularly those with a regional focus such as entities near Greenville, SC. Sustained competitiveness and the ability to address evolving industry demands necessitate a continuous pursuit of new technologies, processes, and business models.

- Advanced Materials and Manufacturing Techniques

Innovation in materials science and manufacturing processes is crucial for developing lighter, stronger, and more durable components. The application of advanced composites, additive manufacturing (3D printing), and nanotechnology can enhance the performance and reduce the lifecycle costs of aerospace and defense systems. For example, 3D printing allows for the creation of complex geometries and customized parts, enabling faster prototyping and more efficient production runs. This capability is particularly relevant for organizations seeking to support niche markets or rapidly respond to changing customer needs.

- Digitalization and Automation

The integration of digital technologies, such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), can transform various aspects of aerospace and defense operations. AI and ML algorithms can be used for predictive maintenance, anomaly detection, and autonomous systems control. IoT sensors can provide real-time data on equipment performance, enabling proactive maintenance and improved operational efficiency. Automation technologies, such as robotics and automated inspection systems, can streamline manufacturing processes and reduce labor costs.

- Cybersecurity Solutions

As aerospace and defense systems become increasingly interconnected and reliant on digital technologies, cybersecurity becomes a paramount concern. Innovation in cybersecurity is essential for protecting sensitive data, preventing cyberattacks, and ensuring the integrity and resilience of critical infrastructure. This includes developing advanced threat detection systems, encryption technologies, and secure communication protocols. Furthermore, it necessitates implementing robust cybersecurity policies and procedures, as well as training employees to recognize and respond to cyber threats.

- Sustainable Technologies

Growing environmental concerns and regulatory pressures are driving innovation in sustainable technologies for the aerospace and defense sectors. This includes developing more fuel-efficient aircraft, alternative propulsion systems (e.g., electric or hybrid-electric propulsion), and environmentally friendly manufacturing processes. The use of biofuels and other sustainable materials can reduce the carbon footprint of aerospace operations. Furthermore, innovative waste management and recycling practices can minimize the environmental impact of manufacturing and maintenance activities.

These innovative facets exemplify the ways in which organizations in the aerospace and defense sectors, especially those located near Greenville, SC, can enhance their capabilities, improve their competitiveness, and contribute to the advancement of the industry. By embracing these technological developments, entities can address the industry’s evolving requirements and sustain long-term growth.

5. Partnerships

Strategic alliances represent a critical component for any organization seeking to thrive within the aerospace and defense sectors, including a hypothetical “stevens aerospace and defense systems greenville sc.” The ability to forge and maintain effective partnerships directly affects access to resources, technological expertise, and market opportunities. This cause-and-effect relationship is evident in how collaborative ventures often enable access to specialized skill sets or proprietary technologies that would otherwise remain inaccessible. The significance of these partnerships lies in their capacity to enhance operational capabilities, expand market reach, and mitigate risks associated with technological development and market volatility. For example, a partnership with a university research lab could provide access to cutting-edge materials science expertise, while a collaboration with a larger defense contractor could open doors to significant government contracts. These collaborations allow each entity to leverage the strengths of the other, resulting in a synergistic effect that benefits all parties involved.

The practical application of strategic alliances extends to various aspects of the business. In manufacturing, partnerships with specialized component suppliers can ensure a reliable supply chain and access to high-quality parts. In research and development, collaborative projects can accelerate the development of new technologies and reduce the financial burden on individual entities. Furthermore, partnerships with international firms can facilitate access to global markets and navigate complex regulatory landscapes. For example, an organization specializing in aircraft maintenance might partner with an avionics manufacturer to offer comprehensive upgrade packages, or with a logistics firm to streamline spare parts delivery. These collaborations enable a broader range of services and provide a competitive edge. Moreover, a joint venture with a foreign firm can create localized production facilities, overcoming trade barriers and reducing transportation costs.

In summary, strategic alliances are not merely beneficial but often essential for sustained success within the aerospace and defense sectors. The ability to cultivate and manage effective partnerships can significantly enhance an organization’s competitiveness, promote innovation, and expand market reach. Challenges associated with partnerships include aligning strategic goals, managing intellectual property, and navigating cultural differences. Ultimately, successful organizations in the space must view partnerships as an integral part of their business strategy, fostering collaborative relationships that drive mutual growth and address the evolving needs of the industry.

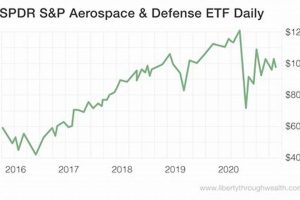

6. Economic Impact

The economic consequences of an aerospace and defense entity in Greenville, SC, are multifaceted, exerting substantial influence on the regional and state economies. Such an organization generates direct employment opportunities for engineers, technicians, manufacturing personnel, and administrative staff. This employment base precipitates indirect economic benefits, as employees spend their wages within the local community, supporting businesses and services. Furthermore, the presence of such a business attracts other related enterprises, forming a cluster that enhances the region’s reputation as a center for advanced manufacturing and technology. Real-world examples include the creation of ancillary industries, such as specialized tooling suppliers, calibration services, and logistics providers, all of which contribute to the regional gross domestic product (GDP). The significance of this economic contribution is reflected in increased tax revenues, improved infrastructure, and enhanced quality of life for local residents.

The practical implications of an aerospace and defense presence extend beyond immediate job creation. These organizations often engage in research and development activities, fostering innovation and technological advancements that can have broader applications across various sectors. This can attract investment from venture capital firms and other funding sources, further stimulating economic growth. Moreover, these entities often collaborate with local universities and technical colleges, providing internships and training opportunities that strengthen the workforce. The presence of a skilled workforce then becomes a powerful incentive for other high-tech companies to locate in the area, creating a virtuous cycle of economic development. Defense contracts awarded to such entities also bring federal dollars into the region, injecting capital into the local economy and supporting national defense initiatives. This flow of funds often facilitates infrastructure upgrades, further promoting economic activity.

In conclusion, the economic impact of an aerospace and defense enterprise is substantial and far-reaching. While immediate job creation is significant, the long-term effects on innovation, workforce development, and regional economic diversification are equally important. Potential challenges include adapting to fluctuations in defense spending and maintaining a competitive edge in a rapidly evolving industry. The organization’s strategic alignment with regional economic development goals and its ability to foster collaboration with other entities will be crucial for maximizing its economic contributions over the long term.

Frequently Asked Questions

The following section addresses common inquiries related to operations within the aerospace and defense sector in Greenville, SC. These questions aim to clarify the scope, function, and impact of entities in this industry.

Question 1: What types of services are typically offered?

Organizations often provide maintenance, repair, and overhaul (MRO) services for aircraft and related components. They may also engage in systems integration, engineering design, and manufacturing of specialized parts.

Question 2: What certifications are typically required for operation?

Entities usually require certifications such as AS9100 for quality management, FAA Part 145 for aircraft maintenance, and compliance with ITAR and EAR for export control regulations.

Question 3: What skills are in demand for employees?

High-demand skills generally include engineering (aerospace, mechanical, electrical), avionics technology, CNC machining, quality assurance, and project management.

Question 4: How do these entities contribute to the local economy?

These operations contribute to economic growth through job creation, tax revenue generation, attraction of related businesses, and stimulation of local supply chains.

Question 5: What are common challenges faced in this industry?

Challenges include maintaining regulatory compliance, attracting and retaining skilled workers, managing supply chain disruptions, and adapting to technological advancements.

Question 6: How important is innovation in this sector?

Innovation is crucial for staying competitive and meeting evolving customer needs. It often involves the development of new materials, advanced manufacturing techniques, and digital technologies.

The above questions and answers offer a concise overview of key aspects regarding the aerospace and defense sector within a regional context. This information is intended to provide a general understanding of the industry’s operations and impacts.

Subsequent sections will delve deeper into specific topics related to the ongoing developments and strategic considerations within the aerospace and defense landscape.

Concluding Remarks

The preceding discussion has illuminated the operational framework of an aerospace and defense enterprise, exemplified by a hypothetical “stevens aerospace and defense systems greenville sc.” From engineering and manufacturing to compliance, innovation, partnerships, and economic impact, each element contributes to the overall success and sustainability of such an organization. This analysis underscores the complex interplay of technical expertise, regulatory adherence, and strategic decision-making required to thrive in a competitive market.

The continued success of organizations like the hypothetical “stevens aerospace and defense systems greenville sc” hinges on their ability to adapt to evolving industry dynamics, cultivate strategic partnerships, and prioritize innovation. Investment in workforce development and adherence to ethical business practices are essential for long-term viability. The broader implications of these activities suggest a need for ongoing dialogue between industry stakeholders, government entities, and academic institutions to foster a robust and sustainable aerospace and defense ecosystem. The future trajectory of this sector will depend on a collective commitment to excellence and a proactive approach to addressing emerging challenges.