An entity providing specialized technical support related to the design, development, and maintenance of aircraft and spacecraft is often structured as a joint stock company. These organizations offer a range of expertise, from initial concept design and computational fluid dynamics analysis to structural testing and certification support. For instance, such a firm might assist in optimizing the aerodynamic performance of a new aircraft wing or ensuring the structural integrity of a satellite component.

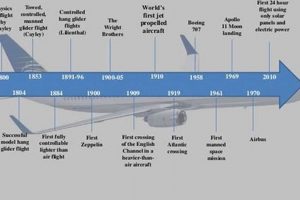

The significance of these specialized companies lies in their capacity to augment the resources of larger aerospace manufacturers or governmental agencies. They provide a flexible workforce and specialized knowledge base, enabling projects to proceed efficiently and cost-effectively. Their historical context reflects the increasing complexity of aerospace projects and the need for readily available, highly skilled engineering support to meet demanding performance and regulatory requirements.

The following sections will explore the specific service offerings, project management methodologies, and quality assurance standards typically employed by entities operating in this sector. Furthermore, examination will be given to the regulatory landscape and the competitive factors shaping the operational strategies of these organizations.

Essential Guidance for Aerospace Engineering Endeavors

The subsequent guidelines are designed to optimize projects within the aerospace engineering domain, drawing upon industry best practices and emphasizing adherence to rigorous standards. These recommendations aim to enhance efficiency, minimize risks, and ensure the successful completion of complex engineering tasks.

Tip 1: Prioritize Comprehensive Requirements Definition: A clearly defined and meticulously documented set of requirements is paramount. Ambiguity at the outset can lead to costly rework and compromised performance. For example, specifications for a satellite payload must explicitly detail weight, power consumption, data throughput, and operational lifespan to avoid design conflicts later in the development cycle.

Tip 2: Implement Robust Risk Management Protocols: Proactive identification and mitigation of potential risks are critical. This includes conducting thorough failure mode and effects analyses (FMEAs) and developing contingency plans for critical system components. Consider the potential for radiation damage to electronic components in spacecraft and implement appropriate shielding or redundancy measures.

Tip 3: Emphasize Rigorous Testing and Validation: Comprehensive testing at each stage of development is essential to verify compliance with requirements and identify potential flaws. This may involve wind tunnel testing of aircraft designs, vibration testing of satellite structures, and extensive software simulation to predict system behavior under various operating conditions.

Tip 4: Foster Effective Communication and Collaboration: Seamless communication between engineering teams, suppliers, and stakeholders is vital for project success. Utilize standardized communication protocols and collaborative platforms to ensure that all parties are informed and aligned on project goals and progress. Regular progress reports and design reviews can facilitate early detection and resolution of issues.

Tip 5: Maintain Strict Configuration Management: Accurate and up-to-date configuration management is crucial for controlling changes and ensuring traceability throughout the project lifecycle. Employ a robust version control system to track modifications to designs, software code, and documentation. This is particularly important when managing complex systems with numerous interconnected components.

Tip 6: Adhere to Stringent Quality Assurance Procedures: Implement a comprehensive quality assurance program to ensure that all processes and products meet the required standards. This includes conducting regular audits, implementing corrective action plans, and maintaining detailed documentation of all quality control activities. Compliance with relevant industry standards, such as ISO 9001 or AS9100, is essential.

Tip 7: Embrace Continuous Improvement: Continuously seek opportunities to improve processes, products, and services through feedback, analysis, and the adoption of new technologies. Implement a system for capturing lessons learned from past projects and incorporating them into future endeavors. This can lead to increased efficiency, reduced costs, and enhanced performance.

In summary, adherence to these guidelines can significantly enhance the likelihood of success in aerospace engineering projects. By prioritizing comprehensive planning, robust risk management, rigorous testing, and effective communication, organizations can mitigate potential challenges and deliver high-quality solutions.

The subsequent discussions will delve into specific technical challenges and innovative solutions within the aerospace engineering field.

1. Expertise and Specialization

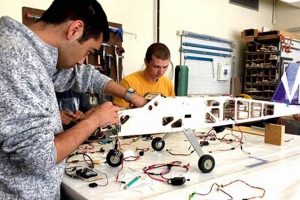

The efficacy of organizations providing aerospace engineering services hinges fundamentally on the depth and breadth of their technical expertise. The modern aerospace sector demands a high degree of specialization across diverse engineering disciplines. Therefore, a company offering such services must possess or have access to experts in fields such as aerodynamics, propulsion systems, materials science, avionics, structural analysis, and software engineering. The specific composition of this expertise dictates the types of projects an entity can effectively undertake and the level of sophistication it can bring to bear on engineering challenges.

The connection is a direct cause and effect. A company lacking the requisite expertise cannot successfully deliver specialized engineering solutions. For instance, designing a novel aircraft wing requires expertise in computational fluid dynamics, materials properties, and flight control systems. Similarly, developing satellite propulsion systems necessitates specialized knowledge of rocket engine design, propellant chemistry, and orbital mechanics. A lack of proficiency in these areas results in suboptimal designs, increased risk of failure, and ultimately, compromised performance. A practical example is the collaboration of such a services company with a traditional aircraft manufacturer. The services company may be brought in specifically because of their deep specialization in composite materials to design a lighter, stronger fuselage component that directly improves fuel efficiency and aircraft range.

In conclusion, the success and value proposition are inextricably linked to the possession of deep and varied expertise. This expertise enables innovation, mitigates risk, and drives efficiency in aerospace projects. The ongoing evolution of the aerospace industry necessitates continuous investment in training and development to maintain a competitive edge and address emerging technological challenges. The ability to adapt and acquire new skillsets is, therefore, as crucial as possessing expertise in established domains.

2. Regulatory Compliance

Regulatory compliance forms an indispensable component of operations. The aerospace sector operates under stringent regulations imposed by national and international bodies, such as the Federal Aviation Administration (FAA) in the United States or the European Union Aviation Safety Agency (EASA). These regulations govern every aspect of aircraft and spacecraft design, manufacturing, operation, and maintenance. A specialized firm assists its clients in navigating this complex regulatory landscape, ensuring that all products and services adhere to applicable rules and standards. Failure to comply results in significant penalties, including project delays, fines, and potentially, revocation of operating licenses. A cause-and-effect relationship exists between robust compliance practices and the ability to legally operate within the aerospace market.

The importance of regulatory compliance stems from the inherently high-risk nature of aerospace activities. Safety is paramount, and regulations are designed to minimize the potential for accidents and incidents. A real-life example is the certification process for a new aircraft engine. An aerospace engineering services firm might be contracted to conduct the necessary testing and analysis to demonstrate compliance with FAA engine certification standards, ensuring the engine meets stringent safety and performance requirements before it is approved for use. This practical application showcases the reliance on expertise to bridge the gap between design and regulatory acceptance.

In conclusion, rigorous adherence to regulatory frameworks is not merely a legal obligation but a fundamental prerequisite for survival in the aerospace industry. Specialized firms play a vital role in enabling aerospace manufacturers and operators to meet these demanding requirements, thus ensuring the safety, reliability, and integrity of aerospace systems. Challenges lie in keeping abreast of constantly evolving regulations and developing innovative solutions that simultaneously meet performance objectives and regulatory mandates. The ability to effectively manage and navigate this complex regulatory environment distinguishes successful organizations from their less capable counterparts.

3. Project Lifecycle Support

Project lifecycle support constitutes a core offering. Such services encompass activities spanning the entire timeline of an aerospace project, from initial conceptual design to final decommissioning and disposal. These services directly address the multifaceted needs of aerospace manufacturers, operators, and government agencies throughout the various stages of a project’s existence. The absence of such comprehensive support can lead to inefficiencies, increased costs, and heightened risks during development, implementation, and operation. A cause-and-effect relationship exists wherein robust lifecycle support directly contributes to the long-term success and sustainability of aerospace endeavors. For example, a firm specializing in these services may be involved in the design phase of a new aircraft, providing expertise in areas such as structural analysis and aerodynamic optimization. Subsequently, the same firm may offer support during the manufacturing phase, ensuring quality control and adherence to design specifications. Finally, the firm may provide ongoing maintenance and repair services throughout the aircraft’s operational life.

The significance stems from the complex and demanding nature of aerospace projects. These projects often involve intricate technologies, stringent regulatory requirements, and substantial financial investments. A real-world example is the development and deployment of a satellite constellation. An aerospace engineering services firm may provide support in areas such as orbital mechanics, communication systems design, and launch vehicle integration. Furthermore, the firm may offer ongoing monitoring and control services throughout the satellite constellation’s operational life, ensuring optimal performance and longevity. The practical application of this support extends to preventing potential failures, optimizing resource utilization, and ensuring mission success.

In conclusion, project lifecycle support represents a critical component of value proposition. It enables clients to mitigate risks, reduce costs, and enhance the overall efficiency of aerospace projects. Ongoing challenges include adapting to evolving technologies, addressing emerging regulatory requirements, and managing complex project interdependencies. The ability to provide comprehensive, integrated support throughout the entire project lifecycle distinguishes successful service providers in this competitive market.

4. Technological Advancement

The integration of technological advancements forms a critical aspect of the services offered. The aerospace industry is characterized by its constant pursuit of innovation, necessitating continuous adoption of new technologies. The relationship is causal: the effectiveness and competitiveness of service providers directly correlate with their ability to leverage and implement cutting-edge technologies. For instance, the use of advanced simulation software for aerodynamic analysis, the adoption of additive manufacturing for rapid prototyping, or the application of artificial intelligence for predictive maintenance are all dependent on the service provider’s capacity to integrate these developments into their operational framework. In this context, a company may invest significantly in developing digital twins of aircraft components to facilitate predictive maintenance, reducing downtime and improving operational efficiency for its clients.

The importance of incorporating technological progress lies in its potential to optimize performance, reduce costs, and enhance safety. Service providers equipped with the latest tools and techniques are better positioned to deliver superior solutions to their clients. Consider the application of advanced sensor technology for structural health monitoring. By continuously monitoring the structural integrity of an aircraft or spacecraft, these sensors enable early detection of potential defects, preventing catastrophic failures and extending the operational lifespan of the asset. The practical significance of this understanding is clear: organizations that embrace technological advancements are more likely to succeed in the competitive aerospace market.

In conclusion, the successful implementation of new technologies represents a fundamental driver of value and competitive advantage. Challenges include the high cost of investment in research and development, the need for specialized expertise to operate and maintain advanced systems, and the constant pressure to adapt to evolving technological landscape. However, companies that overcome these challenges and effectively integrate new technologies into their service offerings are poised to thrive in the dynamic and demanding environment of the aerospace industry.

5. Quality Assurance

Quality Assurance (QA) represents a foundational pillar in the provision of aerospace engineering services. Its systematic implementation is critical for ensuring the reliability, safety, and performance of aerospace systems and components. A robust QA framework mitigates risks, reduces costs associated with defects or failures, and facilitates compliance with stringent regulatory requirements. The following facets illustrate the integral role of QA within organizations providing aerospace engineering services.

- Design Verification and Validation

Design verification and validation (V&V) activities ensure that design outputs meet specified requirements and user needs. V&V processes encompass simulations, testing, and inspections conducted throughout the design phase. For example, computational fluid dynamics (CFD) simulations verify aerodynamic performance, while structural analysis validates the integrity of airframe components. Effective V&V minimizes design flaws and enhances the overall performance and safety of aerospace products. Within the context of aerospace engineering services, thorough design V&V mitigates risks associated with design errors, reducing rework and improving project efficiency.

- Process Control and Monitoring

Process control and monitoring involve the establishment and maintenance of procedures to ensure consistent and controlled manufacturing processes. This includes monitoring critical process parameters, such as temperature, pressure, and humidity, and implementing corrective actions when deviations occur. Statistical process control (SPC) techniques are often employed to identify and address process variations. For instance, in the production of composite aircraft components, precise control of resin curing temperature is essential to achieve optimal material properties. By implementing robust process control and monitoring, aerospace engineering services can ensure the consistent production of high-quality components that meet stringent performance requirements.

- Supplier Quality Management

Supplier quality management focuses on ensuring that suppliers of materials, components, and services meet specified quality standards. This involves conducting supplier audits, performing incoming inspections, and implementing supplier corrective action programs. For example, aerospace engineering services might conduct audits of suppliers of avionics components to verify compliance with industry standards and customer requirements. Effective supplier quality management minimizes the risk of defects or non-conformances originating from external sources, thus enhancing the overall quality and reliability of aerospace products.

- Non-Conformance Management and Corrective Action

Non-conformance management and corrective action procedures outline the process for identifying, documenting, and resolving non-conformances or deviations from specified requirements. This includes root cause analysis, corrective action implementation, and verification of effectiveness. For instance, if a manufacturing defect is detected in an aircraft engine component, a non-conformance report is generated, the root cause is identified (e.g., inadequate training), and corrective actions are implemented (e.g., enhanced training program) to prevent recurrence. Robust non-conformance management and corrective action processes ensure that defects are promptly addressed and that preventive measures are implemented to improve overall product quality.

In conclusion, the facets of QA, including design V&V, process control, supplier management, and non-conformance handling, are inextricably linked to the success of companies providing aerospace engineering support. The effective implementation of these QA practices enables these organizations to deliver reliable, safe, and high-performance products and services that meet the exacting demands of the aerospace sector. Continuing advancement and rigor in QA practices remain essential to maintaining competitiveness and upholding the highest standards of excellence.

6. Risk Management

Effective risk management is paramount in the aerospace industry, given the complex and high-stakes nature of its projects. Companies providing aerospace engineering support must implement comprehensive strategies to identify, assess, and mitigate potential risks across all phases of design, development, and operation. These strategies are not merely reactive measures, but proactive, integrated components of the engineering process.

- Technical Risk Assessment

Technical risk assessment involves identifying potential failures, performance shortfalls, and technological uncertainties that could compromise project objectives. Examples include the risk of encountering unforeseen aerodynamic phenomena during flight testing or the potential for material degradation under extreme environmental conditions. Aerospace engineering service providers employ techniques such as Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to systematically evaluate technical risks. Mitigating actions may involve implementing redundancy in critical systems, conducting extensive simulations, or employing more conservative design margins. Proper assessment directly impacts the ability of a service company to deliver reliable solutions.

- Programmatic Risk Management

Programmatic risk management focuses on risks related to budget, schedule, and resources. Delays in component delivery, cost overruns, and staffing shortages can all derail aerospace projects. Service providers utilize tools like Monte Carlo simulation and Earned Value Management (EVM) to model programmatic risks and track project performance. Mitigation strategies involve developing contingency plans, establishing buffer times in project schedules, and closely monitoring project financials. The consequences of inadequate planning can extend to legal action and brand damage, influencing the company’s market standing.

- Safety and Operational Risk Mitigation

Safety and operational risk mitigation addresses risks related to human safety, environmental impact, and operational disruptions. These risks can range from the potential for accidents during testing to the release of hazardous materials. Aerospace engineering service providers implement safety management systems (SMS) and conduct hazard analyses to identify and mitigate these risks. Mitigation strategies include implementing strict safety protocols, providing comprehensive training, and developing emergency response plans. The ethical implications of risk are key, with many companies using the concept of ALARP (As Low As Reasonably Practicable) in their decision-making.

- Regulatory and Compliance Risk

Regulatory and compliance risk involves the potential for non-compliance with applicable laws, regulations, and industry standards. These risks can result in fines, project delays, and reputational damage. Aerospace engineering service providers maintain up-to-date knowledge of relevant regulations and implement compliance programs to ensure adherence. Mitigation strategies include conducting regular audits, providing training on compliance requirements, and establishing clear lines of communication with regulatory agencies. This element of risk is especially critical for those supporting certification processes for new aircraft, ensuring their clients meet global standards.

In summary, robust risk management is integral to the success of specialized aerospace engineering services. By systematically identifying, assessing, and mitigating potential risks across technical, programmatic, safety, and regulatory domains, these entities enable their clients to achieve project objectives safely, efficiently, and reliably. Effective risk mitigation not only protects assets and reputations but also fosters innovation by creating an environment where calculated risks can be taken with confidence. The ability to manage risk effectively is a key differentiator in the competitive aerospace services market.

Frequently Asked Questions

The following section addresses common inquiries regarding the services provided in the aerospace engineering sector. These questions are intended to provide clarity and understanding of the functions and value offered.

Question 1: What specific engineering disciplines are typically encompassed within the scope of these service providers?

The expertise usually spans a wide spectrum, including but not limited to: aerodynamics, structural analysis, propulsion systems, avionics, control systems, materials science, manufacturing engineering, and systems engineering. Specialization often exists within these broad categories, focusing on specific applications such as aircraft design, spacecraft development, or satellite communications.

Question 2: How is intellectual property protected when engaging these types of engineering support?

Intellectual property protection is typically addressed through contractual agreements. Non-disclosure agreements (NDAs) and clearly defined ownership clauses within the service contract are standard practice. Rigorous data security protocols and access controls are also implemented to safeguard sensitive information. The specific measures employed are tailored to the nature of the project and the client’s requirements.

Question 3: What quality assurance certifications are commonly held or required in this sector?

Common certifications include ISO 9001 (Quality Management Systems) and AS9100 (Quality Management Systems Aerospace). These certifications demonstrate adherence to internationally recognized quality standards and provide assurance of consistent performance and reliability. Clients often require specific certifications based on the nature of the project and applicable regulatory requirements.

Question 4: How are project costs typically structured and what factors influence the overall expense?

Project costs can be structured in various ways, including fixed-price contracts, time-and-materials contracts, or cost-plus-fee arrangements. The overall expense is influenced by factors such as project scope, complexity, required expertise, regulatory requirements, and project timeline. Thoroughly defining project requirements and establishing clear communication channels are crucial for managing costs effectively.

Question 5: What is the typical process for engaging these services, from initial inquiry to project commencement?

The process typically begins with an initial consultation to discuss project requirements and objectives. Following this, a formal proposal outlining the scope of work, timeline, and cost estimate is presented. Upon acceptance of the proposal, a contract is executed, and project execution commences. Ongoing communication and progress reports are maintained throughout the project lifecycle.

Question 6: How are potential conflicts of interest addressed when working with multiple clients?

Conflicts of interest are typically addressed through robust internal policies and procedures. These policies may include confidentiality agreements, ethical guidelines, and mechanisms for identifying and resolving potential conflicts. Transparency and open communication with clients are essential for maintaining trust and ensuring impartiality.

This FAQ section aims to provide a clear understanding of the common considerations related to aerospace engineering support. Addressing these questions proactively can facilitate informed decision-making and effective project execution.

The subsequent sections will delve into specific case studies and examples illustrating the practical application of these services in the aerospace industry.

Conclusion

This exploration has detailed the multifaceted nature of aerospace engineering services jsc. The examination included elements such as expertise, regulatory compliance, lifecycle support, technological advancement, quality assurance, and risk management. Each element is critical to the successful operation and sustainability of organizations providing engineering support to the aerospace sector. The stringent requirements and complex challenges inherent in aerospace development necessitate a comprehensive and integrated approach to ensure safety, reliability, and efficiency.

The continuous evolution of the aerospace industry demands constant adaptation and innovation. Organizations must remain vigilant in embracing new technologies, adhering to evolving regulations, and mitigating emerging risks. Continued commitment to excellence in engineering practices will be crucial for maintaining competitiveness and advancing the boundaries of aerospace capabilities. The information presented serves as a foundation for understanding the vital role these organizations play in shaping the future of flight and space exploration.