These positions encompass a range of skilled trades and engineering roles focused on the design, creation, maintenance, and repair of specialized implements and equipment essential for the manufacturing, assembly, and maintenance of aircraft and spacecraft. These roles require precision and a deep understanding of aerospace materials and processes. For instance, a mold maker crafting forms for composite wing components or a technician calibrating precision measuring instruments are examples of individuals in this field.

The specialized work within this sector is vital for ensuring the safety, reliability, and performance of aerospace vehicles. From initial design and fabrication to ongoing maintenance and upgrades, appropriate equipment is indispensable. Historically, skilled artisans painstakingly crafted bespoke tools. Today, computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are integral, demanding expertise in both traditional techniques and advanced digital methodologies.

The subsequent sections will delve into the specific skill sets required, educational pathways to entry, the projected career outlook, and the impact of technological advancements on the evolution of specialized equipment-related careers within the aerospace industry. This will provide a thorough understanding of opportunities and future trends.

Essential Guidance for Careers in the Sector

Navigating the professional landscape requires strategic planning and a commitment to continuous development. The following guidance provides essential insights for those pursuing or advancing careers within the specialized equipment sector.

Tip 1: Acquire Foundational Knowledge. A robust understanding of materials science, manufacturing processes, and engineering principles is paramount. Formal education in mechanical engineering, manufacturing engineering, or a related field provides a strong basis.

Tip 2: Master CAD/CAM Software. Proficiency in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is increasingly critical. Experience with industry-standard programs such as CATIA, Siemens NX, or Mastercam is highly valued.

Tip 3: Develop Precision Machining Skills. Expertise in operating and maintaining equipment such as CNC milling machines, lathes, and grinders is essential. Hands-on experience through apprenticeships or vocational training programs is beneficial.

Tip 4: Understand Aerospace Standards and Regulations. Familiarity with industry standards set by organizations such as the FAA (Federal Aviation Administration) and AS9100 is crucial. Compliance with these standards is non-negotiable in the aerospace sector.

Tip 5: Pursue Relevant Certifications. Obtaining certifications such as those offered by the National Institute for Metalworking Skills (NIMS) can validate expertise and enhance career prospects.

Tip 6: Network with Industry Professionals. Attending industry conferences, joining professional organizations, and connecting with experienced individuals can provide valuable insights and career opportunities.

Tip 7: Emphasize Problem-Solving Abilities. The ability to diagnose and resolve complex manufacturing challenges is highly sought after. Demonstrating strong analytical and troubleshooting skills is essential.

Success in this field hinges on a combination of technical proficiency, adherence to strict quality standards, and a proactive approach to continuous learning. These guidelines provide a framework for building a rewarding and impactful career within this vital sector.

The concluding section will summarize the key elements discussed and offer a final perspective on the future of equipment-related careers in the aerospace domain.

1. Precision

Precision is not merely a desirable attribute but a fundamental requirement for roles involving specialized equipment within the aerospace industry. The intricate nature of aircraft and spacecraft demands exacting standards in manufacturing, assembly, and maintenance, directly linking precision to the safety, reliability, and performance of aerospace vehicles. Equipment and expertise are crucial for achieving necessary tolerances.

- Dimensional Accuracy

Dimensional accuracy in specialized tools ensures that components meet stringent design specifications. Deviation, even at a microscopic scale, can compromise structural integrity or aerodynamic efficiency. For example, in the production of turbine blades, the molds must be dimensionally perfect to guarantee consistent performance under extreme conditions. The skills of technicians maintaining these tools are vital to maintaining these tolerances.

- Material Compatibility

Materials utilized in aerospace often require unique equipment and specialized techniques. The tools used must have the material hardness, thermal expansion, and corrosion resistance to work with advanced alloys, composites, and ceramics without inducing defects. The creation of jigs and fixtures for assembling carbon fiber components exemplify this need for material compatibility, safeguarding against delamination or structural weakening.

- Calibration and Measurement

Precise calibration and measurement equipment are indispensable for ensuring equipment functions according to specifications. Regular verification and adjustment are necessary to account for wear and tear, environmental factors, and operational drift. Laser trackers and coordinate measuring machines (CMMs) are frequently employed to confirm dimensional accuracy and identify any deviations requiring corrective action.

- Repeatability and Consistency

Achieving repeatable results is vital for mass production. Specialized tools are designed to execute tasks consistently, reducing variability and ensuring uniform quality across all parts. Automated drilling or riveting machines that follow pre-programmed paths are one such example, where the precision of the equipment determines the integrity of the finished product, batch after batch.

The need for precision permeates every aspect. From designing tools to maintaining their functional integrity, skilled technicians must exhibit a mastery of techniques and an unwavering commitment to quality. Precision not only ensures the success of individual operations but also contributes to the overall safety and reliability of flight, impacting the lives of passengers and the operational effectiveness of military assets alike.

2. Manufacturing

The manufacturing sector is inextricably linked to specialized equipment-related roles within the aerospace industry. The efficient and accurate production of aircraft components, from structural elements to intricate engine parts, depends directly on the design, creation, and maintenance of specialized tools. Without skilled professionals developing and managing these tools, the manufacturing of aerospace vehicles would be impossible.

Consider, for example, the production of complex composite structures for modern aircraft wings. This process requires specialized molds, layup tools, and curing fixtures, each meticulously designed and manufactured to precise specifications. Similarly, the fabrication of turbine blades for jet engines demands sophisticated machining tools capable of working with advanced alloys at extremely tight tolerances. These are not off-the-shelf items; they are custom-engineered solutions created by specialized equipment professionals. The effectiveness of the manufacturing process, in terms of speed, cost, and quality, is directly proportional to the capabilities and expertise of those involved in specialized equipment development and maintenance.

In summary, manufacturing acts as the primary domain where the value of specialized equipment professionals becomes most evident. The challenges inherent in aerospace manufacturingcomplex geometries, demanding material requirements, and stringent quality standardsnecessitate a workforce skilled in the design, production, and upkeep of specialized equipment. The relationship underscores the industry’s dependency on these roles for maintaining its competitive edge and ensuring the ongoing advancement of air and space travel.

3. Innovation

Innovation is a critical driver within roles focused on specialized equipment for the aerospace industry. The field’s ever-evolving nature demands continuous improvement and the development of novel solutions to meet new challenges in aircraft design, materials science, and manufacturing processes. The creation of lighter, stronger, and more fuel-efficient aircraft necessitates equipment capable of handling advanced composite materials, complex geometries, and tighter tolerances. Without ongoing innovation in specialized tooling, advancements in aircraft technology would be severely hampered.

Consider the development of additive manufacturing techniques, such as 3D printing, for aerospace components. This requires specialized equipment designed to handle a range of materials, from titanium alloys to high-performance polymers. Professionals involved in these roles must continually innovate to optimize printing processes, improve material properties, and ensure the structural integrity of printed parts. Similarly, the automation of aircraft assembly lines demands the creation of robotic systems capable of performing intricate tasks with speed and precision. These systems rely on advanced sensors, actuators, and control algorithms, all of which require ongoing innovation to enhance efficiency and reduce manufacturing costs. The development of new equipment that allows for non-destructive inspection techniques is critical for ensuring airworthy vehicles.

In summary, innovation forms a cornerstone of specialized equipment-related positions within the aerospace domain. The capacity to design, develop, and implement cutting-edge equipment directly impacts the industry’s ability to push the boundaries of air and space travel. Investment in research and development, coupled with the nurturing of a skilled workforce capable of driving innovation, is crucial for sustaining competitiveness and ensuring the long-term viability of the aerospace industry.

4. Materials

The selection, processing, and application of materials are central to the responsibilities associated with equipment roles in the aerospace sector. The specialized equipment used in the manufacture and maintenance of aircraft and spacecraft is directly determined by the properties and processing requirements of the materials involved. The following details the connection.

- Advanced Composites

The increasing use of carbon fiber reinforced polymers (CFRP) and other advanced composites necessitates specialized equipment for cutting, shaping, and assembling these materials. Ultrasonic cutting tools, automated fiber placement machines, and non-destructive testing equipment are essential for working with composites. The specialized equipment must ensure the structural integrity of these components.

- High-Strength Alloys

Materials such as titanium alloys, nickel-based superalloys, and high-strength aluminum alloys are frequently used in aerospace applications due to their strength-to-weight ratios and high-temperature performance. Machining these alloys requires equipment with high rigidity, power, and precision, along with specialized cutting tools and cooling systems to manage heat generation and prevent work hardening.

- Coatings and Surface Treatments

Surface treatments and coatings are often applied to aerospace components to improve corrosion resistance, wear resistance, and thermal protection. Specialized equipment for applying these treatments, such as plasma spray coating systems, chemical vapor deposition (CVD) reactors, and anodizing tanks, is essential. The equipment must maintain precise control over temperature, pressure, and chemical composition to ensure consistent and high-quality coatings.

- Adhesives and Sealants

Adhesives and sealants are used extensively in aerospace assembly to bond components, seal joints, and provide environmental protection. Specialized dispensing equipment, curing ovens, and inspection tools are required to ensure proper application and bonding. These equipment elements must be compatible with the specific adhesive or sealant being used and capable of maintaining precise control over temperature, pressure, and cure time.

The competence of professionals in equipment-related functions directly influences the quality, reliability, and performance of aerospace vehicles. A thorough understanding of material properties, processing techniques, and equipment capabilities is indispensable for ensuring the safety and efficiency of air and space travel.

5. Maintenance

Maintenance is an intrinsic aspect of specialized equipment roles within the aerospace industry. The reliability and accuracy of implements are crucial to the integrity of aircraft and spacecraft construction and upkeep. These functions are paramount for preventing catastrophic failures and ensuring operational safety.

- Preventative Programs

Systematic preventive routines for tools are critical. They involve regular inspection, cleaning, lubrication, and replacement of components. For example, CNC machines used in aircraft manufacturing require scheduled maintenance to uphold dimensional accuracy, preventing inaccuracies in component fabrication. This also reduces the likelihood of breakdowns that can halt production and cause financial losses.

- Calibration Protocol

Calibration is important for measuring and testing tools. Measuring equipment, such as coordinate measuring machines (CMMs), require periodic adjustment to account for wear and environmental factors. Routine calibration of torque wrenches utilized in assembling aircraft structures guarantees that fasteners meet required tension, preventing structural weaknesses.

- Repair and Overhaul Strategy

Repair protocols and reconditioning for damaged or malfunctioning equipment are essential to minimize downtime. When a composite layup tool sustains damage, skilled technicians must accurately repair it to restore its original form and function. Well-trained personnel with access to appropriate replacement parts can expedite the procedure and reduce the effect on manufacturing schedules.

- Lifecycle Management Solutions

Lifecycle management includes tracking the usage, maintenance history, and condition of equipment throughout its operational life. By monitoring parameters, such as operating hours and repair frequency, predictive maintenance can be implemented to proactively address potential issues before they result in failure. Efficient lifecycle management minimizes equipment-related disruptions, maximizing productivity and decreasing long-term operational expenditures.

The integration of maintenance procedures into these careers ensures that equipment functions as intended, contributing to the overall safety and reliability of air travel. The proficiency of skilled technicians is vital for implementing these measures effectively, which minimizes the dangers linked with equipment malfunctions and maximizes the operational readiness of aircraft.

6. Regulations

Stringent regulations are a defining characteristic of the aerospace industry, profoundly impacting every aspect, including roles tied to specialized equipment. These mandates ensure safety, reliability, and quality throughout the design, manufacturing, and maintenance of aircraft and spacecraft. The following outlines key facets of this relationship.

- Compliance Standards

Roles within this area must adhere to standards established by regulatory bodies such as the FAA (Federal Aviation Administration), EASA (European Aviation Safety Agency), and others. These standards dictate the procedures, materials, and processes used in crafting the specialized implements used to build aircraft. Failure to comply can result in severe penalties, including production delays, fines, and even revocation of certifications. The creation of tools used to assemble aircraft wings, for example, must follow specific guidelines regarding material traceability and dimensional accuracy, as mandated by regulatory authorities.

- Quality Control Procedures

Quality control is non-negotiable in aerospace manufacturing, and specialized equipment plays a vital role in ensuring adherence to required quality levels. Regulations often prescribe the types of inspection equipment that must be used, the frequency of inspections, and the documentation that must be maintained. For instance, coordinate measuring machines (CMMs) are frequently utilized to verify the accuracy of manufactured parts, and their calibration and usage must comply with established quality control protocols. Technicians operating these machines must be trained and certified to perform their duties, as dictated by regulatory requirements.

- Safety Protocols

Safety is the primary concern in aerospace. Regulations mandate strict safety protocols for the design and operation of equipment, with the goal of preventing accidents and injuries. For example, equipment used to handle hazardous materials, such as chemical etching solutions or composite resins, must be designed with appropriate safety features and operated by personnel who have received specialized training. Similarly, equipment used in the maintenance and repair of aircraft must be regularly inspected and certified to ensure that it is safe to operate.

- Documentation and Traceability

Regulations place a strong emphasis on documentation and traceability. All materials, processes, and equipment used in aerospace manufacturing must be documented in detail, and it must be possible to trace the origin of every component used in an aircraft. This requires the implementation of robust record-keeping systems and the use of specialized equipment for marking and identifying parts. The calibration records for measuring tools, for example, must be maintained and readily available for inspection by regulatory authorities.

Regulations are an inherent facet of jobs involved with equipment within the aerospace sector. Compliance is not merely a matter of following rules, but a fundamental commitment to safety and quality. Professionals in this area must possess a thorough understanding of applicable regulations and the skills necessary to ensure adherence. This requirement underscores the importance of ongoing training and professional development in order to remain current with evolving regulatory requirements and technological advancements.

7. Skillset

The array of competencies necessary for success in specialized equipment-related positions within the aerospace industry extends beyond basic technical proficiency. The complex demands of this sector require a combination of theoretical knowledge, practical experience, and adaptability to evolving technologies. This section details essential skills.

- Precision Machining Expertise

Proficiency in operating and maintaining equipment such as CNC milling machines, lathes, and grinders is fundamental. These tools are instrumental in creating components with exacting tolerances. For example, manufacturing turbine blades for jet engines requires machining accuracy to within a few microns. The ability to interpret engineering drawings, program CNC machines, and troubleshoot machining problems is crucial. This directly affects the quality and performance of aircraft parts.

- CAD/CAM Proficiency

Competency in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software is increasingly essential. These software packages are used to design tools, simulate manufacturing processes, and generate CNC programs. For example, design custom molds for composite aircraft structures with CAD software and then use CAM software to create machine code for manufacturing these molds. Skill with CAD/CAM tools improves design efficiency and manufacturing accuracy.

- Materials Science Knowledge

A thorough understanding of the properties and processing requirements of aerospace materials is indispensable. This includes knowledge of metals, composites, ceramics, and polymers, as well as their behavior under different conditions. For instance, knowledge of the thermal expansion coefficients of dissimilar metals used in aircraft construction is crucial for preventing stress corrosion. The selection of materials directly influences the durability, safety, and performance of aerospace components.

- Problem-Solving and Analytical Abilities

The capacity to identify and resolve technical challenges is paramount. Specialized equipment roles often involve troubleshooting equipment malfunctions, optimizing manufacturing processes, and developing innovative solutions to complex engineering problems. For example, diagnosing the root cause of dimensional inaccuracies in manufactured parts requires strong analytical skills and a systematic approach to problem-solving. Effective problem-solving enhances manufacturing efficiency and minimizes downtime.

These facets underscore that success in equipment-related careers depends on a blend of technical capabilities, analytical acumen, and commitment to continuous learning. As aerospace technology evolves, professionals in this area must adapt to new materials, processes, and equipment, continually enhancing their skill set to meet the ever-changing demands of the industry.

Frequently Asked Questions

The following provides responses to common inquiries regarding careers focused on specialized equipment within the aerospace industry. The aim is to offer clarity on the scope, requirements, and prospects of these roles.

Question 1: What educational background is generally required for entry-level positions?

A bachelor’s degree in mechanical engineering, manufacturing engineering, or a related field is often preferred, although some positions may be accessible with an associate’s degree or vocational training, particularly if coupled with relevant experience.

Question 2: Are there specific certifications that can enhance career prospects?

Certifications from organizations such as the National Institute for Metalworking Skills (NIMS) or the American Society for Quality (ASQ) can demonstrate proficiency and increase competitiveness in the job market.

Question 3: What is the typical career progression in this field?

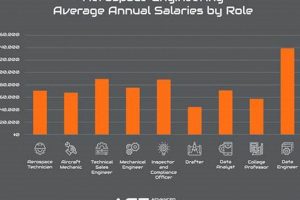

Career paths can vary, but often begin with entry-level technician roles, progressing to more specialized positions such as tool designer, manufacturing engineer, or quality control specialist. Advancement to supervisory or management roles is also possible with experience and additional education.

Question 4: How important is experience with CAD/CAM software?

Proficiency in CAD/CAM software is highly valued, as these tools are integral to designing, simulating, and manufacturing equipment. Experience with industry-standard packages such as CATIA, Siemens NX, or Mastercam can be a significant advantage.

Question 5: What are the key skills that employers typically seek?

Employers generally look for individuals with strong technical skills, problem-solving abilities, attention to detail, and a commitment to quality. Familiarity with aerospace materials, manufacturing processes, and regulatory requirements is also highly desirable.

Question 6: What is the long-term career outlook for these professions?

The long-term outlook is generally positive, driven by the increasing demand for aircraft and spacecraft, as well as the need to maintain and upgrade existing fleets. Technological advancements in manufacturing and materials science will also create new opportunities for skilled professionals.

In summary, a blend of formal education, technical skills, and industry knowledge is essential for success in specialized equipment careers. Continuous learning and professional development are crucial for remaining competitive in this dynamic field.

The subsequent section offers a concluding perspective on the significance of specialized equipment roles within the aerospace industry.

Conclusion

This exploration has illuminated the multifaceted nature and critical importance of careers dedicated to specialized equipment. These positions, encompassing design, manufacturing, maintenance, and regulatory compliance, are fundamental to ensuring the safety, reliability, and performance of aerospace vehicles. The mastery of precision machining, CAD/CAM software, materials science, and problem-solving skills are paramount for professionals in this demanding sector.

As the aerospace industry advances through innovation and heightened demand, the need for skilled individuals in such professions will only intensify. Aspiring professionals are encouraged to pursue robust educational pathways, acquire industry certifications, and remain abreast of technological advancements. The future of flight relies on their unwavering commitment to excellence.