A significant presence in the Pacific Northwest, this entity is a regional operation tied to a global leader in aerospace and defense technologies. Its local facilities contribute to the larger company’s portfolio through engineering, manufacturing, and support services, often focusing on specific product lines or customer segments relevant to the region.

The establishment’s importance stems from its contribution to the local economy through job creation, technological innovation, and collaboration with regional educational institutions. The enterprise often plays a pivotal role in developing advanced aerospace solutions for both commercial and government applications, thereby strengthening the area’s position in the national and international aerospace landscape. Historically, its presence has facilitated the growth of related industries and fostered a skilled workforce in the surrounding community.

Further discussion will explore the range of capabilities offered by this regional operation, the specific technologies and products it supports, and its engagement with the community and the wider aerospace sector. Examination will also be made of the role it plays in the larger framework of its parent company’s global strategy.

Operational and Strategic Guidance

The following represent insights derived from industry best practices and observations related to organizations similar to the regional aerospace operation in question. These points aim to provide a framework for enhancing operational efficiency and strategic positioning.

Tip 1: Focus on Specialized Expertise: Emphasize the development of unique skills and capabilities that distinguish the regional operation from competitors. Specialization can lead to increased market share and stronger customer relationships.

Tip 2: Foster Collaboration with Local Educational Institutions: Partner with universities and technical colleges to create a pipeline of skilled workers and facilitate research and development initiatives. These partnerships provide access to talent and advanced technologies.

Tip 3: Invest in Advanced Manufacturing Technologies: Prioritize the adoption of automation, additive manufacturing, and other advanced technologies to improve productivity, reduce costs, and enhance product quality.

Tip 4: Strengthen Supply Chain Relationships: Cultivate strong, reliable relationships with key suppliers to ensure the timely delivery of high-quality components and materials. A robust supply chain is critical for maintaining operational efficiency.

Tip 5: Prioritize Customer Service and Support: Focus on providing exceptional customer service and support to build customer loyalty and generate repeat business. Customer satisfaction is a key driver of long-term success.

Tip 6: Adaptability and Innovation: Cultivate a culture of continuous improvement and innovation. This could involve actively seeking new technologies or strategies.

Implementing these strategies can lead to enhanced operational efficiency, stronger customer relationships, and a more competitive position in the aerospace market. The principles outlined represent proactive approaches to achieving sustainable growth.

Subsequent sections will build upon these principles, exploring how they can be applied to specific areas within the aerospace sector, including research and development, manufacturing, and customer engagement.

1. Engineering Capabilities

The engineering capabilities inherent within the regional operation are fundamental to its success and overall function. These capabilities form the backbone of its ability to innovate, design, and improve aerospace technologies. The location’s engineering prowess directly contributes to the parent company’s global objectives, enabling the development and refinement of advanced systems, components, and solutions. For instance, the design of more efficient and reliable actuation systems for aircraft wings is driven by the engineering team based in the state, impacting fuel consumption and safety for numerous airlines. The existence of specialized engineering resources allows the site to address the unique needs of clients and projects specific to the regional and global aerospace industries.

A core function of this engineering group is the research, development, and testing of new aerospace technologies. This may involve materials science, aerodynamics, software engineering, and other technical disciplines. The effect of investing in these research capabilities is evident in the development of advanced composite materials utilized in aircraft structures, leading to lighter and more durable aircraft. The group also participates in collaborative engineering projects with other organizations, including local universities and government agencies. These partnerships foster a synergistic environment that drives innovation and knowledge transfer, reinforcing the states position as a center for aerospace development.

In summary, the engineering capabilities are an integral component that determines its operational capacity and contribution to the aerospace sector. Maintaining and enhancing these capabilities through continuous investment in talent, equipment, and research is critical for ensuring the long-term success and relevance of the regional entity. The ability to address both current and future challenges within the aerospace industry through innovative engineering solutions is the key to sustained competitive advantage.

2. Manufacturing Hub

The entity operates as a significant manufacturing hub within the broader Collins Aerospace network. This designation implies more than just physical facilities; it signifies a concentration of resources, expertise, and infrastructure dedicated to the production of aerospace components, systems, and solutions. The establishment of such a hub in the state directly correlates with the area’s pre-existing strengths in aerospace manufacturing and its strategic location, facilitating efficient logistics and supply chain management. For example, the facility may specialize in the fabrication of advanced avionics components, wiring harnesses, or structural elements for aircraft. This manufacturing focus supports both commercial and military aerospace customers.

The designation of a manufacturing hub brings several tangible benefits. It leads to increased local employment, as the operation requires a skilled workforce to operate advanced manufacturing equipment and processes. It attracts investment in new technologies and infrastructure, further enhancing the state’s capabilities in the aerospace sector. The presence of a major manufacturing hub also fosters collaboration with local suppliers and educational institutions, strengthening the entire regional aerospace ecosystem. A concrete illustration of this is the potential partnership with a local technical college to train specialized technicians for operating advanced composite manufacturing equipment, thereby ensuring a steady supply of qualified personnel.

In essence, the role of the regional establishment as a manufacturing hub is a critical component of its identity and contribution to the aerospace industry. This focus not only strengthens the global supply chain of Collins Aerospace but also drives economic growth and technological innovation within the state. Understanding the practical implications of this designation is vital for stakeholders seeking to engage with, invest in, or analyze the aerospace sector. Challenges may arise from global economic fluctuations and technological disruption. The importance of proactively adapting manufacturing processes and capabilities is vital.

3. Regional Employment

The presence of a regional operation has a demonstrable effect on regional employment opportunities. The entity’s operations directly create jobs in engineering, manufacturing, administration, and related support services. These positions span a range of skill levels, from entry-level technicians to highly specialized engineers and managers. The creation of these employment opportunities contributes to the local economy through increased tax revenue, consumer spending, and overall economic stability. The impact on unemployment rates is often measurable, particularly in areas where the aerospace sector is a dominant industry.

Furthermore, the organization’s role as a major employer can have an indirect impact on employment in other sectors. Local businesses, such as restaurants, retailers, and service providers, benefit from the increased economic activity generated by the presence of a large workforce. Additionally, the entity’s demand for goods and services from local suppliers can lead to the creation of additional jobs in these supporting industries. For instance, a machine shop providing precision components to the operation may expand its workforce to meet increased demand. The effect of this can generate broader economic growth beyond the entity itself. Investment into local community colleges and vocational schools will also facilitate the development of a workforce suited to the entity’s needs.

In conclusion, the connection between regional employment and the local presence is significant and multifaceted. The direct creation of jobs, coupled with the indirect economic benefits, underscores the importance of this operation as a driver of regional prosperity. Understanding this relationship is vital for policymakers, economic development agencies, and community stakeholders seeking to foster a thriving local economy. The operation’s success, and the success of related regional industries is reliant on continued investment into local labor resources and infrastructure.

4. Technological Innovation

Technological innovation is a central tenet of the Collins Aerospace operation in Washington State. The organizations presence in the region is intrinsically linked to its pursuit of advanced technologies applicable to the aerospace industry. A key driver of this connection is the investment in research and development, which leads to novel solutions in areas such as avionics, aircraft structures, and cabin systems. A tangible example of this manifests in the development of lighter, more durable composite materials for aircraft, reducing fuel consumption and improving performance. This innovation is not merely theoretical; it directly translates into practical improvements for airlines and aircraft manufacturers.

The emphasis on technological advancement also facilitates collaboration with local universities and research institutions. Through partnerships, Collins Aerospace gains access to cutting-edge research and a pipeline of skilled engineers and scientists. This synergistic relationship fosters the development of innovative solutions that address complex aerospace challenges. Consider the collaborative efforts in developing advanced flight control systems that improve safety and efficiency. Such collaborative work not only contributes to the technological progress of the company but also strengthens the region’s position as an aerospace innovation hub. These advancements enhance competitiveness and promote economic growth.

In summary, technological innovation is a fundamental component of the Collins Aerospace presence in Washington. This commitment drives the creation of advanced aerospace solutions, fuels collaboration with regional institutions, and contributes to the overall competitiveness of the aerospace sector. The sustained focus on innovation ensures that the organization remains at the forefront of aerospace technology, benefiting both the company and the broader community. Maintaining momentum in this area is challenged by global competition, thus requiring continuous investment in research and development.

5. Aerospace Solutions

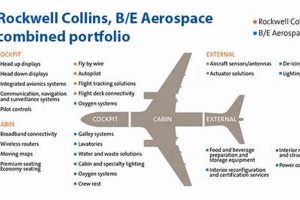

The regional operation’s core function revolves around the development and delivery of aerospace solutions. The practical application of these solutions spans a wide array of products and services, impacting both commercial and defense applications. One can consider the design, manufacturing, and support of flight control systems as a prime example. Such systems are a critical component for the safe and efficient operation of aircraft, directly influencing fuel consumption, maneuverability, and overall flight performance. The specific needs of airlines and aircraft manufacturers drive the ongoing innovation and refinement of these offerings. For instance, bespoke avionics packages tailored to specific aircraft types represent a practical realization of the solutions that stem from this establishment. The design element of these packages, in part, involves consideration of environmental impacts in keeping with regulatory controls.

The integration of these solutions is not confined to new aircraft. Retrofitting existing fleets with advanced avionics or cabin management systems provides a means of extending the lifespan of aircraft and improving passenger experience. The regional operation’s role extends to supporting these solutions throughout their lifecycle, offering maintenance, repair, and overhaul services. This support network provides critical support, impacting aircraft availability and operational costs for airline customers. Furthermore, the entity frequently collaborates with other aerospace companies and research institutions to develop and test new technologies. These partnerships advance the overall state of aerospace and enhance competitiveness.

In summary, the entity’s contribution to the aerospace sector is centered on the design, delivery, and support of comprehensive solutions that meet the evolving needs of its customers. The continuous improvement and adaptation of these solutions are crucial for maintaining its position as a leading provider of aerospace technology and services. A clear understanding of the role and impact of these factors is essential for stakeholders seeking to engage with or analyze the operations. The operation’s ability to address these challenges will determine its long-term success in this competitive market.

Frequently Asked Questions about Regional Aerospace Operations

The following questions address common inquiries and misconceptions concerning regional aerospace operations. The provided responses are designed to offer clarity and promote understanding of the associated dynamics.

Question 1: What specific types of aerospace products or services are typically provided by the regional operation?

The operation focuses on a range of products and services, frequently including the design, manufacturing, and support of avionics systems, aircraft components, and cabin solutions. The precise offerings will depend upon the entity’s specialization and its role within the global aerospace market.

Question 2: How does the existence of a regional aerospace operation impact local employment and the economy?

A regional operation contributes to local employment by creating positions in engineering, manufacturing, and administrative roles. This creates a multiplier effect on the local economy, increasing tax revenues and stimulating consumer spending in the surrounding community.

Question 3: What role does the regional operation play in fostering technological innovation within the aerospace sector?

The regional operation is typically involved in research and development activities, contributing to advancements in aerospace technology. This can involve collaboration with local universities and research institutions, promoting the development of novel solutions to industry challenges.

Question 4: How does the regional operation contribute to the global supply chain of its parent company, Collins Aerospace?

The regional operation serves as a critical node in the company’s global supply chain, providing manufactured components and assembled systems for integration into larger aerospace projects. It ensures timely delivery of high-quality products.

Question 5: What are the key challenges facing regional aerospace operations in the current economic and technological environment?

Regional operations face several challenges, including fluctuating global economic conditions, increasing competition from other aerospace companies, and the rapid pace of technological change. They must proactively adapt to these factors to maintain a competitive advantage.

Question 6: How can local communities best support the growth and success of regional aerospace operations?

Local communities can support these operations by investing in education and training programs to develop a skilled workforce, streamlining regulatory processes, and fostering a business-friendly environment. Collaboration between industry, government, and educational institutions is essential for success.

The answers above provide a concise overview of the key considerations surrounding regional aerospace operations. They illustrate the role they play in innovation, economic growth, and global supply chains. Further examination of these topics can provide greater insight into these dynamics.

Subsequent sections will delve into specific case studies and examples to illustrate the practical impact of the points discussed above.

Conclusion

Collins Aerospace Washington represents a strategic component of the broader aerospace landscape. The regional operation’s influence on innovation, employment, and the global supply chain has been established. Its continued success is contingent upon adaptation to evolving economic conditions and a sustained commitment to technological advancement. Understanding this entity is critical for those engaged with the aerospace sector and the communities it impacts.

The challenges and opportunities facing Collins Aerospace Washington underscore the need for proactive strategies and collaborative partnerships. Further investigation into the specific technologies and solutions offered by the organization is encouraged to gain a more comprehensive perspective on its role in shaping the future of aerospace. Continued focus on these factors ensures it remains an important player.

![Understanding Collins Aerospace Market Cap [Insights] Innovating the Future of Flight with Reliable Aviation Solutions Understanding Collins Aerospace Market Cap [Insights] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-112-300x200.jpg)

![U.S. Hubs: Collins Aerospace US Locations Guide [2024] Innovating the Future of Flight with Reliable Aviation Solutions U.S. Hubs: Collins Aerospace US Locations Guide [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-97-300x200.jpg)

![Collins Aerospace Holiday Schedule: [Year] Dates & Guide Innovating the Future of Flight with Reliable Aviation Solutions Collins Aerospace Holiday Schedule: [Year] Dates & Guide | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-71-300x200.jpg)