The facility in Irvine, California, represents a significant operational hub for a major player in the aerospace and defense industry. It focuses on the design, development, and manufacturing of advanced technology solutions for both commercial and government applications. Specific activities conducted at this location encompass engineering, research and development, and potentially manufacturing of products related to aircraft systems and components.

The presence of such a facility contributes to the local economy through job creation, technological innovation, and potential partnerships with local universities and businesses. Its activities support the advancement of aerospace technology and contribute to the safety and efficiency of air travel. Furthermore, its location within a technology-rich environment like Irvine provides access to a skilled workforce and a supportive ecosystem for innovation.

This overview provides context for subsequent discussions regarding the specific technologies, research initiatives, and career opportunities associated with this important aerospace center. Further discussion will detail the innovations stemming from the Irvine location and their impact on the broader aerospace sector.

The following guidance aims to assist individuals seeking engagement with the Collins Aerospace facility in Irvine, California, whether for employment, partnership, or general understanding of its operations.

Tip 1: Research Core Competencies: Prior to application or inquiry, identify the facility’s specific areas of expertise. Publicly available information regarding projects and technologies developed onsite can focus your efforts. For instance, understanding whether the site specializes in avionics or communication systems allows targeted preparation.

Tip 2: Tailor Resumes and Applications: Generic applications are often overlooked. Customize your resume to highlight skills and experience directly relevant to the advertised positions or the known activities of the Irvine facility. Use keywords from the job description and showcase relevant projects.

Tip 3: Network Strategically: Utilize professional networking platforms to connect with current or former employees of the Irvine location. Informational interviews can provide valuable insights into the company culture and hiring practices.

Tip 4: Prepare for Technical Assessments: Anticipate technical interviews or assessments aligned with the facility’s specializations. Review fundamental engineering principles, software development practices, or relevant hardware knowledge, depending on the target role.

Tip 5: Demonstrate Industry Awareness: Stay informed about current trends and challenges in the aerospace industry. Knowledge of emerging technologies, regulatory changes, and competitive landscapes will demonstrate a proactive and informed perspective.

Tip 6: Understand the Company Culture: Research the values and mission of Collins Aerospace. Aligning personal work ethic and goals with the company’s stated principles enhances suitability and demonstrates genuine interest.

Adhering to these guidelines increases the probability of successful engagement with the Collins Aerospace facility in Irvine, California. Proactive preparation and a targeted approach are essential.

The following sections will explore specific career paths and potential research collaborations within this important location.

1. Engineering at Collins Aerospace Irvine, CA

Engineering forms the bedrock of operations at the Collins Aerospace facility in Irvine, California. It is the driving force behind the design, development, and testing of advanced aerospace systems and components produced at that location. Without a robust engineering division, the facility could not fulfill its mandate of delivering cutting-edge solutions to the aerospace industry. The presence of engineering teams directly enables the facility to contribute to innovation and maintain a competitive edge. For example, if the Irvine facility is involved in developing a new flight management system, the engineering team will be responsible for the architecture, software, hardware, and testing required to bring that system to fruition. The functionality, reliability, and safety of the end product are directly attributable to the quality and rigor of the engineering processes employed.

The engineering work conducted impacts practical applications in numerous ways. Highly skilled professionals located at the Irvine facility allow the company to rapidly design, prototype, and implement new technologies. This translates into improved aircraft performance, greater fuel efficiency, enhanced passenger experience, and increased safety for airlines and their passengers. Furthermore, the presence of an advanced engineering workforce in Irvine enables Collins Aerospace to partner with universities and research institutions, fostering collaborative research and development efforts that further contribute to the aerospace industry. This could manifest as joint projects focused on developing more sustainable aviation technologies or improving the accuracy of navigational systems.

In summary, engineering is an indispensable component of the Collins Aerospace operation in Irvine. It serves as the engine driving technological advancement and ensuring the production of safe, reliable, and high-performance aerospace systems. Understanding the central role of engineering at this location is essential for comprehending its broader impact on the aerospace industry, from enhancing aircraft capabilities to driving economic growth through technological innovation. Challenges faced by the engineering teams, such as ever-increasing regulatory requirements and intense competition, require a continuous commitment to excellence and adaptability.

2. Manufacturing

Manufacturing at the Collins Aerospace facility in Irvine, California, is a critical operation. It represents the tangible realization of engineering designs and innovations, transforming concepts into physical products that are deployed in aircraft and aerospace systems globally. The efficiency and precision of the manufacturing processes directly impact the quality, reliability, and performance of the final aerospace products.

- Precision Component Production

This facet involves the fabrication of highly specialized components with tight tolerances and exacting specifications. Examples include avionics components, communication systems parts, and structural elements that demand adherence to strict aerospace industry standards. Failure to meet these standards can lead to system malfunctions, safety hazards, and regulatory non-compliance.

- Assembly and Integration Processes

This stage focuses on combining individual components into functional modules and systems. The Irvine facility likely employs advanced assembly techniques, including robotic automation and precision instrumentation, to ensure proper alignment, connection, and operation. For example, assembling a complex flight control system requires careful integration of sensors, actuators, and processing units, each contributing to the overall functionality.

- Quality Control and Assurance

Rigorous quality control measures are implemented throughout the manufacturing process to identify and correct defects or deviations from design specifications. This includes dimensional inspections, functional testing, and environmental stress screening. Such procedures guarantee that manufactured items meet the required performance criteria, and are robust enough to function reliably in the harsh conditions of flight. This may be through X-ray or ultrasonic testing of composite materials.

- Supply Chain Management

The manufacturing operation is inextricably linked to a complex supply chain that sources raw materials, components, and sub-assemblies from various vendors. Efficient management of the supply chain is vital to ensure timely delivery of materials, minimize inventory costs, and maintain consistent product quality. This may include tracking components or materials from around the world to make sure they arrive when needed.

The interplay of these facets underscores the significance of manufacturing within the Collins Aerospace facility in Irvine. Effective manufacturing processes directly support the companys ability to deliver innovative, high-quality aerospace solutions to meet the stringent demands of the industry. Without a strong manufacturing base, the engineering and design efforts would remain unrealized, hindering technological advancement in aviation. The ability of the Irvine location to scale its manufacturing operations in response to market demand is a crucial factor in its long-term success.

3. Research

Research constitutes a vital element of the operations at the Collins Aerospace facility in Irvine, California. It fuels innovation and underpins the development of next-generation aerospace technologies. This research encompasses various areas, including materials science, avionics, communication systems, and software engineering. The presence of dedicated research teams enables the facility to stay at the forefront of technological advancements and respond effectively to the evolving demands of the aerospace sector. Without research, the facility would be limited to incremental improvements rather than breakthroughs. For example, research into advanced composite materials can lead to lighter and stronger aircraft structures, resulting in improved fuel efficiency and reduced operating costs. Such advancements translate directly into practical benefits for airlines and passengers.

The impact of research extends beyond internal product development. The Irvine facility likely engages in collaborative research projects with universities and government agencies. These partnerships facilitate the exchange of knowledge and expertise, accelerating the pace of innovation. For instance, collaborative research on artificial intelligence and machine learning could result in the development of autonomous flight systems or predictive maintenance tools that enhance aircraft safety and reliability. This collaborative approach expands the reach of the facility’s research efforts and contributes to the broader advancement of aerospace technology. The results of this research may be published in academic journals or presented at industry conferences, further disseminating knowledge and promoting collaboration.

In summary, research is integral to the success and competitiveness of the Collins Aerospace facility in Irvine. It drives innovation, enhances product performance, and fosters collaboration within the aerospace community. While the specific research areas may evolve in response to industry trends and customer needs, the commitment to research remains a constant. Sustained investment in research is crucial for maintaining the facility’s position as a leader in aerospace technology and ensuring its long-term growth and contribution to the industry. The constant challenge for research teams is to balance long-term exploratory investigations with the need for short-term, commercially viable outcomes.

4. Innovation

The Collins Aerospace facility in Irvine, California, relies heavily on innovation to maintain its competitive edge and contribute meaningfully to the advancement of aerospace technology. Innovation at this location is not merely an aspirational goal, but a fundamental operational imperative. It manifests as the continuous improvement of existing products and services, as well as the development of entirely new technologies that address emerging needs in the aviation sector. This commitment to innovation is a primary driver of the facility’s activities and shapes its overall strategic direction. One example is the development of more efficient avionics systems, which can improve fuel economy and reduce carbon emissions. Such innovations are crucial for meeting increasingly stringent environmental regulations and the growing demand for sustainable aviation practices.

The facility’s location within the technology-rich environment of Irvine, California, fosters a culture of innovation by providing access to a skilled workforce, research institutions, and a network of technology partners. This ecosystem facilitates collaboration and knowledge sharing, accelerating the innovation process. The Irvine facility’s engagement with local universities often results in joint research projects and the recruitment of top talent, further strengthening its innovation capabilities. For instance, collaboration with local engineering schools may lead to the development of novel sensor technologies or advanced control systems. These practical applications ultimately enhance the safety, reliability, and efficiency of aircraft operations.

In conclusion, innovation is an essential component of the Collins Aerospace facility in Irvine, driving its technological advancements and shaping its role within the broader aerospace industry. This commitment requires sustained investment in research and development, a supportive ecosystem, and a culture that encourages experimentation and risk-taking. While the challenges of maintaining a constant stream of impactful innovations are significant, the long-term benefits for both the company and the aerospace industry are undeniable. The Irvine facility’s continued success hinges on its ability to foster and leverage innovation effectively.

5. Technology

The Collins Aerospace facility in Irvine, California, is inextricably linked to technology. Technology serves as the foundational element underpinning its operations, directly impacting its ability to design, develop, manufacture, and support advanced aerospace systems. Technology acts as the cause, with improved aircraft safety, enhanced operational efficiency, and greater passenger comfort as effects. This facility leverages a broad spectrum of technologies, including advanced materials science, software engineering, embedded systems, and communication protocols. Failure to maintain technological competence would directly impair the facility’s ability to compete effectively in the aerospace market. A specific example is the use of computational fluid dynamics (CFD) software to optimize aircraft wing designs, resulting in reduced drag and improved fuel efficiency. This requires not only the software itself but also highly skilled engineers capable of interpreting the results and applying them to practical designs.

Technological advancements drive the evolution of products and services offered by the Irvine facility. Practical applications of these technologies are numerous. For instance, the development of more robust and reliable avionics systems enhances flight safety and operational efficiency for airlines globally. Furthermore, the integration of advanced communication technologies into aircraft cabins improves the passenger experience by providing enhanced connectivity and entertainment options. Research into new sensor technologies allows for improved aircraft health monitoring, reducing maintenance costs and minimizing downtime. The practical significance of understanding this connection is evident in the investment strategies of Collins Aerospace, which prioritize research and development in key technology areas. These areas align with anticipated future demands of the aviation industry, thus improving sustainability.

In summary, technology is not merely a component of the Collins Aerospace facility in Irvine; it is the lifeblood of its operations. Technological innovation drives product development, enhances operational efficiency, and improves the overall safety and comfort of air travel. Challenges related to rapid technological change require a constant commitment to research and development and a willingness to adopt new methodologies. The long-term success of the Irvine facility depends on its ability to remain at the forefront of technological advancements in the aerospace sector.

6. Development

The Collins Aerospace facility in Irvine, California, emphasizes development as a core function. Development translates theoretical concepts and research findings into tangible, marketable aerospace products and services. Without a robust development pipeline, innovations remain unrealized and fail to contribute to the company’s commercial success or the broader advancement of aerospace technology. The presence of a dedicated development team at the Irvine facility directly enables the company to transform research breakthroughs into practical solutions for its customers. For example, if the facility develops a new type of aircraft sensor, it is the development team that refines the sensor design, integrates it into existing aircraft systems, and validates its performance through rigorous testing. This process ensures the sensor meets industry standards and customer requirements before being deployed in commercial or military aircraft.

The development activities at the Irvine facility encompass a wide range of aerospace applications. These applications can include advanced avionics systems, communication and navigation equipment, and cabin management solutions. The successful development of these products often relies on collaboration between various engineering disciplines, including electrical, mechanical, and software engineering. The Irvine facility also leverages its location within a technology-rich region to partner with universities and research institutions on development projects. This collaborative approach allows Collins Aerospace to access specialized expertise and resources, accelerating the development process. Successful products developed at the Irvine location directly impact the aerospace industry by enhancing aircraft safety, improving operational efficiency, and providing a more comfortable passenger experience. A practical example includes the development of lighter, more fuel-efficient cabin systems, which reduce aircraft weight and lower fuel consumption, contributing to both environmental sustainability and cost savings for airlines. This also may apply to the development of quieter, more efficient airplane turbine engines.

In summary, development is crucial to the Collins Aerospace facility in Irvine, bridging the gap between research and marketable aerospace products. This process requires a multi-disciplinary approach, collaboration with external partners, and a focus on meeting customer needs and industry standards. While the challenges of navigating regulatory requirements and managing complex development projects are significant, the long-term benefits for the company and the aerospace industry are substantial. The Irvine facility’s commitment to development ensures that innovative technologies are translated into practical solutions that enhance the safety, efficiency, and sustainability of air travel.

Frequently Asked Questions

This section addresses common inquiries regarding the Collins Aerospace facility located in Irvine, California. The information provided aims to offer clarity on its operations, employment opportunities, and contributions to the aerospace industry.

Question 1: What are the primary operational areas of the Collins Aerospace facility in Irvine, CA?

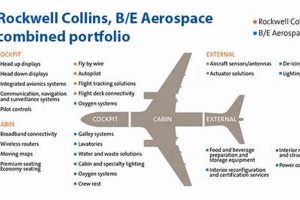

The facility focuses on engineering design, development, manufacturing, and support of aerospace systems and components. Specific areas of expertise may include avionics, communication systems, and cabin management solutions, although these may change based on market demands and internal priorities.

Question 2: What types of employment opportunities are typically available at the Irvine location?

Common roles include engineers (electrical, mechanical, software), manufacturing specialists, research scientists, and administrative staff. Specific openings will vary depending on the facility’s current projects and hiring needs. Interested parties should consult the Collins Aerospace careers website for the most up-to-date listings.

Question 3: Does the Irvine facility engage in research and development activities?

Yes, research and development are integral parts of the facility’s operations. These activities aim to advance aerospace technology and develop innovative solutions for the aviation industry. The specific areas of research will depend on current strategic initiatives.

Question 4: How does the Collins Aerospace Irvine facility contribute to the local economy?

The facility contributes through job creation, investment in local businesses, and partnerships with universities and research institutions. Its presence in Irvine strengthens the region’s position as a hub for aerospace technology.

Question 5: Does the Irvine facility offer internships or student programs?

Internship and student programs may be available, providing opportunities for students to gain practical experience in the aerospace industry. Information regarding such programs can be found on the Collins Aerospace website or through university career services.

Question 6: How can individuals or businesses explore potential partnerships with the Collins Aerospace facility in Irvine?

Interested parties should contact the Collins Aerospace business development team to discuss potential collaboration opportunities. A clear articulation of mutual benefits and alignment with the company’s strategic goals is essential for successful partnership inquiries.

This information should provide a basic understanding of the Collins Aerospace facility in Irvine, California. Direct inquiries to Collins Aerospace are recommended for specific details.

The following section will explore career paths and potential collaborations.

Conclusion

This article has explored the significance of Collins Aerospace Irvine CA, detailing its functions in engineering, manufacturing, research, innovation, technology, and development within the aerospace sector. The facility’s impact extends to the local economy and the broader advancement of aviation technologies.

Continued monitoring of Collins Aerospace Irvine CA’s activities and contributions is warranted, given its crucial role in shaping the future of aerospace. Further exploration of its specific projects and partnerships will offer additional insights into its strategic importance and industry impact.

![U.S. Hubs: Collins Aerospace US Locations Guide [2024] Innovating the Future of Flight with Reliable Aviation Solutions U.S. Hubs: Collins Aerospace US Locations Guide [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-97-300x200.jpg)

![Collins Aerospace Holiday Schedule: [Year] Dates & Guide Innovating the Future of Flight with Reliable Aviation Solutions Collins Aerospace Holiday Schedule: [Year] Dates & Guide | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-71-300x200.jpg)