The primary manufacturing and operational center for Collins Aerospace represents a significant concentration of resources, expertise, and infrastructure. This central facility typically houses key functions such as engineering, research and development, production lines, testing facilities, and administrative offices. An example would be the facility responsible for the design and fabrication of critical avionics systems or aircraft components.

Such a pivotal location offers numerous advantages, including enhanced coordination between different departments, streamlined supply chain management, and improved communication channels. The historical development of these facilities often reflects the growth and evolution of the aerospace industry, showcasing technological advancements and significant milestones in aviation history. Its existence allows for economies of scale, fostering innovation and driving down costs through shared resources and optimized processes.

The subsequent sections will delve into the specific operations, technological innovations, and economic impact associated with this core manufacturing hub, illustrating its contribution to the broader aerospace landscape.

Operational Insights

The following represent key considerations for stakeholders and observers interested in the operational efficacy and strategic importance of a Collins Aerospace core manufacturing location.

Tip 1: Focus on Process Optimization: A central tenet of operational efficiency involves the continuous refinement of manufacturing and supply chain processes. Regular audits and the implementation of lean manufacturing principles are crucial to minimizing waste and maximizing throughput. For instance, employing Six Sigma methodologies to reduce defects in component production directly enhances overall productivity.

Tip 2: Invest in Advanced Technology: Maintaining a competitive edge necessitates ongoing investment in cutting-edge technologies such as additive manufacturing, advanced robotics, and automation systems. Implementing these technologies can lead to reduced labor costs, increased precision, and the ability to produce complex components with greater efficiency. An example would be integrating automated inspection systems to ensure consistent product quality.

Tip 3: Prioritize Workforce Development: A skilled and adaptable workforce is essential for navigating the complexities of advanced manufacturing. Offering comprehensive training programs, supporting apprenticeships, and fostering a culture of continuous learning will ensure that employees possess the necessary expertise to operate and maintain sophisticated equipment. Specific training on new software or machinery implementations is crucial.

Tip 4: Enhance Cybersecurity Measures: Protecting sensitive intellectual property and operational data is paramount in the modern manufacturing environment. Implementing robust cybersecurity protocols, conducting regular vulnerability assessments, and training employees on cybersecurity best practices can mitigate the risk of data breaches and cyberattacks. For example, segregating network access based on job function limits potential damage from compromised accounts.

Tip 5: Foster Strong Supplier Relationships: A reliable and responsive supply chain is vital for ensuring the uninterrupted flow of materials and components. Cultivating strong relationships with key suppliers, establishing clear communication channels, and implementing contingency plans for potential disruptions can minimize supply chain vulnerabilities. Diversifying suppliers for critical components can also reduce dependency risks.

Tip 6: Promote Collaboration and Communication: Breaking down silos between departments and fostering open communication channels can improve efficiency and facilitate innovation. Implementing collaborative platforms, conducting regular cross-functional meetings, and encouraging knowledge sharing can enhance problem-solving and decision-making capabilities. For example, establishing a dedicated communication channel between engineering and manufacturing can speed up the resolution of design-related production issues.

Tip 7: Emphasize Quality Control: A commitment to rigorous quality control throughout the manufacturing process is non-negotiable. Implementing comprehensive testing procedures, utilizing statistical process control techniques, and empowering employees to identify and report potential quality issues can prevent defects from reaching customers. Implementing automated quality checks and machine learning based predictions will reduce the risk of sending defects to customers.

These considerations highlight the necessity of strategic planning, continuous improvement, and investment in both technology and human capital to ensure optimal performance and sustained competitiveness. An efficient, secure, and innovative core manufacturing location is crucial for continued success.

The following sections will explore the long-term outlook and potential challenges facing these critical manufacturing hubs.

1. Manufacturing Capacity

Manufacturing capacity within the central Collins Aerospace facility directly dictates the organization’s ability to fulfill existing contracts and respond to emergent market opportunities. Its scale and efficiency are not merely logistical considerations but fundamental determinants of revenue generation and strategic market positioning. A facility operating at maximum capacity, utilizing advanced automation and lean manufacturing principles, can significantly reduce per-unit costs and delivery times, providing a tangible competitive advantage. Insufficient manufacturing capacity, conversely, results in order backlogs, delayed deliveries, and potential loss of market share to competitors with superior production capabilities. This cause-and-effect relationship underscores the importance of meticulously planning and managing the output capabilities.

The significance of optimized manufacturing capacity is further exemplified by considering high-demand periods, such as surges in orders for aircraft components related to new aircraft production or maintenance contracts. An adequately scaled central facility can absorb these fluctuations without compromising delivery schedules or product quality. For instance, investment in advanced robotic assembly lines allows for increased production rates without proportional increases in labor costs, enabling the facility to meet accelerated demand with minimal disruption. Conversely, a lack of foresight in capacity planning can lead to bottlenecks, requiring outsourcing at higher costs or, in severe cases, cancellation of contracts. The facility that produces parts for airliners’ seats and interiors must be able to meet the standards of each customer to supply the parts that will be used by airlines globally.

In conclusion, manufacturing capacity is not a static metric but a dynamic element requiring constant monitoring and strategic investment within the central operational site. Accurately forecasting demand, implementing flexible manufacturing systems, and continuously optimizing production processes are essential for maintaining a competitive edge and ensuring the ability to meet the evolving needs of the aerospace market. Challenges surrounding supply chain disruptions, labor shortages, and technological obsolescence further emphasize the need for proactive capacity management strategies to maintain operational efficiency and market leadership.

2. Technological Innovation

Technological innovation is a driving force behind the capabilities and competitiveness of any major manufacturing center, particularly within the aerospace sector. Within the main Collins Aerospace plant, advancements in technology directly influence production efficiency, product quality, and the ability to meet evolving industry demands. The successful integration of these innovations is essential for maintaining a leading position in the global aerospace market.

- Advanced Materials and Manufacturing Processes

The incorporation of novel materials, such as lightweight composites and advanced alloys, alongside innovative manufacturing techniques like additive manufacturing (3D printing) and automated fiber placement, is revolutionizing aerospace component production. These advancements enable the creation of lighter, stronger, and more complex parts, reducing aircraft weight and improving fuel efficiency. The central plant acts as a proving ground for these new materials and processes, rigorously testing their performance and reliability before widespread adoption. For example, 3D printing allows for rapid prototyping and the creation of customized parts with intricate geometries, previously unattainable through traditional methods. This accelerates product development cycles and reduces lead times.

- Automation and Robotics

The deployment of advanced robotics and automation systems significantly enhances production efficiency and reduces the potential for human error. Automated assembly lines, robotic inspection systems, and computer-controlled machining equipment ensure consistent product quality and increased output. The main facility often serves as a showcase for these advanced automation technologies, demonstrating their effectiveness and driving further adoption across the company’s global operations. An example would be the use of robotic arms for the precision assembly of avionics systems, ensuring each unit meets exacting specifications.

- Digitalization and Data Analytics

The integration of digital technologies, such as the Industrial Internet of Things (IIoT) and advanced data analytics, provides real-time insights into manufacturing processes, enabling predictive maintenance and optimized resource allocation. Sensors embedded in equipment monitor performance, allowing for early detection of potential failures and preventing costly downtime. Data analytics tools analyze production data to identify bottlenecks, optimize workflows, and improve overall efficiency. For example, predictive maintenance algorithms can analyze vibration data from CNC machines to identify signs of wear and tear, scheduling maintenance before a breakdown occurs. This leads to significant cost savings and improved operational reliability.

- Sustainable Technologies

The development and implementation of sustainable manufacturing practices are becoming increasingly important, driven by environmental regulations and a growing emphasis on corporate social responsibility. The central manufacturing plant plays a vital role in developing and testing new technologies aimed at reducing energy consumption, minimizing waste, and utilizing environmentally friendly materials. Examples include the implementation of closed-loop water systems, the use of renewable energy sources, and the adoption of recycling programs. The adoption of greener technologies within the main production plant can provide a strategic advantage by attracting environmentally conscious customers and reducing the plant’s overall carbon footprint.

These facets of technological innovation are intricately interwoven within the Collins Aerospace core production location, collectively driving efficiency, quality, and sustainability. These advancements represent a strategic imperative, enabling the company to maintain its competitive edge and meet the evolving demands of the aerospace industry. As the central hub, the location acts not only as a production center, but also as an engine for new developments with a focus on research, development and implementation of new innovations across the organization.

3. Supply Chain Integration

Supply chain integration is crucial to the effective operation of the central manufacturing location. A well-coordinated supply chain ensures the timely delivery of components and materials, directly impacting production schedules and product quality. Disruptions in the supply chain can lead to delays, increased costs, and potential damage to the company’s reputation.

- Supplier Relationship Management

Effective supplier relationship management is paramount. It involves establishing strong, collaborative relationships with key suppliers to ensure a reliable flow of high-quality materials. This includes negotiating favorable pricing, implementing quality control measures, and fostering open communication channels. An example is long-term contracts with preferred suppliers of specialized alloys, ensuring consistent availability and predictable costs. The absence of this management can lead to material shortages and production slowdowns.

- Inventory Management

Optimizing inventory levels is essential for minimizing holding costs and preventing stockouts. Employing techniques such as just-in-time (JIT) inventory management and demand forecasting can streamline the flow of materials and reduce waste. However, over-reliance on JIT can create vulnerabilities in the event of unexpected disruptions. The core plant must balance inventory efficiency with supply chain resilience. Example: Usage of predictive analytics to anticipate spikes in demand for specific components, allowing for proactive inventory adjustments.

- Logistics and Transportation

Efficient logistics and transportation are critical for delivering components and finished goods to the right place at the right time. Selecting appropriate transportation modes, optimizing shipping routes, and utilizing real-time tracking systems can improve delivery times and reduce transportation costs. Delays in transportation can significantly impact production schedules. Implementation of streamlined customs clearance procedures and strategic placement of distribution centers are also important to consider. Air freight of critical parts can be implemented, but that needs to be implemented while being cost-aware of transportation choices.

- Risk Management and Redundancy

Identifying and mitigating supply chain risks is essential for ensuring business continuity. This includes diversifying the supplier base, developing contingency plans for potential disruptions, and monitoring geopolitical factors that could impact supply chains. The central manufacturing location should have alternative sources of supply for critical components and a well-defined plan for responding to unforeseen events such as natural disasters or trade embargoes. Consider holding more material on-site to prevent manufacturing operation disruptions.

These elements of supply chain integration are inextricably linked to the performance of the main manufacturing plant. A robust and resilient supply chain is a key enabler of operational efficiency, product quality, and ultimately, the company’s success in the competitive aerospace market. A proactive and well-thought-out strategy is crucial to ensure long-term operational success by minimizing production disruptions.

4. Workforce Expertise

Workforce expertise forms the bedrock of operational success within the central Collins Aerospace facility. The advanced manufacturing processes, intricate technologies, and rigorous quality standards necessitate a highly skilled and knowledgeable workforce. Without this expertise, the facility’s potential for innovation and efficient production is severely hampered. A direct cause-and-effect relationship exists between workforce competence and output quality; higher levels of skill translate to fewer defects and improved product reliability. For instance, certified welders are crucial in producing aircraft structural components that meet stringent safety regulations. A failure in weld integrity due to inadequate expertise can have catastrophic consequences, underscoring the vital importance of specialized training and certifications.

The value of workforce expertise extends beyond basic operational tasks. Skilled engineers and technicians are essential for troubleshooting complex equipment malfunctions, implementing process improvements, and adapting to technological advancements. The continuous improvement initiatives that drive efficiency and innovation within the facility rely on the collective knowledge and problem-solving abilities of its employees. Real-world examples include the implementation of lean manufacturing principles, which requires the active participation and expertise of workers at all levels to identify and eliminate waste. Furthermore, the integration of new technologies, such as additive manufacturing, demands specialized training to operate and maintain the equipment effectively. Employees working on the machine, setting up the machine and retrieving parts must have knowledge to properly implement the equipment.

In conclusion, workforce expertise is not merely a component of the central manufacturing location; it is the very engine that drives its performance and competitiveness. Challenges such as skills gaps in emerging technologies and the aging of the workforce necessitate ongoing investment in training, development, and knowledge transfer. By prioritizing the cultivation of a highly skilled workforce, the facility ensures its ability to meet the evolving demands of the aerospace industry and maintain its position as a leader in innovation and manufacturing excellence. This connection highlights the practical significance of viewing human capital as a strategic asset within the organization.

5. Quality Assurance

Quality assurance is not merely a procedural requirement within the central Collins Aerospace facility; it represents a comprehensive, integrated system designed to guarantee the reliability, safety, and performance of all manufactured products. Its importance is underscored by the stringent regulatory standards and the critical nature of aerospace components, where even minor defects can have severe consequences.

- Stringent Inspection Protocols

The facility implements a multi-tiered inspection process, beginning with raw material verification and extending through each stage of manufacturing to final product testing. Non-destructive testing (NDT) methods, such as ultrasonic and radiographic inspections, are routinely employed to detect internal flaws in critical components without compromising their structural integrity. For example, turbine blades undergo rigorous X-ray analysis to identify any casting defects that could lead to premature failure during operation. These inspection protocols are constantly reviewed and updated to incorporate advancements in testing technology and address emerging quality concerns.

- Statistical Process Control (SPC)

Statistical process control techniques are utilized to monitor manufacturing processes in real time, identifying and addressing deviations from established quality standards before they result in defective products. Data collected from various stages of production are analyzed to track process variability and identify potential sources of error. Control charts are used to visualize process performance and trigger corrective actions when processes drift outside acceptable limits. For instance, SPC is applied to monitor the precision of CNC machining operations, ensuring that components are manufactured to exacting tolerances. This proactive approach minimizes waste, reduces rework, and improves overall product quality.

- Compliance with Regulatory Standards

The facility operates in compliance with stringent regulatory standards, including those set by aviation authorities such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). This compliance requires meticulous documentation, rigorous testing, and adherence to established quality management systems, such as AS9100. Regular audits by regulatory bodies ensure that the facility maintains the highest standards of quality and safety. For example, adherence to FAA regulations governing the manufacturing of aircraft engines necessitates comprehensive testing of each engine to verify its performance and reliability under various operating conditions.

- Continuous Improvement Initiatives

Quality assurance is not a static function but an ongoing process of continuous improvement. The facility fosters a culture of quality by encouraging employees to identify and report potential quality issues and by implementing corrective actions to prevent recurrence. Root cause analysis is used to investigate defects and identify underlying causes, leading to improvements in manufacturing processes and product design. Lean manufacturing principles are applied to eliminate waste and improve efficiency, while Six Sigma methodologies are used to reduce process variability and improve product quality. For example, implementing a suggestion program that encourages employees to submit ideas for improving quality and efficiency. These ideas are reviewed and implemented, leading to tangible improvements in the facility’s performance.

These facets of quality assurance are critical to the success of the main Collins Aerospace location, safeguarding the integrity of manufactured products and upholding the company’s reputation for excellence. The unwavering commitment to quality not only ensures compliance with regulatory requirements but also drives innovation and continuous improvement, enhancing the facility’s competitiveness in the global aerospace market.

6. Global Distribution

Effective global distribution is inextricably linked to the strategic importance and operational success of the main Collins Aerospace plant. The plant serves as a primary source for components, systems, and aftermarket services that are deployed worldwide. Therefore, the efficiency and reach of its distribution network directly impact the companys ability to meet customer demands, maintain its competitive edge, and support its global customer base.

- Logistics Network Optimization

A highly optimized logistics network is essential for ensuring timely and cost-effective delivery of products from the central plant to customers across the globe. This involves strategic placement of distribution centers, efficient transportation management, and streamlined customs clearance procedures. For example, establishing regional distribution hubs in key markets allows for faster delivery times and reduced transportation costs. Failure to optimize the logistics network can lead to delays, increased expenses, and customer dissatisfaction. The plant should also have access to major airports and seaports to provide fast global delivery.

- Export Compliance and Trade Regulations

Navigating complex export compliance and trade regulations is a critical aspect of global distribution. The main plant must adhere to all applicable international laws and regulations governing the export of aerospace components and systems, including export licenses, customs declarations, and trade sanctions. Non-compliance can result in significant penalties, delays, and reputational damage. For instance, strict adherence to International Traffic in Arms Regulations (ITAR) is essential for exporting certain sensitive technologies. Maintaining a dedicated team of export compliance specialists is critical.

- Aftermarket Services and Support

Global distribution plays a vital role in supporting aftermarket services and maintenance operations for Collins Aerospace products. Timely delivery of spare parts, repair components, and technical support is essential for minimizing aircraft downtime and ensuring customer satisfaction. The main plant must have a robust system for managing and distributing aftermarket components to service centers and maintenance facilities around the world. A global network of authorized repair stations that can receive components from the plant quickly is required. The plant’s customer service operations can work to get parts to customers needing replacements.

- Supply Chain Visibility and Traceability

Maintaining comprehensive supply chain visibility and traceability is crucial for ensuring the authenticity and integrity of products throughout the global distribution network. This involves implementing tracking systems that provide real-time information on the location and status of components and systems, from the manufacturing floor to the final customer. Traceability is essential for identifying and addressing potential counterfeit products and ensuring compliance with regulatory requirements. For example, the plant can implement blockchain technology to create an immutable record of each component’s journey through the supply chain. This may include scanning items into the supply chain using QR codes or part numbers.

These multifaceted considerations underscore the strategic importance of global distribution in relation to the main Collins Aerospace plant. A well-managed and efficient global distribution network not only supports the companys commercial objectives but also enhances its reputation for reliability, quality, and customer service in the highly competitive aerospace market. The efficiency of this distribution network, sourced from this key production site, directly impacts the brand reputation and the overall competitiveness of the company. The location should have the means to efficiently supply the global locations.

Frequently Asked Questions

This section addresses common inquiries regarding the core manufacturing facility of Collins Aerospace, offering clarifications on its operations, capabilities, and significance within the aerospace industry.

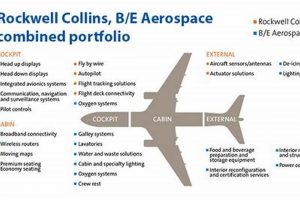

Question 1: What specific products are manufactured at the central Collins Aerospace plant?

The product range varies depending on the specific location, but typically includes avionics systems, aircraft interiors, mechanical systems, and power & control systems. Specific product details are often proprietary and not publicly disclosed. Inquiries regarding specific products should be directed to the company’s sales or customer service departments.

Question 2: How does the central facility contribute to technological innovation within Collins Aerospace?

The main plant often houses research and development activities, serving as a testing ground for new materials, manufacturing processes, and technologies. It fosters collaboration between engineers, scientists, and production staff, accelerating the development and implementation of innovative solutions for the aerospace industry. It’s often the site where new advancements are prototyped and tested.

Question 3: What measures are in place to ensure product quality and safety at the central manufacturing location?

Stringent quality assurance protocols are implemented throughout the manufacturing process, including rigorous inspections, statistical process control, and compliance with aviation regulatory standards such as AS9100. Non-destructive testing methods are employed to detect hidden flaws, and continuous improvement initiatives are in place to enhance product reliability and safety.

Question 4: How does the central Collins Aerospace plant manage its supply chain to ensure timely delivery of components and materials?

The facility employs a comprehensive supply chain management system, including strategic supplier relationships, optimized inventory control, and efficient logistics and transportation arrangements. Risk management strategies are in place to mitigate potential disruptions, such as natural disasters or geopolitical events. Technologies such as blockchain can be used to monitor the product throughout the supply chain. This will reduce or eliminate counterfeit parts and products.

Question 5: What role does sustainability play in the operations of the central manufacturing facility?

Collins Aerospace is committed to sustainable manufacturing practices. The central plant implements various measures to reduce energy consumption, minimize waste, and utilize environmentally friendly materials. Investments in renewable energy sources and closed-loop water systems reflect this commitment.

Question 6: What kind of career opportunities are available at the main Collins Aerospace plant?

Career opportunities span a wide range of disciplines, including engineering, manufacturing, quality assurance, supply chain management, and administration. Skilled technicians, machinists, and assembly workers are also in high demand. Information on open positions can be found on the company’s careers website.

This FAQ section provides a general overview of the central Collins Aerospace manufacturing facility. Detailed information can be found in the company’s official publications and investor relations materials.

The next section will explore potential future trends and challenges facing this critical manufacturing hub.

Conclusion

This exploration has elucidated the crucial functions and intricate operations of the Collins Aerospace main plant. It is a central node within the organization’s global network, critical for manufacturing capacity, technological innovation, supply chain integration, workforce expertise, quality assurance, and global distribution. These elements combine to establish its significance in the aerospace sector.

Continued success requires sustained commitment to innovation, efficiency, and adaptability. Addressing challenges surrounding workforce development, supply chain resilience, and regulatory compliance is essential for maintaining a competitive edge in the dynamic aerospace landscape. Further research and analysis are needed to fully understand the long-term implications of this site’s activities on the industry and global economy.