The discipline blends fundamental principles governing matter, energy, and their interactions with the design, development, and operation of vehicles and systems within Earth’s atmosphere and beyond. It encompasses a wide array of subjects, including aerodynamics, propulsion, structural mechanics, thermodynamics, and control systems. For example, calculating the lift and drag forces on an aircraft wing requires a deep understanding of fluid dynamics, a core component of physical study, as well as materials science to ensure structural integrity.

Its significance lies in its ability to enable advancements in air and space travel, satellite technology, and related fields. Historical developments, from the first powered flights to modern-day space exploration, have been driven by a continuous application of these principles. The pursuit of increased efficiency, reduced environmental impact, and enhanced performance in aerial and space vehicles necessitates ongoing innovation in the field, benefiting society through improved transportation, communication, and scientific discovery.

The following sections will delve into specific areas where a rigorous application of physical laws is paramount to successful design and operation, examining topics such as propulsion systems, flight dynamics, and the unique challenges presented by the space environment. These topics showcase how theoretical knowledge translates into practical solutions, pushing the boundaries of what is achievable in air and space.

Essential Considerations in Applied Physical Science for Air and Space Vehicle Development

The following are critical considerations and best practices for professionals and students working in areas related to the application of fundamental physical laws to the design and operation of aerial and space vehicles.

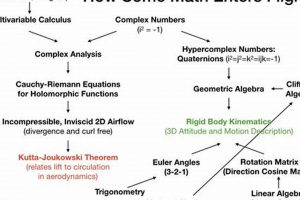

Tip 1: Master Fundamental Principles: A strong foundation in classical mechanics, thermodynamics, electromagnetism, and quantum mechanics is essential. Aerodynamic analysis, for instance, necessitates a solid grasp of fluid dynamics and the Navier-Stokes equations.

Tip 2: Emphasize Computational Modeling: Modern vehicle design relies heavily on computational fluid dynamics (CFD) and finite element analysis (FEA). Proficiency in these tools is crucial for simulating performance and predicting potential failures.

Tip 3: Understand Materials Science: The selection of materials with specific strength, weight, and thermal properties is critical. For example, composite materials are widely used to reduce weight without compromising structural integrity.

Tip 4: Prioritize System-Level Thinking: Recognize the interdependencies between various subsystems, such as propulsion, avionics, and control. Optimizing one subsystem in isolation may negatively impact overall performance.

Tip 5: Account for Environmental Effects: Consider the impact of atmospheric conditions, radiation, and vacuum on vehicle performance and longevity. Spacecraft design, in particular, requires careful consideration of radiation shielding and thermal management.

Tip 6: Rigorously Validate Models with Experimental Data: Computational models should be validated with wind tunnel testing, flight tests, or other experimental methods to ensure accuracy and reliability.

Tip 7: Embrace Interdisciplinary Collaboration: Effective vehicle development requires collaboration between engineers, scientists, and technicians from various disciplines. Clear communication and shared understanding are essential.

These guidelines highlight the importance of a deep understanding of underlying physical principles, combined with practical skills in modeling, materials, and systems integration. Successful application contributes to safer, more efficient, and more capable air and space vehicles.

The subsequent sections will build upon these principles, exploring specific applications and challenges in greater detail, providing a comprehensive perspective on the role of physical science in the advancement of air and space technology.

1. Aerodynamics

Aerodynamics, as a core sub-discipline, is inextricably linked to the broader scope. It furnishes the theoretical and empirical basis for understanding how air interacts with moving objects, particularly vehicles designed for atmospheric flight. The shape of an aircraft wing, for instance, is directly determined by aerodynamic principles derived from fluid dynamics, specifically the Bernoulli equation and the Navier-Stokes equations. These equations describe the relationship between air pressure, velocity, and density, allowing engineers to calculate lift and drag forces, essential parameters for aircraft design and performance.

The impact extends beyond fixed-wing aircraft. Helicopter rotor design, missile trajectory optimization, and even the external shape of high-speed trains are all influenced by aerodynamic considerations. Wind tunnels are crucial in this context, enabling the physical validation of theoretical models and computational simulations. For example, the design of the Boeing 787 Dreamliner involved extensive wind tunnel testing to optimize its wing shape for fuel efficiency, demonstrating the practical significance of precise aerodynamic analysis in the pursuit of improved aircraft performance. The design must also consider issues such as stall, flutter and aeroelasticity, where the interaction of aerodynamic forces with structural deformation can lead to catastrophic failure.

Aerodynamic knowledge is not static; it evolves alongside advancements in computational power and experimental techniques. As flight vehicles become faster, more complex, and operate in increasingly challenging environments, a thorough understanding of aerodynamic principles is crucial for designing efficient, stable, and safe air and space vehicles. Advancements in areas like computational fluid dynamics enable engineers to explore a wider range of design options, optimize performance, and mitigate potential risks before physical prototypes are even built.

2. Propulsion

Propulsion, a fundamental aspect, is integral to the practical application of physical laws within atmospheric and space systems. The efficacy and design of any aerial or space vehicle hinge on the efficiency and reliability of its propulsion system, which directly translates to mission success and overall system performance.

- Thermodynamic Cycles

The operation of many aerospace engines, such as gas turbines and ramjets, is based on thermodynamic cycles. Understanding the Brayton cycle, for example, is critical to the design and optimization of gas turbine engines used in aircraft. These cycles describe the transformation of thermal energy into mechanical work, defining parameters such as efficiency and thrust output. Deviations from ideal thermodynamic behavior, due to factors such as friction and incomplete combustion, directly impact engine performance and require sophisticated modeling and analysis.

- Rocket Motor Chemistry and Physics

Rocket propulsion involves the chemical reactions that produce high-velocity exhaust gases. The principles of chemical kinetics and thermodynamics dictate the selection of propellants and the optimization of combustion chamber design. Solid rocket motors utilize pre-mixed solid propellants, while liquid rocket engines combine liquid oxidizers and fuels. Achieving optimal performance requires a precise understanding of the energy released during combustion and the factors that influence reaction rates. Issues such as nozzle erosion and propellant stability also demand thorough material science and engineering considerations.

- Fluid Dynamics in Nozzle Design

The design of a rocket or jet engine nozzle relies heavily on fluid dynamics. The nozzle’s geometry accelerates the exhaust gases to supersonic speeds, converting thermal energy into kinetic energy, which produces thrust. Convergent-divergent nozzles are commonly used in rocket engines to achieve supersonic flow. The shape and dimensions of the nozzle must be carefully designed to minimize losses and maximize thrust efficiency. Computational fluid dynamics simulations are routinely employed to optimize nozzle performance and predict flow behavior under various operating conditions.

- Electric Propulsion

Electric propulsion systems, such as ion thrusters and Hall-effect thrusters, utilize electromagnetic fields to accelerate ions, generating thrust. These systems are particularly well-suited for long-duration space missions due to their high specific impulse. The underlying physics involves the interaction of charged particles with electric and magnetic fields, requiring a detailed understanding of plasma physics and electromagnetic theory. Electric propulsion systems offer significantly higher fuel efficiency compared to chemical rockets, enabling more ambitious space exploration missions. The design and operation of these systems require expertise in both electrical engineering and physical science.

The interplay between these facets underscores the essential nature in realizing successful air and space vehicles. The ongoing refinement of propulsion technologies continues to drive advancements in both atmospheric and space exploration, with each new development relying on the foundational principles of physical science.

3. Materials

Materials science is a cornerstone discipline, directly influencing the performance, safety, and longevity of air and space vehicles. The selection and application of suitable materials are governed by physical laws and principles, ensuring structural integrity under extreme conditions.

- Strength-to-Weight Ratio

A primary consideration is the strength-to-weight ratio of materials used in vehicle construction. Lighter materials reduce overall weight, leading to improved fuel efficiency and increased payload capacity. Aluminum alloys, titanium alloys, and composite materials are frequently employed due to their high strength-to-weight ratios. For example, carbon fiber reinforced polymers (CFRPs) are extensively used in aircraft wings and fuselages, offering significant weight savings compared to traditional aluminum structures. The structural design must account for stress concentrations and potential failure modes, applying principles of solid mechanics and fracture mechanics to ensure safety.

- High-Temperature Performance

Components exposed to high temperatures, such as engine turbine blades and heat shields, require materials with exceptional thermal resistance. Nickel-based superalloys are commonly used in turbine blades due to their ability to maintain strength at elevated temperatures. Ceramic matrix composites (CMCs) are employed in heat shields to protect spacecraft during re-entry, withstanding temperatures exceeding 1,500 degrees Celsius. The design and selection of high-temperature materials involve a deep understanding of thermodynamics, heat transfer, and material degradation mechanisms.

- Corrosion Resistance

Exposure to corrosive environments, such as saltwater or atmospheric pollutants, can compromise the structural integrity of vehicles. Stainless steels and specialized coatings are used to mitigate corrosion. For example, anodizing aluminum alloys creates a protective oxide layer that prevents further corrosion. The selection of corrosion-resistant materials requires knowledge of electrochemistry and material degradation processes. Regular inspection and maintenance programs are essential to detect and address corrosion before it leads to structural failure.

- Radiation Shielding

Spacecraft operating in Earth orbit or deep space are exposed to high levels of radiation, which can damage electronic components and pose a health risk to astronauts. Materials with high atomic numbers, such as lead or aluminum, are effective at shielding against radiation. The design of radiation shielding involves understanding the interaction of radiation with matter and optimizing the shielding configuration to minimize exposure. Research is ongoing to develop new, lightweight materials that offer enhanced radiation protection.

These materials considerations are vital within the broader field. Ongoing materials research and development efforts are focused on creating stronger, lighter, and more durable materials that enable advancements in both air and space technology. The successful application of these materials relies on a deep understanding of physical laws and principles, ensuring the safe and efficient operation of aircraft and spacecraft across a range of operating conditions.

4. Thermodynamics

Thermodynamics is an indispensable component within the broader framework. Its principles govern energy transfer and transformation, dictating the performance and efficiency of numerous systems critical to air and space vehicle operation.

- Engine Efficiency and the Laws of Thermodynamics

The efficiency of aerospace engines, such as jet engines and rocket engines, is fundamentally limited by the laws of thermodynamics. The Carnot cycle, as a theoretical ideal, establishes an upper bound on the efficiency of any heat engine operating between two temperature reservoirs. Real-world engines deviate from this ideal due to factors such as friction, incomplete combustion, and heat losses. Understanding these deviations and applying thermodynamic principles to minimize them is crucial for maximizing engine performance and reducing fuel consumption. For example, advanced gas turbine engines incorporate complex blade designs and cooling systems to operate at higher temperatures, thereby increasing thermal efficiency.

- Heat Transfer in Aerospace Systems

Heat transfer mechanisms conduction, convection, and radiation play a critical role in the thermal management of aerospace systems. Aircraft and spacecraft components generate heat due to internal processes and external environmental factors. Effective heat dissipation is essential to prevent overheating and ensure reliable operation. Heat sinks, radiators, and thermal insulation materials are employed to regulate temperature. Spacecraft operating in the vacuum of space rely primarily on radiation for heat rejection, requiring specialized surface coatings and radiator designs to maintain thermal equilibrium. The design of these systems necessitates a thorough understanding of heat transfer coefficients, thermal conductivity, and radiative properties of materials.

- Thermodynamic Properties of Working Fluids

The performance of many aerospace systems depends on the thermodynamic properties of working fluids, such as air, fuel, and refrigerants. The behavior of these fluids under varying temperature and pressure conditions dictates system efficiency and stability. Equations of state, such as the ideal gas law and more complex equations of state, are used to model fluid behavior. For example, the design of a cryogenic rocket engine requires a detailed knowledge of the thermodynamic properties of liquid hydrogen and liquid oxygen at extremely low temperatures. The selection of appropriate working fluids is crucial for optimizing system performance and ensuring safe operation.

- Aerodynamic Heating

High-speed flight generates significant aerodynamic heating due to the compression of air at the vehicle’s surface. This effect is particularly pronounced during atmospheric re-entry, where spacecraft experience extremely high temperatures. The design of thermal protection systems (TPS) is essential to prevent structural damage and ensure the survival of the vehicle. TPS materials, such as ceramic tiles and ablative coatings, are designed to withstand intense heat fluxes and minimize heat transfer to the underlying structure. Understanding the physics of aerodynamic heating and developing effective TPS solutions is crucial for enabling hypersonic flight and space exploration.

These thermodynamic considerations are central to the development of efficient, reliable, and safe air and space vehicles. Ongoing research and development efforts are focused on advancing thermodynamic technologies to improve engine performance, enhance thermal management, and enable new capabilities in aerospace transportation and exploration.

5. Control Systems

Control systems are fundamental to the operation and stability of air and space vehicles, serving as the interface between theoretical physical models and real-world performance. These systems manipulate vehicle dynamics to achieve desired flight paths and orientations, relying on sensor data, computational algorithms, and actuator mechanisms to maintain stability and execute commands.

- Stability Augmentation Systems

Stability augmentation systems (SAS) counteract inherent instabilities in aircraft design. Aircraft are subject to aerodynamic forces that can lead to unwanted oscillations or deviations from the intended flight path. SAS employs sensors, such as gyroscopes and accelerometers, to detect these deviations and automatically adjust control surfaces to maintain stability. For example, in high-performance fighter jets, SAS is essential to compensate for aerodynamic instabilities at high speeds and angles of attack, enabling pilots to maintain precise control. Without SAS, many modern aircraft would be virtually unmanageable.

- Fly-by-Wire Systems

Fly-by-wire (FBW) systems replace traditional mechanical control linkages with electronic interfaces. Pilot commands are transmitted to a flight control computer, which then calculates the necessary control surface deflections based on aerodynamic models and stability algorithms. FBW systems offer several advantages, including reduced weight, improved maneuverability, and enhanced safety features. For instance, FBW systems can incorporate envelope protection functions that prevent pilots from exceeding the aircraft’s structural limits or entering dangerous flight regimes. The Airbus A320 and Boeing 777 families of aircraft utilize FBW technology, demonstrating its widespread adoption in commercial aviation.

- Guidance, Navigation, and Control (GNC) Systems

Guidance, navigation, and control (GNC) systems are essential for autonomous operation of spacecraft and missiles. These systems integrate sensors, such as GPS receivers, inertial measurement units (IMUs), and star trackers, to determine the vehicle’s position, velocity, and attitude. Based on this information, the GNC system calculates the necessary control commands to achieve the desired trajectory or target. GNC systems are critical for satellite orbit maintenance, interplanetary navigation, and precision targeting. The Mars rovers, for example, rely on sophisticated GNC systems to navigate the Martian surface and execute scientific missions.

- Autopilot Systems

Autopilot systems automate flight operations, reducing pilot workload and improving efficiency. Autopilots can maintain altitude, heading, and airspeed, as well as execute complex flight plans. Modern autopilots incorporate advanced algorithms, such as model predictive control (MPC) and adaptive control, to optimize performance and adapt to changing flight conditions. Autopilots are widely used in commercial aviation to reduce pilot fatigue on long-haul flights and improve fuel efficiency. They are also essential for unmanned aerial vehicles (UAVs), enabling autonomous surveillance, reconnaissance, and delivery missions.

The effectiveness of any air or space vehicle’s control system depends on a thorough understanding of physical principles, sensor technology, and control algorithms. The ongoing development of advanced control systems is crucial for enabling safer, more efficient, and more capable aircraft and spacecraft. As vehicles become more complex and operate in increasingly challenging environments, the sophistication and reliability of their control systems will remain a critical factor in mission success.

6. Orbital Mechanics

Orbital mechanics, a specialized area, is a direct application of classical mechanics and gravitation within the broader discipline. It provides the theoretical framework for understanding and predicting the motion of artificial satellites and other celestial bodies. The principles of Newtonian physics, particularly Newton’s law of universal gravitation and the laws of motion, are fundamental to calculating orbital trajectories, velocities, and periods. For example, the precise placement of a communications satellite into geostationary orbit relies on accurate calculations of gravitational forces and orbital maneuvers, requiring a thorough understanding of Kepler’s laws and orbital perturbations.

The design and execution of space missions are inextricably linked to orbital mechanics. Mission planners use orbital mechanics to determine the optimal trajectories for spacecraft traveling to other planets, minimizing fuel consumption and mission duration. The Hohmann transfer orbit, a fuel-efficient trajectory between two circular orbits, is a classic example of the application of orbital mechanics principles. Furthermore, orbital mechanics is essential for collision avoidance in Earth orbit, where thousands of satellites and debris objects pose a potential hazard. Organizations like the U.S. Space Command constantly monitor the orbits of these objects and issue warnings to satellite operators when a close approach is predicted.

In summary, orbital mechanics is a vital subfield, enabling the design, operation, and safety of space-based systems. The ongoing development of more sophisticated orbital models and computational techniques is crucial for supporting future space exploration endeavors and ensuring the long-term sustainability of activities in space. This directly highlights the practical significance of theoretical study in addressing real-world engineering challenges within the aerospace domain.

7. Space Environment

The space environment presents a unique and hostile set of conditions that profoundly impact the design and operation of aerospace vehicles and systems, thereby establishing its critical importance within the broader field. The vacuum of space, characterized by near-zero pressure, necessitates specialized materials and designs to prevent outgassing and maintain structural integrity. Extreme temperature variations, ranging from intense solar radiation to frigid darkness, demand robust thermal management systems to protect sensitive components. High-energy particle radiation and micrometeoroid impacts pose significant threats to spacecraft electronics and surfaces, requiring shielding and damage mitigation strategies. These environmental factors directly influence material selection, structural design, propulsion systems, and control mechanisms, underscoring the intrinsic connection between these considerations and successful engineering outcomes.

For instance, the International Space Station (ISS) serves as a prime example of an engineered system meticulously designed to withstand the rigors of the space environment. The ISS employs multi-layered insulation to regulate temperature, radiation shielding to protect astronauts and equipment, and redundant systems to ensure continued operation in the event of component failure. Similarly, the design of interplanetary probes, such as the Voyager spacecraft, incorporates specialized materials and power systems to enable long-duration missions in the harsh radiation belts and extreme temperatures far from Earth. The degradation of solar panels over time due to radiation exposure illustrates the long-term effects of the space environment on spacecraft performance, highlighting the need for durable materials and advanced power management strategies.

The understanding and mitigation of space environment effects are essential for ensuring the reliability and longevity of space assets. Ongoing research focuses on developing new materials with enhanced radiation resistance, more efficient thermal management techniques, and improved methods for detecting and avoiding space debris. Accurate modeling of the space environment and its impact on aerospace systems is crucial for predicting mission performance and mitigating potential risks. As space activities expand and become increasingly complex, a comprehensive understanding of the space environment and its integration into engineering practices will remain paramount for achieving mission objectives and ensuring the continued exploration and utilization of space.

Frequently Asked Questions

This section addresses common inquiries regarding the application of physical science in the design and operation of air and space vehicles. The goal is to provide clear and concise answers to frequently raised questions within the field.

Question 1: What are the primary areas of physics directly applicable to aerospace engineering?

Key areas include mechanics (both classical and fluid), thermodynamics, electromagnetism, and materials science. Mechanics governs motion and forces, essential for flight dynamics and structural analysis. Thermodynamics is critical for understanding engine performance and heat transfer. Electromagnetism plays a role in avionics and communication systems. Materials science is vital for selecting appropriate materials for vehicle construction.

Question 2: How is computational modeling used in the design of air and space vehicles?

Computational fluid dynamics (CFD) and finite element analysis (FEA) are extensively used to simulate aerodynamic performance, structural behavior, and thermal characteristics. CFD allows engineers to analyze airflow around vehicles, predicting lift, drag, and stability. FEA is used to assess structural stresses and strains under various loading conditions, ensuring structural integrity.

Question 3: What role does materials science play in aerospace vehicle development?

Materials science is critical for selecting materials with specific strength, weight, and thermal properties. Lightweight materials, such as aluminum alloys and composite materials, are used to reduce vehicle weight and improve fuel efficiency. High-temperature materials, such as nickel-based superalloys and ceramic matrix composites, are used in engines and heat shields to withstand extreme temperatures.

Question 4: How does the space environment impact the design of spacecraft?

The space environment presents unique challenges, including vacuum, extreme temperatures, radiation, and micrometeoroids. Spacecraft must be designed to withstand these conditions. Vacuum requires specialized materials to prevent outgassing. Thermal management systems regulate temperature. Radiation shielding protects electronic components and astronauts. Micrometeoroid shielding prevents damage to critical systems.

Question 5: What are some of the key challenges currently facing aerospace engineers?

Current challenges include improving fuel efficiency, reducing emissions, developing hypersonic vehicles, enabling long-duration space missions, and mitigating space debris. These challenges require innovative solutions in aerodynamics, propulsion, materials, and control systems.

Question 6: How is “physics aerospace engineering” research contributing to advancements in space exploration?

Research in this domain contributes to the development of new propulsion systems, advanced materials, and autonomous control systems. These advancements enable more efficient and cost-effective space exploration, allowing for longer-duration missions, more capable spacecraft, and greater scientific discovery.

In summary, the effective application of physical laws and principles is paramount to success in air and space vehicle design and operation. The field continues to evolve, driven by ongoing research and technological advancements.

The following section explores future directions and emerging trends in the application of physics within aerospace vehicle development.

Conclusion

The preceding exploration has demonstrated the integral role of physical laws and principles in aerospace vehicle engineering. From aerodynamic design to propulsion system development and the selection of appropriate materials, a deep understanding of physics is essential for creating safe, efficient, and effective air and space vehicles. The unique challenges presented by the space environment further emphasize the need for rigorous application of physical science in spacecraft design and operation.

Continued advancement in air and space technology hinges on ongoing innovation in physics and its application to engineering challenges. Further research and development are critical for pushing the boundaries of what is achievable in air and space, enabling new capabilities in transportation, exploration, and scientific discovery. The commitment to the principles of physics aerospace engineering is paramount to shaping the future of flight and space exploration.