Opportunities in the manufacturing sector specializing in aviation components are available in the greater Nashville area. These openings generally involve roles at various levels, from entry-level positions to specialized engineering or managerial roles, within a company focused on producing parts and systems for the aerospace industry. An example of a relevant function may include the assembly of structural elements for aircraft.

The significance of these employment opportunities stems from their contribution to the regional economy and the advancement of the aerospace sector. These jobs often provide competitive compensation packages, benefits, and opportunities for professional development. Furthermore, they contribute to the continued growth of advanced manufacturing capabilities within the local area. The historical context reveals a strengthening presence of the aerospace industry within the region over the past decade, supported by a skilled workforce and favorable business environment.

The subsequent discussion will delve into specific aspects of aerospace manufacturing functions in the region, encompassing job descriptions, required qualifications, and the outlook for this segment of the local job market. Information on relevant educational resources and training programs that support career advancement in this industry will also be examined.

The following guidelines offer strategic advice for individuals seeking roles related to aviation component manufacturing within the Nashville region.

Tip 1: Target Specific Skill Sets: Emphasize skills directly applicable to the aviation industry. This includes proficiency in CAD/CAM software, knowledge of aerospace materials (e.g., aluminum alloys, composites), and experience with precision machining techniques.

Tip 2: Obtain Relevant Certifications: Industry-recognized certifications, such as those offered by the National Institute for Aviation Training (NIAT), enhance candidate profiles and demonstrate commitment to professional development.

Tip 3: Network Strategically: Attend industry events, join professional organizations (e.g., SAE International), and connect with individuals working in aerospace manufacturing through online platforms. Focused networking can reveal unadvertised opportunities.

Tip 4: Research Target Companies: Conduct thorough research on potential employers. Understand their specific product lines, manufacturing processes, and company culture. This knowledge can be leveraged during interviews.

Tip 5: Tailor Application Materials: Customize resumes and cover letters to align with the specific requirements of each position. Highlight relevant experience and skills, and quantify accomplishments whenever possible. Avoid generic applications.

Tip 6: Prepare for Technical Assessments: Expect technical assessments to evaluate skills in areas such as blueprint reading, geometric dimensioning and tolerancing (GD&T), and statistical process control (SPC). Proactive preparation is crucial.

Tip 7: Demonstrate Problem-Solving Abilities: Highlight examples of successful problem-solving in previous roles. Aerospace manufacturing demands a proactive approach to identifying and resolving technical challenges.

Adherence to these recommendations can significantly increase an applicant’s likelihood of securing a desirable position. Diligent preparation and a targeted approach are essential for success.

The concluding section of this article will provide a comprehensive overview of the educational pathways that lead to advancement within the aviation manufacturing sector.

1. Manufacturing Processes

Manufacturing processes are fundamentally linked to employment opportunities in the aviation sector within the Nashville region. The specific techniques and methodologies employed directly influence the skill sets required of the workforce and the nature of available positions. These processes represent the tangible activities that transform raw materials into finished aerospace components.

- Precision Machining and CNC Operation

Precision machining, particularly utilizing Computer Numerical Control (CNC) equipment, is integral to aerospace manufacturing. This involves the precise removal of material to create components that meet stringent dimensional tolerances. Roles associated with this facet include CNC machinists, programmers, and quality control inspectors. The demand for personnel with expertise in operating and maintaining CNC machinery is consistently high.

- Composite Material Fabrication

The increasing use of composite materials in aircraft construction has created a need for specialized manufacturing processes, such as resin transfer molding (RTM) and automated fiber placement (AFP). These processes require skilled technicians and engineers who understand the properties of composite materials and can operate sophisticated fabrication equipment. Opportunities exist in areas such as composite layup, curing, and non-destructive testing.

- Assembly and Integration

The assembly and integration of individual components into larger subassemblies or complete systems represents another crucial aspect of aviation manufacturing. This requires meticulous attention to detail and adherence to strict quality standards. Positions in assembly and integration range from entry-level technicians to experienced mechanics and engineers with expertise in aircraft systems.

- Surface Treatment and Finishing

Surface treatment and finishing processes, such as anodizing, painting, and coating, are essential for protecting aerospace components from corrosion and wear. These processes require specialized equipment and skilled operators who understand the chemical and physical properties of various surface treatments. Opportunities exist in areas such as surface preparation, coating application, and quality inspection.

The aforementioned manufacturing processes collectively shape the demand for qualified personnel within the Nashville aviation sector. A thorough understanding of these processes is critical for individuals seeking employment and for companies aiming to optimize their operations.

2. Aerospace Materials

The selection and application of materials represent a cornerstone of aviation manufacturing, directly impacting job functions within the Nashville aerospace sector. Material properties dictate manufacturing processes, quality control procedures, and the skills demanded of personnel.

- Aluminum Alloys

Aluminum alloys, characterized by their high strength-to-weight ratio, remain a prevalent material in aircraft construction. Roles involving aluminum alloys require expertise in machining, forming, and welding. Examples include aircraft skin manufacturing and structural component fabrication. Consequently, job roles in CNC machining, welding, and non-destructive testing (NDT) are frequently tied to the processing of aluminum alloys.

- Titanium Alloys

Titanium alloys offer superior strength and corrosion resistance at elevated temperatures, making them suitable for engine components and structural parts subjected to high stress. The machining and fabrication of titanium alloys necessitate specialized equipment and expertise due to the material’s high hardness and tendency to work harden. Job roles in precision machining and advanced welding are often associated with titanium alloys.

- Composite Materials

Composite materials, such as carbon fiber reinforced polymers (CFRP), provide exceptional strength-to-weight ratios and design flexibility. Their use in aircraft structures is steadily increasing. Working with composite materials requires specialized skills in layup, curing, and non-destructive inspection. Job roles in composite manufacturing, including composite technicians and engineers, are in growing demand.

- High-Temperature Alloys (Nickel-Based Superalloys)

High-temperature alloys, such as nickel-based superalloys, are used in gas turbine engines due to their ability to withstand extreme temperatures and stresses. The processing of these alloys requires specialized equipment and expertise in casting, forging, and welding. Job roles in engine component manufacturing and repair frequently involve these materials, demanding skills in advanced welding techniques and heat treatment.

The selection and application of aerospace materials directly influence the skill sets required in the Nashville aerospace sector. From machining aluminum alloys to fabricating composite structures and processing high-temperature alloys, materials expertise is integral to various job functions. Opportunities often exist for skilled professionals with a comprehensive understanding of these materials and their associated manufacturing processes.

3. Quality Control

Quality control is a paramount function within aerospace manufacturing, directly influencing the nature and availability of positions related to this field. The rigorous standards and regulatory requirements of the aviation industry mandate meticulous oversight throughout the entire production process, from raw material inspection to final product testing. This emphasis on quality drives the need for skilled personnel and specialized roles within “tect aerospace nashville jobs”.

- Non-Destructive Testing (NDT)

Non-destructive testing is essential for identifying internal flaws or defects in aerospace components without compromising their structural integrity. Methods such as ultrasonic testing, radiographic inspection, and dye penetrant inspection are routinely employed. “tect aerospace nashville jobs” related to NDT require certified technicians with expertise in interpreting test results and adhering to industry standards. An example of NDT application would be inspecting a turbine blade for micro-cracks after heat treatment. The consequences of undetected flaws could be catastrophic, underscoring the importance of qualified NDT personnel.

- Dimensional Inspection

Dimensional inspection ensures that manufactured parts meet precise dimensional tolerances specified in engineering drawings. This involves using precision measuring instruments, such as coordinate measuring machines (CMMs), to verify part dimensions. “tect aerospace nashville jobs” in dimensional inspection require metrologists and quality control inspectors with proficiency in GD&T (Geometric Dimensioning and Tolerancing) and CMM operation. A real-world example is verifying the precise dimensions of an aircraft wing spar to ensure proper fit and structural integrity. Incorrect dimensions can lead to assembly issues and compromise flight safety, highlighting the critical role of dimensional inspection.

- Material Testing and Analysis

Material testing and analysis involves verifying the mechanical properties and chemical composition of materials used in aerospace manufacturing. Tests such as tensile testing, hardness testing, and chemical analysis are performed to ensure that materials meet specified requirements. “tect aerospace nashville jobs” in this area require materials engineers and lab technicians with expertise in material testing procedures and data analysis. For instance, testing the tensile strength of a new batch of aluminum alloy used in fuselage construction is vital to validate that it meets the aircraft design requirements. Failing to do so could lead to structural failure under stress.

- Statistical Process Control (SPC)

Statistical process control (SPC) utilizes statistical methods to monitor and control manufacturing processes, ensuring consistent product quality. SPC charts are used to track process performance and identify potential issues before they lead to defects. “tect aerospace nashville jobs” related to SPC require quality engineers and process engineers with knowledge of statistical analysis and process improvement techniques. An example is monitoring the diameter of machined holes on an aircraft engine component using an SPC chart. If the process begins to drift outside of acceptable control limits, corrective actions can be taken to prevent the production of out-of-tolerance parts.

The multifaceted nature of quality control directly impacts “tect aerospace nashville jobs” by creating a demand for skilled professionals in various specialized roles. The stringent quality requirements of the aviation industry necessitate a robust quality control system, leading to numerous employment opportunities for individuals with the requisite knowledge and expertise. Failure to maintain rigorous quality control standards can have severe consequences, highlighting the critical importance of these positions within the aerospace manufacturing sector.

4. Precision Machining

Precision machining forms a critical component of “tect aerospace nashville jobs” due to the stringent requirements of the aerospace industry. This process involves removing material from a workpiece with exceptionally high accuracy to achieve specific dimensions, tolerances, and surface finishes. The inherent complexity and tight specifications associated with aircraft components necessitate specialized skills and advanced equipment, thereby driving the demand for qualified precision machinists and related personnel within the Nashville area. The causal relationship is direct: the need for extremely accurate parts in aerospace manufacturing creates a corresponding demand for individuals proficient in precision machining techniques.

Consider the example of manufacturing turbine blades for jet engines. These blades must conform to precise aerodynamic profiles to ensure optimal engine performance and efficiency. Deviations from the specified dimensions, even by a few microns, can significantly impact engine performance or, in extreme cases, lead to catastrophic failure. Therefore, precision machining is not merely a desirable skill, but a fundamental requirement for ensuring the safety and reliability of aircraft. Specific job roles directly tied to precision machining include CNC machinists, tool and die makers, and quality control inspectors specializing in dimensional metrology. These positions are integral to the entire aerospace manufacturing process, from initial part creation to final inspection and certification.

In summary, the connection between precision machining and “tect aerospace nashville jobs” is both vital and pervasive. The aerospace industrys demand for high-precision components necessitates a workforce skilled in advanced machining techniques. Understanding this relationship is crucial for individuals seeking employment in the aerospace sector and for companies aiming to maintain a competitive edge in the global market. Challenges in this area often include keeping up with rapidly evolving technologies and ensuring a continuous supply of qualified personnel through effective training programs. Furthermore, the sector is subject to strict regulatory oversight, imposing significant compliance requirements on all aspects of the manufacturing process.

5. Engineering Roles

Engineering roles are foundational to “tect aerospace nashville jobs” due to the complex design, analysis, and manufacturing processes inherent in the aerospace sector. The industry requires engineers across various disciplines to ensure the safety, performance, and reliability of aircraft components and systems. A direct causal relationship exists: without skilled engineers, the design and production of intricate aerospace parts would be impossible. The importance of these roles stems from the need to meet stringent regulatory standards and exacting performance requirements. For example, mechanical engineers are crucial for designing structural components capable of withstanding extreme stress, while electrical engineers are essential for developing and integrating complex avionics systems.

The practical application of engineering principles is evident in every stage of aerospace manufacturing. Design engineers utilize CAD/CAM software to create detailed models of parts, while manufacturing engineers develop efficient production processes. Materials engineers select appropriate alloys and composites to optimize strength and weight. Aerospace engineers analyze flight dynamics and performance characteristics. A real-world illustration involves the development of a new composite wing design. This requires collaboration between structural engineers, materials engineers, and manufacturing engineers to ensure that the wing meets performance requirements, is structurally sound, and can be manufactured efficiently. Each of these roles contributes directly to the creation of a safe and reliable aircraft component.

In summary, engineering roles represent a critical component of “tect aerospace nashville jobs”. These positions drive innovation, ensure quality, and maintain safety within the aerospace industry. The challenges faced by engineers in this sector include keeping pace with rapidly evolving technologies, complying with strict regulatory requirements, and managing complex projects with demanding timelines. The continuous demand for skilled engineers reflects the ongoing growth and technological advancement of the aerospace industry. Understanding this relationship is paramount for individuals seeking careers in this field and for companies striving to maintain a competitive edge.

6. Regulatory Compliance

Regulatory compliance forms a fundamental element influencing the landscape of “tect aerospace nashville jobs”. The aerospace industry operates under stringent rules and regulations mandated by governmental bodies, primarily the Federal Aviation Administration (FAA). These regulations dictate every aspect of design, manufacturing, testing, and maintenance, thereby shaping job roles and skill requirements.

- FAA Regulations and Certification

FAA regulations, such as 14 CFR Part 21 (Certification Procedures for Products and Parts) and 14 CFR Part 145 (Repair Stations), establish rigorous standards for aerospace manufacturing and maintenance. “tect aerospace nashville jobs” related to compliance involve ensuring adherence to these regulations. For example, a quality assurance engineer must verify that all manufacturing processes comply with FAA requirements and that products meet specified performance standards. Failure to comply can result in penalties, production delays, and damage to reputation.

- AS9100 Certification

AS9100 is a widely adopted quality management system standard specific to the aerospace industry. Obtaining and maintaining AS9100 certification demonstrates a company’s commitment to quality and compliance. “tect aerospace nashville jobs” related to AS9100 involve implementing and maintaining the quality management system, conducting internal audits, and ensuring continuous improvement. For instance, a documentation specialist may be responsible for maintaining records and procedures to demonstrate compliance with AS9100 requirements.

- Export Control Regulations (ITAR/EAR)

Export control regulations, such as the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR), govern the export of sensitive technologies and defense-related items. “tect aerospace nashville jobs” related to export compliance involve ensuring that products and technologies are exported in accordance with these regulations. This may require obtaining export licenses, screening customers, and implementing security measures to prevent unauthorized access to controlled information. For example, a compliance officer may be responsible for ensuring that all exports comply with ITAR regulations and that proper documentation is maintained.

- Safety and Environmental Regulations

Aerospace manufacturing is subject to various safety and environmental regulations designed to protect workers and the environment. “tect aerospace nashville jobs” related to safety and environmental compliance involve implementing and maintaining safety programs, managing hazardous materials, and complying with environmental regulations. For instance, an environmental health and safety (EHS) manager may be responsible for ensuring that the facility complies with all applicable safety and environmental regulations, such as those related to air emissions and waste disposal.

These facets of regulatory compliance demonstrate their significance in shaping “tect aerospace nashville jobs.” Adherence to these standards is not merely a legal obligation but a fundamental aspect of ensuring product safety, operational efficiency, and market access within the global aerospace industry. Companies that prioritize regulatory compliance are better positioned to attract and retain skilled personnel, mitigate risks, and maintain a competitive advantage.

7. Skilled Workforce

The availability of a proficient and well-trained workforce is a critical determinant of success for “tect aerospace nashville jobs”. The aerospace industry, characterized by complex manufacturing processes and stringent quality standards, relies heavily on individuals possessing specialized skills and technical expertise. The competencies of this workforce directly impact productivity, innovation, and the ability of companies to meet regulatory requirements.

- Technical Training Programs

Technical training programs, offered by vocational schools, community colleges, and industry associations, provide individuals with the skills necessary to succeed in aerospace manufacturing roles. These programs typically cover topics such as blueprint reading, CNC machining, welding, and composite materials. For example, the Tennessee College of Applied Technology (TCAT) offers programs specifically tailored to the needs of the aerospace industry. Graduates of these programs are often highly sought after by aerospace companies seeking qualified technicians and machinists. The existence of robust technical training programs is a key factor in attracting aerospace manufacturers to the Nashville area.

- Engineering Expertise

A skilled engineering workforce is essential for designing, developing, and improving aerospace products and processes. Engineers with expertise in mechanical, aerospace, materials, and electrical engineering are needed to meet the challenges of designing complex aircraft components and systems. Local universities, such as Vanderbilt University and Tennessee Technological University, offer engineering programs that provide graduates with the knowledge and skills needed to excel in the aerospace industry. The presence of a strong engineering talent pool is a major advantage for aerospace companies operating in the Nashville region.

- Quality Assurance Professionals

Quality assurance professionals play a critical role in ensuring that aerospace products meet stringent quality standards and regulatory requirements. These professionals are responsible for implementing and maintaining quality management systems, conducting inspections, and identifying and resolving quality issues. Certification programs, such as those offered by the American Society for Quality (ASQ), provide quality assurance professionals with the knowledge and skills needed to excel in their roles. A highly skilled quality assurance workforce is essential for maintaining the reputation and competitiveness of the Nashville aerospace sector.

- Continuous Learning and Development

The aerospace industry is constantly evolving, with new technologies and processes emerging on a regular basis. Therefore, continuous learning and development are essential for maintaining a skilled workforce. Companies that invest in training and development programs for their employees are better able to adapt to change and remain competitive. Industry associations, such as the Aerospace Industries Association (AIA), offer training programs and resources to help companies and individuals stay up-to-date on the latest trends and technologies. A commitment to continuous learning is a hallmark of a highly skilled aerospace workforce.

The interrelated nature of these facets underscores the integral role of a skilled workforce in driving the success of “tect aerospace nashville jobs”. A region with robust training programs, strong engineering talent, and a commitment to quality and continuous improvement is well-positioned to attract and retain aerospace manufacturers and to foster innovation and growth in this vital sector. The availability of such a workforce is a key differentiator in the competitive landscape of aerospace manufacturing.

Frequently Asked Questions about Aviation Manufacturing Opportunities in Nashville

This section addresses common inquiries regarding employment in aviation component manufacturing in the Nashville region, providing factual information to assist potential applicants.

Question 1: What qualifications are generally required for entry-level positions in aviation component manufacturing?

Entry-level roles typically require a high school diploma or equivalent. Specific requirements vary based on the position but may include basic mechanical aptitude, familiarity with hand tools, and the ability to read blueprints. Some positions may require completion of a vocational training program or certification.

Question 2: Are there opportunities for professional development and advancement within this sector?

Opportunities for professional development are available through on-the-job training, company-sponsored educational programs, and industry certifications. Advancement may be possible through promotions to supervisory roles or specialization in a particular skill set.

Question 3: What types of skills are most in-demand for experienced professionals seeking aviation component manufacturing roles?

In-demand skills include proficiency in CNC machining, composite materials fabrication, quality control inspection, and engineering design. Knowledge of aerospace materials, manufacturing processes, and regulatory requirements is also highly valued.

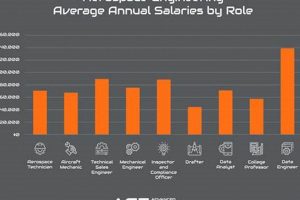

Question 4: How does the compensation compare to other manufacturing sectors in the Nashville area?

Compensation is competitive with other manufacturing sectors, often reflecting the specialized skills and technical knowledge required for aviation component manufacturing roles. Benefit packages typically include health insurance, retirement plans, and paid time off.

Question 5: What are the typical working conditions in aviation component manufacturing facilities?

Working conditions generally involve a manufacturing environment with exposure to machinery, noise, and potential hazards. Strict adherence to safety protocols is mandatory. Cleanliness and orderliness are emphasized to maintain product quality.

Question 6: What is the future outlook for aviation component manufacturing jobs in the Nashville area?

The future outlook is generally positive, with continued growth expected due to the increasing demand for aircraft and aerospace components. Investments in new technologies and infrastructure are expected to further stimulate the industry.

In summary, opportunities in aviation manufacturing in the Nashville area offer potential for stable employment, career advancement, and contributions to a critical sector.

The concluding segment of this material will offer a summary encompassing vital aspects of the “tect aerospace nashville jobs” discussion.

tect aerospace nashville jobs

The preceding analysis has explored the multifaceted landscape of “tect aerospace nashville jobs,” emphasizing the critical interplay between specialized skills, regulatory compliance, and technological advancements. Opportunities within this sector are shaped by the rigorous demands of the aerospace industry, requiring a workforce proficient in precision manufacturing, quality control, and engineering design. The significance of adherence to FAA regulations and industry standards, such as AS9100, cannot be overstated, influencing job functions across various departments.

The continued growth and innovation within the aerospace sector suggest a promising future for individuals seeking “tect aerospace nashville jobs.” It is incumbent upon aspiring professionals to invest in relevant education and training to acquire the necessary skills. The ongoing demand for qualified personnel in this sector presents opportunities for both individual career advancement and the sustained economic development of the Nashville region.