Roles within the aerospace sector focused on the acquisition of materials, components, and services necessary for aircraft production, maintenance, and operations are critical. These positions involve sourcing suppliers, negotiating contracts, and ensuring timely delivery of quality products, often under stringent regulatory guidelines. For example, a professional in this area might be responsible for procuring specialized alloys for engine construction or securing long-term agreements for avionics systems.

The careful management of the supply chain in the aviation industry is paramount for safety, efficiency, and cost-effectiveness. Skilled professionals in this domain contribute directly to maintaining operational readiness and competitive pricing. Historically, the function has evolved from basic procurement to a strategic aspect of aerospace businesses, integrating risk management and advanced planning to mitigate disruptions and optimize resource allocation.

The following sections will explore specific responsibilities within these positions, required qualifications and skill sets, and career pathways for individuals seeking to enter or advance in this specialized area of the aerospace industry.

Essential Guidance for Aerospace Procurement Roles

Success within roles focused on acquiring goods and services for the aviation sector requires a blend of technical knowledge, negotiation skills, and adherence to regulatory standards. The following guidelines are crucial for individuals operating in this specialized domain.

Tip 1: Cultivate Technical Proficiency: A comprehensive understanding of aerospace materials, components, and manufacturing processes is essential. This knowledge facilitates informed decision-making during supplier selection and contract negotiation, mitigating potential risks associated with substandard or inappropriate materials.

Tip 2: Master Contract Negotiation Strategies: Securing favorable pricing, delivery terms, and quality assurances is a core responsibility. Effective negotiation skills, coupled with a thorough understanding of market dynamics and supplier capabilities, are paramount for achieving optimal outcomes.

Tip 3: Prioritize Regulatory Compliance: The aerospace industry is heavily regulated. Strict adherence to standards set by organizations like the FAA and EASA is non-negotiable. Professionals must remain current on evolving regulations and ensure that all procurement activities align with established guidelines.

Tip 4: Establish Robust Supplier Relationships: Fostering strong, collaborative relationships with key suppliers can lead to preferential treatment, early access to new technologies, and increased supply chain resilience. Open communication and mutual respect are critical for building trust and long-term partnerships.

Tip 5: Implement Stringent Quality Control Measures: Rigorous quality assurance processes must be in place to verify that all procured goods meet specified requirements. This includes conducting thorough inspections, audits, and testing to identify and address any deviations from established standards.

Tip 6: Leverage Data Analytics for Optimization: Utilizing data analytics tools to monitor procurement trends, identify cost-saving opportunities, and improve supply chain efficiency is increasingly important. Data-driven insights can inform strategic decision-making and enhance overall performance.

Tip 7: Continuously Develop Professional Skills: The aerospace industry is dynamic, and professionals must commit to ongoing learning and development. Pursuing certifications, attending industry conferences, and staying abreast of technological advancements are crucial for maintaining a competitive edge.

These guidelines emphasize the importance of technical expertise, strategic negotiation, regulatory compliance, and relationship management within positions focused on acquisition for the aviation industry. Adherence to these principles will enhance performance and contribute to the overall success of the organization.

The subsequent sections will delve into specific career pathways and resources available for individuals seeking to excel in this vital area of the aerospace sector.

1. Strategic Sourcing

Strategic sourcing constitutes a fundamental component of roles centered on acquisition in the aerospace sector. The effectiveness of this activity directly influences an organization’s ability to secure materials and services at optimal cost, quality, and delivery terms. Because of the long lead times and specialized requirements inherent in aerospace manufacturing, a reactive procurement approach is untenable. Instead, professionals must proactively identify and cultivate relationships with suppliers capable of meeting stringent performance criteria. Selection criteria include, but are not limited to, technical capabilities, adherence to regulatory standards (e.g., AS9100), financial stability, and proven track record. A failure to implement a robust strategic sourcing process can lead to supply chain disruptions, increased costs, and compromised product quality, ultimately affecting operational efficiency and profitability.

Real-world examples underscore the practical significance of strategic sourcing. Consider a scenario where a major aircraft manufacturer needs to procure specialized composite materials for wing construction. A strategic sourcing approach would involve a thorough analysis of the global composites market, identification of potential suppliers with the requisite technical expertise and production capacity, and rigorous evaluation of their offerings based on factors such as material properties, cost, and delivery timelines. Subsequently, long-term contracts might be established with a select group of suppliers to ensure a stable and reliable supply of high-quality materials. This proactive approach mitigates the risk of relying on a single supplier or procuring materials from unqualified sources, thereby safeguarding the integrity of the manufacturing process and the safety of the final product.

In summary, strategic sourcing is an indispensable element of acquisition roles in the aviation industry. Its importance lies in proactively identifying and cultivating relationships with capable suppliers, mitigating supply chain risks, and ensuring the procurement of high-quality materials and services at competitive prices. Overlooking the strategic aspect of sourcing can lead to increased costs, compromised product quality, and potential disruptions to production schedules. Professionals operating in this domain must, therefore, possess a deep understanding of market dynamics, supplier capabilities, and best practices in sourcing to effectively contribute to the success of their organizations.

2. Contract Negotiation

Contract negotiation is a critical function within roles focused on acquisition for the aerospace sector. The ability to secure advantageous agreements directly impacts profitability, supply chain stability, and adherence to stringent regulatory requirements. Effective negotiation skills are, therefore, paramount for professionals in this domain.

- Price Determination and Cost Management

Negotiating favorable pricing is essential for controlling project costs. Aerospace components often involve significant development and manufacturing expenses. Skilled negotiators must analyze cost breakdowns, benchmark against market rates, and leverage volume discounts to secure competitive pricing without compromising quality. An example includes negotiating the price per unit for specialized sensors, requiring a detailed understanding of the sensor’s manufacturing process and alternative suppliers.

- Terms and Conditions

Beyond price, contract terms govern delivery schedules, payment milestones, intellectual property rights, and liability. Negotiating favorable terms protects the organization from potential risks associated with late deliveries, defective products, or intellectual property disputes. For instance, securing a clause that penalizes a supplier for late delivery of critical engine components can mitigate potential disruptions to the assembly line.

- Performance Metrics and Quality Standards

Contracts must clearly define performance metrics and quality standards to ensure that procured goods and services meet required specifications. Negotiating these metrics and establishing a process for monitoring performance allows for early detection of deviations and prompt corrective action. Including clauses that mandate adherence to AS9100 standards for aerospace suppliers, with provisions for regular audits, exemplifies this facet.

- Risk Mitigation and Liability

Aerospace contracts often involve substantial financial risks due to the complexity and high value of the components being procured. Negotiating clauses that limit liability, allocate risk appropriately, and provide for dispute resolution mechanisms is crucial for protecting the organization’s interests. Securing indemnification clauses in contracts with software providers to protect against potential cybersecurity breaches represents an important aspect of risk mitigation.

These elements of contract negotiation are inextricably linked to the responsibilities inherent in roles focused on acquisition for the aviation sector. Effective negotiation strategies, encompassing pricing, terms, performance, and risk mitigation, contribute directly to the operational efficiency, cost-effectiveness, and regulatory compliance of aerospace organizations. Mastery of these skills is, therefore, essential for success in this specialized field.

3. Quality Assurance

Quality assurance (QA) occupies a pivotal position in the intersection with aerospace procurement. Strict adherence to quality benchmarks is non-negotiable within the aviation industry, directly impacting safety, reliability, and regulatory compliance. Therefore, professionals engaged in procurement must integrate QA principles throughout the acquisition process, from supplier selection to final acceptance of delivered goods.

- Supplier Evaluation and Selection

QA begins with the rigorous evaluation of potential suppliers. Professionals must assess suppliers’ quality management systems, certifications (e.g., AS9100), and track records for consistently delivering conforming products. On-site audits, review of quality manuals, and analysis of statistical process control data are integral components of this evaluation. For instance, a supplier of turbine blades must demonstrate meticulous control over the manufacturing process, ensuring dimensional accuracy, material integrity, and adherence to specified heat treatment protocols. Failure to thoroughly vet suppliers can result in the procurement of substandard components, leading to performance degradation or catastrophic failure.

- Inspection and Testing Protocols

Comprehensive inspection and testing protocols are essential for verifying that procured items meet specified requirements. Procurement specialists collaborate with quality engineers to define acceptance criteria, implement sampling plans, and conduct destructive and non-destructive testing as needed. For example, incoming shipments of fasteners may undergo tensile strength testing, dimensional verification, and surface finish analysis to ensure conformance to engineering drawings and material specifications. Deficiencies identified during inspection trigger corrective actions, potentially including rejection of the shipment, rework by the supplier, or revisions to the procurement contract.

- Documentation and Traceability

Meticulous documentation and traceability are critical for maintaining accountability and facilitating root cause analysis in the event of failures. Procurement personnel must ensure that suppliers provide complete and accurate documentation, including material certifications, test reports, and manufacturing records. Components must be clearly identified and traceable throughout the supply chain, enabling identification of the source of any defects or non-conformances. This rigorous documentation trail is essential for complying with regulatory requirements and supporting product liability investigations.

- Continuous Improvement Initiatives

QA is not a static process but rather an ongoing effort to identify and eliminate sources of defects and variability. Procurement professionals play a vital role in supporting continuous improvement initiatives by providing feedback to suppliers, participating in problem-solving teams, and implementing process changes to enhance quality performance. Analysis of supplier performance data, tracking of defect rates, and implementation of corrective action plans are all integral aspects of this effort. By fostering a culture of continuous improvement, procurement can contribute to the overall enhancement of product quality and reliability within the aerospace sector.

In summary, quality assurance is inextricably linked to acquisition roles within the aviation industry. The integration of QA principles throughout the procurement process is essential for ensuring the safety, reliability, and regulatory compliance of aerospace products. Professionals must prioritize supplier evaluation, inspection protocols, documentation, and continuous improvement initiatives to mitigate risks and achieve optimal quality outcomes.

4. Supply Chain Management

Supply chain management is inextricably linked to roles focused on acquisition in the aviation industry. The efficient flow of materials, components, and information from suppliers to manufacturers is crucial for maintaining production schedules, controlling costs, and ensuring product quality. Effective coordination across the supply chain directly impacts an aerospace organization’s ability to meet customer demand and remain competitive.

- Demand Forecasting and Planning

Accurate demand forecasting is essential for aligning procurement activities with production requirements. Professionals must analyze historical data, market trends, and customer orders to anticipate future demand for specific components. For example, predicting increased demand for aircraft maintenance services necessitates proactive procurement of spare parts and maintenance supplies. Inaccurate forecasting can lead to stockouts, production delays, or excess inventory, all of which negatively impact profitability.

- Supplier Relationship Management

Cultivating strong relationships with key suppliers is critical for ensuring a reliable supply of high-quality materials. Acquisition specialists must actively manage supplier performance, communicate requirements clearly, and foster collaboration to address potential challenges. For example, establishing long-term contracts with preferred suppliers can provide price stability and priority access to scarce resources. Neglecting supplier relationships can result in delayed deliveries, quality issues, and increased costs.

- Logistics and Transportation

Efficient logistics and transportation are essential for moving materials and components from suppliers to manufacturing facilities. Professionals must optimize transportation routes, select appropriate shipping methods, and manage customs clearance procedures to minimize transit times and costs. For example, utilizing expedited shipping services for critical components can prevent production line shutdowns. Inefficient logistics can result in delays, damage to goods, and increased transportation expenses.

- Inventory Management

Effective inventory management is crucial for balancing the need for readily available materials with the cost of holding excess stock. Acquisition specialists must implement inventory control systems, track inventory levels, and optimize order quantities to minimize storage costs and prevent stockouts. For example, implementing a just-in-time inventory system can reduce storage space requirements and minimize the risk of obsolescence. Poor inventory management can result in lost sales, production delays, and increased storage costs.

These facets of supply chain management underscore the multifaceted nature of acquisition roles in the aerospace sector. Skilled professionals must possess a deep understanding of demand forecasting, supplier relationship management, logistics, and inventory control to effectively manage the flow of materials and information across the supply chain. By optimizing these processes, acquisition specialists contribute directly to an organization’s ability to meet customer demand, control costs, and maintain a competitive advantage.

5. Regulatory Compliance

The aerospace sector operates under a complex web of regulations, primarily aimed at ensuring airworthiness, safety, and security. Acquisition roles within this sector are directly impacted by these regulations, as compliance requirements dictate acceptable materials, manufacturing processes, and supplier qualifications. Failure to adhere to regulatory standards can result in severe consequences, including production delays, aircraft grounding, financial penalties, and reputational damage. Therefore, a thorough understanding of applicable regulations is essential for procurement professionals in the aerospace industry.

Several real-world examples illustrate the practical significance of regulatory compliance in acquisition. The Federal Aviation Administration (FAA) mandates specific requirements for materials used in aircraft construction, such as fire resistance, strength, and durability. Professionals responsible for procuring these materials must ensure that suppliers provide certifications demonstrating compliance with FAA standards. Similarly, the European Aviation Safety Agency (EASA) imposes stringent regulations on aircraft maintenance and repair, requiring that only approved parts and procedures are utilized. Individuals involved in sourcing maintenance services must verify that providers hold the necessary certifications and adhere to EASA guidelines. A failure to comply with these regulations could compromise the safety and airworthiness of the aircraft.

Acquisition roles in aerospace necessitate a proactive approach to regulatory compliance. Professionals must stay abreast of evolving regulations, engage with regulatory agencies, and implement robust compliance programs. This includes developing comprehensive supplier qualification processes, conducting regular audits, and maintaining detailed documentation to demonstrate adherence to all applicable requirements. Addressing these challenges ensures that procurement activities align with regulatory expectations, mitigating potential risks and promoting the safety and reliability of aerospace products and services. The effectiveness of regulatory compliance, therefore, serves as a critical determinant of success within roles focused on acquisition within the aerospace field.

Frequently Asked Questions

The following addresses common inquiries regarding positions focused on acquisition within the aviation sector, offering clarity on key responsibilities, required qualifications, and career advancement opportunities.

Question 1: What distinguishes acquisition in the aerospace sector from procurement in other industries?

Acquisition in the aerospace sector is characterized by stringent regulatory oversight, exacting quality standards, and a focus on long-term reliability. The high stakes associated with aircraft safety necessitate meticulous attention to detail and unwavering adherence to industry-specific requirements.

Question 2: What educational background and experience are typically required for roles involving acquisition for the aviation industry?

A bachelor’s degree in engineering, supply chain management, or a related field is generally expected. Prior experience in procurement, preferably within the aerospace or defense industries, is highly advantageous. Knowledge of relevant regulations (e.g., FAA, EASA) and quality standards (e.g., AS9100) is also crucial.

Question 3: What are the key skills required for success in this area?

Critical skills include negotiation, contract management, supplier relationship management, technical proficiency in aerospace materials and processes, and a thorough understanding of regulatory requirements. Analytical skills and the ability to interpret technical drawings and specifications are also essential.

Question 4: How does one advance within this career path?

Career advancement typically involves assuming increasing responsibility for larger and more complex procurement projects, specializing in a particular commodity or area of expertise, or moving into a management role. Professional certifications, such as Certified Professional in Supply Management (CPSM), can enhance career prospects.

Question 5: What are the primary challenges facing professionals in these positions today?

Major challenges include managing supply chain disruptions, mitigating risks associated with sole-source suppliers, navigating complex regulatory landscapes, and adapting to rapidly evolving technologies. Cost reduction pressures and the need to maintain stringent quality standards further complicate the role.

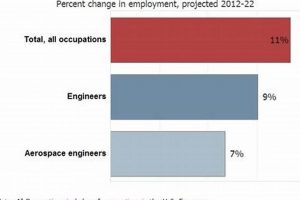

Question 6: What is the future outlook for opportunities in aviation-related acquisition?

The long-term outlook for opportunities in this area is generally positive, driven by projected growth in air travel, increased demand for new aircraft, and the need to maintain and upgrade existing fleets. However, automation and technological advancements may reshape the specific skills required for these roles.

In summary, positions centered on acquisition for the aviation sector demand a unique combination of technical expertise, business acumen, and a commitment to regulatory compliance. The challenges are significant, but the rewards are substantial for those who possess the requisite skills and dedication.

The following section will provide a concluding overview and highlight key takeaways related to aerospace purchasing jobs.

Aerospace Purchasing Jobs

This exploration has detailed the multifaceted nature of aerospace purchasing jobs, encompassing strategic sourcing, rigorous contract negotiation, unwavering quality assurance, and comprehensive supply chain management, all within a stringent regulatory framework. The success of individuals in these roles hinges on a deep understanding of technical specifications, market dynamics, and the critical importance of compliance.

The aviation sector demands precision and reliability, and the individuals responsible for acquiring the necessary components and services bear a significant responsibility. The future of air travel and defense capabilities relies, in part, on the diligence and expertise of those who navigate the complexities of aerospace purchasing jobs. Continued professional development and a commitment to excellence are essential for ensuring the continued success and safety of the industry.

![Guide to Aerospace Welder Job Description [+Skills] Innovating the Future of Flight with Reliable Aviation Solutions Guide to Aerospace Welder Job Description [+Skills] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-692-300x200.jpg)