Opportunities within the Pexco Aerospace sector encompass a range of positions related to the design, manufacturing, and maintenance of components and systems for aircraft and spacecraft. These roles may include engineering, quality assurance, project management, and skilled trades positions that directly contribute to the aerospace industry. For example, a mechanical engineer might design a new aircraft seating system, while a quality assurance specialist ensures compliance with rigorous industry standards.

The significance of careers within this domain lies in their contribution to advancements in air travel, space exploration, and national defense. These positions often offer competitive salaries, opportunities for professional development, and the chance to work on cutting-edge technologies. Historically, the aerospace industry has been a driver of innovation, and individuals in these roles are positioned to be at the forefront of technological progress.

The following sections will delve into specific aspects of pursuing a career in this field, including required qualifications, potential career paths, and resources for finding available positions. This information aims to provide a comprehensive overview for individuals interested in exploring employment possibilities within this dynamic and vital industry.

This section provides strategic guidance for individuals seeking careers within the Pexco Aerospace domain. Focusing on key areas, it presents actionable steps to enhance one’s prospects.

Tip 1: Focus Skill Development. Prioritize acquiring skills relevant to aerospace manufacturing and engineering. Certification in CAD software or specific manufacturing processes can significantly improve candidacy.

Tip 2: Tailor Resume and Cover Letter. Customize application materials to reflect the specific requirements of each advertised role. Highlight accomplishments and experience directly relevant to the aerospace sector.

Tip 3: Leverage Networking Opportunities. Attend industry conferences, career fairs, and networking events. Building connections with professionals in the field can provide valuable insights and potential leads.

Tip 4: Research Specific Companies. Thoroughly investigate companies of interest within the Pexco network. Understanding their culture, products, and values demonstrates a genuine interest and commitment.

Tip 5: Optimize Online Presence. Ensure a professional and consistent online presence, particularly on platforms like LinkedIn. Showcase relevant skills, experience, and professional achievements.

Tip 6: Prepare for Technical Interviews. Anticipate technical questions related to aerospace principles, manufacturing processes, and materials science. Practice problem-solving and clearly articulate technical knowledge.

Tip 7: Seek Internships or Entry-Level Positions. Consider internships or entry-level roles to gain practical experience and industry exposure. These positions can serve as a valuable stepping stone to more advanced roles.

Adhering to these strategies can markedly increase the likelihood of securing a position within the desired area. Demonstrating a strong foundation of relevant skills and a proactive approach to career development is crucial for success.

The subsequent sections will further explore resources and pathways within the aerospace industry, providing additional insights for career advancement.

1. Engineering Design

Engineering design forms a cornerstone of opportunities within Pexco Aerospace. Positions in this area are inherently linked to the creation, modification, and analysis of aerospace components and systems. The performance, safety, and efficiency of aircraft and spacecraft directly depend on the quality of engineering design. A failure in design can lead to catastrophic consequences, highlighting its critical importance within the sector. For instance, aerodynamic engineers are responsible for shaping aircraft wings to optimize lift and minimize drag, directly impacting fuel efficiency and flight range. Structural engineers ensure that airframes can withstand the immense stresses of flight, preventing structural failure. These roles are central to the realization of aerospace projects.

Consider the development of a new aircraft interior. Engineering design teams collaborate to optimize passenger comfort, minimize weight, and ensure compliance with safety regulations. This involves selecting appropriate materials, designing seating arrangements, and integrating entertainment systems. Another practical example is the design of spacecraft propulsion systems, where engineers must balance performance, reliability, and cost-effectiveness. Software engineers design the complex control systems that govern aircraft operation. Each of these scenarios demonstrates the practical application of engineering design principles in the aerospace context.

In summary, engineering design is an indispensable component of Pexco Aerospace careers. The demand for skilled engineers who can innovate, problem-solve, and adhere to stringent industry standards is constant. Individuals seeking employment should prioritize developing relevant skills and pursuing continuing education to remain competitive in this evolving field. The challenges inherent in aerospace engineering necessitate a strong foundation in mathematics, physics, and materials science, as well as a commitment to safety and quality.

2. Manufacturing Processes

Manufacturing processes constitute a critical element within Pexco Aerospace operations and significantly influence the spectrum of available positions. The fabrication of aircraft and spacecraft components demands precision, adherence to stringent standards, and proficiency in specialized techniques. Understanding the role of these processes is crucial for individuals seeking careers in this sector.

- Precision Machining

Precision machining, utilizing CNC (Computer Numerical Control) milling and turning, plays a central role in shaping metal parts to exacting tolerances. The creation of turbine blades or structural components necessitates meticulous control and advanced equipment. Professionals in this area are responsible for programming machines, monitoring production, and ensuring dimensional accuracy. Errors in machining can compromise the structural integrity of aerospace components, making this facet particularly critical for safety and reliability.

- Composites Manufacturing

The growing use of composite materials in aircraft construction necessitates expertise in composite lay-up, curing, and bonding. Technicians involved in this area manipulate carbon fiber or fiberglass materials, meticulously layering them to create lightweight yet strong structures. The manufacturing process requires specialized equipment and adherence to strict environmental controls to ensure material properties meet design specifications. Opportunities in composite manufacturing are expanding as aerospace companies seek to improve fuel efficiency and reduce aircraft weight.

- Additive Manufacturing (3D Printing)

Additive manufacturing, also known as 3D printing, presents an innovative approach to creating complex aerospace components. This process involves building parts layer by layer from materials such as titanium or nickel alloys. Advantages include the ability to produce intricate geometries and reduce material waste. Engineers and technicians in this field must possess knowledge of materials science, design for additive manufacturing, and post-processing techniques. The implementation of additive manufacturing is revolutionizing prototyping and production in the aerospace industry.

- Assembly and Integration

The assembly and integration of aerospace components represent the culmination of various manufacturing processes. Skilled technicians and engineers work collaboratively to connect subassemblies, install systems, and perform final testing. This phase demands meticulous attention to detail and adherence to strict quality control procedures. Challenges include ensuring proper alignment, verifying functionality, and meeting weight and balance requirements. The assembly and integration process is a critical step in transforming individual components into a fully functional aircraft or spacecraft.

These facets illustrate the diverse range of manufacturing processes integral to Pexco Aerospace. Each element demands specialized skills and expertise, creating a multitude of career opportunities for individuals with the appropriate training and experience. The ongoing advancements in manufacturing technology are further shaping the landscape, requiring professionals to continuously adapt and learn. Understanding these processes is essential for navigating and succeeding within the aerospace sector.

3. Quality Assurance

Quality Assurance (QA) is an indispensable function within Pexco Aerospace, fundamentally shaping the nature of positions and the requirements for personnel in this sector. Given the critical safety and performance demands of aerospace applications, QA procedures are paramount. Consequently, a robust understanding of these processes is essential for individuals pursuing careers in this field.

- Inspection and Testing Protocols

Rigorous inspection and testing protocols are core tenets of QA. These involve meticulous examination of materials, components, and finished products at various stages of manufacturing and assembly. Non-destructive testing methods, such as ultrasonic and radiographic inspection, are frequently employed to detect internal flaws without damaging the component. This facet necessitates skilled inspectors and technicians capable of interpreting results and identifying deviations from specifications. For example, the inspection of an aircraft engine turbine blade requires precise measurements and visual examination to ensure compliance with strict tolerances. Personnel involved in inspection and testing play a direct role in mitigating risks and ensuring airworthiness.

- Compliance with Regulatory Standards

The aerospace industry operates under stringent regulatory frameworks established by agencies such as the FAA (Federal Aviation Administration) and EASA (European Aviation Safety Agency). QA departments are responsible for ensuring that all processes and products adhere to these regulations. This involves maintaining comprehensive documentation, conducting audits, and implementing corrective actions when necessary. A QA specialist might oversee the implementation of AS9100 standards, a widely recognized quality management system for the aerospace industry. Failure to comply with regulatory standards can result in significant penalties and reputational damage, underscoring the importance of this QA function.

- Statistical Process Control (SPC)

Statistical Process Control (SPC) utilizes statistical methods to monitor and control manufacturing processes. Data is collected and analyzed to identify trends and variations that may indicate potential quality problems. By implementing SPC, QA teams can proactively address issues before they result in defective products. For example, SPC charts might be used to monitor the dimensions of machined parts, enabling operators to adjust machine settings and maintain consistent quality. SPC requires a strong understanding of statistical principles and the ability to interpret data effectively. This approach contributes to continuous improvement and reduces the risk of defects.

- Root Cause Analysis and Corrective Action

When quality issues arise, QA professionals conduct root cause analysis to identify the underlying factors contributing to the problem. This involves a systematic investigation to determine the source of the defect, rather than simply addressing the symptoms. Once the root cause is identified, corrective actions are implemented to prevent recurrence. For example, if a batch of fasteners fails to meet strength requirements, the QA team might investigate the material supplier, manufacturing process, and testing procedures to determine the cause. This process demands analytical skills, problem-solving abilities, and a commitment to continuous improvement. The effectiveness of root cause analysis directly impacts the long-term quality and reliability of aerospace products.

These facets highlight the integral role of Quality Assurance within Pexco Aerospace. Positions in this area necessitate a thorough understanding of inspection techniques, regulatory requirements, statistical methods, and problem-solving skills. The demand for qualified QA professionals remains strong, reflecting the unwavering commitment to safety and quality within the aerospace industry. Individuals pursuing careers in this field contribute directly to the reliability and performance of aircraft and spacecraft, ensuring the safety of passengers and the success of aerospace missions.

4. Project Management

Project Management is a critical discipline within Pexco Aerospace, influencing the structure and execution of numerous roles across the organization. Effective project management ensures that complex aerospace projects are completed on time, within budget, and to the required specifications. The success of these projects directly impacts the company’s competitiveness and reputation.

- Project Planning and Scope Definition

Project planning is a foundational element. It involves defining project objectives, scope, deliverables, and timelines. A project manager in Pexco Aerospace might be responsible for creating a detailed work breakdown structure for the development of a new aircraft component. This includes identifying all necessary tasks, assigning resources, and estimating durations. Clear scope definition prevents scope creep and ensures that the project remains focused on its intended goals. A poorly defined scope can lead to cost overruns, schedule delays, and compromised quality. These are critical in aerospace applications.

- Risk Management and Mitigation

Aerospace projects inherently involve numerous risks, including technical challenges, regulatory hurdles, and supply chain disruptions. Project managers are tasked with identifying, assessing, and mitigating these risks. A risk management plan might include contingency plans for potential delays in obtaining regulatory approvals or for addressing technical issues encountered during testing. Effective risk mitigation strategies minimize the impact of unforeseen events and ensure project continuity. The failure to adequately manage risks can jeopardize project success and potentially compromise safety.

- Resource Allocation and Team Leadership

Project managers in Pexco Aerospace are responsible for allocating resources effectively and leading cross-functional teams. This involves assigning tasks to team members with the appropriate skills and experience, managing budgets, and coordinating activities across different departments. A project manager might lead a team comprising engineers, manufacturing specialists, and quality assurance personnel. Effective team leadership fosters collaboration, motivates team members, and ensures that everyone is working towards a common goal. Poor resource allocation and ineffective team leadership can hinder progress and reduce overall efficiency.

- Monitoring and Control

Continuous monitoring and control are essential for tracking project progress and identifying potential problems. Project managers use various tools and techniques, such as Gantt charts and earned value management, to monitor schedules, budgets, and performance. Regular progress reports are generated to communicate project status to stakeholders. Corrective actions are implemented promptly to address deviations from the plan. For instance, if a project is falling behind schedule, the project manager might reallocate resources or adjust the timeline. Proactive monitoring and control ensure that projects remain on track and within budget. This vigilance upholds Pexco’s standards.

The outlined elements illustrate the integral role of project management within Pexco Aerospace positions. Effective project management skills are highly valued, as they directly contribute to the successful completion of complex aerospace projects. Individuals seeking opportunities in this field should possess strong leadership, communication, and problem-solving abilities, as well as a thorough understanding of project management methodologies. The demand for skilled project managers in the aerospace industry remains strong, reflecting the ongoing need for efficient and effective project execution. The value of these skills is not merely abstract; it is demonstrable in the successful completion of ambitious aerospace endeavors.

5. Regulatory Compliance

Regulatory compliance forms an inextricable link to careers within Pexco Aerospace. The stringent standards governing the design, manufacture, and maintenance of aircraft and spacecraft dictate the qualifications and responsibilities inherent in numerous positions. A failure to adhere to these regulations can result in severe consequences, including fines, operational restrictions, and, most significantly, compromised safety. Consequently, positions requiring a comprehensive understanding of and adherence to regulatory mandates are of paramount importance. For example, roles focused on quality assurance, engineering, and product development are heavily influenced by regulatory requirements dictated by entities such as the FAA and EASA. These regulations serve as the foundational framework within which employees operate, shaping decision-making processes and daily tasks. The selection of materials, design methodologies, and manufacturing processes are all subject to rigorous scrutiny and must align with established regulatory criteria.

Practical application of this understanding is evident in various scenarios. Consider the development of a new aircraft seating system. Engineers must ensure that the design complies with flammability standards, crashworthiness requirements, and passenger safety regulations. Similarly, manufacturing processes must adhere to strict quality control measures to prevent defects that could compromise the integrity of the aircraft. Employees involved in maintenance and repair operations are responsible for following approved procedures and using certified parts to maintain airworthiness. The interconnectedness is clear: Regulatory compliance is not a tangential concern but an integral component of every stage of the product lifecycle within Pexco Aerospace. Positions associated with regulatory compliance often require specialized training, certifications, and a thorough understanding of relevant legal frameworks.

In summary, the connection between regulatory compliance and opportunities within Pexco Aerospace is characterized by a critical dependency. While offering careers with significant responsibility, regulatory demands pose a continual challenge to those working in the field. Success requires a steadfast commitment to upholding standards and navigating the complexities of an ever-evolving regulatory landscape. The significance of this understanding cannot be overstated; it directly impacts the safety, reliability, and operational viability of the products and services provided.

6. Research and Development

Research and Development (R&D) serves as a catalyst for innovation within Pexco Aerospace, directly impacting the skill sets, expertise, and opportunities associated with various positions. It fuels advancements in materials science, aerodynamics, propulsion systems, and avionics, thereby shaping the nature of employment within the company.

- Materials Innovation

R&D efforts centered on materials innovation focus on the development of lighter, stronger, and more heat-resistant materials for aircraft and spacecraft components. This necessitates the employment of materials scientists, engineers, and technicians skilled in materials characterization, testing, and processing. For example, research into advanced composites may lead to the development of new aircraft wings that reduce weight and improve fuel efficiency. Such advancements create opportunities for specialists in composite manufacturing and structural analysis. Positions in this area require a strong foundation in materials science and engineering, as well as experience with advanced testing and simulation techniques.

- Aerodynamic Optimization

Aerodynamic optimization is critical for enhancing aircraft performance and reducing fuel consumption. R&D activities in this area involve computational fluid dynamics (CFD) simulations, wind tunnel testing, and flight testing to refine aircraft designs. This requires the expertise of aerodynamic engineers, fluid dynamicists, and test pilots. For example, research into boundary layer control techniques may lead to the development of aircraft wings that reduce drag and improve lift. Such advancements create opportunities for specialists in aerodynamic design, CFD simulation, and flight testing. These positions demand a deep understanding of fluid mechanics, aerodynamics, and experimental techniques.

- Propulsion Systems Advancement

R&D in propulsion systems focuses on the development of more efficient, reliable, and environmentally friendly engines for aircraft and spacecraft. This necessitates the employment of mechanical engineers, combustion specialists, and control systems engineers. For example, research into advanced turbine engine technologies may lead to the development of engines that reduce fuel consumption and emissions. These advancements create opportunities for specialists in engine design, combustion modeling, and control system development. The roles require a strong foundation in thermodynamics, fluid mechanics, and control systems.

- Avionics and Control Systems Innovation

R&D in avionics and control systems focuses on the development of more advanced navigation, communication, and flight control systems. This requires the expertise of electrical engineers, software engineers, and control systems engineers. For example, research into autonomous flight control systems may lead to the development of aircraft that can operate safely and efficiently in complex environments. These advancements create opportunities for specialists in avionics design, software development, and control systems engineering. The positions demand a deep understanding of electronics, software engineering, and control theory.

These facets of R&D collectively drive innovation and progress within Pexco Aerospace, directly impacting the demand for skilled professionals in various engineering and scientific disciplines. The ongoing pursuit of technological advancements ensures that R&D remains a critical component of the company’s strategy, shaping the future of aerospace and the opportunities available to those seeking careers in this dynamic field.

7. Skilled Trades

Skilled trades are integral to the operational framework within Pexco Aerospace. These occupations, encompassing roles such as aircraft mechanics, avionics technicians, welders, and machinists, directly contribute to the manufacturing, maintenance, and repair of aerospace components and systems. The absence of proficient individuals in these trades would impede the company’s capacity to produce high-quality products and maintain existing fleets, demonstrating a cause-and-effect relationship between these roles and Pexco Aerospace’s productivity. The importance of skilled trades extends beyond mere functionality; it is inextricably linked to the safety and reliability of aerospace operations.

Consider, for example, the role of an aircraft mechanic. These technicians are responsible for conducting routine inspections, performing repairs, and ensuring that aircraft meet stringent airworthiness standards. The precision and expertise required in this role are paramount; a misdiagnosed issue or a poorly executed repair could have catastrophic consequences. Similarly, welders specializing in aerospace applications must possess advanced skills and certifications to fabricate structural components that can withstand extreme stresses. These skilled trades are not merely supportive functions; they are central to the execution of Pexco Aerospace’s core business objectives. Furthermore, the demand for skilled trades professionals within the aerospace sector is consistently high, driven by factors such as an aging workforce, technological advancements, and increased air travel.

In conclusion, the availability and proficiency of skilled trades professionals directly influence Pexco Aerospace’s ability to operate efficiently, maintain safety standards, and innovate. Challenges related to workforce development and training must be addressed to ensure a sustainable pipeline of qualified individuals. The significance of skilled trades should not be underestimated; these roles form the backbone of the aerospace industry, contributing directly to its continued growth and technological advancement. The ability to attract and retain skilled trades professionals is therefore a strategic imperative for Pexco Aerospace.

Frequently Asked Questions Regarding Opportunities at Pexco Aerospace

The following questions and answers address common inquiries concerning employment prospects, qualifications, and career pathways within Pexco Aerospace.

Question 1: What specific academic qualifications are generally required for engineering positions at Pexco Aerospace?

A Bachelor’s or Master’s degree in Aerospace Engineering, Mechanical Engineering, or a closely related field is typically required. Specific roles may necessitate specialized knowledge in areas such as aerodynamics, structural analysis, or propulsion systems. Certifications relevant to specific software or hardware used within the company can also enhance candidacy.

Question 2: Does Pexco Aerospace offer opportunities for individuals without prior experience in the aerospace industry?

Entry-level positions, internships, and apprenticeships are often available for individuals with relevant academic backgrounds or technical skills but limited professional experience. These roles provide opportunities to gain practical experience and develop industry-specific knowledge under the guidance of experienced professionals.

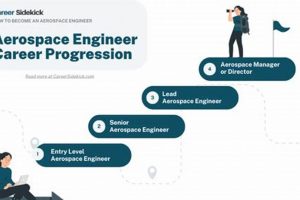

Question 3: What is the typical career progression path for a manufacturing technician at Pexco Aerospace?

A manufacturing technician may advance to roles such as senior technician, team lead, or supervisor based on performance, experience, and completion of relevant training programs. Opportunities may also exist to transition into specialized areas such as quality control or process engineering.

Question 4: How does Pexco Aerospace ensure the safety and well-being of its employees, particularly those working in manufacturing or maintenance roles?

Pexco Aerospace maintains a strong commitment to workplace safety, providing comprehensive training programs, adhering to strict safety protocols, and conducting regular safety audits. Employees are provided with appropriate personal protective equipment and are encouraged to report any safety concerns.

Question 5: What are the key skills and attributes that Pexco Aerospace seeks in candidates for project management positions?

Strong leadership, communication, and problem-solving skills are essential. A thorough understanding of project management methodologies, such as Agile or Waterfall, is also highly valued. Experience managing complex projects within a regulated industry, such as aerospace, is often preferred.

Question 6: How does Pexco Aerospace support the professional development and continued learning of its employees?

Pexco Aerospace offers various professional development opportunities, including tuition reimbursement for relevant coursework, internal training programs, and participation in industry conferences. Employees are encouraged to pursue certifications and acquire new skills to enhance their capabilities and advance their careers.

These responses provide a general overview of common inquiries. Specific requirements and opportunities may vary depending on the position and location within Pexco Aerospace. It is advisable to consult the company’s website or contact its human resources department for more detailed information.

The next section will provide resources for finding “pexco aerospace jobs.”

Pexco Aerospace Jobs

This exploration has detailed various facets of positions within Pexco Aerospace, ranging from engineering and manufacturing to quality assurance and project management. It emphasized the requisite skills, qualifications, and responsibilities inherent in these roles, highlighting their contribution to the advancement of aerospace technology and safety. The discussion also underscored the significance of regulatory compliance and continuous professional development in maintaining competitiveness within this dynamic sector.

The information presented is intended to provide prospective candidates with a comprehensive understanding of the opportunities and challenges associated with pursuing a career at Pexco Aerospace. A commitment to excellence, continuous learning, and adherence to stringent industry standards are essential for success. Individuals seeking to contribute to the future of aerospace should carefully consider the insights provided and diligently prepare themselves for the demands of this challenging yet rewarding field.