Positions suitable for individuals who have recently completed their undergraduate or graduate studies in aerospace engineering, and are seeking their initial professional experience in the field, can be described as initial career opportunities for aerospace engineers in the local area. These roles typically involve foundational tasks like design support, testing, data analysis, and assisting senior engineers on various projects. An example might include a junior design engineer role at a local aerospace manufacturing company.

Identifying these local opportunities is crucial for new graduates seeking to launch their careers, offering practical application of academic knowledge and the chance to develop essential skills. Historically, proximity to aerospace hubs has been a major factor in career placement, and finding such roles enables engineers to contribute to regional innovation and economic growth while building their professional network. The benefit lies in gaining hands-on experience, mentorship, and establishing a career trajectory within the aerospace industry.

The following sections will delve into specific job roles within the industry, explore strategies for effective job searching, and provide advice on optimizing qualifications to increase the likelihood of securing relevant opportunities. This includes examining common required skills, typical salary ranges, and the long-term career prospects associated with commencing an aerospace engineering career in the local area.

Tips for Finding Initial Aerospace Engineering Positions

The following outlines key strategies for recent graduates seeking initial aerospace engineering employment in their geographic area.

Tip 1: Focus on Location-Specific Searches: Utilize online job boards and company websites, filtering specifically by the desired geographic radius. Include location keywords in search terms to refine results and identify opportunities within commuting distance.

Tip 2: Target Local Aerospace Companies: Research aerospace manufacturers, research and development facilities, and government contractors with operations in the area. Direct applications often yield higher success rates than relying solely on general job postings.

Tip 3: Leverage University Career Services: Attend career fairs and workshops organized by the university’s career center. These events provide direct access to employers actively recruiting aerospace engineers in the region.

Tip 4: Network with Local Professionals: Connect with aerospace engineers working in the desired area through professional organizations and online platforms. Informational interviews can provide valuable insights into the local job market and potential openings.

Tip 5: Tailor Resumes and Cover Letters: Customize application materials to highlight relevant skills and experiences that align with the specific requirements of each position and the overall needs of aerospace employers in the area.

Tip 6: Consider Internships and Co-ops: Prior relevant work experience, even in the form of internships or co-op programs, significantly increases the chances of securing full-time employment. Actively seek out and participate in these opportunities during undergraduate studies.

Tip 7: Highlight Relevant Software Proficiency: Demonstrate proficiency in industry-standard software used in aerospace engineering, such as CAD, CAE, and simulation tools. Emphasize these skills on resumes and during interviews.

Employing these strategies will significantly enhance the likelihood of successfully locating suitable aerospace engineering employment opportunities in the local area and launching a fulfilling career in the field.

The subsequent section will address common interview questions and best practices for preparing for the selection process.

1. Location accessibility

Geographic proximity to aerospace industry clusters significantly influences the availability of initial employment for aerospace engineers. The presence of major aerospace manufacturers, research institutions, and government facilities creates localized job markets, impacting the ease with which recent graduates can secure their first professional role.

- Proximity to Industry Hubs

Concentrations of aerospace companies in regions like Southern California, Seattle, and Florida lead to increased opportunities. These areas foster a competitive job market, attracting talent and offering diverse roles across design, manufacturing, and testing. The accessibility of these hubs directly correlates with the likelihood of finding entry-level positions.

- Regional Economic Factors

Economic health within a given region impacts aerospace investment and hiring trends. Regions experiencing growth in aerospace-related sectors offer more entry-level positions. Conversely, economic downturns may lead to hiring freezes or reductions, limiting opportunities for recent graduates.

- University Relationships

Universities with strong aerospace engineering programs often establish close ties with local aerospace companies. These partnerships can facilitate internships, co-op programs, and direct recruitment opportunities, providing graduates with a competitive advantage within the regional job market.

- Infrastructure and Transportation

Adequate transportation infrastructure can improve access to aerospace employers within a given region. Well-connected cities and metropolitan areas reduce commuting barriers and expand the geographic range within which engineers can effectively seek and maintain employment.

These interconnected factors demonstrate that geographic location significantly shapes the landscape for those seeking initial aerospace engineering employment. Areas with robust aerospace industries, healthy regional economies, strong university relationships, and reliable infrastructure offer greater accessibility to opportunities and a higher probability of securing initial career positions.

2. Required Skills

The attainment of initial aerospace engineering positions in any locality necessitates a specific skill set. The connection between proficiency in key technical areas and securing an entry-level role is causal: lacking requisite skills hinders the probability of gaining employment. Required skills form a foundational component of an engineer’s profile, directly influencing their suitability for available opportunities. For example, a graduate applying for a design engineer position at a local aerospace manufacturer must demonstrate competence in CAD software, finite element analysis, and understanding of aerospace materials. Without these skills, the application is unlikely to progress.

Furthermore, soft skills complement technical capabilities and are crucial. Effective communication, teamwork, and problem-solving are consistently valued by employers. In practical application, an engineer may be required to present design modifications to a team or collaborate on troubleshooting a system malfunction. An inability to communicate technical concepts clearly or work effectively within a group can impede project success and, consequently, limit career advancement opportunities, even if technical skills are present. A candidate with strong grades in relevant coursework might still be overlooked if they cannot demonstrate teamwork and clear communication during the interview process.

In summary, acquiring the necessary skills, both technical and interpersonal, is paramount for securing an entry-level aerospace engineering position. The combination of these capabilities represents a significant investment in career readiness. Challenges remain in bridging the gap between academic knowledge and practical application, underscoring the importance of internships and project-based learning experiences. The understanding of these skill requirements ensures that graduating engineers focus on developing competencies that align with industry demands, thereby increasing their competitiveness in the local job market.

3. Education Level

The education level attained by an aspiring aerospace engineer exerts a direct influence on the availability and nature of initial employment prospects in their local area. A bachelor’s degree in aerospace engineering or a closely related field is generally considered the minimum requirement for securing most entry-level positions. This foundational degree provides the necessary theoretical framework in areas such as aerodynamics, propulsion, structural mechanics, and control systems. Without this formal education, candidates are unlikely to meet the baseline expectations of employers. For instance, a regional aerospace component manufacturer typically requires that design engineers possess at least a bachelor’s degree to ensure competence in applying relevant engineering principles.

However, the pursuit of advanced degrees, such as a master’s or doctorate, can significantly enhance employment opportunities and potentially lead to more specialized or research-oriented roles. A master’s degree often provides a deeper understanding of specific aerospace disciplines and can improve competitiveness in a job market. For example, individuals with a master’s degree focusing on computational fluid dynamics may be favored for roles involving aerodynamic simulations or design optimization at a local aerospace research facility. Furthermore, possessing a doctorate often opens doors to positions in research and development, academic institutions, or specialized engineering teams focused on cutting-edge technologies. A local university, for example, might seek doctoral graduates for research roles in hypersonic vehicle development.

In conclusion, the level of formal education serves as a primary determinant of access to initial aerospace engineering positions. While a bachelor’s degree provides a baseline qualification, advanced degrees can unlock more specialized opportunities. Understanding the interplay between educational attainment and job prospects is crucial for recent graduates seeking to navigate the local aerospace job market effectively. Aspiring engineers should consider their long-term career goals when deciding on the appropriate level of education, recognizing that advanced degrees may enhance competitiveness and access to specialized roles.

4. Application Process

The application process is a critical gateway for candidates seeking initial aerospace engineering roles in a specific geographical location. A structured and strategic approach to the application significantly enhances the likelihood of securing interviews and ultimately, employment. Understanding the nuances of this process is paramount for recent graduates aiming to enter the aerospace field locally.

- Online Application Portals

Most aerospace companies utilize online platforms for receiving and managing applications. These portals often require detailed information regarding educational background, work experience, skills, and professional certifications. Submitting accurate and complete information is essential; discrepancies can lead to immediate disqualification. The online system may also incorporate automated screening processes that filter applications based on keyword matching and predefined criteria.

- Resume and Cover Letter Customization

A generic resume and cover letter are often insufficient. Tailoring these documents to align with the specific requirements and desired qualifications outlined in the job description is critical. Highlighting relevant skills, projects, and experiences, using keywords from the job posting, and demonstrating a clear understanding of the company’s mission and values can significantly improve an applicant’s chances. An effective cover letter should articulate the candidate’s unique value proposition and express genuine interest in the specific role and the company.

- Technical Assessments and Interviews

Many aerospace companies employ technical assessments to evaluate candidates’ problem-solving abilities and engineering knowledge. These assessments may involve written tests, coding challenges, or design exercises. Successful completion demonstrates the candidate’s technical competence. Subsequent interviews, whether conducted in-person or virtually, provide an opportunity to further assess technical skills, communication abilities, and cultural fit. Preparing for common aerospace engineering interview questions and practicing responses is essential.

- Background Checks and Security Clearances

Due to the sensitive nature of many aerospace projects, background checks and security clearances are often required. These checks may involve verifying educational credentials, employment history, and criminal records. Candidates may also need to undergo a security clearance process, which can involve extensive interviews and investigations. Maintaining transparency and providing accurate information throughout this process is crucial for avoiding delays or denials.

In summary, the application process for initial aerospace engineering employment demands a comprehensive and meticulous approach. Successfully navigating each stage, from online application to background checks, requires careful attention to detail, effective communication, and a clear demonstration of relevant skills and qualifications. Proficiency in this process directly impacts the candidates ability to secure opportunities within their desired geographic area.

5. Industry Contacts

Establishing and maintaining industry contacts is a vital element in the pursuit of initial aerospace engineering employment within a given geographic area. These connections provide access to unadvertised job opportunities, mentorship, and critical insights into the local job market.

- Networking Events and Professional Organizations

Attendance at industry-specific conferences, workshops, and career fairs facilitates direct interaction with potential employers and established professionals. Organizations such as the American Institute of Aeronautics and Astronautics (AIAA) offer networking opportunities and access to job boards. Active participation in these events allows job seekers to cultivate relationships and learn about upcoming openings before they are widely publicized.

- Informational Interviews

Reaching out to aerospace engineers and professionals in the desired geographic area for informational interviews provides invaluable insights into specific companies, job functions, and the overall local industry landscape. These interviews offer an opportunity to learn about the day-to-day realities of the job, gain advice on skill development, and potentially uncover unadvertised job openings. Demonstrating initiative and genuine interest through informational interviews can leave a positive impression and lead to further connections.

- University Alumni Networks

Leveraging university alumni networks connects recent graduates with experienced professionals who have a shared educational background and potential ties to local aerospace companies. Alumni can provide valuable guidance, mentorship, and introductions to hiring managers. Actively engaging with alumni networks through online platforms and university-sponsored events can significantly expand a job seeker’s professional reach.

- Online Professional Platforms

Utilizing professional networking platforms such as LinkedIn to connect with aerospace engineers and recruiters in the local area can broaden an applicant’s visibility and access to job opportunities. Actively participating in relevant industry groups, sharing insights, and engaging in thoughtful discussions can establish a professional presence and attract the attention of potential employers. Direct messaging recruiters and expressing interest in specific roles can also be an effective strategy.

The cultivation of industry contacts provides a strategic advantage for job seekers in the competitive aerospace engineering field. These connections not only facilitate access to employment opportunities but also offer valuable mentorship and industry insights that can significantly enhance career prospects in a specific geographic region. Therefore, proactive engagement in networking activities is essential for those pursuing initial employment opportunities.

6. Salary Outlook

The compensation associated with initial aerospace engineering positions is a critical consideration for job seekers evaluating opportunities in their local area. Salary expectations often factor into the decision-making process and affect the attractiveness of potential job offers. Furthermore, understanding prevailing salary ranges provides valuable context for negotiating terms and planning long-term financial goals.

- Geographic Location Impact

Regional economic conditions and cost-of-living differences significantly influence compensation levels for aerospace engineers. Areas with higher living costs, such as major metropolitan areas or those proximate to large aerospace manufacturers, often offer higher starting salaries to compensate for increased expenses. Conversely, less urbanized or economically depressed regions may present lower initial salary offers, reflecting local economic realities. For example, an aerospace design engineer initiating their career in Los Angeles might receive a higher salary than a counterpart in a rural area due to the prevailing cost of living and competitive labor market.

- Educational Attainment and Experience

Educational qualifications, particularly advanced degrees, and prior relevant experience gained through internships or co-op programs affect entry-level compensation. Candidates with a master’s degree typically command higher starting salaries than those with only a bachelor’s degree, reflecting their increased knowledge and specialized skills. Similarly, prior industry experience can enhance a candidate’s bargaining power and result in a more competitive salary offer. A recent graduate with a summer internship at a local aerospace company may receive a higher starting salary than a peer with no prior practical experience.

- Company Size and Type

The size and type of aerospace organization also influences compensation. Larger, established aerospace manufacturers and government contractors often offer more competitive salaries and benefits packages than smaller, privately held companies or startups. However, smaller companies may offer more rapid career advancement opportunities and a more entrepreneurial work environment. The compensation structure often varies depending on the financial stability and available resources of the employer.

- Specific Job Role and Responsibilities

The specific job role and associated responsibilities impact the salary range. Entry-level positions in high-demand areas, such as systems engineering or avionics, may command higher salaries compared to roles with more readily available skill sets. The complexity of the tasks, the level of responsibility, and the required expertise contribute to determining appropriate compensation levels. Engineers focusing on cutting-edge technologies may earn premium salaries due to the scarcity of qualified professionals.

Consideration of these factors provides a more complete understanding of the salary expectations associated with initiating an aerospace engineering career in a specific location. The synthesis of geographic factors, educational attainment, company attributes, and specific role characteristics determines the initial compensation level and sets the stage for career progression and future earnings growth. Analyzing these elements ensures that job seekers make informed decisions and realistically evaluate opportunities available to them.

7. Career Development

Initiating a career in aerospace engineering, particularly in local settings, necessitates a strategic approach to continuous professional development. Long-term career success depends not only on securing an initial entry-level position but also on proactively enhancing skills and knowledge throughout one’s career trajectory.

- Continuing Education and Certifications

The aerospace industry continually evolves, requiring engineers to stay abreast of technological advancements and regulatory changes. Pursuing advanced degrees, specialized certifications (e.g., Project Management Professional, Certified Systems Engineering Professional), and industry-specific training courses enhances expertise and competitiveness. For example, an engineer working on aircraft structures might pursue certification in finite element analysis to improve proficiency in stress analysis and design optimization. These credentials demonstrate a commitment to professional growth and enhance career prospects within local aerospace firms.

- Skill Diversification and Cross-Functional Training

Expanding skill sets beyond one’s core area of expertise increases adaptability and value to employers. Acquiring knowledge in related disciplines, such as systems engineering, project management, or software development, broadens career options and enables contribution to diverse project teams. An aerospace engineer specializing in propulsion systems might pursue training in control systems to understand the integration of propulsion with overall aircraft performance. Local aerospace companies often value engineers with broad skill sets who can contribute to multiple phases of product development.

- Mentorship and Professional Networking

Seeking guidance from experienced mentors and actively participating in professional networks provides valuable insights and career advice. Mentors can offer guidance on skill development, career advancement, and navigating industry challenges. Engaging in networking events and industry associations allows engineers to connect with peers, learn about emerging trends, and identify potential job opportunities within their local area. Local AIAA chapters, for example, offer mentorship programs and networking events that facilitate professional growth.

- Leadership Development and Management Skills

Developing leadership and management skills is crucial for career advancement into supervisory or project management roles. Participating in leadership training programs, taking on team lead responsibilities, and pursuing project management certifications prepares engineers for greater levels of responsibility. As engineers advance, local aerospace companies seek individuals who can effectively lead teams, manage budgets, and oversee complex projects. Demonstrating leadership potential is essential for career progression beyond entry-level positions.

These facets of career development directly impact an aerospace engineer’s long-term success in a local context. Continuous learning, skill diversification, mentorship, and leadership development enhance an engineer’s value to employers, expanding their career opportunities and contributing to their sustained growth within the dynamic aerospace industry. Effective career development positions individuals for greater responsibility and career fulfillment within local aerospace companies and research institutions.

Entry Level Aerospace Engineering Positions

This section addresses common inquiries concerning initial aerospace engineering opportunities, focusing on factors influencing job prospects and career progression.

Question 1: What qualifications are essential for securing an initial position in aerospace engineering?

A bachelor’s degree in aerospace engineering or a closely related field is typically the minimum requirement. Furthermore, proficiency in industry-standard software such as CAD and CAE tools is often expected. Relevant internship or co-op experience enhances a candidate’s competitiveness.

Question 2: How does geographic location impact the availability of entry-level aerospace engineering jobs?

The concentration of aerospace companies and government facilities in a particular region directly affects job availability. Proximity to major aerospace hubs, such as those in California, Washington, or Florida, typically offers greater employment opportunities.

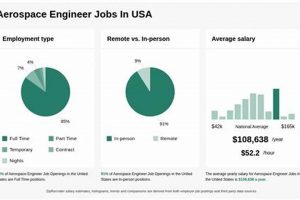

Question 3: What is the typical salary range for entry-level aerospace engineering positions?

Salaries vary based on location, company size, educational qualifications, and specific job responsibilities. Researching industry salary surveys and consulting with career advisors provides insight into prevailing compensation levels in a given region.

Question 4: What role does networking play in finding initial aerospace engineering employment?

Networking significantly enhances job prospects. Attending industry events, connecting with professionals on online platforms, and leveraging university alumni networks can reveal unadvertised job openings and provide valuable career advice.

Question 5: How important are soft skills in addition to technical expertise?

Soft skills, such as communication, teamwork, and problem-solving, are essential complements to technical expertise. Aerospace projects typically involve collaboration among diverse teams, requiring engineers to communicate effectively and contribute to problem resolution.

Question 6: What are some strategies for career advancement beyond an initial entry-level role?

Continuous professional development is critical for career progression. Pursuing advanced degrees, obtaining industry certifications, and diversifying skill sets enhances an engineer’s long-term career prospects.

Understanding these frequently asked questions provides valuable insights for individuals seeking to launch their aerospace engineering careers and develop a strategic approach to job searching and professional development.

The following section will summarize the key points covered in this article and provide concluding remarks.

entry level aerospace engineering jobs near me

This exposition has explored factors pertinent to securing an initial aerospace engineering position within a specific geographical radius. Critical elements include: the accessibility of opportunities influenced by location, required skill sets encompassing both technical proficiency and interpersonal capabilities, educational attainment levels, the strategic navigation of the application process, the establishment of effective industry contacts, an understanding of prevailing salary expectations, and a commitment to continuous career development.

The aerospace engineering profession demands rigorous preparation and proactive engagement. Successfully navigating the local employment landscape necessitates a multifaceted approach that encompasses both academic achievements and strategic career planning. Aspiring engineers are encouraged to rigorously assess their skill sets, network effectively, and remain adaptable to the evolving demands of the industry to maximize their potential for career success.