The array of career paths available after pursuing an aerospace engineering degree is extensive, encompassing roles centered on the design, development, testing, and production of aircraft and spacecraft. These roles demand a strong foundation in physics, mathematics, and engineering principles. For instance, graduates may find themselves working on the aerodynamics of a new aircraft wing, developing guidance systems for satellites, or contributing to the structural integrity of spacecraft components.

These specialist roles contribute significantly to advancements in air travel, space exploration, and national defense. Historically, the need for skilled professionals in this discipline has driven innovation and propelled technological progress. The benefits of their expertise extend beyond engineering itself, fostering economic growth and contributing to scientific discovery. The design and implementation of more efficient aircraft, for example, leads to lowered fuel costs and reduced environmental impact, while the exploration of space expands the boundaries of human knowledge.

The following sections will delve into some specific areas within aerospace engineering and provide a more detailed look at the responsibilities and required skills for various positions. Considerations such as job market trends, salary expectations, and necessary qualifications will also be examined.

Guidance for Aspiring Professionals

The following recommendations are offered to individuals seeking to navigate career options following the completion of their academic training.

Tip 1: Specialization is Advantageous. Focus on a specific area, such as propulsion, aerodynamics, or structures, to develop in-depth expertise. This targeted approach can increase competitiveness in a particular segment of the industry.

Tip 2: Proficiency in Relevant Software is Essential. Develop skills in industry-standard software for CAD, simulation, and analysis. Familiarity with tools like MATLAB, ANSYS, or SolidWorks demonstrates preparedness for practical application.

Tip 3: Seek Internship or Research Opportunities. Practical experience gained through internships or research projects is invaluable. These experiences offer exposure to real-world engineering challenges and provide opportunities for networking.

Tip 4: Continuous Learning is Paramount. The field is constantly evolving; therefore, a commitment to ongoing professional development is crucial. This includes staying abreast of new technologies, materials, and design methodologies.

Tip 5: Networking is a Valuable Tool. Attend industry conferences and workshops to connect with professionals and learn about emerging trends. Building a professional network can provide access to job opportunities and mentorship.

Tip 6: Strong Communication Skills are Necessary. The ability to communicate technical information clearly and effectively is critical for collaboration and project management. Develop strong written and verbal communication skills.

Tip 7: Consider Advanced Degrees. A Master’s degree or Ph.D. can provide a competitive edge, particularly for roles involving research and development or specialized engineering tasks.

Adhering to these guidelines will help strengthen qualifications and increase prospects for success in this challenging and rewarding field.

The subsequent discussion addresses the long-term outlook and potential for career growth within various segments of the aerospace sector.

1. Design and Development

The design and development phase is a cornerstone of the aerospace sector, fundamentally shaping the diverse professional opportunities available. Its influence stems from the critical need for innovative solutions in aircraft and spacecraft technology. The types of positions directly involved include aerodynamicists, structural engineers, propulsion specialists, and systems engineers, each contributing specialized expertise. The effect of robust design and development is safer, more efficient, and more capable aerospace vehicles. The absence of rigorous design processes would lead to catastrophic failures, underscoring the component’s importance to every stage of the aerospace product lifecycle. For example, the development of composite materials has significantly improved aircraft fuel efficiency, requiring design engineers to implement these materials effectively into airframe structures.

The iterative nature of design and development requires a multidisciplinary approach, integrating various engineering domains. This collaboration is essential for optimizing performance, minimizing risk, and ensuring regulatory compliance. Practical applications include the design of advanced control systems for unmanned aerial vehicles, the development of life support systems for manned space missions, and the refinement of launch vehicle propulsion systems. Each application demands a high degree of precision and attention to detail, demonstrating the interconnectedness of design and development with manufacturing, testing, and operations.

In summary, design and development serves as the intellectual engine of aerospace activity, defining the spectrum of roles available, from initial concept to finalized product. The challenges involved include navigating complex regulatory frameworks, managing technological obsolescence, and adapting to evolving market demands. The ability to effectively address these challenges is crucial for maintaining a competitive edge and driving sustained progress in the aerospace engineering domain.

2. Testing and Analysis

Testing and analysis are integral to the aerospace sector, directly shaping career opportunities by necessitating rigorous validation of designs and components. These processes ensure airworthiness, reliability, and compliance with stringent safety standards. Without robust testing and analysis, the inherent risks in aerospace operations would be unacceptable.

- Structural Testing

Structural testing involves subjecting aerospace components and assemblies to simulated operational loads to verify their ability to withstand stress and fatigue. This includes static testing, fatigue testing, and non-destructive inspection. Examples include testing an aircraft wing to its breaking point or using ultrasonic techniques to detect flaws in composite materials. Professionals involved are structural test engineers, materials scientists, and NDT (Non-Destructive Testing) technicians. The implications of inadequate structural testing can be catastrophic, leading to structural failure during flight.

- Aerodynamic Testing

Aerodynamic testing uses wind tunnels, computational fluid dynamics (CFD), and flight tests to evaluate the aerodynamic performance of aircraft and spacecraft. This includes measuring lift, drag, stability, and control characteristics. Wind tunnel technicians, CFD analysts, and flight test engineers are involved. For instance, wind tunnel testing is crucial in optimizing the design of aircraft wings to reduce drag and improve fuel efficiency. Errors in aerodynamic analysis can lead to unexpected flight characteristics and reduced performance.

- Propulsion Testing

Propulsion testing assesses the performance and reliability of engines, rockets, and other propulsion systems. This involves measuring thrust, fuel consumption, and emissions. Test engineers, combustion specialists, and control systems engineers are essential. Rocket engine testing, for example, involves firing engines under simulated altitude conditions to verify performance and stability. Deficiencies in propulsion testing can result in engine failure and mission aborts.

- Systems Integration Testing

Systems integration testing ensures that all components of an aerospace system function correctly together. This includes testing avionics, control systems, communication systems, and navigation systems. Systems engineers, test pilots, and avionics technicians participate. Simulated flight tests are used to evaluate the integrated performance of all systems. Failure to properly integrate systems can lead to critical malfunctions and loss of control.

These facets of testing and analysis define specialized roles within aerospace engineering. The demand for professionals proficient in these areas is driven by the critical need for safety, reliability, and performance in aerospace applications. As technology advances, the sophistication of testing and analysis techniques will continue to evolve, creating ongoing opportunities for skilled engineers and technicians.

3. Manufacturing and Production

Manufacturing and production form a vital segment of the aerospace sector, directly impacting the nature of available engineering roles. This area encompasses the physical creation of aircraft, spacecraft, and related components, demanding a diverse skill set and specialized knowledge.

- Materials Engineering and Fabrication

This facet involves the selection, processing, and fabrication of materials used in aerospace construction. Roles include materials engineers who specify appropriate alloys, composites, and polymers, as well as fabrication specialists who employ techniques such as welding, machining, and additive manufacturing. The Boeing 787 Dreamliner, for example, utilizes a significant proportion of carbon fiber reinforced polymer, necessitating advanced manufacturing processes and skilled engineers capable of working with these materials. The implications extend to aircraft weight reduction, improved fuel efficiency, and enhanced structural performance.

- Assembly and Integration

Assembly and integration focuses on the precise assembly of individual components into larger subsystems and ultimately complete aircraft or spacecraft. This requires meticulous planning, skilled technicians, and robust quality control measures. Examples include assembling aircraft wings, integrating avionics systems, and connecting propulsion units. Roles involve assembly technicians, integration engineers, and quality control inspectors. Improper assembly can lead to critical system failures, underscoring the importance of rigorous processes and well-trained personnel.

- Quality Assurance and Control

Quality assurance and control ensure that all manufactured components and assembled systems meet stringent specifications and standards. This includes dimensional inspections, non-destructive testing, and functional testing. Quality control engineers, inspectors, and auditors play crucial roles. For instance, radiographic inspection of welds is used to identify defects that could compromise structural integrity. Deficiencies in quality control can result in costly rework, delays, and safety hazards.

- Process Engineering and Optimization

Process engineering and optimization involves the continuous improvement of manufacturing processes to enhance efficiency, reduce costs, and minimize waste. This includes implementing lean manufacturing principles, automating production lines, and optimizing material flow. Process engineers, industrial engineers, and manufacturing specialists are involved. The implementation of automated drilling and riveting processes in aircraft assembly lines demonstrates process optimization aimed at improving productivity and precision. Inefficient processes can lead to higher production costs and longer lead times.

These aspects of manufacturing and production exemplify the range of specialized positions within the aerospace field. The demand for skilled professionals in these areas remains strong, driven by the ongoing need for safe, reliable, and cost-effective aerospace vehicles. Continuous advancements in manufacturing technology will further shape the evolution of these roles, necessitating a commitment to lifelong learning and adaptation.

4. Research and Innovation

Research and innovation are fundamental drivers shaping the landscape of aerospace engineering, influencing not only the evolution of technology but also the specific career paths available within the sector. The continuous pursuit of advancements necessitates specialized roles that focus on exploring new concepts, developing novel technologies, and refining existing systems.

- Advanced Materials Development

This facet focuses on the investigation and development of new materials with enhanced properties suitable for aerospace applications. This includes research into lightweight composites, high-temperature alloys, and self-healing materials. For example, the development of ceramic matrix composites for turbine blades allows for higher operating temperatures, increasing engine efficiency. This area creates opportunities for materials scientists, metallurgists, and chemical engineers specializing in aerospace applications. The implications extend to improved aircraft performance, reduced weight, and enhanced durability.

- Hypersonic Propulsion Systems

Hypersonic propulsion research centers on the development of engines capable of propelling vehicles at speeds exceeding Mach 5. This involves the study of scramjets, ramjets, and combined-cycle engines. The development of a reliable hypersonic engine could revolutionize air travel and space access. This domain offers career prospects for propulsion engineers, combustion specialists, and fluid dynamicists. Success in this field will dramatically reduce travel times and enable more efficient space launches.

- Autonomous Systems and Robotics

This area explores the integration of autonomous systems and robotics into aerospace vehicles and operations. This includes the development of autonomous flight control systems, unmanned aerial vehicles (UAVs), and robotic systems for spacecraft maintenance. For instance, UAVs are increasingly used for aerial surveillance, infrastructure inspection, and search and rescue missions. This sector generates positions for robotics engineers, control systems engineers, and software developers specializing in artificial intelligence and machine learning. Autonomous systems promise to reduce operational costs, increase safety, and enable new capabilities.

- Space Exploration Technologies

Space exploration technologies research is dedicated to developing the technologies required for future space missions. This includes research into advanced life support systems, in-situ resource utilization (ISRU), and deep space communication systems. The development of ISRU technologies could enable sustainable long-duration space missions by allowing astronauts to produce fuel and other resources from materials found on other planets. This area creates opportunities for aerospace engineers, mechanical engineers, and chemical engineers focused on space applications. Advancements in these technologies are crucial for expanding human presence beyond Earth.

These facets underscore the profound influence of research and innovation on defining the types of careers available within aerospace engineering. The pursuit of cutting-edge technologies not only drives scientific progress but also necessitates specialized expertise in areas such as materials science, propulsion, autonomous systems, and space exploration. As research continues to push the boundaries of what is possible, new and exciting career paths will undoubtedly emerge, requiring a highly skilled and adaptable workforce.

5. Management and Oversight

Effective management and oversight are critical components of the aerospace sector, shaping career trajectories and ensuring project success. These functions provide strategic direction, resource allocation, and regulatory compliance across various engineering domains.

- Project Management

Project management involves planning, executing, monitoring, and closing aerospace projects, ensuring they are completed on time, within budget, and to the required specifications. Project managers oversee teams of engineers, track progress, and mitigate risks. For instance, the development of a new satellite system requires meticulous project management to coordinate the efforts of numerous engineering disciplines, from propulsion to communications. These roles are crucial for maintaining project timelines, controlling costs, and achieving performance objectives. Improper project management can lead to delays, cost overruns, and compromised performance.

- Engineering Management

Engineering management focuses on the technical aspects of aerospace projects, ensuring that engineering designs and processes meet technical requirements and regulatory standards. Engineering managers provide technical guidance to engineering teams, review designs, and oversee testing and analysis. The design and construction of a new aircraft wing requires engineering management to ensure structural integrity and aerodynamic performance. Engineering managers are essential for upholding technical standards, resolving engineering challenges, and driving innovation. Ineffective engineering management can result in design flaws, safety hazards, and performance deficits.

- Program Management

Program management involves managing multiple related projects to achieve strategic objectives. Program managers coordinate the activities of project managers, allocate resources across projects, and ensure alignment with overall organizational goals. The development of a new space launch system, comprising multiple rockets, launch facilities, and support infrastructure, demands program management to integrate these elements effectively. Program managers play a key role in maximizing efficiency, minimizing redundancies, and achieving strategic outcomes. Poor program management can lead to disjointed efforts, resource conflicts, and missed opportunities.

- Regulatory Compliance and Safety Oversight

Regulatory compliance and safety oversight ensure that aerospace operations adhere to applicable regulations and safety standards. This includes developing and implementing safety management systems, conducting audits, and investigating incidents. Safety managers, compliance officers, and regulatory affairs specialists are essential. Air traffic control systems, for instance, are subject to stringent regulatory oversight to ensure the safe and efficient flow of air traffic. Rigorous regulatory compliance is critical for preventing accidents, protecting the public, and maintaining the integrity of the aerospace sector. Failure to comply with regulations can result in fines, operational restrictions, and reputational damage.

These facets highlight the impact of management and oversight on the landscape. Effective leadership, strategic planning, and adherence to regulations are essential for ensuring the safety, reliability, and success of aerospace ventures. As the industry evolves, the demand for skilled professionals in these areas will continue to grow, driving innovation and maintaining the sector’s high standards.

Frequently Asked Questions Regarding Aerospace Engineering Careers

The following section addresses common inquiries concerning aerospace engineering career paths, providing clarity on opportunities, qualifications, and professional development.

Question 1: What foundational skills are most critical for success in this discipline?

Proficiency in mathematics, physics, and computer-aided design (CAD) software forms the basis for effective practice. Strong analytical and problem-solving skills are equally vital.

Question 2: Are advanced degrees necessary for career advancement?

While entry-level positions may be accessible with a Bachelor’s degree, a Master’s or Ph.D. often provides a competitive advantage, especially for roles in research and development or specialized engineering areas.

Question 3: What are the primary areas of specialization?

Specializations include aerodynamics, propulsion, structures, avionics, and control systems. Each area demands specific expertise and offers distinct career opportunities.

Question 4: How important are internships and co-op experiences?

Practical experience gained through internships or cooperative education programs is highly valued. These experiences provide exposure to real-world engineering challenges and enhance job prospects.

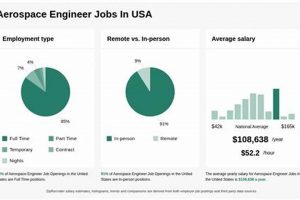

Question 5: What is the employment outlook for aerospace engineers?

The employment outlook remains positive, driven by ongoing demand for innovation in aircraft and spacecraft technology, national defense, and space exploration. However, competition for positions can be intense.

Question 6: What professional certifications are beneficial?

Professional certifications, such as those offered by the American Institute of Aeronautics and Astronautics (AIAA), can demonstrate expertise and enhance credibility within the field.

In summary, a strong educational foundation, practical experience, and a commitment to continuous learning are essential for a successful career. Specialization in a specific area and the pursuit of advanced degrees can further enhance opportunities.

The subsequent section provides a comprehensive conclusion summarizing key takeaways and insights regarding the various career trajectories within aerospace engineering.

Conclusion

This exploration of aerospace engineering types of jobs reveals a multifaceted landscape characterized by diverse roles and specialized expertise. The analysis has examined the critical functions of design and development, testing and analysis, manufacturing and production, research and innovation, and management and oversight. Each aspect contributes uniquely to the advancement of aerospace technology and offers distinct career pathways for skilled professionals. Understanding these various career paths is essential for aspiring engineers seeking to navigate the opportunities and challenges within this dynamic field.

The future of aerospace engineering hinges on continued innovation, adherence to rigorous standards, and the cultivation of a highly skilled workforce. As technology evolves and new challenges emerge, the need for competent engineers will remain paramount. The insights presented herein underscore the importance of strategic career planning, ongoing professional development, and a commitment to excellence in all facets of aerospace endeavor. Continued pursuit of advancements will ensure the industry sustains safety and effectiveness in aerospace applications.