Institutions within the United States that offer specialized education in the design, development, and testing of aircraft and spacecraft are crucial for the advancement of aviation and space exploration. These establishments provide curricula encompassing aerodynamics, propulsion, materials science, and control systems, among other essential disciplines. A prospective engineer might seek programs at institutions such as the Massachusetts Institute of Technology, California Institute of Technology, or Stanford University.

The availability of robust academic programs in this engineering field within the U.S. is vital to maintaining the nation’s leadership in aerospace technology and national defense. These programs foster innovation, contribute to economic growth through the creation of high-skilled jobs, and ensure a steady supply of qualified professionals for government agencies and private sector companies. Historically, the establishment and growth of these educational programs have mirrored significant milestones in aviation and space endeavors.

A detailed analysis of the leading academic institutions, program structures, research opportunities, and career pathways is presented in the subsequent sections. This will provide a framework for understanding the breadth and depth of educational options available to aspiring aerospace engineers.

Guidance for Prospective Aerospace Engineers

Selecting the appropriate academic institution for pursuing a career in aerospace engineering requires careful consideration. The following points offer essential guidance for navigating this important decision.

Tip 1: Evaluate Curriculum Rigor: Examine the depth and breadth of the coursework offered. A strong program will incorporate fundamental principles alongside specialized subjects such as computational fluid dynamics and spacecraft design.

Tip 2: Research Faculty Expertise: Investigate the research interests and publications of the faculty. Engaging with instructors actively involved in cutting-edge research can provide invaluable insights and opportunities.

Tip 3: Assess Laboratory and Facilities: Confirm the availability of state-of-the-art laboratories and testing facilities. Hands-on experience with wind tunnels, propulsion systems, and materials characterization equipment is crucial for practical skill development.

Tip 4: Consider Accreditation Status: Verify that the program is accredited by ABET (Accreditation Board for Engineering and Technology). Accreditation ensures the program meets established quality standards and is recognized by employers.

Tip 5: Explore Internship Opportunities: Inquire about internship programs with aerospace companies and government agencies. Practical experience in real-world settings enhances employability and career prospects.

Tip 6: Investigate Research Opportunities: Determine the extent of undergraduate and graduate research opportunities. Participating in research projects provides exposure to the scientific method and fosters innovation.

Tip 7: Analyze Program Outcomes: Review the program’s graduate employment rates and average starting salaries. This information provides an indication of the program’s effectiveness in preparing students for successful careers.

Adhering to these guidelines ensures a more informed and strategic approach to selecting a program, maximizing the likelihood of a fulfilling and successful career in this dynamic field.

The subsequent sections will address specific programs and their distinguishing features, providing a comparative analysis to assist prospective students in making well-informed choices.

1. Accreditation Standards

Accreditation standards play a pivotal role in validating the quality and rigor of aerospace engineering programs within the United States. These standards, primarily overseen by ABET (Accreditation Board for Engineering and Technology), ensure that educational programs meet defined criteria concerning curriculum content, faculty qualifications, facilities, and student outcomes. The cause-and-effect relationship is evident: adherence to accreditation standards results in a higher likelihood of graduates possessing the knowledge and skills demanded by the aerospace industry. Without such standards, the consistency and comparability of educational programs would be significantly compromised.

The practical significance of accreditation is manifested in several ways. Graduates from accredited programs are often preferred by employers in the aerospace sector. For example, major aerospace companies frequently require that job applicants hold degrees from ABET-accredited institutions. Furthermore, accreditation facilitates the acceptance of graduates into postgraduate programs. The standards also necessitate continuous improvement, prompting institutions to regularly evaluate and refine their programs based on industry feedback and technological advancements. This constant evaluation helps institutions adapt to the evolving demands of the aerospace field, keeping their curricula relevant and up-to-date.

In summary, accreditation standards provide a framework for quality assurance within aerospace engineering education in the U.S. They directly influence program design, student learning outcomes, and ultimately, the employability and future success of graduates. Challenges remain in ensuring that accreditation processes adequately address emerging technologies and interdisciplinary approaches, but the fundamental importance of these standards in maintaining the integrity and relevance of aerospace engineering education is undeniable.

2. Research Opportunities

Research opportunities are inextricably linked to the strength and prestige of aerospace engineering education within the United States. These opportunities, typically manifested through faculty-led projects, specialized laboratories, and partnerships with industry and government entities, represent a crucial component of a comprehensive academic experience. The availability of such research initiatives directly influences student learning, technological advancement, and the overall reputation of the institution. For example, universities like MIT and Stanford consistently rank among the top institutions due, in part, to their extensive research programs in areas such as hypersonic flight, advanced materials, and space systems engineering. These research endeavors not only contribute to the existing body of knowledge but also provide students with invaluable hands-on experience and exposure to cutting-edge technologies.

The practical significance of integrating research into the curriculum extends beyond theoretical knowledge acquisition. Students involved in research projects develop critical thinking skills, problem-solving abilities, and the capacity for independent inquiry. This prepares them for leadership roles in industry, government, or academia. Consider the case of a student participating in research focused on developing more efficient rocket propulsion systems. This experience not only deepens their understanding of thermodynamics and fluid mechanics but also equips them with the practical skills needed to contribute to the design and optimization of future launch vehicles. These research experiences often translate into internships, co-op positions, and ultimately, full-time employment opportunities with leading aerospace organizations.

In conclusion, research opportunities are an indispensable element of aerospace engineering colleges in the U.S., fostering innovation, enhancing student preparedness, and strengthening the nation’s position in the global aerospace arena. While challenges persist in securing adequate funding and ensuring equitable access to research opportunities for all students, the continued investment in and expansion of these programs remain vital to sustaining the long-term health and vitality of the field. The symbiotic relationship between research and education within these institutions ensures a constant stream of highly skilled engineers ready to tackle the complex challenges of the 21st century.

3. Faculty Expertise

The quality of aerospace engineering education within the United States is intrinsically linked to the expertise of the faculty. Faculty members not only disseminate established knowledge but also contribute to the advancement of the field through research and innovation, directly influencing the caliber of graduates and the reputation of their institutions.

- Research Contributions

A primary indicator of faculty expertise is their active involvement in cutting-edge research. This includes publishing in peer-reviewed journals, securing research grants from government agencies and private companies, and presenting findings at international conferences. Faculty engaged in research translate their discoveries into classroom instruction, providing students with access to the latest advancements and methodologies. For example, a professor researching advanced composite materials might incorporate this knowledge into a course on aircraft structures, enhancing students’ understanding of these critical components. The impact is clear: faculty research directly enriches the educational experience.

- Industry Experience

Many faculty members possess substantial experience working in the aerospace industry, often prior to entering academia or concurrently as consultants. This experience provides valuable practical insights that complement theoretical knowledge. Professors with backgrounds in aircraft design, propulsion systems, or space mission planning can offer real-world perspectives on the challenges and opportunities facing the aerospace sector. They can also leverage their industry connections to facilitate internships, co-op programs, and job placements for their students, bridging the gap between academia and industry practice.

- Teaching Pedagogy and Mentorship

Expert faculty members demonstrate proficiency in teaching methodologies and excel at mentoring students. They employ effective pedagogical approaches to convey complex concepts clearly and engage students in active learning. They also provide individualized guidance to students, assisting them in developing their technical skills, research abilities, and career paths. The ability to inspire and motivate students, fostering a passion for aerospace engineering, is a hallmark of outstanding faculty. Dedicated mentorship often translates into successful student projects, research publications, and competitive job applications.

- Professional Recognition and Awards

External recognition of faculty expertise, through awards, fellowships, and memberships in professional organizations, further validates their contributions to the field. Awards from organizations such as the American Institute of Aeronautics and Astronautics (AIAA) or the National Academy of Engineering (NAE) signal a high level of achievement and peer recognition. Such distinctions not only enhance the prestige of the institution but also attract talented students and researchers who seek to learn from and collaborate with leading experts in aerospace engineering.

In summary, the faculty at aerospace engineering colleges in the U.S. form the cornerstone of these institutions. Their research contributions, industry experience, teaching abilities, and professional recognition collectively determine the quality of education and the future success of their students. The investment in attracting and retaining highly qualified faculty is thus a crucial factor in maintaining the nation’s leadership in aerospace technology.

4. Industry Partnerships

Industry partnerships form a critical nexus connecting aerospace engineering colleges in the U.S. with the practical realities of the aerospace sector. These partnerships, encompassing collaborations with companies like Boeing, Lockheed Martin, SpaceX, and NASA, directly influence curriculum development, research agendas, and student career prospects. The cause-and-effect relationship is evident: strong industry engagement leads to curricula aligned with industry needs, which in turn enhances graduate employability. For instance, collaborative projects between universities and aerospace manufacturers provide students with hands-on experience in designing and testing actual aircraft components, a skill highly valued by potential employers. Without such partnerships, academic programs risk becoming detached from the evolving demands of the aerospace industry. The importance of these collaborations is further underscored by the financial support they often provide, enabling the acquisition of advanced equipment and the funding of cutting-edge research. This support is essential for maintaining the technological competitiveness of U.S. aerospace engineering programs.

The practical significance of industry partnerships extends to multiple facets of aerospace education. Guest lectures delivered by industry professionals offer students insights into real-world challenges and innovative solutions. Internship programs at aerospace companies provide invaluable experience in applying theoretical knowledge to practical engineering problems. Joint research projects, often funded by industry partners, facilitate the development of new technologies and the training of the next generation of aerospace engineers. Consider the example of a university partnering with a space exploration company to develop advanced propulsion systems. Students involved in this project gain expertise in areas such as combustion dynamics, materials science, and control systems, skills that are directly transferable to industry positions. These partnerships also foster a culture of innovation and entrepreneurship, encouraging students to develop their own ideas and pursue careers in aerospace startups.

In conclusion, industry partnerships are integral to the success and relevance of aerospace engineering colleges in the U.S. These collaborations provide essential resources, enhance curriculum quality, and improve student career prospects. While challenges remain in ensuring equitable access to partnership opportunities and managing potential conflicts of interest, the benefits of strong industry engagement are undeniable. The continued cultivation of these relationships is crucial for maintaining the competitiveness and innovation of U.S. aerospace education and the broader aerospace industry.

5. Curriculum Specialization

Curriculum specialization within aerospace engineering programs in the United States reflects the diverse and technologically advanced nature of the field. These specializations allow students to focus their studies on specific areas of interest, equipping them with the knowledge and skills required for specialized roles within the aerospace industry.

- Aerodynamics and Fluid Mechanics

This specialization centers on the study of air and fluid flow, essential for designing efficient and stable aircraft and spacecraft. Coursework typically covers topics such as boundary layer theory, computational fluid dynamics (CFD), and wind tunnel testing. Graduates with this specialization may pursue careers in aircraft design, wind energy, or race car engineering. Example: A student focusing on aerodynamics might work on optimizing the wing design of a new commercial airliner, reducing drag and improving fuel efficiency. This contributes directly to the advancement of air transportation and reinforces the importance of specialization.

- Propulsion Systems

This area of specialization focuses on the design, analysis, and testing of various propulsion systems, including jet engines, rocket engines, and electric propulsion. Coursework includes thermodynamics, combustion, and heat transfer. Graduates find opportunities in aerospace companies, research labs, and government agencies involved in developing and improving propulsion technologies. Example: Specialization in propulsion allows engineers to work on designing more efficient rocket engines, making space travel more sustainable and affordable. This also plays a crucial role in future space missions.

- Structures and Materials

This specialization deals with the mechanical behavior of materials and structures used in aerospace applications. Students learn about stress analysis, composite materials, and finite element analysis (FEA). Graduates may work in structural design, materials testing, or failure analysis. Example: An engineer specialized in structures and materials could be tasked with designing a lightweight yet robust airframe for an unmanned aerial vehicle (UAV), balancing performance with safety and durability.

- Control Systems and Robotics

This specialization focuses on the design and implementation of control systems for aircraft, spacecraft, and autonomous systems. Coursework covers topics such as feedback control, robotics, and navigation. Graduates find employment in designing autopilot systems, guidance systems for missiles, or control algorithms for robots used in space exploration. Example: Curriculum specialization in control systems could lead to the design of an automated landing system for drones, enhancing their precision and reliability. This has significant implications for various applications, including package delivery and surveillance.

These specializations, while distinct, often intersect and require a strong foundation in fundamental aerospace engineering principles. The availability of these focused areas of study allows aerospace engineering colleges in the U.S. to produce graduates with the precise skills and knowledge needed to meet the evolving demands of the aerospace industry, driving innovation and ensuring the continued success of American aerospace endeavors. Furthermore, they also prepare engineers for advanced research and development.

Frequently Asked Questions

The following section addresses common inquiries regarding aerospace engineering education within the United States. The information presented is intended to provide clarity and guidance to prospective students and stakeholders.

Question 1: What are the primary accreditation bodies for aerospace engineering programs in the U.S.?

The Accreditation Board for Engineering and Technology (ABET) is the principal accrediting organization for engineering programs in the United States, including those in aerospace engineering. Accreditation by ABET signifies that a program meets established quality standards related to curriculum, faculty, and student outcomes.

Question 2: What are the typical admission requirements for aerospace engineering programs?

Admission requirements typically include a strong academic record in mathematics, physics, and other science courses. Standardized test scores, such as the SAT or ACT, are often required, along with letters of recommendation and a personal essay. Graduate programs may require a bachelor’s degree in engineering or a related field, along with GRE scores.

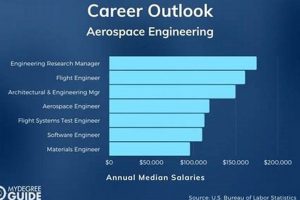

Question 3: What career opportunities are available to graduates of aerospace engineering programs?

Graduates can pursue careers in a variety of sectors, including aircraft design, spacecraft development, propulsion systems, and control systems. Employment opportunities exist in aerospace companies, government agencies, research institutions, and consulting firms.

Question 4: What is the average duration of a bachelor’s degree program in aerospace engineering?

A bachelor’s degree program in aerospace engineering typically requires four years of full-time study. Some programs may offer accelerated options or combined bachelor’s and master’s degree programs that can reduce the overall time to completion.

Question 5: Are there opportunities for financial aid and scholarships for aerospace engineering students?

Financial aid and scholarship opportunities are available from various sources, including the federal government, state governments, universities, and private organizations. Eligibility criteria and application procedures vary depending on the specific program or scholarship.

Question 6: How important are internships and co-op programs in aerospace engineering education?

Internships and cooperative education (co-op) programs are highly valuable for aerospace engineering students. These experiences provide practical, hands-on experience in real-world engineering settings, enhancing students’ skills and increasing their competitiveness in the job market.

These frequently asked questions provide a baseline understanding of aerospace engineering education in the U.S. Prospective students are encouraged to consult with individual institutions for more detailed information about specific programs and requirements.

The following section will examine emerging trends and future directions in aerospace engineering education.

Conclusion

This exploration of aerospace engineering colleges in US has highlighted the critical roles these institutions play in shaping the future of aviation and space exploration. Key aspects examined include the importance of accreditation standards, the value of research opportunities, the significance of faculty expertise, the impact of industry partnerships, and the necessity of curriculum specialization. These elements collectively contribute to the development of highly skilled engineers prepared to address the complex challenges facing the aerospace sector.

As technology continues to advance at an accelerating pace, the need for well-equipped and innovative aerospace engineers will only intensify. Continued investment in these academic programs and a commitment to fostering collaboration between academia and industry are essential to maintaining the nation’s leadership in aerospace technology and ensuring a robust pipeline of talent for years to come. The collective effort toward excellence within these institutions will define the trajectory of aerospace innovation for generations.