Powerplant systems designed and manufactured by Rolls-Royce for aircraft are complex machines critical to flight. These engines are integral components of both commercial airliners and military aircraft, converting fuel into thrust, enabling aerial navigation and transportation. These systems represent a significant investment in research, development, and engineering.

The sophisticated engineering inherent in these systems provides safe, reliable, and efficient air travel. Technological advancements implemented in these powerplants have demonstrably reduced fuel consumption, emissions, and noise levels, contributing to environmental sustainability and operational cost savings. The historical evolution of these engine designs highlights a commitment to innovation, leading to progressively more powerful and efficient systems used across a wide spectrum of aircraft types. Their reliability directly influences on-time performance in the aviation industry.

The following discussion will elaborate on the specific designs, technologies, and applications of these advanced propulsion systems, emphasizing their role in shaping the future of air transport and defense capabilities.

Operational Considerations for High-Performance Aircraft Powerplants

The following recommendations address key aspects of operating and maintaining advanced turbine engines to maximize performance, ensure safety, and extend service life. These tips are crucial for engineers, maintenance personnel, and operators who work directly with these sophisticated systems.

Tip 1: Adhere Strictly to Maintenance Schedules: Scheduled maintenance intervals are crucial to prevent failures. Deviations from the recommended maintenance schedule, as outlined by the engine manufacturer, can result in unforeseen component degradation and subsequent operational risks. For example, neglecting periodic inspections of turbine blades can lead to crack propagation, potentially causing catastrophic engine failure.

Tip 2: Implement Comprehensive Foreign Object Damage (FOD) Prevention Programs: The ingestion of foreign objects represents a significant threat to engine integrity. Rigorous FOD prevention protocols within and around operating airfields and maintenance facilities are essential. Training personnel to identify and remove potential FOD hazards, such as loose hardware or debris, minimizes the risk of damage to compressor blades and other sensitive engine components.

Tip 3: Monitor Engine Performance Parameters Continuously: Real-time monitoring of critical engine parameters, including exhaust gas temperature (EGT), oil pressure, and vibration levels, provides early indications of potential problems. Analyzing trends in these parameters enables proactive maintenance interventions, preventing minor issues from escalating into major failures. Installing and utilizing modern engine health monitoring systems will enable these processes.

Tip 4: Utilize OEM-Approved Parts and Repair Procedures: Employing only genuine, manufacturer-approved replacement parts and adhering strictly to the manufacturer’s specified repair procedures is paramount. Using non-approved parts or unauthorized repair methods may compromise engine performance, reliability, and safety, potentially voiding warranties and increasing operational risks.

Tip 5: Maintain Detailed Service Records: Meticulous record-keeping of all maintenance activities, repairs, and inspections is essential for tracking engine history and identifying potential recurring issues. Detailed service records also facilitate troubleshooting and enable data-driven decisions regarding engine overhaul or replacement.

Tip 6: Ensure Proper Fuel and Oil Quality: Consistent use of fuel and oil grades that meet or exceed manufacturer specifications is critical. Contamination or degradation of fuel or oil can lead to reduced engine performance, increased wear, and potential component failures. Regular fuel and oil sampling and analysis are recommended.

Successful implementation of these guidelines will contribute significantly to maximizing the operational efficiency, longevity, and safety of these complex aircraft powerplants.

The information presented serves as an introductory guide for operating and maintaining high-performance aircraft engines. Further research and consultation with relevant technical documentation is recommended to ensure comprehensive understanding and adherence to best practices.

1. Thrust Generation

Thrust generation is fundamental to the function and performance characteristics of aircraft engines. In the context of Rolls-Royce aerospace powerplants, this refers to the propulsive force developed by the engine to overcome drag and propel the aircraft forward. Higher thrust enables aircraft to carry heavier payloads, operate from shorter runways, and achieve higher cruise speeds. The sophisticated design and engineering of compressor blades, turbine blades, and nozzle systems within these engines are all explicitly optimized to maximize thrust output while maintaining structural integrity at extreme operating temperatures and pressures. An increase in engine generated thrust is a direct cause of higher fuel usage, the engineers at Rolls-Royce are always seeking the perfect balance in the designs to have high thrust capabilities at minimal fuel usage.

Rolls-Royce implements advanced aerodynamic principles and materials science in the design and manufacture of its engines to achieve targeted thrust levels. For example, the Trent 900 engine, utilized on the Airbus A380, generates significant thrust enabling this large aircraft to operate efficiently on long-haul routes. By refining blade profiles, optimizing the combustion process, and incorporating high-strength, lightweight materials, the engines can produce the necessary thrust while minimizing fuel consumption and noise emissions. In this case, proper design of each area of the engine allows for the full thrust required while mitigating noise or environmental concerns.

In conclusion, thrust generation is a pivotal aspect of engines’ overall performance and operational capabilities. Through continuous innovation in design, materials, and control systems, Rolls-Royce strives to optimize this essential parameter, ensuring safe, reliable, and efficient air transportation. Understanding the relationship between thrust generation and advanced propulsion systems is crucial for engineers, operators, and stakeholders seeking to improve aircraft performance and reduce operating costs.

2. Fuel Efficiency

Fuel efficiency is a paramount performance criterion in modern aviation, significantly impacting operational costs and environmental impact. Optimizing fuel consumption in aircraft powerplants is a continuous focus in engine design and operation. Its influence on overall aircraft economics and environmental sustainability is a driving force in technological advancements.

- High Bypass Ratio Turbofans

The high bypass ratio turbofan configuration significantly improves propulsive efficiency. By bypassing a large portion of the incoming air around the core engine, these designs produce thrust through a larger volume of slower-moving air, requiring less energy expenditure for a given thrust output. The Trent family of engines exemplifies this, achieving substantial fuel savings compared to earlier engine generations.

- Advanced Compressor and Turbine Aerodynamics

Optimizing the aerodynamic profiles of compressor and turbine blades minimizes energy losses within the engine. Computational fluid dynamics (CFD) simulations are extensively used to design blades that maximize airflow efficiency, reduce turbulence, and improve pressure recovery. These enhancements translate directly into lower specific fuel consumption (SFC).

- Combustion Chamber Technology

Efficient combustion is crucial for extracting maximum energy from the fuel. Lean burn combustion systems, for example, operate with a higher air-to-fuel ratio, reducing the formation of nitrogen oxides (NOx) and improving overall combustion efficiency. Precise control of fuel injection and air mixing ensures complete combustion and minimizes unburned hydrocarbons.

- Weight Reduction Initiatives

Decreasing the overall weight of the engine components contributes directly to improved fuel efficiency. The use of lightweight materials, such as titanium alloys and composite materials, in engine construction reduces the engine’s mass, lowering the energy required to propel it through the air. Lighter engines also translate to reduced aircraft drag.

These integrated strategies underscore the commitment to enhancing fuel efficiency within aircraft engines. Continuous innovation in design, materials, and operational techniques ensures that these engines operate with the lowest possible fuel consumption, reducing both environmental impact and operational costs for airlines worldwide.

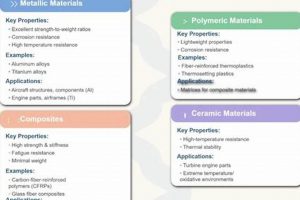

3. Material Science

The development and performance of high-thrust, fuel-efficient aircraft engines are intrinsically linked to advancements in material science. Materials deployed in the construction of engines must withstand extreme conditions, including high temperatures, immense pressures, and corrosive environments. Therefore, the selection, modification, and processing of materials are critical components in the design and operational effectiveness of propulsion systems. A direct correlation exists between improved material properties and enhanced engine performance metrics, such as thrust-to-weight ratio, fuel consumption, and service life.

Specific examples illustrate this connection. Nickel-based superalloys, extensively used in turbine blades, exhibit exceptional high-temperature strength and creep resistance, allowing engines to operate at higher turbine inlet temperatures, which directly increases thermal efficiency. Similarly, the incorporation of ceramic matrix composites (CMCs) in static engine components facilitates weight reduction, contributing to improved fuel efficiency and lower emissions. Furthermore, coatings, such as thermal barrier coatings (TBCs), protect underlying metallic components from oxidation and corrosion, prolonging their lifespan and reducing maintenance requirements. Without continual advancements in material science, the performance gains observed in modern turbine engines would not be achievable.

In summary, material science is not merely a supporting discipline but an integral and enabling factor in the progression of aircraft engine technology. The ongoing pursuit of novel materials and advanced processing techniques directly impacts the capabilities and operational economics of air transport. Challenges remain in developing materials capable of withstanding even more extreme environments, thereby necessitating continued investment in research and development within this critical field.

4. Digital Control

Digital control systems are indispensable in modern aircraft engines, providing precise and automated management of engine operation. Integration of advanced digital controllers is essential to achieving optimal performance, efficiency, and safety across diverse flight conditions. These systems are integral to the advanced capabilities of aerospace powerplants.

- Full Authority Digital Engine Control (FADEC)

FADEC is a core element of digital control, managing all aspects of engine performance, from fuel injection to variable geometry. By continuously monitoring engine parameters such as temperature, pressure, and speed, FADEC adjusts operating parameters to maximize efficiency and prevent exceedances. FADEC optimizes the operation of the engine at all times.

- Engine Health Monitoring (EHM)

Digital control facilitates comprehensive EHM, using sensors and data analytics to assess engine condition in real time. This enables proactive maintenance strategies, reducing downtime and enhancing safety. Continuous monitoring of vibration levels, oil quality, and exhaust gas temperature allows for early detection of potential problems. EHM reduces costs and increases the engine lifespan.

- Automated Flight Control Integration

Digital engine control systems seamlessly integrate with aircraft flight control systems, enabling coordinated control of thrust and aerodynamic surfaces. This integration is vital for advanced flight modes, such as autoland and flight envelope protection. Automated integration is essential to flight control and safety.

- Data Logging and Analysis

Digital systems record vast amounts of operational data, providing valuable insights for engine design improvements and maintenance optimization. Analyzing historical data allows engineers to identify trends, predict failures, and refine engine control algorithms. Data logging and analysis is essential for data driven innovation.

These facets demonstrate the profound influence of digital control on powerplants. Integrating these systems optimizes performance, enhances safety, and contributes to the overall efficiency of air transport. Ongoing advancements in digital technology will continue to shape the future of aircraft propulsion.

5. Emissions Reduction

The imperative to minimize environmental impact has placed significant emphasis on emissions reduction in the aviation sector. Manufacturers of high-performance engines are tasked with developing technologies and strategies to curtail harmful emissions while maintaining operational efficiency. These advancements are crucial for achieving sustainability goals within the aerospace industry.

- Lean Burn Combustion Systems

Lean burn combustion technology involves operating engines with a higher air-to-fuel ratio. This approach lowers combustion temperatures, which in turn reduces the formation of nitrogen oxides (NOx), a significant contributor to air pollution. Specific implementations include advanced fuel injectors and redesigned combustion chambers that ensure thorough mixing of air and fuel. For example, the ALECSys lean-burn system reduced NOx emissions by up to 80% during testing.

- Advanced Materials and Coatings

The use of advanced materials, such as ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs), allows engines to operate at higher temperatures without compromising component durability. This increased thermal efficiency translates into reduced fuel consumption and, consequently, lower carbon dioxide (CO2) emissions. Rolls-Royce’s Advance and UltraFan engine designs leverage such materials to maximize fuel efficiency and minimize environmental impact.

- Alternative Fuel Compatibility

Ensuring compatibility with sustainable aviation fuels (SAF) is another critical aspect of emissions reduction efforts. SAFs, derived from renewable sources, offer a substantial reduction in lifecycle CO2 emissions compared to conventional jet fuel. Engine designs are being adapted to accommodate a range of SAF blends without compromising performance or safety. Initiatives involve material compatibility testing and modifications to fuel systems to ensure seamless integration of SAFs.

- Engine Design and Aerodynamic Improvements

Optimizing engine design and improving aerodynamic efficiency directly contributes to lower fuel consumption and reduced emissions. Examples include advanced fan blade designs, improved compressor and turbine aerodynamics, and reduced engine weight. These advancements minimize energy losses within the engine, increasing overall propulsive efficiency and lowering the amount of fuel required for a given flight.

These strategies demonstrate a comprehensive approach to minimizing the environmental footprint of aircraft engines. Continuous innovation in combustion technology, materials science, fuel compatibility, and aerodynamic design is essential for achieving long-term sustainability within the aviation industry. The integration of these advancements represents a commitment to reducing emissions while maintaining the high-performance standards expected of modern aircraft engines.

6. Modular Design

Modular design represents a fundamental approach to the engineering and construction of modern aerospace engines. This strategy involves dividing the engine into discrete, self-contained modules or sections, each performing a specific function. This approach enhances manufacturing, maintenance, and upgrade capabilities, significantly impacting the lifecycle management of these complex systems.

- Reduced Maintenance Downtime

Modular design allows for the rapid replacement of individual engine sections without requiring a complete engine overhaul. If a specific module, such as the high-pressure compressor, experiences a failure, it can be removed and replaced with a serviceable unit. This minimizes aircraft downtime, enhancing operational efficiency and reducing costs for airlines. Examples include the ability to swap out a fan module within hours, compared to days for non-modular engines.

- Simplified Manufacturing and Assembly

Modular construction streamlines the manufacturing process. Each module can be manufactured and tested independently before being integrated into the complete engine assembly. This parallel processing reduces overall production time and improves quality control. The Trent XWB engine, for instance, is assembled from multiple modules, each produced in specialized facilities and then integrated at a central assembly location.

- Enhanced Upgrade Capabilities

Modular architecture facilitates the incorporation of technological upgrades and improvements without requiring a complete engine redesign. Specific modules can be updated or replaced with more advanced versions, enhancing engine performance, fuel efficiency, or emissions characteristics. The ability to retrofit new turbine blades or combustion systems into existing engines extends their operational lifespan and keeps them competitive.

- Efficient Logistics and Inventory Management

The standardization of modules simplifies logistics and inventory management. Airlines and maintenance providers can stock a limited number of replacement modules to support a fleet of engines, reducing inventory costs and improving responsiveness to maintenance demands. The modular nature of Rolls-Royce’s CorporateCare service program relies on the availability of interchangeable modules to minimize disruption to aircraft operations.

In conclusion, modular design is a cornerstone of modern aerospace engine engineering, impacting every aspect of engine lifecycle management from manufacturing to maintenance and upgrades. Its benefits extend to airlines, maintenance providers, and engine manufacturers, enhancing efficiency, reducing costs, and facilitating continuous improvement in engine performance and reliability.

Frequently Asked Questions

The following addresses common queries regarding aircraft engine technology, performance, and maintenance considerations. The content is intended to provide clear and concise answers to prevalent questions.

Question 1: What factors determine the lifespan of an aircraft engine?

The lifespan of an aircraft engine is determined by several interdependent factors, including operating environment, maintenance practices, flight cycles (takeoffs and landings), and adherence to manufacturer’s recommended procedures. The engine’s design, materials, and the quality of maintenance significantly impact its durability and longevity.

Question 2: How is fuel efficiency measured in aircraft engines?

Fuel efficiency is quantified using specific fuel consumption (SFC), which represents the amount of fuel consumed per unit of thrust produced per unit of time. Lower SFC values indicate greater fuel efficiency. Factors influencing SFC include engine design, operating conditions, and advancements in combustion and aerodynamic technologies.

Question 3: What are the primary causes of engine failure in commercial aviation?

Engine failures can stem from diverse sources, including foreign object damage (FOD), component defects, lubrication system failures, improper maintenance, and exceeding operational limits. Rigorous inspection protocols, robust maintenance programs, and effective FOD prevention measures are essential for mitigating these risks.

Question 4: What is the role of digital control systems in modern aircraft engines?

Digital control systems, such as Full Authority Digital Engine Control (FADEC), manage and optimize engine performance by continuously monitoring operating parameters and adjusting engine settings. These systems enhance efficiency, improve safety, and enable predictive maintenance capabilities.

Question 5: How do environmental regulations impact the design and operation of aircraft engines?

Increasingly stringent environmental regulations necessitate the development of engines with reduced emissions and noise levels. Manufacturers employ technologies such as lean burn combustion, advanced materials, and noise-attenuating designs to comply with these regulations. Compliance also drives research into alternative fuels and propulsion systems.

Question 6: What are the key considerations for selecting an engine for a specific aircraft application?

Engine selection involves evaluating factors such as thrust requirements, fuel efficiency, weight, reliability, maintenance costs, and environmental impact. These criteria are balanced to optimize aircraft performance and operational economics for the intended mission profile.

These FAQs provide a foundational understanding of aircraft engine technology and related considerations. For more in-depth information, consulting technical documentation and subject matter experts is recommended.

The following section will explore future trends in aircraft propulsion technology.

Concluding Remarks

This exposition has examined the multifaceted aspects of aircraft powerplants, emphasizing core characteristics such as thrust generation, fuel efficiency, advanced materials, digital control systems, emissions reduction strategies, and modular designs. These elements collectively determine the performance, reliability, and technological advancement of these systems, thereby shaping the capabilities of modern air transport and defense operations.

Continued investment in research, development, and innovation within the field remains crucial. The pursuit of enhanced propulsion technologies is not merely an engineering endeavor, but a strategic imperative. Future progress will depend on sustained commitment to pushing the boundaries of materials science, digital control, and environmental stewardship. Such dedication will yield advancements essential for meeting the growing demands of global aviation and ensuring its long-term sustainability.