One field focuses on the design, analysis, and manufacturing of mechanical systems. This encompasses a broad range of applications, including power generation, transportation, robotics, and manufacturing processes. The other discipline centers on the design, development, testing, and production of aircraft, spacecraft, and related systems. This area includes aerodynamics, propulsion, structural analysis, and control systems for flight vehicles.

The significance of these engineering branches lies in their contributions to technological advancement and societal progress. They are critical for developing efficient and sustainable energy solutions, improving transportation infrastructure, enabling space exploration, and enhancing manufacturing capabilities. Their historical roots can be traced back to the Industrial Revolution and the early days of aviation, respectively, evolving significantly with advancements in materials science, computer technology, and engineering principles.

This article will explore the distinct educational paths, core competencies, typical job responsibilities, and career opportunities associated with each of these engineering specializations. It will also delve into the areas of overlap and potential for interdisciplinary collaboration, providing a comprehensive overview for prospective students and professionals considering a career in either domain.

Selecting an engineering path requires careful consideration of interests, aptitude, and career aspirations. These guidelines aim to provide clarity in distinguishing between two prominent fields.

Tip 1: Evaluate Foundational Interests. Determine a natural inclination towards the design and analysis of general mechanical systems or a specific fascination with flight and space-related technology. Mechanical engineering involves a broader scope, while aerospace engineering is more specialized.

Tip 2: Examine Curriculum Focus. Review the core coursework of each discipline. Mechanical engineering programs emphasize thermodynamics, heat transfer, and machine design. Aerospace programs prioritize aerodynamics, propulsion, and aerospace structures.

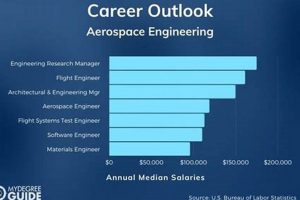

Tip 3: Consider Career Trajectory. Research typical job roles associated with each field. Mechanical engineers find employment in diverse sectors, including manufacturing, automotive, and energy. Aerospace engineers often work in the aviation, defense, and space exploration industries.

Tip 4: Assess Required Skill Sets. Identify essential technical skills. Mechanical engineering often requires proficiency in CAD software and manufacturing processes. Aerospace engineering demands expertise in computational fluid dynamics and finite element analysis.

Tip 5: Explore Research Opportunities. Investigate available research labs and projects. Many universities offer research opportunities in areas such as robotics, renewable energy, or advanced materials within mechanical engineering, and in areas such as hypersonic flight, satellite design, or space exploration within aerospace engineering.

Tip 6: Network with Professionals. Seek informational interviews with engineers in both fields. This provides firsthand insights into the daily tasks, challenges, and rewards of each profession.

Tip 7: Understand Industry Trends. Stay informed about emerging technologies and industry demands. This helps assess the long-term career prospects and growth potential of each specialization. Areas like sustainable engineering and electric propulsion systems are experiencing growth.

In essence, a thoughtful assessment of personal interests, academic rigor, career objectives, and skill development should guide the selection process. Understanding the nuances of each specialization is paramount for making an informed decision.

The following sections delve deeper into the specific distinctions, providing a comprehensive analysis to aid in career planning.

1. Core Principles

The fundamental scientific and mathematical tenets underlying each engineering discipline significantly influence its practical applications and problem-solving approaches. Mechanical engineering rests on a broad foundation of mechanics, thermodynamics, heat transfer, materials science, and control systems. These principles enable mechanical engineers to design, analyze, and optimize a diverse range of systems, from internal combustion engines to robotic arms. For instance, the design of an efficient automobile engine relies heavily on the principles of thermodynamics to maximize energy conversion and minimize waste heat. Similarly, the development of a robust industrial robot requires a deep understanding of mechanics, materials science, and control systems to ensure precise and reliable operation.

Aerospace engineering, while also grounded in physics and mathematics, emphasizes specialized areas such as aerodynamics, propulsion, flight mechanics, and aerospace structures. Aerodynamics, based on fluid dynamics, is crucial for designing efficient airfoils and optimizing aircraft performance. Propulsion principles, particularly those related to jet propulsion and rocket propulsion, are essential for developing engines that can generate the thrust necessary for flight in the atmosphere or space. Furthermore, aerospace structures must be designed to withstand extreme loads and environmental conditions, necessitating a strong understanding of materials science and structural analysis. The design of a spacecraft, for example, demands intricate knowledge of orbital mechanics and control systems to maintain its trajectory and orientation in space.

The divergence in core principles dictates the specific skill sets and knowledge base required for each field. While mechanical engineers possess a broader understanding of general mechanical systems, aerospace engineers have in-depth expertise in flight-related technologies. This distinction is pivotal for students choosing between these career paths, as it highlights the specialized nature of aerospace engineering and the wider applicability of mechanical engineering. Understanding these fundamental differences ensures informed decisions aligning with individual interests and career aspirations.

2. Application Scope

The breadth of applicability distinguishes these two engineering fields. Mechanical engineering offers a considerably wider range of applications spanning diverse industries. Its principles are instrumental in designing and manufacturing mechanical systems, power generation equipment, transportation vehicles, and robotics. The automotive industry, for example, relies heavily on mechanical engineers for engine design, vehicle dynamics, and manufacturing processes. Similarly, the energy sector employs mechanical engineers to develop and optimize power plants, renewable energy systems, and energy storage technologies. This extensive reach contributes to the ubiquitous presence of mechanical engineering in everyday life, impacting areas from consumer products to industrial machinery.

Aerospace engineering, conversely, concentrates on applications related to aircraft, spacecraft, and related systems. This specialization leads to involvement in the design, development, and testing of airplanes, helicopters, satellites, and rockets. For instance, aerospace engineers are critical to the design of commercial airliners, ensuring aerodynamic efficiency, structural integrity, and passenger safety. Furthermore, they play a vital role in the development of spacecraft for scientific research, communication, and exploration. The application scope, while narrower than mechanical engineering, is crucial for advancing aviation and space exploration technologies, often pushing the boundaries of engineering innovation and requiring specialized expertise.

Understanding the distinct application scopes is paramount for prospective engineers. Mechanical engineering provides a versatile foundation applicable to various industries, offering diverse career options. Aerospace engineering, with its specialized focus, appeals to those passionate about flight and space, providing opportunities to contribute to cutting-edge technological advancements in these domains. This delineation facilitates informed career decisions, aligning individual interests with the appropriate engineering specialization. The application scope is not merely a descriptor; its a defining characteristic shaping the professional landscape for each discipline.

3. System Focus

The term “system focus” differentiates the scale and complexity of projects typically undertaken by each discipline. Mechanical engineering generally addresses systems characterized by their integration of mechanical, thermal, and fluid components. Examples include power plants, manufacturing lines, and transportation systems. These systems, while complex, often operate within terrestrial environments and adhere to well-established engineering principles. The success of a mechanical engineering project hinges on the efficient interaction of its various components to achieve a specific functional outcome, such as converting energy or producing goods. A nuanced understanding of component behavior and system integration is essential. An example of this is the design of a modern automotive engine, integrating thermodynamics, fluid mechanics, and materials science to achieve optimal performance and emissions control.

Aerospace engineering, conversely, focuses on systems designed to operate in extreme environments, such as the upper atmosphere or outer space. These systems, including aircraft, spacecraft, and satellites, require meticulous consideration of factors like aerodynamic forces, structural integrity, and propulsion efficiency. The development of a spacecraft, for example, necessitates integrating numerous subsystems, including communication, navigation, and life support, while accounting for the hostile conditions of space. This necessitates a highly specialized skill set and a deep understanding of the unique challenges associated with operating in these environments. The system-level considerations within aerospace engineering are often more constrained by weight, performance, and reliability due to the demanding operational requirements.

In essence, the “system focus” highlights the distinct challenges and priorities of each field. Mechanical engineering emphasizes optimizing the performance and efficiency of complex systems operating in relatively predictable environments. Aerospace engineering prioritizes ensuring the reliable operation of highly specialized systems in extreme and often unpredictable environments. Understanding these differences is crucial for students choosing between these fields, as it provides insight into the types of projects they might undertake and the specific skills they will need to develop. The selection process should involve careful consideration of system-level focus based on individual interest.

4. Fluid Dynamics

Fluid dynamics, the study of fluids (liquids and gases) in motion, is a cornerstone of both mechanical and aerospace engineering. Its relevance stems from its direct influence on the design, analysis, and performance of systems ranging from pumps and turbines to aircraft and spacecraft. The manner in which fluid dynamics principles are applied, however, differs significantly between the two fields, shaping the specific expertise required of engineers in each discipline.

- Internal Flow Systems

Mechanical engineers frequently deal with internal flow systems, such as pipelines, HVAC systems, and turbomachinery components like pumps and compressors. Their application of fluid dynamics involves analyzing pressure drops, flow rates, and energy transfer within confined spaces. For example, the design of an efficient HVAC system in a building requires a thorough understanding of fluid dynamics to optimize airflow, minimize energy consumption, and ensure comfortable temperature distribution. This contrasts with the external flow problems that are more typical in aerospace engineering.

- External Aerodynamics

Aerospace engineers are primarily concerned with external aerodynamics, focusing on the interaction of air with objects moving through it, such as aircraft wings, fuselages, and control surfaces. The application of fluid dynamics centers on calculating lift, drag, and stability characteristics. Understanding airflow patterns around an aircraft wing, for instance, is crucial for optimizing lift and minimizing drag to improve fuel efficiency and overall performance. This involves advanced computational fluid dynamics (CFD) simulations and wind tunnel testing.

- Compressible Flow

Both fields encounter compressible flow, where fluid density changes significantly. Mechanical engineers see it in high-speed machinery; aerospace engineers confront it with supersonic and hypersonic flight. The design of a supersonic jet engine, therefore, necessitates accurate modeling of compressible flow effects to optimize thrust and fuel consumption at high speeds, requiring specialized knowledge of shock waves and expansion fans.

- Computational Fluid Dynamics (CFD)

CFD is a vital tool. Mechanical engineers might simulate flow in a complex heat exchanger; aerospace engineers model airflow around a complete aircraft. The use of CFD allows engineers to virtually test different designs and optimize performance characteristics before physical prototypes are built, saving time and resources. Sophisticated CFD software packages are used to solve the governing equations of fluid flow, providing detailed insights into flow behavior.

These facets illustrate how fluid dynamics, though fundamental to both mechanical and aerospace engineering, is applied in distinct contexts. Mechanical engineers often optimize internal flow systems for efficiency and performance, while aerospace engineers focus on external aerodynamics to enhance flight characteristics and vehicle stability. Understanding these differences is crucial for students and professionals navigating their career paths in these diverse engineering fields.

5. Structural Analysis

Structural analysis, the determination of stresses and strains within a structure subjected to various loads, serves as a critical element in both mechanical and aerospace engineering. While the fundamental principles remain consistent, the application, focus, and associated challenges differ significantly, shaping the expertise required of engineers in each field.

- Load Types and Environments

Mechanical engineers commonly analyze structures subjected to static loads, dynamic loads, and thermal stresses within terrestrial environments. Examples include bridges, buildings, and industrial machinery. Consideration is given to factors such as wind loads, seismic activity, and operational stresses. Aerospace engineers, however, contend with more extreme loading conditions, including aerodynamic forces, inertial loads during flight maneuvers, and pressure differentials in space. The design of aircraft structures necessitates accounting for fatigue caused by repeated flight cycles and the potential for impact damage from foreign objects.

- Material Considerations

Mechanical engineering often involves the use of conventional materials such as steel, aluminum, and concrete. While these materials are also utilized in aerospace engineering, the field frequently employs advanced composite materials like carbon fiber reinforced polymers due to their high strength-to-weight ratios. The analysis of composite structures requires specialized techniques to account for anisotropic material properties and potential failure modes such as delamination. The selection of materials depends on the specific requirements of the application, but aerospace structures often prioritize lightweight designs to enhance performance.

- Analysis Techniques

Both fields leverage finite element analysis (FEA) as a primary tool for structural analysis. However, the complexity and scale of FEA models can vary. Mechanical engineering applications might involve analyzing the stress distribution in a machine component or the deformation of a bridge under load. Aerospace engineering applications often entail simulating the behavior of entire aircraft structures or spacecraft under extreme conditions, requiring significant computational resources and specialized software. Additionally, aerospace engineers frequently employ analytical methods based on beam theory, plate theory, and shell theory to assess the structural integrity of airframes and space vehicles.

- Design Optimization

Structural analysis is inextricably linked to design optimization in both mechanical and aerospace engineering. The goal is to create structures that are both strong and efficient, minimizing weight and material usage while meeting performance requirements. In mechanical engineering, this might involve optimizing the shape of a machine component to reduce stress concentrations. In aerospace engineering, this could entail tailoring the lay-up of composite materials to maximize strength and stiffness while minimizing weight, using techniques like topology optimization to remove unnecessary material. The iterative process of analysis and design refinement is essential for achieving optimal structural performance.

These facets illuminate how structural analysis, a shared foundational principle, manifests differently in mechanical and aerospace engineering. The contrasting load types, material considerations, analysis techniques, and design optimization strategies reflect the unique demands and priorities of each field. These distinctions are crucial for prospective engineers to understand as they consider their career paths and the specialized skill sets they will need to develop. The choice depends on individual interest and commitment.

6. Design Emphasis

The divergence in design priorities constitutes a significant differentiator between mechanical and aerospace engineering. Mechanical engineering design often prioritizes cost-effectiveness, manufacturability, and durability within established technological frameworks. The design of an internal combustion engine, for example, balances performance, fuel efficiency, and compliance with emissions regulations, while also considering manufacturing constraints and cost targets. This emphasis reflects the need to produce reliable and affordable products for a broad consumer base. The integration of existing technologies and materials is common, with incremental improvements driving design evolution.

Aerospace engineering design, conversely, places a premium on performance, efficiency, and safety, often pushing the boundaries of existing technologies. Weight reduction, aerodynamic efficiency, and structural integrity are paramount, even if it necessitates the use of exotic materials and complex manufacturing processes. The design of a spacecraft, for instance, demands extreme measures to minimize weight and maximize reliability due to the high cost and inherent risks associated with space missions. This frequently involves the development and implementation of novel technologies and unconventional design approaches. Innovation is a driving force, with design decisions heavily influenced by the need to achieve ambitious performance targets.

Understanding the design emphasis inherent in each field is crucial for aspiring engineers. Mechanical engineering provides opportunities to refine and optimize existing technologies for widespread application. Aerospace engineering offers the chance to develop groundbreaking solutions for specialized and demanding environments. These varying priorities shape the design process, skill requirements, and career paths within each discipline. Thus, the choice between mechanical and aerospace engineering should be guided by an individual’s passion for incremental improvement versus radical innovation.

7. Career Paths

Career paths directly correlate with specialization within the broader engineering landscape. The distinction between a mechanical engineer and an aerospace engineer dictates the trajectory of their professional life. Mechanical engineering, with its broader applicability, yields a wider array of potential roles across diverse industries. For instance, a mechanical engineer might find employment in automotive design, power generation, or manufacturing process optimization. This versatility allows for lateral movement between sectors and the potential for career shifts throughout their professional life. Conversely, aerospace engineering, with its specialized focus, leads to more defined career paths within the aviation, defense, and space exploration industries. An aerospace engineer may design aircraft components, develop satellite systems, or work on rocket propulsion technologies. The implications of selecting one path over another extend to the types of projects undertaken, the specific skill sets developed, and the overall industry exposure.

The importance of understanding these career paths lies in making informed educational and professional choices. Students considering an engineering degree should carefully evaluate their interests and aptitudes to align with the appropriate specialization. For example, an individual with a strong interest in aerodynamics and spacecraft design may be better suited for aerospace engineering, while someone fascinated by mechanical systems and manufacturing processes might find mechanical engineering more appealing. Real-life examples illustrate this point: engineers who transition from mechanical engineering to aerospace engineering often require additional training or certifications to acquire the necessary specialized knowledge, highlighting the distinct skill sets demanded by each field. The practical significance is that a well-informed decision can lead to a more fulfilling and successful career trajectory.

In summary, career paths serve as a crucial component in differentiating between mechanical and aerospace engineering. Understanding the potential roles, industry sectors, and required skill sets associated with each field is essential for making informed decisions about education and career planning. While challenges exist in predicting future job market trends, a solid understanding of the fundamental differences between these disciplines provides a strong foundation for navigating the engineering profession. Ultimately, aligning individual interests with the appropriate career path is paramount for achieving long-term professional success and contributing meaningfully to the chosen field.

Frequently Asked Questions

This section addresses common inquiries regarding the distinction between mechanical and aerospace engineering, providing clarity on key aspects of each field.

Question 1: What is the fundamental difference in focus?

Mechanical engineering encompasses a broad range of mechanical systems, while aerospace engineering concentrates on aircraft, spacecraft, and related technologies.

Question 2: Which field offers a wider range of job opportunities?

Mechanical engineering typically offers a more diverse array of career paths due to its applicability across numerous industries.

Question 3: Is a background in mathematics equally important for both fields?

A strong foundation in mathematics is essential for success in both mechanical and aerospace engineering. However, aerospace engineering often requires more specialized mathematical knowledge, particularly in areas like differential equations and linear algebra.

Question 4: Which engineering discipline is more competitive?

The level of competition varies depending on the specific job market and the reputation of the engineering program. However, aerospace engineering positions are often highly sought after due to the specialized nature of the field.

Question 5: Can skills be transferable between these engineering fields?

While there is some overlap in fundamental engineering principles, transitioning between mechanical and aerospace engineering may require additional training or specialized coursework to acquire the necessary expertise.

Question 6: Which field is considered more challenging academically?

Both mechanical and aerospace engineering programs present academic challenges. Aerospace engineering may be perceived as more difficult due to its specialized coursework and emphasis on complex systems.

In summary, understanding the distinct characteristics of mechanical and aerospace engineering is crucial for prospective students and professionals making informed career decisions. Careful consideration of interests, aptitudes, and career goals is paramount.

The subsequent sections will provide a detailed comparison of educational pathways and curriculum structures for each engineering specialization.

Mechanical Engineer vs. Aerospace Engineer

This article has explored the distinct characteristics defining the mechanical engineer and aerospace engineer disciplines. Key differentiators include scope of application, focus on system design, and specific expertise in fluid dynamics and structural analysis. While both fields share fundamental engineering principles, the context in which these principles are applied creates unique specializations. Mechanical engineering offers a broader range of career options across various industries, emphasizing cost-effectiveness and manufacturability. Aerospace engineering, conversely, concentrates on pushing technological boundaries within aviation and space exploration, prioritizing performance and safety in extreme environments.

Understanding these nuanced differences is critical for prospective engineers charting their career paths. The decision to pursue mechanical or aerospace engineering should be driven by a careful evaluation of individual interests, aptitudes, and long-term career aspirations. Continued advancements in technology will undoubtedly blur the lines between these disciplines, fostering interdisciplinary collaboration and requiring engineers to possess a diverse skill set. Choosing the right path hinges on discerning the distinct demands and opportunities inherent in each field, ensuring a fulfilling and impactful contribution to the engineering profession.

![Top Aerospace Engineering Undergraduate Colleges [Guide] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Undergraduate Colleges [Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-398-300x200.jpg)