The typical duration of a workday for professionals in the aerospace engineering field often extends beyond the standard eight-hour period. Demands of project deadlines, testing schedules, and the iterative nature of design and development frequently require additional hours to ensure successful completion of tasks and adherence to strict industry regulations. For example, during critical phases of a project, such as pre-launch testing or final design reviews, the time commitment can increase significantly.

The importance of managing workload effectively within this profession is paramount to maintain both productivity and well-being. Extended work periods, while sometimes necessary, can contribute to increased stress and potential burnout if not balanced with sufficient rest and recovery. Recognizing the potential for these negative consequences, many organizations are actively promoting strategies to mitigate these risks, including flexible scheduling options and emphasizing the importance of work-life integration.

Understanding the demands on an aerospace engineer’s time provides a necessary context for exploring strategies for effective time management, the influence of specific project roles on daily hours, and the evolving trends towards more sustainable work practices within the aerospace industry.

Strategies for Managing Workload in Aerospace Engineering

The demanding nature of aerospace engineering often necessitates careful management of time and resources. These strategies aim to provide practical guidance for navigating the pressures associated with extended work periods.

Tip 1: Prioritize Tasks Ruthlessly: Effective prioritization is crucial. Employ methodologies such as the Eisenhower Matrix (urgent/important) to discern critical tasks from those that can be delegated or deferred. Focus energy on items directly impacting project milestones.

Tip 2: Implement Time Blocking: Allocate specific time blocks to particular tasks or projects. This structured approach can improve focus and reduce the likelihood of multitasking, which often decreases overall efficiency. Schedule breaks to prevent mental fatigue.

Tip 3: Leverage Collaborative Tools: Utilize project management software and collaborative platforms to streamline communication, track progress, and identify potential bottlenecks. Shared visibility enhances team coordination and minimizes redundant efforts.

Tip 4: Establish Clear Boundaries: Define clear boundaries between work and personal life. Avoid checking emails or engaging in work-related activities during designated personal time to promote mental restoration and prevent burnout.

Tip 5: Proactively Seek Support: When workload becomes unmanageable, proactively seek assistance from colleagues or supervisors. Open communication about challenges can facilitate resource allocation and prevent individual overload.

Tip 6: Optimize Meeting Effectiveness: Minimize the number and duration of meetings. Ensure a clear agenda, defined objectives, and actionable outcomes are established for each meeting to maximize productivity and minimize wasted time.

These strategies can help aerospace engineers effectively manage their workload, optimize their time, and maintain a sustainable balance between professional demands and personal well-being, ultimately contributing to both individual success and project outcomes.

Implementing these tips can significantly contribute to a more balanced and productive work experience for those in the field.

1. Project Deadlines

Project deadlines exert a substantial influence on the duration of an aerospace engineer’s workday. These deadlines, frequently associated with critical milestones in the development, testing, and deployment of aerospace systems, necessitate concentrated efforts and, consequently, longer working hours. The relationship between project deadlines and work hours is primarily causal; the proximity of a significant deadline directly correlates with an increase in the engineer’s daily time commitment. For instance, in the lead-up to a crucial launch date, engineers involved in systems integration or testing may routinely work extended shifts to ensure all parameters are within acceptable limits and that potential issues are addressed proactively.

The significance of project deadlines as a determinant of working hours stems from the high-stakes nature of the aerospace industry. Failure to meet deadlines can result in significant financial penalties, reputational damage, and, in some cases, safety risks. Therefore, engineers prioritize meeting these deadlines, even if it requires exceeding standard work schedules. Consider the example of a satellite deployment; if the launch window is missed, the entire mission could be delayed by months, resulting in substantial cost overruns. To avoid such scenarios, engineers dedicate the necessary time to resolve any challenges and ensure the project remains on track.

Understanding the impact of project deadlines on the daily workload is crucial for both engineers and management. Recognizing this connection allows for more realistic project planning, resource allocation, and employee support. By acknowledging the potential for increased workloads during specific project phases, companies can implement strategies to mitigate the negative effects of overwork, such as fatigue and burnout, thereby ensuring the long-term well-being and productivity of their engineering teams. Effectively managing the demands imposed by project deadlines is essential for maintaining project success and fostering a sustainable work environment in the aerospace engineering sector.

2. Testing Schedules

Testing schedules are a critical factor influencing the daily hours of aerospace engineers. The stringent validation processes inherent in aerospace engineering require rigorous testing phases, which often demand extended periods of observation, data analysis, and troubleshooting. The correlation is direct: complex and compressed testing schedules inherently lead to longer workdays for the engineers responsible for their execution. These schedules are rarely predictable, as unforeseen issues often arise during testing, requiring immediate attention and resolution, further impacting the engineers’ time commitment. Examples include wind tunnel testing of aircraft models, propulsion system evaluations, and materials testing under extreme conditions, all of which can run for extended durations, potentially around the clock, to gather comprehensive data.

The importance of adhering to strict testing schedules is paramount to ensuring the safety and reliability of aerospace systems. Missed deadlines or incomplete testing can have severe consequences, ranging from costly project delays to catastrophic failures in flight. Consider the development of a new jet engine; the testing phase involves numerous parameters, including thrust, fuel consumption, and vibration levels, each requiring meticulous monitoring. Engineers must be present to oversee these tests, analyze the data in real time, and make immediate adjustments as needed. Such responsibilities necessitate flexibility and often result in irregular work patterns, where engineers may be required to work shifts outside of standard business hours. Simulation and virtual testing is reducing the time demands, but physical tests still hold essential position.

In conclusion, testing schedules represent a significant determinant of the daily workload for aerospace engineers. Understanding this relationship is essential for effective project management and resource allocation within aerospace organizations. Recognizing the potential for extended hours during testing phases allows for better planning, staffing, and support for engineering teams, ultimately contributing to both project success and the well-being of the engineers involved. The effective management of testing schedules is paramount to the successful development and operation of aerospace technologies, and it plays a crucial role in shaping the professional lives of aerospace engineers.

3. Design Iterations

Design iterations, the cyclical process of refining aerospace designs through analysis, testing, and modification, directly influence the duration of an aerospace engineer’s workday. Each iteration demands focused attention, as engineers analyze simulation results, assess physical test data, and implement design changes based on findings. The number and complexity of these iterations are intrinsically linked to the daily hours expended; a design encountering numerous unforeseen issues or requiring significant performance enhancements will invariably lead to extended work periods. The iterative nature of aerospace design, where progress is often incremental and reliant on meticulous refinement, ensures that engineers dedicate substantial time to each phase, from initial concept to final validation.

The significance of design iterations lies in their role in ensuring the safety, efficiency, and performance of aerospace systems. Each iteration provides an opportunity to identify and correct potential flaws, optimize performance characteristics, and adapt to evolving requirements. For example, the design of an aircraft wing may undergo multiple iterations to improve lift-to-drag ratio or reduce structural weight. Engineers involved in these iterations must meticulously analyze computational fluid dynamics (CFD) simulations, conduct wind tunnel tests, and modify the wing’s geometry based on the results. This comprehensive process ensures that the final design meets stringent performance and safety criteria, and it directly contributes to the length of the workday, particularly during critical design phases. The frequency of required alterations during testing, further necessitates long hours to deliver design adjustments to the shop floor within tight deadlines.

In conclusion, design iterations represent a crucial factor shaping the daily workload of aerospace engineers. The iterative process, essential for achieving optimal designs, necessitates dedicated time and focused effort, leading to extended work hours, especially during intensive design phases. Understanding the connection between design iterations and working hours is vital for project planning, resource allocation, and managing the well-being of engineering teams. Recognizing the demands imposed by iterative design enables aerospace organizations to effectively support their engineers and ensure project success.

4. Company Culture

Company culture significantly influences the length of the workday for aerospace engineers. It encompasses the shared values, beliefs, and practices within an organization, directly affecting expectations regarding work hours and overall work-life balance.

- Emphasis on Presenteeism

Some companies foster a culture where physical presence in the office for extended hours is valued, regardless of actual productivity. This can lead to engineers feeling pressured to stay late, even if their tasks are completed, simply to demonstrate commitment. For example, if senior management regularly works long hours, junior engineers may emulate this behavior to gain favor, resulting in a longer average workday.

- Focus on Output vs. Input

Organizations that prioritize measurable output and results are less likely to promote excessive hours. These companies often implement flexible work arrangements and focus on efficiency, allowing engineers to manage their time more effectively. For instance, a company utilizing Agile methodologies and emphasizing sprint goals may allow engineers to complete their tasks within a standard workday, provided they meet their objectives.

- Availability Expectations

The expectation of constant availability, often driven by company culture, can extend the workday beyond regular hours. If engineers are expected to respond to emails or address urgent issues outside of work hours, their effective workday extends considerably. This is especially prevalent in companies dealing with global clients or operating in different time zones, where engineers may be expected to be accessible at unconventional times.

- Support for Work-Life Integration

A company culture that actively supports work-life integration can significantly reduce the pressure to work extended hours. Such organizations typically offer benefits like flexible work schedules, generous parental leave, and employee wellness programs, allowing engineers to better balance their professional and personal lives. For example, a company with on-site childcare or flexible working hours may enable engineers to manage family responsibilities without consistently working longer hours.

These aspects of company culture collectively shape the norms and expectations surrounding working hours for aerospace engineers. The degree to which a company values presenteeism, emphasizes output, expects constant availability, and supports work-life integration directly impacts how long engineers spend at work each day. Understanding these cultural influences is critical for both engineers seeking employment and companies aiming to create a sustainable and productive work environment.

5. Position Specifics

The duration of an aerospace engineer’s workday is significantly influenced by the specific role and responsibilities assigned. Certain positions necessitate longer hours due to their inherent demands and the critical nature of their tasks. Understanding these position-specific variations provides valuable insight into the diverse workload expectations within the aerospace engineering field.

- Flight Test Engineer

Flight test engineers are frequently required to work irregular and extended hours. This stems from the need to conduct flight tests during specific weather conditions or at particular times of day to gather accurate data. Furthermore, unexpected issues discovered during flight testing may necessitate immediate problem-solving and design adjustments, leading to prolonged workdays. These tests can also require travel to remote locations, further impacting work schedules.

- Systems Integration Engineer

Systems integration engineers are responsible for ensuring that all components of an aerospace system function cohesively. This often involves troubleshooting complex interactions between different subsystems, which can be time-consuming and require meticulous attention to detail. During critical integration phases, these engineers may work long hours to identify and resolve any compatibility issues before deadlines.

- Propulsion Engineer

Propulsion engineers, particularly those involved in the design and testing of rocket engines or advanced propulsion systems, often face demanding schedules. The complex nature of propulsion systems, coupled with the need for rigorous testing and validation, necessitates extended periods of data analysis and design optimization. Meeting stringent performance targets often requires intensive effort and extended hours.

- Structural Analysis Engineer

Structural analysis engineers are responsible for assessing the integrity and safety of aerospace structures. Their work involves conducting extensive simulations and analyses to ensure that structures can withstand the stresses and strains encountered during flight. Complex structural designs or the discovery of potential weaknesses may necessitate extended hours to perform detailed analyses and propose design modifications.

These examples illustrate the significant impact of position specifics on the typical workday of an aerospace engineer. While some roles may adhere to a more standard schedule, others inherently demand longer and more irregular hours due to the nature of their responsibilities and the criticality of their tasks. This variation in workload expectations is essential to consider when evaluating career paths and managing resources within the aerospace engineering profession.

6. Work-life Balance

The duration of an aerospace engineer’s workday directly impacts the potential for achieving work-life balance. Extended work hours, often necessitated by project deadlines, testing schedules, and design iterations, can encroach upon personal time, leading to diminished opportunities for rest, recreation, and family engagement. This imbalance can negatively affect overall well-being, potentially resulting in increased stress, burnout, and reduced job satisfaction. Work-life balance, therefore, is not merely a desirable perk but a critical component of a sustainable and productive career for aerospace engineers. The practical significance of understanding this connection lies in its implications for recruitment, retention, and overall workforce performance. For instance, companies that prioritize and actively support work-life balance through flexible work arrangements and reasonable workload expectations often attract and retain top talent, reducing turnover and fostering a more engaged and productive workforce. In contrast, organizations that implicitly or explicitly encourage excessively long hours may experience higher rates of attrition and decreased employee morale.

The effects of insufficient work-life balance within the aerospace engineering field can extend beyond individual well-being, impacting project outcomes and organizational success. Fatigue and stress resulting from prolonged work hours can impair cognitive function, increasing the likelihood of errors and compromising decision-making abilities. This is especially critical in a field where even minor errors can have significant consequences. Furthermore, a lack of adequate rest and personal time can diminish creativity and innovation, stifling the development of novel solutions and hindering the progress of aerospace technologies. To mitigate these risks, proactive measures are necessary. Organizations should implement strategies to promote work-life balance, such as workload management programs, flexible scheduling options, and robust support systems that encourage employees to prioritize their personal well-being alongside their professional responsibilities.

In conclusion, the pursuit of work-life balance is inextricably linked to the duration of an aerospace engineer’s workday and has significant implications for individual well-being, organizational performance, and the advancement of the field as a whole. Addressing the challenges associated with extended work hours requires a multifaceted approach involving organizational policies, management practices, and individual self-care strategies. A commitment to fostering a culture that values work-life balance is essential for creating a sustainable and thriving aerospace engineering workforce, capable of meeting the demands of the industry while maintaining a high quality of life.

Frequently Asked Questions

This section addresses common inquiries regarding the length of the typical workday for professionals in the aerospace engineering field. The information aims to provide clarity and realistic expectations for individuals considering a career in this demanding yet rewarding profession.

Question 1: Is a standard 40-hour workweek typical for aerospace engineers?

While a 40-hour workweek is the nominal standard, the actual hours often exceed this due to project demands, testing schedules, and design iterations. Expect periods of longer hours, particularly around critical project milestones.

Question 2: Do all aerospace engineering positions require long hours?

No, the required hours vary depending on the specific role and responsibilities. Positions such as flight test engineer or systems integration engineer often demand longer and more irregular hours than roles focused on research or analysis.

Question 3: How do project deadlines affect the workday length?

Project deadlines are a primary driver of extended work hours. As deadlines approach, engineers may need to work extra hours to ensure tasks are completed on time and within budget.

Question 4: Is work-life balance achievable in aerospace engineering?

Achieving work-life balance can be challenging but is not impossible. Proactive time management, prioritization, and a supportive company culture are essential for maintaining a healthy balance.

Question 5: Do companies in the aerospace industry encourage long hours?

Company culture varies significantly. Some companies prioritize efficiency and output, while others may implicitly encourage longer hours through expectations of presenteeism or constant availability.

Question 6: What strategies can aerospace engineers use to manage their workload?

Effective strategies include prioritizing tasks, implementing time blocking, leveraging collaborative tools, establishing clear boundaries between work and personal life, and proactively seeking support when needed.

In summary, the length of an aerospace engineer’s workday is influenced by various factors, including project demands, position specifics, and company culture. While extended hours are often necessary, effective management and a focus on work-life balance are crucial for long-term career sustainability.

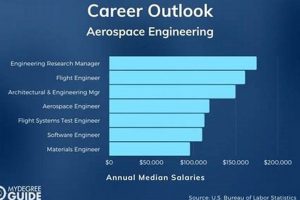

The next section will delve into the career outlook and potential for growth within the aerospace engineering field.

Conclusion

This exploration of “how long do aerospace engineers work a day” reveals that the profession’s demands often extend beyond conventional work hours. Factors such as project deadlines, testing schedules, design iterations, company culture, and specific job roles exert significant influence on the time commitment required. While a standard 40-hour workweek is nominally in place, the realities of the field frequently necessitate longer hours, particularly during critical project phases or within specific positions.

The information presented serves to inform prospective engineers, current professionals, and organizations about the realities of time commitment within the aerospace sector. Recognition of these demands allows for more realistic career planning, optimized project management, and the development of supportive work environments that promote both productivity and the long-term well-being of engineering teams. Addressing the challenge of extended work hours necessitates a continued commitment to fostering sustainable practices and prioritizing work-life integration within the aerospace industry.