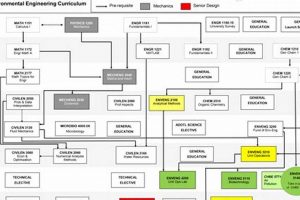

This academic and professional path integrates the principles of mechanics, materials science, thermodynamics, and design with specialized knowledge in aerodynamics, propulsion, and aerospace structures. It equips individuals with the expertise to analyze, design, and manufacture mechanical systems for both general applications and the specific demands of the aerospace industry. Examples include designing aircraft engines, spacecraft components, or satellite deployment mechanisms.

The significance of this specialized training lies in its ability to address complex engineering challenges within the rapidly evolving aerospace sector. Graduates are well-positioned to contribute to advancements in air travel, space exploration, and satellite technology. Historically, this field has been crucial to national defense, scientific discovery, and global communication, and its continued development is essential for future technological progress and economic competitiveness.

The following sections will delve into the specific coursework, career opportunities, and future trends associated with this interdisciplinary field, providing a detailed overview of its scope and potential impact.

Essential Guidance for Pursuing a Mechanical Engineering Degree with a Focus on Aerospace

The following recommendations are designed to assist individuals considering or currently enrolled in a mechanical engineering program with a specialization in aerospace. These tips emphasize academic preparation, professional development, and strategic planning for a successful career.

Tip 1: Cultivate a Strong Foundation in Mathematics and Physics: A robust understanding of calculus, differential equations, linear algebra, Newtonian mechanics, and thermodynamics is fundamental. This knowledge forms the basis for advanced coursework in aerodynamics, structural analysis, and propulsion systems.

Tip 2: Seek Opportunities for Hands-on Experience: Participate in research projects, internships, or design competitions related to aerospace engineering. These experiences provide practical skills and enhance the application of theoretical concepts learned in the classroom. For example, involvement in a student-led rocketry project offers invaluable insight into design, manufacturing, and testing processes.

Tip 3: Develop Proficiency in Relevant Software Tools: Acquire expertise in computer-aided design (CAD) software, finite element analysis (FEA) software, and computational fluid dynamics (CFD) software. These tools are essential for designing, analyzing, and simulating aerospace systems and components.

Tip 4: Join Professional Organizations: Membership in organizations such as the American Institute of Aeronautics and Astronautics (AIAA) provides access to networking opportunities, technical conferences, and industry publications. Active participation in these organizations facilitates professional development and keeps individuals abreast of the latest advancements in the field.

Tip 5: Tailor Elective Courses to Specific Interests: Select elective courses that align with individual career aspirations within the aerospace sector. Options include courses in spacecraft design, propulsion systems, control systems, and composite materials.

Tip 6: Consider a Graduate Degree: A master’s or doctoral degree can provide specialized knowledge and research experience that can significantly enhance career prospects, particularly in research and development roles.

Tip 7: Network with Professionals in the Aerospace Industry: Attend industry events, career fairs, and informational sessions to connect with engineers and recruiters from aerospace companies. Building relationships with industry professionals can open doors to internship and employment opportunities.

Adhering to these guidelines can maximize the potential for success in this challenging but rewarding field. By prioritizing academic excellence, practical experience, and professional development, individuals can position themselves for fulfilling careers in the aerospace industry.

The following sections will explore various career paths and the future outlook for individuals with this specialized engineering background.

1. Aerodynamics

Aerodynamics forms a foundational pillar within the “mechanical engineering with aerospace concentration,” dictating the principles governing the motion of air and other gaseous fluids, and their interaction with solid objects. This knowledge is crucial for designing efficient and stable aircraft, spacecraft, and related systems.

- Lift Generation and Drag Reduction

Aerodynamics directly impacts the ability to generate lift, enabling flight, and minimize drag, which reduces fuel consumption and increases speed. For example, airfoil design, a core component of aerodynamic study, is optimized to create a pressure differential that produces lift. Similarly, understanding boundary layer effects is essential for minimizing skin friction drag on aircraft surfaces.

- Stability and Control Analysis

Aerodynamic principles are applied to analyze the stability and control characteristics of aircraft and spacecraft. This includes determining the effects of control surfaces (e.g., ailerons, elevators, rudders) on aircraft maneuverability and stability. Understanding aerodynamic forces and moments is critical for designing effective control systems that allow pilots or automated systems to maintain stable flight.

- Compressible Flow and Supersonic Flight

At high speeds, the compressibility of air becomes significant, leading to phenomena such as shock waves. This area of aerodynamics deals with the analysis and design of aircraft and propulsion systems operating at transonic and supersonic speeds. For example, the design of supersonic aircraft wings and inlets requires specialized knowledge of compressible flow theory to minimize wave drag and optimize engine performance.

- Computational Fluid Dynamics (CFD)

CFD is a powerful tool used to simulate and analyze complex aerodynamic flows around aircraft and spacecraft. This enables engineers to predict performance characteristics, identify potential design flaws, and optimize designs before physical prototypes are built. CFD simulations are used extensively in the design of new aircraft, rockets, and other aerospace vehicles.

The principles of aerodynamics are integral to numerous facets within the “mechanical engineering with aerospace concentration”. From conceptual design to detailed analysis and testing, a strong understanding of aerodynamic theory and its applications is essential for success in this field. The ability to apply these principles to real-world engineering problems is a critical skill for aerospace engineers.

2. Propulsion Systems

Propulsion systems are an indispensable component of the training and skillset cultivated within a “mechanical engineering with aerospace concentration.” These systems provide the means by which aircraft, spacecraft, and missiles overcome gravity and atmospheric resistance, enabling sustained flight and space travel. Mechanical engineers specializing in aerospace apply principles of thermodynamics, fluid mechanics, and combustion to design, analyze, and optimize these systems. A failure in propulsion can have catastrophic consequences; therefore, the subject holds paramount importance within the curriculum. Rocket engines, jet engines, and electric propulsion systems represent diverse applications of these core engineering principles. For instance, the design of a turbine blade within a jet engine necessitates precise calculations of airflow, thermal stresses, and material properties, all areas of expertise gained through rigorous mechanical engineering coursework coupled with an aerospace focus.

The practical significance of understanding propulsion systems extends beyond theoretical knowledge. It encompasses the ability to troubleshoot performance issues, improve fuel efficiency, and develop innovative propulsion technologies. Simulations and real-world testing of engine components are critical aspects of this discipline. Furthermore, the evolution of propulsion systems directly influences the advancement of aerospace capabilities. The development of more efficient and powerful engines has enabled longer-range flights, heavier payloads, and deeper space exploration. For example, research into scramjet technology aims to achieve hypersonic flight, while advancements in ion propulsion could drastically reduce travel times for interplanetary missions.

In summary, propulsion systems form a critical element of “mechanical engineering with aerospace concentration,” necessitating a strong foundation in fundamental engineering principles and a deep understanding of specialized aerospace applications. Challenges within this field include reducing emissions, increasing efficiency, and developing alternative propulsion methods for future space exploration. Continued innovation in propulsion is essential for sustaining progress in the aerospace industry and expanding human presence in space.

3. Structural Analysis

Structural analysis is a core competency within “mechanical engineering with aerospace concentration” due to the critical importance of ensuring the integrity and safety of aircraft, spacecraft, and related components. Aerospace structures are subjected to extreme conditions, including high aerodynamic loads, thermal stresses, and vibrations. The purpose of structural analysis is to predict the behavior of these structures under such conditions, enabling engineers to design robust and reliable systems. Accurate prediction of stress, strain, and deformation is essential to prevent structural failure, which can have catastrophic consequences. For example, the analysis of an aircraft wing involves calculating the stress distribution caused by lift and drag forces, ensuring that the wing can withstand these loads without exceeding its material strength.

The practical application of structural analysis involves a combination of theoretical calculations, computational modeling, and experimental testing. Finite element analysis (FEA) software is widely used to simulate the behavior of complex structures under various loading scenarios. These simulations allow engineers to identify potential weak points in a design and optimize the structure for maximum strength and minimum weight. Furthermore, physical testing, such as wind tunnel tests and static load tests, is often conducted to validate the results of computational analyses and ensure that the structure performs as expected in real-world conditions. The combination of these analytical and experimental techniques provides a comprehensive assessment of structural integrity.

In summary, structural analysis is an indispensable aspect of “mechanical engineering with aerospace concentration”. It provides the tools and methodologies necessary to design safe and reliable aerospace structures, minimizing the risk of failure and ensuring the continued advancement of air and space travel. The challenges within this field include developing new materials and analysis techniques to meet the demands of increasingly complex and demanding aerospace applications.

4. Materials Science

Materials science plays a crucial, enabling role within the broader field of “mechanical engineering with aerospace concentration.” The selection, characterization, and application of materials are fundamental to the design and performance of aerospace vehicles and systems. The extreme operational environments, including high and low temperatures, significant mechanical stress, and exposure to radiation, necessitate the use of materials with specific properties. Failure to properly consider material properties can lead to catastrophic structural failure, component degradation, or reduced system performance. For example, the development of high-temperature alloys for jet turbine blades is a direct result of materials science research, enabling engines to operate at higher efficiencies. Similarly, the use of lightweight composite materials in aircraft structures reduces weight, improving fuel economy and payload capacity.

The application of materials science in aerospace extends beyond traditional metals and alloys. Advanced materials, such as ceramics, polymers, and composites, are increasingly utilized to meet the demanding requirements of aerospace applications. Composites, for example, offer high strength-to-weight ratios and can be tailored to specific structural requirements. Shape memory alloys are used in actuators and deployable structures, while nanomaterials are being explored for their potential to enhance material properties and create new functionalities. Furthermore, understanding material degradation mechanisms, such as corrosion, fatigue, and creep, is critical for predicting component lifespan and implementing effective maintenance strategies. The selection process involves trade-offs between cost, performance, manufacturability, and service life, demanding a deep understanding of materials behavior and processing techniques.

In summary, materials science provides the essential foundation for innovation and advancement within “mechanical engineering with aerospace concentration”. Ongoing research in materials science continues to push the boundaries of aerospace capabilities, enabling the development of lighter, stronger, and more durable vehicles and systems. Challenges include the development of sustainable materials, reducing the environmental impact of material processing, and ensuring the long-term reliability of materials in extreme environments. The continued synergy between materials science and aerospace engineering is critical for meeting the future demands of air and space travel.

5. Control Engineering

Control engineering is intrinsically linked to “mechanical engineering with aerospace concentration,” serving as the mechanism through which stability, precision, and autonomy are achieved in aerospace systems. The design and implementation of control systems are essential for maintaining stable flight, guiding spacecraft trajectories, and operating robotic systems in demanding environments. Without effective control, aircraft would be unstable, spacecraft would deviate from their planned courses, and remotely operated systems would be rendered unusable. This dependency underscores the fundamental role of control engineering within the aerospace domain.

Practical applications of control engineering in aerospace are diverse and critical. Autopilots, for example, utilize feedback control systems to maintain desired altitude, heading, and speed, reducing pilot workload and improving flight safety. Guidance, navigation, and control (GNC) systems are crucial for spacecraft to accurately reach their intended destinations. Furthermore, control systems are essential for operating unmanned aerial vehicles (UAVs) and robotic manipulators in remote or hazardous environments. A real-world instance of this is demonstrated in the precise control required for the robotic arm on the International Space Station, enabling astronauts to perform delicate operations and conduct scientific experiments. The development of fault-tolerant control systems also addresses the critical need for reliable operation in the face of potential sensor or actuator failures, enhancing the safety and robustness of aerospace systems.

In summary, control engineering is not merely an adjunct to “mechanical engineering with aerospace concentration” but a foundational element that enables the safe, reliable, and efficient operation of aerospace systems. Continued innovation in control algorithms, sensor technology, and actuator design will be essential for meeting the evolving demands of the aerospace industry and enabling new capabilities in air and space exploration. The development of autonomous systems, adaptive control strategies, and robust control techniques remains a central focus for future research and development in this area.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions surrounding the academic and professional discipline of mechanical engineering with an aerospace concentration. These questions are answered in a straightforward and informative manner.

Question 1: What distinguishes a mechanical engineering degree with an aerospace concentration from a traditional aerospace engineering degree?

A mechanical engineering degree with an aerospace concentration provides a broader foundation in mechanical engineering principles, while also offering specialized coursework in aerospace-related subjects. A traditional aerospace engineering degree typically focuses more narrowly on aerospace-specific topics from the outset.

Question 2: Is a graduate degree necessary to secure employment in the aerospace industry with this background?

While a graduate degree is not always a strict requirement, it can significantly enhance career prospects, particularly for research and development roles. Advanced degrees often provide specialized knowledge and research experience that are highly valued by employers.

Question 3: What types of job functions can individuals with this specialization typically pursue?

Graduates can pursue a wide range of job functions, including design engineering, manufacturing engineering, research and development, testing and analysis, and project management, all within the aerospace sector or related industries.

Question 4: How important is it to gain practical experience, such as internships, during the course of study?

Practical experience is highly valuable. Internships and research projects provide hands-on experience, allowing individuals to apply theoretical knowledge and develop essential skills that are highly sought after by employers.

Question 5: What are the key software skills that individuals in this field should possess?

Proficiency in computer-aided design (CAD) software, finite element analysis (FEA) software, and computational fluid dynamics (CFD) software is essential for designing, analyzing, and simulating aerospace systems and components.

Question 6: What is the future outlook for the aerospace industry and related job opportunities?

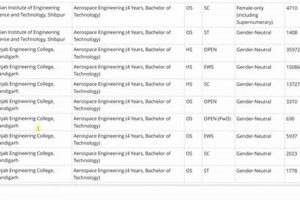

The aerospace industry is expected to continue to grow, driven by increasing demand for air travel, space exploration, and satellite technology. This growth is projected to create numerous job opportunities for qualified engineers with expertise in mechanical engineering and aerospace.

This FAQ section aims to clarify key aspects of pursuing a mechanical engineering degree with an aerospace concentration. It is intended to provide guidance and address common concerns for prospective students and professionals.

The following sections will explore related topics in greater detail, offering further insights into this specialized engineering field.

Conclusion

The preceding sections have presented a detailed examination of mechanical engineering with aerospace concentration, encompassing its foundational principles, core competencies, career pathways, and future outlook. The analysis has underscored the integration of mechanical engineering fundamentals with specialized knowledge in aerodynamics, propulsion, structural analysis, materials science, and control engineering. The importance of practical experience, software proficiency, and continued professional development has also been emphasized.

As the aerospace sector continues to evolve and innovate, the demand for skilled engineers with expertise in this interdisciplinary field is expected to persist. Continued dedication to academic rigor, practical application, and lifelong learning will be essential for individuals seeking to contribute to the advancement of air and space technology. The challenges and opportunities within this dynamic field necessitate a commitment to innovation, sustainability, and ethical engineering practices to ensure the continued progress and safety of aerospace endeavors.

![[GUIDE] Aerospace Engineer Internships: Launch Your Career! Innovating the Future of Flight with Reliable Aviation Solutions [GUIDE] Aerospace Engineer Internships: Launch Your Career! | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-872-300x200.jpg)