The application of scientific and technological principles to the design, development, and construction of aircraft and spacecraft in a specific Connecticut town. This field involves various disciplines, including aerodynamics, propulsion, materials science, and control systems. Individuals or firms specializing in this area contribute to the advancement of flight technology within the local geographic region.

Activities related to this technical discipline within this locale are crucial for economic development, technological innovation, and national security. Historically, this geographic region has played a significant role in aerospace manufacturing and research, contributing to advancements in both commercial and military aviation. The presence of specialized expertise fosters job creation and stimulates related industries.

Subsequent sections will delve into specific aerospace companies located in this region, educational opportunities available for aspiring engineers, and the ongoing research and development activities shaping the future of flight technologies within the area.

Guidance Regarding Specialization within the Aviation and Spacecraft Sector in a Designated Connecticut Locality

The following guidance is offered to individuals pursuing or currently engaged in activities related to the scientific and technological principles involved in the design, development, and construction of aircraft and spacecraft in a Connecticut community.

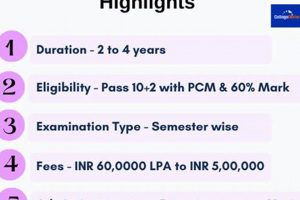

Tip 1: Educational Foundation. A strong foundation in mathematics, physics, and computer science is paramount. Pursue a Bachelor’s or Master’s degree in aerospace engineering or a closely related field from an accredited institution. For example, focus on coursework involving fluid dynamics and structural analysis.

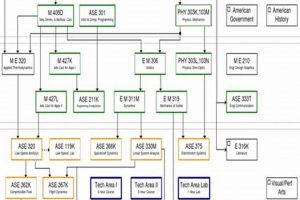

Tip 2: Specialization. Consider specializing in a specific area such as aerodynamics, propulsion, or control systems. Deepening expertise allows for contribution to niche areas within the field. Example: Concentrate on hypersonic aerodynamics research.

Tip 3: Professional Development. Obtain relevant certifications and licenses to enhance credibility and expertise. Continuing education is essential to stay abreast of technological advancements. Example: Seek certification in computational fluid dynamics (CFD) software.

Tip 4: Networking. Engage with industry professionals through conferences, workshops, and professional organizations. Networking facilitates the exchange of knowledge and potential career opportunities. Example: Attend the American Institute of Aeronautics and Astronautics (AIAA) SciTech Forum.

Tip 5: Practical Experience. Seek internships or co-op opportunities to gain hands-on experience in aerospace engineering. Practical experience provides valuable insights and builds skills. Example: Participate in a design project involving aircraft structural analysis.

Tip 6: Software Proficiency. Develop proficiency in industry-standard software tools used for design, analysis, and simulation. Software skills are essential for completing engineering tasks efficiently. Example: Become proficient in using CATIA, ANSYS, or MATLAB.

Tip 7: Regulatory Awareness. Maintain an understanding of aviation regulations and safety standards. Adherence to regulations is critical to ensure the safety and compliance of aerospace products. Example: Familiarize with FAA regulations related to aircraft design and maintenance.

The principles outlined above are essential for success within this domain. Through continuous learning, professional engagement, and a commitment to excellence, individuals can contribute meaningfully to the advancement of aerospace technology.

Subsequent discussions will explore career prospects, innovative projects, and future trends shaping the field within the given locale.

1. Innovation

Innovation serves as a critical driver within activities related to scientific and technological progress involving aircraft and spacecraft in a specific Connecticut town. The pursuit of novel solutions, materials, and designs fuels the ongoing advancement of aerospace capabilities. A direct correlation exists between investments in research and development and the emergence of innovative technologies relevant to this field in this geographic region. For example, the development of advanced composite materials for aircraft structures, pioneered within this area, demonstrates how innovation can enhance performance, reduce weight, and improve fuel efficiency. The ability to translate theoretical concepts into tangible applications constitutes a significant marker of progress.

Moreover, innovation fosters a competitive environment, encouraging companies within this geographic area to continually refine their processes and product offerings. This competition leads to improvements in manufacturing techniques, the adoption of automation, and the exploration of new design paradigms. For instance, the integration of additive manufacturing (3D printing) for producing complex aerospace components within the local industry streamlines production, reduces waste, and allows for customized designs that were previously unattainable. This adaptation reflects a commitment to embracing technological advancements to maintain a competitive edge in the global aerospace market.

In summary, innovation is an indispensable element for the aerospace industry operating within this Connecticut location. It catalyzes technological breakthroughs, drives economic growth, and positions the region as a contributor to advancements in flight technologies. Sustaining this momentum necessitates continued investment in education, research, and infrastructure to support the development and implementation of innovative solutions.

2. Precision Manufacturing

Precision manufacturing represents a cornerstone of activities associated with the scientific and technological development of aircraft and spacecraft in a Connecticut locale. The aerospace sector demands exacting tolerances and unwavering reliability in component fabrication; therefore, meticulous manufacturing processes are indispensable. Even minor deviations from specifications can compromise performance or safety, making precision a non-negotiable requirement. This dependence on precision directly influences the operations and skill sets found within the industrial ecosystem of this town. For instance, the production of turbine blades for jet engines necessitates adherence to micron-level tolerances to ensure efficient energy conversion and structural integrity. Such exacting standards require specialized equipment and highly trained technicians.

The practical applications of precision manufacturing extend to numerous facets of this locale’s aviation and spacecraft industries. The assembly of airframes, the fabrication of hydraulic systems, and the production of electronic control units all rely on controlled processes to ensure consistency and functionality. Advanced techniques, such as computer numerical control (CNC) machining, non-destructive testing, and advanced metrology, are prevalent. Consider the fabrication of landing gear components. These parts must withstand immense stress during landings; thus, precise machining, heat treatment, and surface finishing are essential to achieve the required strength and fatigue resistance. The capacity to achieve this degree of precision directly impacts the competitiveness of local aerospace firms.

In summary, precision manufacturing is an integral aspect of activities within the realm of aerospace in this Connecticut region. It is not merely a desirable attribute, but a fundamental requirement for ensuring the performance, reliability, and safety of aircraft and spacecraft components. Maintaining and enhancing precision manufacturing capabilities presents ongoing challenges, including the need for continuous technological upgrades, workforce training, and rigorous quality control measures. Addressing these challenges is essential for sustaining this region’s prominence in the aerospace industry.

3. Material Science

Material science plays a pivotal role in shaping the landscape of scientific and technological advancements in aircraft and spacecraft development within this Connecticut town. The properties of materials directly influence the performance, safety, and lifespan of aerospace components. Therefore, advancements in materials science directly contribute to improvements in this region’s aerospace capabilities.

- Advanced Composites

The utilization of advanced composite materials, such as carbon fiber reinforced polymers, presents a significant advantage in aerospace applications. These materials offer high strength-to-weight ratios, leading to improved fuel efficiency and increased payload capacity for aircraft manufactured or engineered in this locale. The replacement of traditional aluminum alloys with composites can reduce aircraft weight by as much as 20%, resulting in substantial cost savings over the lifespan of the aircraft. Additionally, composites exhibit superior corrosion resistance compared to metals, extending the operational life of aerospace structures.

- High-Temperature Alloys

The development and application of high-temperature alloys, such as nickel-based superalloys, are critical for components operating in extreme thermal environments, such as jet engine turbines. These alloys maintain their mechanical strength and creep resistance at elevated temperatures, enabling engines to operate more efficiently and produce higher thrust. Research and development efforts in this region focus on improving the high-temperature performance of these alloys through advanced alloying techniques and microstructural control, directly impacting engine performance and efficiency.

- Lightweight Metals

Lightweight metals, including aluminum-lithium alloys and titanium alloys, offer a balance of strength and weight reduction, making them suitable for various aerospace applications. These materials are employed in airframes, landing gear components, and other structural elements to minimize weight and enhance performance. Efforts in this location are directed toward improving the processing and manufacturing techniques for these lightweight metals to enhance their mechanical properties and reduce production costs, thereby increasing their adoption in aerospace designs.

- Smart Materials

The incorporation of smart materials, such as shape memory alloys and piezoelectric materials, enables the development of adaptive structures and systems. Shape memory alloys can change shape in response to temperature variations, enabling the creation of morphing wings and other adaptive components. Piezoelectric materials generate electrical energy when subjected to mechanical stress, enabling the development of self-powered sensors and actuators. Research within this region explores the integration of smart materials into aerospace systems to enhance performance, reduce noise, and improve energy efficiency.

These material science innovations are deeply interwoven with the scientific and technological progress in the Connecticut locale. Advancements in each of these areas lead to safer, more efficient, and more sustainable aerospace technologies. Continued investment in materials research and development remains essential to sustaining this region’s competitive advantage in the global aerospace market.

4. Regulatory Compliance

Adherence to regulatory standards forms an inextricable link with activities pertaining to aerospace engineering within the Windsor, Connecticut area. These regulations, primarily dictated by agencies such as the Federal Aviation Administration (FAA), govern every stage of aircraft and spacecraft design, manufacture, operation, and maintenance. Non-compliance can lead to significant penalties, including grounding of aircraft, fines, and reputational damage. For aerospace firms located in Windsor, CT, understanding and adhering to these regulations is not simply a legal obligation, but a prerequisite for conducting business.

The impact of regulatory compliance is pervasive. Design engineers must account for airworthiness directives and safety standards during the development phase of new aircraft components. Manufacturing processes must adhere to stringent quality control measures to ensure that parts meet specified performance criteria. Maintenance procedures are meticulously documented and must be followed precisely to maintain the ongoing safety and reliability of aircraft. For example, a Windsor, CT-based company producing aircraft fasteners must comply with FAA regulations concerning material composition, strength testing, and traceability. Failure to meet these standards can result in the rejection of the fasteners and potential safety risks.

In summary, regulatory compliance is an indispensable component of aerospace engineering activities in Windsor, CT. It dictates design practices, manufacturing processes, and maintenance protocols. The complex regulatory landscape presents both challenges and opportunities for companies operating in this field. Successfully navigating this landscape requires a deep understanding of applicable regulations, a commitment to quality control, and a robust compliance program. Prioritizing regulatory adherence is essential for sustaining a safe and reliable aerospace industry within this region.

5. Education

Education represents a foundational element underpinning the success and sustainability of aerospace engineering within Windsor, CT. The availability of robust educational programs and training opportunities directly influences the availability of skilled professionals and the innovative capacity of the local aerospace sector.

- University Programs

Degree programs in engineering, particularly aerospace, mechanical, and electrical engineering, provided by universities within reasonable proximity of Windsor, CT, contribute significantly. These programs supply a pipeline of graduates equipped with the theoretical knowledge and practical skills necessary to contribute to aerospace companies. The curriculum often incorporates coursework in aerodynamics, propulsion systems, control systems, and structural analysis, providing a comprehensive understanding of aerospace principles. For example, nearby universities with accredited engineering programs are a key supplier of specialized talent.

- Community College Initiatives

Community colleges in the region play a vital role in providing technical training and workforce development programs that support the aerospace industry in Windsor, CT. These institutions offer courses in areas such as advanced manufacturing, CNC machining, welding, and electronics technology, which are directly applicable to the production and maintenance of aerospace components. Partnerships between community colleges and local aerospace companies can ensure that training programs align with the specific needs of the industry.

- STEM Outreach Programs

STEM (Science, Technology, Engineering, and Mathematics) outreach programs, targeted at students in primary and secondary schools, foster an early interest in aerospace engineering and related fields. These programs can include hands-on activities, workshops, and mentoring opportunities designed to inspire students to pursue careers in STEM disciplines. Organizations such as the Connecticut Science Center and local chapters of professional engineering societies often conduct these programs, contributing to the long-term growth of the aerospace workforce.

- Continuing Education and Professional Development

Continuing education and professional development opportunities are essential for maintaining the skills and knowledge of aerospace engineers throughout their careers. These opportunities can include short courses, workshops, conferences, and online training programs focused on emerging technologies and industry best practices. Professional organizations such as the American Institute of Aeronautics and Astronautics (AIAA) offer continuing education courses and certifications that enhance the expertise of aerospace professionals working in Windsor, CT.

The presence of these educational resources in and around Windsor, CT, fosters a supportive ecosystem for the aerospace industry. By ensuring a steady supply of skilled professionals and promoting ongoing learning and innovation, education plays a crucial role in sustaining the competitiveness and growth of the local aerospace sector.

6. Economic Impact

The aerospace sector within Windsor, CT, generates substantial economic benefits. Companies engaged in the design, manufacture, and maintenance of aircraft and spacecraft components contribute significantly to local employment, tax revenues, and related economic activity. The presence of a skilled workforce, fostered by specialized training programs and educational institutions, attracts investment and further development. For instance, a local aerospace manufacturer’s expansion creates new jobs, boosts local supplier revenue, and increases property tax income for the town. This ripple effect demonstrates the direct correlation between aerospace activities and economic prosperity in the region.

Furthermore, the concentration of aerospace expertise within Windsor, CT, encourages the growth of supporting industries and services. Businesses providing specialized machining, engineering consulting, and supply chain management benefit from the demand generated by the aerospace sector. This creates a diversified economic base, reducing reliance on a single industry and mitigating the impact of economic downturns. Consider a local machine shop specializing in high-precision aerospace components. Its success is directly tied to the demand from larger aerospace firms in the area, illustrating the interconnectedness of the aerospace ecosystem.

In summary, the aerospace sector’s economic impact on Windsor, CT, extends beyond direct employment and revenue generation. It fosters innovation, supports related industries, and enhances the region’s overall economic resilience. Recognizing and nurturing this connection through strategic investments in education, infrastructure, and business development is crucial for sustaining the long-term economic prosperity of the region.

Frequently Asked Questions Regarding Aerospace Engineering in Windsor, CT

The following questions and answers address common inquiries concerning the application of scientific and technological principles to aircraft and spacecraft design, development, and construction within the Windsor, Connecticut area.

Question 1: What specific types of aerospace engineering activities occur in Windsor, CT?

Activities include the design, manufacture, and testing of aircraft components, systems, and sub-systems. This encompasses areas such as engine components, airframe structures, and avionics integration.

Question 2: What educational background is recommended for pursuing aerospace engineering opportunities in Windsor, CT?

A Bachelor’s or Master’s degree in aerospace engineering, mechanical engineering, or a related field is generally required. Strong coursework in mathematics, physics, and computer science is essential.

Question 3: Are there internship or co-op opportunities available for aerospace engineering students in Windsor, CT?

Yes, several aerospace companies in the Windsor area offer internships and co-op programs to provide students with practical experience in the field. These opportunities are often advertised through university career services and online job boards.

Question 4: What are the typical job titles available for aerospace engineers in Windsor, CT?

Common job titles include aerospace engineer, design engineer, manufacturing engineer, test engineer, and systems engineer. The specific roles vary depending on the size and focus of the aerospace company.

Question 5: What are the key skills required for success in aerospace engineering roles in Windsor, CT?

Essential skills include proficiency in CAD/CAM software, knowledge of aerospace materials and manufacturing processes, strong analytical and problem-solving abilities, and excellent communication skills.

Question 6: What is the general outlook for the aerospace engineering job market in Windsor, CT?

The aerospace sector in Windsor, CT, is generally stable, with ongoing demand for skilled engineers and technicians. However, the job market is subject to fluctuations based on economic conditions, government spending, and industry trends.

These questions provide a general overview of aerospace engineering in the Windsor area. Individuals seeking more specific information should consult with local aerospace companies and educational institutions.

The subsequent section will explore case studies of successful aerospace projects originating from this specific Connecticut location.

Conclusion

The preceding analysis has examined various facets of aerospace engineering windsor ct, encompassing its technological innovation, manufacturing precision, material science contributions, stringent regulatory environment, the role of education, and its measurable economic impact. A cohesive understanding of these elements is crucial for appreciating the significance of this specialized field within this specific geographic region.

Continued progress within aerospace engineering in Windsor, CT, hinges upon sustained investment in research, development, and a highly skilled workforce. The ability to adapt to evolving technological landscapes and regulatory requirements will determine the region’s future competitiveness and contribution to the broader aerospace industry. Therefore, strategic planning and proactive engagement are essential for realizing the full potential of this sector within this locale.