Doctoral-level education in the field concerned with the design, development, and testing of aircraft and spacecraft, delivered through internet-based platforms, provides opportunities for advanced study. The program focuses on research, complex problem-solving, and innovation within aeronautics and astronautics, utilizing remote learning technologies. Students typically engage with course materials, lectures, and faculty through online portals.

This mode of instruction expands accessibility to individuals geographically separated from traditional university campuses or those with professional obligations hindering conventional on-site attendance. It permits doctoral candidates to pursue rigorous academic training while maintaining existing careers or managing other commitments. The increasing prevalence of this educational option reflects the growing demand for skilled aerospace engineers coupled with advancements in online education infrastructure.

The subsequent sections will examine specific aspects of doctoral programs in this engineering discipline offered remotely, including curriculum structure, research opportunities, faculty expertise, and the potential career pathways available to graduates. The emphasis will be on providing a thorough overview of the academic and professional advantages associated with this educational pursuit.

Essential Guidance for Pursuing a Doctoral Degree in Aerospace Engineering via Online Platforms

Individuals considering a doctoral program focused on aerospace engineering through online instruction should carefully assess various factors to ensure a successful and productive academic journey. The following points offer crucial guidance.

Tip 1: Evaluate Program Accreditation and Reputation: Verify the accreditation status of the offering institution and the specific engineering program. Accreditation by recognized bodies ensures adherence to established educational standards and enhances the degree’s credibility. Research the university’s standing within the aerospace engineering field.

Tip 2: Scrutinize Faculty Expertise and Research Opportunities: Investigate the qualifications and research interests of the faculty members associated with the online program. A strong faculty with active research portfolios provides invaluable mentorship and opportunities for doctoral research collaboration. Identify potential faculty advisors whose research aligns with individual interests.

Tip 3: Assess Technological Infrastructure and Support: Ensure the online platform utilizes robust technology and offers comprehensive technical support. A user-friendly learning management system, reliable video conferencing capabilities, and readily available IT assistance are essential for a smooth and effective online learning experience. Evaluate the accessibility of necessary software and simulation tools.

Tip 4: Analyze Curriculum Structure and Course Content: Thoroughly review the program’s curriculum to ensure it covers core aerospace engineering principles and advanced specialized topics. The coursework should align with current industry trends and research frontiers. Examine the availability of elective courses to tailor the curriculum to specific career goals.

Tip 5: Plan for Time Management and Self-Discipline: Online doctoral studies demand significant time commitment and self-discipline. Establish a structured study schedule and adhere to it consistently. Minimize distractions and create a dedicated workspace conducive to focused learning. Prioritize tasks and manage deadlines effectively.

Tip 6: Network with Peers and Professionals: Actively participate in online forums, virtual conferences, and professional organizations to connect with fellow students and aerospace engineering professionals. Networking opportunities are crucial for knowledge sharing, collaboration, and career advancement. Attend virtual seminars and workshops to expand industry knowledge.

Tip 7: Clarify Dissertation Requirements and Support: Gain a complete understanding of the dissertation requirements, including proposal development, research methodology, and defense procedures. Ascertain the level of support provided by the faculty advisor and the university throughout the dissertation process. Inquire about available resources for literature reviews, data analysis, and manuscript preparation.

Adherence to these guidelines can significantly enhance the likelihood of successful completion of doctoral-level studies in aerospace engineering via a distance learning format, ultimately enabling graduates to contribute meaningfully to the field.

The subsequent sections will delve into the career prospects for individuals possessing a doctoral degree in this highly specialized domain, elaborating on potential roles and industries where their expertise is most valued.

1. Accreditation Validation

Accreditation validation is paramount when considering a doctoral program in aerospace engineering offered via online platforms. Accreditation, conferred by recognized agencies, signifies that the program has undergone rigorous evaluation and meets established quality standards for curriculum, faculty qualifications, student support services, and learning outcomes. The absence of accreditation raises serious concerns about the program’s academic rigor and the value of the degree earned.

The practical significance of accreditation lies in its impact on graduates’ career prospects. Employers often prioritize candidates holding degrees from accredited institutions, as it provides assurance of a certain level of competence and knowledge. Furthermore, accreditation may be a prerequisite for professional licensure or certification in certain engineering specializations. For instance, a graduate seeking a research position at a national laboratory or a senior design role within a major aerospace corporation will likely find that accreditation is a key consideration. Therefore, failing to confirm proper validation is akin to investing substantial time and resources into a venture with uncertain returns. Accreditation serves as a safeguard, ensuring the program adheres to industry benchmarks.

In summary, accreditation validation forms a critical component of a credible doctoral aerospace engineering program delivered online. It acts as a quality assurance mechanism, bolstering the degree’s value and expanding career opportunities for graduates. Before enrolling, thorough verification of accreditation status from a reputable agency is an indispensable step.

2. Faculty research alignment

Faculty research alignment within a doctoral aerospace engineering program offered online is a critical determinant of a student’s research experience and overall program quality. This alignment refers to the congruence between the candidate’s research interests and the research expertise of the faculty members associated with the program. When a student’s research interests align closely with those of their faculty advisor, a more effective mentorship relationship is fostered. This, in turn, results in more focused research, increased productivity, and ultimately, a stronger dissertation. For instance, if a student is interested in computational fluid dynamics for hypersonic flows, they should seek a program where faculty members actively conduct research in this area and possess the necessary computational resources. Conversely, a misalignment can lead to frustration, delays, and a diminished research experience.

The importance of this alignment extends beyond the individual student’s experience. Faculty research activity directly informs the curriculum and the availability of research projects. A faculty deeply engaged in cutting-edge research is more likely to integrate current findings and methodologies into their teaching, ensuring the curriculum remains relevant and up-to-date. Furthermore, active research programs often attract external funding, which can provide students with opportunities to participate in externally funded projects, gain access to specialized equipment, and attend conferences to present their work. Consider a scenario where an online aerospace engineering program is affiliated with a university known for its work in space propulsion. Students specializing in propulsion systems will benefit significantly from this research proximity, even in an online environment, through access to data, collaboration opportunities, and potentially, virtual laboratory experiences.

In conclusion, faculty research alignment is not merely a desirable feature but a fundamental requirement for a successful doctoral aerospace engineering program delivered online. It enhances mentorship, enriches the curriculum, and expands research opportunities. Prospective students should meticulously investigate faculty research interests and publications to ascertain the degree of alignment before committing to a program. While online programs offer flexibility and accessibility, the quality of the research experience remains paramount, and this is largely determined by the expertise and focus of the faculty. This careful assessment ensures that the candidate benefits from a rich and meaningful research journey, contributing to advancements in the field of aerospace engineering.

3. Technology Infrastructure

The successful execution of a doctoral aerospace engineering program via online platforms hinges critically on a robust and reliable technology infrastructure. This infrastructure encompasses the hardware, software, and network systems that enable the delivery of course content, facilitate communication between students and faculty, and support research activities. The effectiveness of this infrastructure directly impacts the quality of the educational experience and the ability of students to conduct advanced research in aerospace engineering.

- Learning Management System (LMS) Functionality

The LMS serves as the central hub for online doctoral studies. Its functionality must extend beyond basic content delivery to include interactive features such as discussion forums, virtual laboratories, simulation software integration, and assessment tools. For example, a student researching computational fluid dynamics requires access to high-performance computing resources accessible through the LMS, alongside software licenses for specialized simulation packages. The LMS must also support secure video conferencing for lectures, office hours, and dissertation defenses. Inadequate LMS functionality can impede collaboration, hinder research progress, and diminish the overall learning experience.

- High-Performance Computing and Simulation Resources

Doctoral research in aerospace engineering often requires access to significant computational power for running complex simulations and analyzing large datasets. The technology infrastructure must provide access to high-performance computing clusters, either locally or through cloud-based services. Furthermore, students must have access to industry-standard simulation software for modeling aircraft aerodynamics, spacecraft dynamics, propulsion systems, and structural mechanics. For instance, a student researching the design of a new type of wing requires access to computational fluid dynamics (CFD) software and the computing power to run simulations of airflow around the wing at various speeds and angles of attack. Insufficient computing resources can severely limit the scope and depth of doctoral research.

- Network Connectivity and Bandwidth

Reliable network connectivity and adequate bandwidth are fundamental for online doctoral studies. Students require a stable internet connection to access course materials, participate in live lectures, and collaborate with peers. Insufficient bandwidth can lead to dropped connections, lagging video streams, and difficulties in accessing large files. The technology infrastructure should ensure that students, regardless of their geographic location, have access to a reliable and high-speed internet connection. Furthermore, the university must provide technical support to assist students with troubleshooting network connectivity issues. For example, if a student needs to download a 5GB dataset for their research, slow internet speeds may take multiple days. Access to resources requires a consistent and fast connection.

- Cybersecurity and Data Protection

The technology infrastructure must incorporate robust cybersecurity measures to protect sensitive data and prevent unauthorized access. This includes measures such as encryption, firewalls, intrusion detection systems, and regular security audits. Students and faculty must be trained on cybersecurity best practices to protect their accounts and data from phishing attacks and other threats. Given the sensitive nature of some aerospace engineering research, such as classified defense-related projects, maintaining a secure online environment is of paramount importance. Any data breach or security vulnerability could have serious consequences for the university, the researchers, and the industry.

In summary, technology infrastructure is the backbone of online doctoral aerospace engineering. The effectiveness of the LMS, availability of high-performance computing resources, reliability of network connectivity, and strength of cybersecurity measures collectively determine the quality of the online learning experience and the potential for students to conduct cutting-edge research. Institutions offering these programs must prioritize investment in technology infrastructure to ensure that their students have the tools and resources they need to succeed.

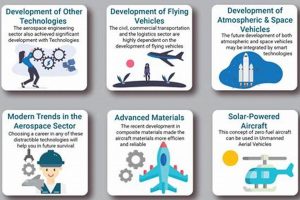

4. Curriculum Specialization

Doctoral-level studies in aerospace engineering offered online necessitate a degree of curriculum specialization that aligns with both the evolving demands of the industry and the individual research interests of the student. The structure of the curriculum should allow for in-depth study within a chosen area of concentration, fostering expertise in a specific sub-discipline. This specialization is crucial for preparing graduates to tackle complex challenges and contribute meaningfully to advancements in aerospace technology. The following facets highlight key aspects of curriculum specialization in this context.

- Focus on Specific Aerospace Disciplines

A specialized curriculum allows students to concentrate on areas such as aerodynamics, propulsion, structures, control systems, or astronautics. This focus enables a deeper understanding of the fundamental principles and advanced techniques relevant to their chosen field. For example, a student specializing in propulsion may delve into advanced topics such as hypersonic propulsion, electric propulsion, or advanced combustion techniques. This depth of knowledge is essential for conducting original research and developing innovative solutions to complex engineering problems. In online environments, this is delivered through advanced modules, specific software training, and directed independent research.

- Integration of Advanced Theoretical Concepts

Curriculum specialization involves the integration of advanced theoretical concepts and mathematical models relevant to the chosen area of concentration. This includes topics such as advanced computational methods, non-linear control theory, or finite element analysis. A student specializing in structures, for example, would need to master advanced finite element techniques to accurately model the behavior of complex aerospace structures under various loading conditions. Online instruction often involves interactive simulations and virtual laboratories to reinforce these theoretical concepts. Furthermore, access to powerful computing resources is critical for the successful application of these advanced methods.

- Emphasis on Research Methodology and Dissertation Development

A specialized curriculum emphasizes research methodology and dissertation development within the chosen area of concentration. This includes training in experimental design, data analysis, and scientific writing. Students are guided through the process of formulating a research question, conducting a literature review, designing experiments or simulations, analyzing data, and writing a dissertation that makes a significant contribution to the field. The research component of this can cover novel aerospace application to software engineering problems. The online format facilitates access to a wider range of digital resources and collaborative tools to support the research process.

- Exposure to Emerging Technologies and Industry Trends

Curriculum specialization should provide exposure to emerging technologies and industry trends relevant to the chosen area of concentration. This includes topics such as additive manufacturing, artificial intelligence, nanotechnology, or advanced materials. Students need to be aware of the latest advancements in their field and be prepared to adapt to the rapidly changing landscape of the aerospace industry. Online programs can leverage virtual conferences, webinars, and guest lectures from industry experts to keep students informed about the latest developments. This element may be conducted as an addendum to the doctorate program which requires further accreditation.

In conclusion, curriculum specialization within a doctoral aerospace engineering program offered online is crucial for developing the expertise and research skills necessary to succeed in the field. By focusing on specific aerospace disciplines, integrating advanced theoretical concepts, emphasizing research methodology, and providing exposure to emerging technologies, these programs prepare graduates to become leaders and innovators in the aerospace industry. The adaptability inherent in online delivery allows for continuous updating of curricula to reflect the most current advancements, thereby ensuring graduates are well-prepared for the challenges and opportunities that lie ahead.

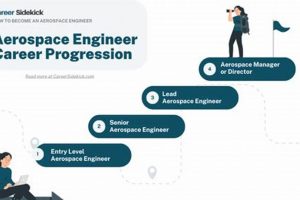

5. Career Advancement

Career advancement, subsequent to the completion of a doctoral program in aerospace engineering pursued online, represents a significant opportunity for individuals seeking leadership positions and specialized roles within the aerospace industry. This advanced degree equips graduates with the expertise and research skills necessary to excel in demanding and innovative environments, opening doors to diverse career paths.

- Leadership Roles in Research and Development

A doctorate often serves as a prerequisite for leadership positions in research and development (R&D) departments within aerospace companies and government agencies. Graduates are positioned to lead teams of engineers and scientists, guiding the development of new technologies and innovative solutions. This may involve overseeing the design and testing of advanced aircraft, spacecraft, or propulsion systems. For example, leading a team responsible for developing the next-generation satellite propulsion system requires in-depth knowledge of advanced propulsion concepts, materials science, and system integration. The doctorate signifies the ability to manage complex projects and drive innovation.

- Specialized Engineering Positions

Individuals holding a doctorate in aerospace engineering are well-suited for specialized engineering positions that require advanced technical knowledge and problem-solving skills. These roles may involve expertise in areas such as computational fluid dynamics, structural analysis, or control systems design. For example, a specialist in computational fluid dynamics may be responsible for simulating airflow around complex aerodynamic shapes, providing critical insights for aircraft design. Another specialist may focus on optimizing the structural integrity of spacecraft components using advanced finite element analysis techniques. These specialized roles demand a mastery of advanced engineering principles and the ability to apply them to real-world problems.

- Academia and Research Institutions

A doctoral degree is essential for pursuing a career in academia, whether as a professor, researcher, or lecturer. These roles involve conducting original research, teaching undergraduate and graduate courses, and mentoring students. A professor in aerospace engineering may lead a research laboratory, securing grants and publishing research findings in peer-reviewed journals. They also contribute to the advancement of knowledge in the field and train the next generation of aerospace engineers. Research institutions also employ doctoral graduates to conduct basic and applied research in areas relevant to aerospace technology, such as materials science, propulsion, and avionics.

- Consulting and Entrepreneurship

Doctoral graduates often pursue careers as consultants, providing specialized expertise to aerospace companies, government agencies, and other organizations. Consultants may advise on a wide range of topics, such as aircraft design, system integration, or regulatory compliance. Their expertise and experience allow them to offer valuable insights and solutions to complex engineering challenges. Some graduates also choose to pursue entrepreneurial ventures, starting their own companies focused on developing innovative aerospace technologies. For example, someone could create a business specializing in novel drone technologies or innovative solutions for space exploration challenges.

In conclusion, career advancement following the completion of an online aerospace engineering doctorate is characterized by access to leadership roles, specialized engineering positions, opportunities in academia, and potential for consulting or entrepreneurship. The degree signifies a high level of technical competence, research expertise, and problem-solving ability, positioning graduates for success in a rapidly evolving and technologically demanding field. The flexibility afforded by online learning allows professionals to advance their education while maintaining their careers, resulting in significant long-term career benefits.

Frequently Asked Questions

This section addresses common inquiries regarding doctoral programs in aerospace engineering delivered through online modalities, providing clarity on key aspects of these educational pathways.

Question 1: Is the rigor of a doctoral program in aerospace engineering maintained when delivered online?

The rigor of a doctoral program primarily stems from its curriculum, faculty expertise, and research requirements, not the delivery method. Accredited online programs adhere to the same academic standards as their on-campus counterparts, demanding equivalent coursework, comprehensive examinations, and dissertation requirements. Faculty expertise and access to resources are critical in maintaining the program’s standards.

Question 2: How does the online format impact research opportunities for doctoral candidates in aerospace engineering?

Online doctoral programs in aerospace engineering typically provide access to remote computational resources, virtual laboratories, and collaborative platforms to support research activities. Students may collaborate with faculty advisors and research teams remotely, utilizing advanced simulation software and data analysis tools. Some programs may also offer opportunities for limited on-campus research experiences or internships.

Question 3: Are online aerospace engineering doctoral degrees recognized by employers and professional organizations?

Accreditation is the primary factor determining the recognition of an online doctoral degree. Employers and professional organizations generally recognize degrees from accredited institutions, regardless of the delivery method. A degree from a reputable accredited online program is viewed favorably, showcasing knowledge and research skills.

Question 4: What types of support services are available to online doctoral students in aerospace engineering?

Reputable online programs provide a range of support services, including academic advising, technical support, library access, career counseling, and online tutoring. These services are designed to ensure that online students have access to the resources and support they need to succeed in their studies.

Question 5: How does one network with peers and faculty in an online doctoral program?

Online programs typically utilize various communication tools, such as discussion forums, video conferencing, and virtual office hours, to facilitate interaction between students and faculty. Furthermore, online students can participate in virtual conferences, workshops, and professional organizations to expand their network and connect with other professionals in the field.

Question 6: What are the typical admission requirements for a doctoral program in aerospace engineering offered online?

Admission requirements typically include a master’s degree in aerospace engineering or a closely related field, a strong academic record, standardized test scores (GRE may be required), letters of recommendation, and a statement of purpose outlining research interests and career goals. Some programs may also require a portfolio of previous research work.

In summary, a doctoral degree in aerospace engineering earned through an online platform holds substantial value, contingent upon the program’s accreditation and the student’s commitment. Understanding the program’s structure and the support systems available is crucial to maximizing its benefits.

The ensuing section examines successful strategies for navigating the challenges inherent in online doctoral studies within the aerospace engineering discipline.

Conclusion

The preceding analysis has detailed the multifaceted aspects of pursuing a phd aerospace engineering online. The discussion encompassed program quality considerations, curriculum nuances, technological requirements, and career trajectory implications. A thorough investigation of these areas demonstrates that accessibility and flexibility are not mutually exclusive to rigor and quality in advanced engineering education. Successful participation, however, necessitates careful evaluation of program accreditation, faculty alignment, and technological infrastructure.

Ultimately, the decision to undertake doctoral-level studies in aerospace engineering via an online platform warrants careful deliberation. This choice represents a significant commitment, demanding disciplined self-direction and focused engagement. The potential for professional advancement and contribution to the field, however, remains substantial for candidates who meticulously select and diligently complete a program aligned with their individual aspirations and the evolving needs of the aerospace industry. Prospective candidates must exercise due diligence to ascertain the credibility and suitability of a given program before embarking on this rigorous academic path.