The field encompasses the design, development, testing, and production of aircraft and spacecraft. Professionals in this discipline apply scientific and technological principles to create efficient, safe, and functional aerial and space-bound vehicles. Their responsibilities include analyzing aerodynamic forces, designing propulsion systems, and ensuring structural integrity under extreme conditions. For instance, they might work on improving fuel efficiency in commercial airliners or developing heat shields for spacecraft re-entering Earth’s atmosphere.

The relevance of this field is paramount to advancements in air travel, space exploration, and national defense. Its impact spans economic growth, scientific discovery, and technological innovation. Historically, it has driven progress from the first powered flights to the current endeavors in space colonization, constantly pushing the boundaries of what is achievable. The benefits are far-reaching, contributing to global connectivity, scientific understanding, and technological prowess.

The subsequent sections will delve into the specific areas of specialization within this field, exploring the core principles applied in various projects, and examining the essential skills required for a career in this technologically advanced and vital area of engineering. It will outline how these professionals shape the future of transportation, exploration, and technology.

Guidance for Aspiring Aerospace Professionals

The following recommendations are designed to offer guidance to individuals considering a career path focused on the practical application of scientific principles to the design, construction, and testing of aircraft and spacecraft.

Tip 1: Acquire a Robust Foundation in STEM: A strong understanding of mathematics, physics, and computer science is fundamental. Focus on mastering calculus, differential equations, thermodynamics, and programming languages relevant to engineering simulations.

Tip 2: Cultivate Analytical and Problem-Solving Skills: Engage in activities that demand critical thinking and the ability to dissect complex problems into manageable components. Participate in engineering competitions or research projects to refine these abilities.

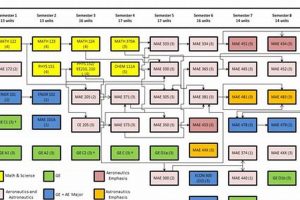

Tip 3: Pursue Relevant Education and Certifications: Obtain a bachelor’s or master’s degree in a related engineering discipline. Consider pursuing specialized certifications in areas such as aerodynamics, propulsion, or avionics to enhance career prospects.

Tip 4: Seek Internship Opportunities: Gain practical experience through internships at aerospace companies or research institutions. These opportunities provide exposure to real-world projects and allow one to apply theoretical knowledge in a professional setting.

Tip 5: Develop Strong Communication Skills: Effectively conveying technical information to both technical and non-technical audiences is crucial. Practice writing technical reports and presenting findings clearly and concisely.

Tip 6: Stay Abreast of Industry Advancements: Remain informed about the latest technological developments in areas such as advanced materials, additive manufacturing, and autonomous systems. Attend industry conferences and subscribe to relevant publications.

Tip 7: Specialize Based on Interest and Aptitude: The field encompasses a broad range of specializations, from aerodynamics to propulsion. Identify an area that aligns with your interests and aptitudes and focus your development efforts accordingly.

By adhering to these recommendations, individuals can position themselves for a successful and impactful career in this demanding and evolving field.

The subsequent sections will elaborate on the specific skills, educational pathways, and career opportunities available within this essential engineering discipline.

1. Aircraft Design

Aircraft design is a central component of the activities performed within the field. It represents the practical application of theoretical knowledge to create functional and efficient aerial vehicles. Every aspect of a modern aircraft, from its aerodynamic profile to its internal systems, is the direct result of engineering design principles applied to specific performance requirements. The effectiveness of this design directly influences the aircraft’s safety, fuel efficiency, speed, range, and payload capacity.

A tangible example of the link between aircraft design and aerospace engineering is seen in the development of composite materials for aircraft structures. Traditional aluminum structures are gradually being replaced by lighter, stronger composite materials that allow for more aerodynamically efficient designs. The design process necessitates meticulous analysis of stress distribution, material properties, and manufacturing processes to ensure structural integrity and minimize weight. This iterative process involves simulation, testing, and refinement, all of which are integral parts of engineering practice. The Boeing 787 Dreamliner, with its extensive use of composite materials, exemplifies the practical application of these design principles.

In summary, aircraft design constitutes a core element of the activities performed within the broader field. It not only necessitates a deep understanding of fundamental engineering principles but also demands continuous innovation to meet evolving performance and safety demands. The effective integration of design processes translates directly into more efficient, reliable, and capable aircraft, highlighting the practical significance of this understanding in shaping the future of air transportation.

2. Spacecraft Development

Spacecraft development is a critical application of principles. It involves the comprehensive process of designing, constructing, testing, and launching vehicles intended for operation in the unique and demanding environment of space. The rigorous requirements of this endeavor necessitate a diverse range of engineering expertise and innovative technological solutions.

- Orbital Mechanics and Trajectory Design

Determining the optimal path for a spacecraft to reach its intended destination is paramount. This requires precise calculations of gravitational forces, fuel consumption, and orbital maneuvers. For instance, missions to Mars rely on complex trajectory designs to minimize travel time and fuel expenditure. The accuracy of these calculations directly impacts mission success and the longevity of the spacecraft’s operational life.

- Life Support Systems

For crewed missions, creating a habitable environment within the spacecraft is non-negotiable. This involves regulating temperature, pressure, and air composition, as well as managing waste and water recycling. The International Space Station (ISS) exemplifies the complexity of life support systems, requiring continuous monitoring and maintenance to sustain a viable environment for astronauts.

- Radiation Shielding

The space environment exposes spacecraft to high levels of radiation that can damage electronics and pose health risks to astronauts. Effective shielding designs are therefore essential for mission success and crew safety. Considerations include material selection, thickness, and placement to minimize radiation exposure while optimizing weight and cost.

- Communication Systems

Maintaining reliable communication between spacecraft and ground control is vital for data transmission, command execution, and mission monitoring. These systems must overcome significant challenges such as signal attenuation, interference, and long transmission delays. Missions to distant planets, such as the Voyager probes, rely on advanced communication technologies to transmit data across vast distances.

These facets highlight the intricate relationship between spacecraft development and the core tenets of engineering. The successful implementation of these principles is fundamental to advancing space exploration, scientific discovery, and our understanding of the universe. The ongoing innovations in these areas continue to shape the future of space travel and its contribution to societal advancement.

3. Propulsion Systems

Propulsion systems represent a crucial element within the larger scope of aerospace engineering. They are directly responsible for enabling aircraft and spacecraft to overcome gravitational forces and atmospheric resistance, achieving and maintaining controlled flight. The effectiveness and efficiency of these systems profoundly influence the performance capabilities, operational range, and overall mission success of any airborne or space-bound vehicle. The design and integration of propulsion systems demand a comprehensive understanding of thermodynamics, fluid mechanics, and materials science, necessitating close collaboration among various engineering disciplines. An example of this interconnectedness is the development of modern jet engines, where advancements in materials science allow for higher operating temperatures, leading to improved fuel efficiency and increased thrust. Thus, the study and advancement of propulsion systems form a core activity within the broader field.

The practical applications of this engineering expertise extend beyond mere functionality. For instance, the development of electric propulsion systems for satellites allows for more precise orbital control and extended mission lifetimes, directly impacting communication, navigation, and Earth observation capabilities. Similarly, ongoing research into hypersonic propulsion systems aims to revolutionize air travel, potentially reducing flight times between continents to a matter of hours. These examples illustrate that propulsion systems are not merely components; they are enabling technologies that drive innovation across the entire spectrum of aerospace activities. The design process requires balancing performance requirements with factors such as weight, cost, reliability, and environmental impact, necessitating a holistic and integrated approach.

In summary, propulsion systems are intrinsically linked to the core objectives. The advancement of these systems has a direct and profound effect on the capabilities of flight. Challenges remain in achieving higher efficiency, reduced emissions, and increased reliability, necessitating ongoing research and development efforts. The future of air and space travel is inextricably tied to innovations in propulsion technology, underscoring its central role in the broader advancement of aerospace engineering as a discipline.

4. Aerodynamics Analysis

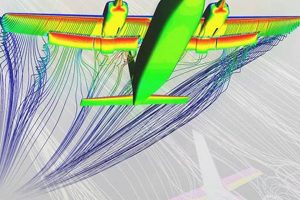

Aerodynamics analysis constitutes a cornerstone of engineering practice. It provides critical insights into how air interacts with moving objects, enabling engineers to design efficient, stable, and safe aircraft and spacecraft. Understanding these interactions is not merely theoretical; it is fundamental to ensuring the successful operation of vehicles operating within Earth’s atmosphere and beyond.

- Lift and Drag Prediction

Accurate prediction of lift and drag forces is crucial for determining aircraft performance. Computational Fluid Dynamics (CFD) simulations, wind tunnel testing, and analytical methods are employed to quantify these forces under various flight conditions. For example, minimizing drag on a commercial airliner reduces fuel consumption and increases range, directly impacting operational costs and environmental impact.

- Stability and Control Analysis

Ensuring that an aircraft or spacecraft maintains stable flight characteristics is paramount. Aerodynamic analysis helps engineers to understand how control surfaces, such as rudders and elevators, affect the vehicle’s attitude and trajectory. This analysis informs the design of control systems that allow pilots or automated systems to maintain stable flight even in turbulent conditions. The stability analysis of a rocket during atmospheric ascent is crucial for preventing catastrophic failures.

- Aerodynamic Heating

At high speeds, particularly during atmospheric re-entry, aerodynamic heating can become a significant concern. Aerodynamic analysis is used to predict the temperature distribution on the vehicle’s surface, enabling engineers to design thermal protection systems that prevent structural damage or failure. The design of heat shields for spacecraft, such as those used by the Space Shuttle, relies heavily on accurate aerodynamic heating predictions.

- Computational Fluid Dynamics (CFD) Applications

CFD simulations are extensively used to model airflow around complex geometries. These simulations provide detailed information about pressure distributions, velocity fields, and turbulence characteristics. CFD is employed in the design of aircraft wings, engine inlets, and control surfaces to optimize aerodynamic performance. The accuracy of these simulations is continuously improved through validation against experimental data.

The aforementioned facets underscore the indispensable role of aerodynamics analysis in enabling the creation of safe and efficient vehicles. The applications of these principles span the entire spectrum of aerospace activities. As technology continues to advance, so too will the sophistication of aerodynamic analysis techniques, further enhancing our ability to design and operate advanced aircraft and spacecraft.

5. Materials Science

Materials science is inextricably linked to the activities performed within engineering. The selection, characterization, and application of materials directly impact the performance, safety, and longevity of aircraft and spacecraft. The stringent demands placed on aerospace vehicles necessitate a deep understanding of material properties under extreme conditions, including high and low temperatures, high stress, and exposure to radiation and corrosive environments. For example, the development of high-temperature alloys for jet engine turbines directly contributes to increased engine efficiency and thrust, leading to improved fuel economy and reduced emissions in commercial aviation. Furthermore, the design and fabrication of lightweight composite materials, such as carbon fiber reinforced polymers, enable the construction of lighter and more aerodynamically efficient aircraft structures, reducing drag and increasing payload capacity. Therefore, advancements in materials science directly facilitate progress in air and space vehicle design and operation.

The connection between materials science and engineering extends beyond simply selecting existing materials. It often involves the development of novel materials tailored to specific aerospace applications. Consider the development of ablative heat shields for spacecraft re-entering Earth’s atmosphere. These materials are designed to undergo controlled decomposition, dissipating heat and protecting the spacecraft from extreme temperatures generated during re-entry. The design of such materials requires a deep understanding of material behavior at high temperatures, including thermal conductivity, ablation rates, and chemical reactions. The ongoing research into advanced materials such as ceramic matrix composites and shape memory alloys aims to address future challenges in aerospace engineering, including the development of hypersonic aircraft and space-based infrastructure.

In conclusion, materials science is not merely a supporting discipline but an essential and integral component of engineering activities. Its influence spans the entire lifecycle of aerospace vehicles, from initial design and fabrication to operational performance and long-term durability. The continuing advancement of new materials and a deeper understanding of existing material properties are crucial for addressing the ever-increasing demands placed on air and space vehicles, ensuring their safety, efficiency, and reliability.

6. Flight Testing

Flight testing serves as a critical validation phase within engineering, bridging the gap between theoretical design and practical application. It allows engineers to assess the performance, handling qualities, and safety characteristics of aircraft and spacecraft under realistic operational conditions. The data obtained during flight testing informs design refinements, validates analytical models, and ensures compliance with regulatory requirements.

- Performance Evaluation

Flight testing provides empirical data on crucial performance metrics such as takeoff distance, climb rate, maximum speed, and fuel consumption. These measurements are compared against predicted values to identify discrepancies and optimize aircraft design. For instance, flight testing of a new commercial airliner confirms that it meets its advertised fuel efficiency targets, ensuring its economic viability.

- Handling Qualities Assessment

Pilots evaluate the handling qualities of an aircraft during various maneuvers, providing subjective feedback on its responsiveness, stability, and ease of control. This information is used to refine the aircraft’s control systems and aerodynamic characteristics, ensuring that it is safe and comfortable to fly. Flight testing of a military fighter jet assesses its agility and maneuverability, confirming its suitability for combat operations.

- Systems Validation

Flight testing verifies the functionality and reliability of all aircraft systems, including avionics, propulsion, and environmental control systems. Potential issues are identified and addressed before the aircraft enters service, preventing costly and potentially dangerous malfunctions. Flight testing of a new spacecraft validates the performance of its navigation, communication, and life support systems, ensuring the success of its mission.

- Safety Certification

Flight testing is a mandatory requirement for obtaining airworthiness certification from regulatory agencies such as the Federal Aviation Administration (FAA). Compliance with safety standards is demonstrated through rigorous testing and analysis, ensuring that the aircraft meets minimum safety requirements before it is allowed to carry passengers or cargo. The FAA’s certification of a new aircraft type confirms that it has undergone extensive flight testing and meets all applicable safety regulations.

In summary, flight testing provides essential validation of designs, contributing directly to the safety, performance, and reliability of air and space vehicles. The data obtained during these test programs informs continuous improvement, ensuring that aircraft and spacecraft meet the stringent requirements of their intended operational environments.

7. System Integration

System integration is an indispensable facet of the activities associated with designing, developing, and deploying both aircraft and spacecraft. This process involves harmonizing disparate components and subsystems into a cohesive, functional whole capable of meeting stringent performance and safety requirements. The complexity inherent in aerospace systems necessitates meticulous planning, execution, and verification to ensure all elements operate in concert.

- Avionics Integration

Avionics systems, encompassing navigation, communication, flight control, and electronic warfare capabilities, must be seamlessly integrated to provide pilots with the information and control necessary for safe and efficient flight. For instance, the integration of GPS navigation with autopilot systems allows for precise course tracking and automated flight management. The failure of avionics integration can lead to navigational errors, loss of communication, and compromised flight control, underscoring the criticality of this aspect.

- Propulsion and Airframe Integration

The propulsion system must be effectively integrated with the airframe to optimize aerodynamic performance and structural integrity. Factors such as engine placement, inlet design, and exhaust nozzle configuration directly impact aircraft drag, lift, and stability. For example, the proper integration of turbofan engines with a wide-body airliner minimizes fuel consumption and maximizes payload capacity. Inadequate integration can lead to increased drag, reduced thrust, and potential structural failure.

- Payload Integration

Integrating payloads, such as scientific instruments, communication equipment, or weaponry, requires careful consideration of factors such as weight distribution, power requirements, and thermal management. The successful integration of a satellite payload ensures that it can perform its intended function without compromising the overall performance or reliability of the spacecraft. Improper integration can result in payload malfunction, interference with other systems, or structural damage to the vehicle.

- Software and Hardware Integration

Aerospace systems increasingly rely on sophisticated software to control and monitor various functions. Seamless integration of software and hardware components is essential for reliable and predictable operation. For example, flight control software must accurately interpret sensor data and execute control commands to maintain stable flight. Faulty software integration can lead to erratic behavior, system crashes, and potentially catastrophic consequences.

The successful system integration provides efficiency, reliability and safety. The process touches upon and is key to engineering activities from initial design stages through deployment. The discipline encompasses a wide range of skills and knowledge, demanding a holistic understanding of engineering.

Frequently Asked Questions about Aerospace Engineering

This section addresses common inquiries regarding the roles and responsibilities of professionals in the field. The answers provided aim to offer clarity and insight into the diverse aspects of this engineering discipline.

Question 1: What specific tasks are undertaken on a daily basis?

The daily activities can vary significantly based on the role and specialization. Tasks may include designing components using CAD software, conducting simulations to analyze performance, writing technical reports, collaborating with multidisciplinary teams, and troubleshooting technical issues that arise during development or testing.

Question 2: What are the primary areas of specialization?

Specialization areas are numerous. These include aerodynamics, propulsion, structural analysis, avionics, control systems, materials science, and space systems engineering. Each area demands a focused skillset and contributes to specific aspects of aircraft and spacecraft design and operation.

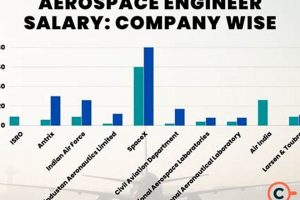

Question 3: What types of industries employ individuals?

Employment opportunities exist in diverse sectors. These encompass aircraft manufacturers, space agencies, government research laboratories, defense contractors, and aerospace consulting firms. Each offers unique challenges and opportunities for contributing to advancements in air and space travel.

Question 4: What level of education is typically required?

A bachelor’s degree in engineering is generally the minimum requirement for entry-level positions. Advanced roles often necessitate a master’s degree or doctorate, particularly in research-intensive areas. Specialized certifications can also enhance career prospects.

Question 5: What are the essential skills for success?

Essential skills include strong analytical and problem-solving abilities, proficiency in mathematics and physics, familiarity with CAD and simulation software, effective communication skills, and the ability to work collaboratively within teams. Adaptability and a commitment to lifelong learning are also crucial.

Question 6: What is the typical career progression path?

Career progression often involves starting as a design engineer or research assistant, followed by advancement to senior engineer, project manager, or technical specialist. Some individuals may pursue leadership roles or transition into specialized areas such as consulting or entrepreneurship.

In summary, this field offers a diverse range of career paths and opportunities for individuals with a strong foundation in science and engineering. Success requires a combination of technical expertise, problem-solving skills, and a commitment to continuous learning.

The subsequent sections will explore the future trends and emerging technologies within this dynamic field, providing insights into the evolving landscape of air and space exploration.

Conclusion

This exploration has delineated the diverse and intricate tasks that constitute the engineering domain. It has clarified that the profession involves a multifaceted skillset that spans design, development, testing, and analysis within air and space contexts. From fundamental aerodynamics to complex system integration, the discussed elements highlight the pivotal role these activities play in advancing technological frontiers.

Given the ongoing global emphasis on technological innovation and space exploration, the continued commitment to research, education, and practical application remains paramount. Continued dedication to these goals will ensure future progress within the broader scientific community.