The necessity of a background in chemical principles for individuals pursuing the design, development, and testing of aircraft and spacecraft is a frequent inquiry. Understanding material properties, propulsion systems, and environmental interactions forms a critical aspect of the discipline. For instance, the selection of appropriate alloys for airframes involves consideration of their resistance to corrosion and their behavior under varying temperatures, both topics deeply rooted in chemical understanding.

Knowledge of chemical processes offers significant advantages in aerospace engineering. It facilitates informed decision-making regarding fuel efficiency, exhaust emissions, and the longevity of structural components. Historically, advancements in materials science, driven by chemical research, have enabled the creation of lighter and stronger materials, leading to improved aircraft performance and reduced fuel consumption. A firm grasp of chemical principles enables engineers to innovate and optimize existing systems and develop novel technologies.

Therefore, the following sections will delve into specific areas within aerospace engineering where a foundation in chemistry proves indispensable. This includes, but is not limited to, propulsion, materials science, and environmental considerations, providing a detailed exploration of the subject’s relevance.

Essential Insights for Aerospace Engineering Studies

The subsequent points underscore the value of chemical knowledge within the aerospace engineering field, providing actionable insights for students and professionals.

Tip 1: Prioritize Materials Science Fundamentals: A strong understanding of chemical bonding, material structure, and property relationships is vital. Focus on coursework covering metallurgy, polymer chemistry, and composite materials, as these form the backbone of airframe and spacecraft design.

Tip 2: Master Propulsion Chemistry: Combustion processes, rocket propellants, and their associated chemical reactions directly impact engine efficiency and performance. In-depth study of thermodynamics and chemical kinetics is highly recommended.

Tip 3: Investigate Corrosion and Degradation: Aerospace structures are constantly exposed to harsh environments. Understanding the chemical mechanisms of corrosion and material degradation allows for the selection of appropriate protective coatings and preventative measures.

Tip 4: Explore Polymer and Composite Applications: Modern aircraft increasingly utilize polymer composites for their high strength-to-weight ratio. Detailed knowledge of polymer synthesis, crosslinking, and composite fabrication techniques is advantageous.

Tip 5: Understand Environmental Impact: Consider the environmental implications of aerospace activities, including exhaust emissions and the disposal of hazardous materials. Study atmospheric chemistry and pollution control technologies.

Tip 6: Focus on Electrochemistry Principles: The understanding of electrochemistry concepts is invaluable when selecting proper coating of the materials. For example, electrodeposition is used to deposit thin films of materials in aerospace manufacturing.

Tip 7: Strengthen laboratory skills: Chemical analysis is a core element. Learn the best laboratory practices to avoid error.

These recommendations highlight how chemical literacy empowers aerospace engineers to design safer, more efficient, and environmentally responsible aircraft and spacecraft.

The ensuing conclusion will consolidate the central arguments presented and offer a final perspective on the role of chemistry in advancing aerospace engineering.

1. Material Properties

Material properties are inextricably linked to the practice of aerospace engineering. The selection and application of materials in aircraft and spacecraft design are fundamentally governed by chemical principles. Understanding the chemical composition, bonding, and structure of materials allows engineers to predict their behavior under the extreme conditions encountered in aerospace applications. For instance, the high temperatures generated during hypersonic flight necessitate materials with exceptional thermal stability and oxidation resistance, properties directly related to the material’s chemical makeup. Similarly, the lightweighting of aircraft structures relies on advanced composite materials, whose mechanical properties are dictated by the chemical interactions between the matrix and reinforcement phases.

The chemical characteristics of materials also dictate their long-term performance and durability in service. Corrosion, a chemical process, can significantly degrade the structural integrity of aircraft components. Thus, aerospace engineers require a comprehensive understanding of corrosion mechanisms and mitigation strategies, involving both material selection and surface treatments. Furthermore, the development of new aerospace materials often hinges on manipulating their chemical composition and processing techniques to achieve desired properties, such as enhanced strength, fatigue resistance, or radiation shielding. Examples include the development of nickel-based superalloys for turbine blades and carbon-carbon composites for thermal protection systems, all driven by chemical innovation.

In conclusion, a solid grasp of material properties, rooted in chemical knowledge, is indispensable for aerospace engineers. It enables them to make informed decisions regarding material selection, processing, and application, ultimately ensuring the safety, performance, and longevity of aerospace vehicles. Challenges remain in developing materials that can withstand increasingly demanding operating conditions, necessitating continuous research and innovation in materials science and engineering.

2. Propulsion Systems

The design and operation of propulsion systems in aerospace engineering heavily depend on a robust understanding of chemical principles. These systems, responsible for generating thrust and enabling flight, involve complex chemical reactions and processes that directly impact their efficiency, performance, and environmental footprint. A chemical foundation is not merely beneficial but fundamentally essential for engineers working in this domain.

- Combustion Chemistry and Thermodynamics

The core of many aerospace propulsion systems, such as jet engines and rocket engines, relies on the controlled combustion of fuel. Understanding the chemical kinetics and thermodynamics of combustion reactions is crucial for optimizing fuel-air mixtures, maximizing energy release, and minimizing the formation of pollutants. The selection of fuels and oxidizers also depends on their chemical properties, such as energy density, ignition temperature, and stability. Without a thorough grasp of these chemical concepts, engineers cannot effectively design and operate efficient and reliable propulsion systems.

- Rocket Propellants

Rocket propulsion presents unique chemical challenges due to the need for self-contained propellants that can function in the vacuum of space. The selection and development of rocket propellants involve careful consideration of their chemical composition, reactivity, and performance characteristics. Liquid propellants, such as liquid hydrogen and liquid oxygen, offer high performance but require cryogenic storage. Solid propellants, such as composite mixtures of oxidizers and fuels, offer simplicity and storability but typically have lower performance. Understanding the chemical properties and reaction mechanisms of these propellants is critical for designing effective rocket propulsion systems.

- Exhaust Emissions and Environmental Impact

The exhaust emissions from aerospace propulsion systems contribute to air pollution and climate change. Understanding the chemical composition of exhaust gases and their impact on the atmosphere is essential for developing cleaner propulsion technologies. Research efforts focus on reducing the formation of nitrogen oxides (NOx), particulate matter, and other pollutants through optimized combustion processes and aftertreatment systems. Alternative fuels, such as biofuels and synthetic fuels, are also being investigated to reduce the carbon footprint of aerospace propulsion.

- Materials for High-Temperature Environments

Propulsion systems operate at extremely high temperatures and pressures, requiring materials with exceptional thermal and mechanical properties. The selection of materials for combustion chambers, turbine blades, and nozzles depends on their chemical resistance to oxidation, corrosion, and creep. Materials such as nickel-based superalloys and ceramic matrix composites are commonly used in these applications. Understanding the chemical interactions between these materials and the hot gases is crucial for ensuring their long-term durability and reliability.

In summary, the intricacies of aerospace propulsion are deeply intertwined with chemical knowledge. From optimizing combustion processes to developing advanced propellants and minimizing environmental impact, a strong chemical foundation is indispensable for engineers working to advance the field of propulsion systems. The pursuit of more efficient, sustainable, and high-performing propulsion technologies will continue to rely on chemical innovation and expertise.

3. Corrosion Prevention

Corrosion prevention is a paramount concern within aerospace engineering, fundamentally reliant on a deep understanding of chemical principles. The aerospace industry operates in diverse and often harsh environments, exposing aircraft and spacecraft to conditions that accelerate corrosion processes. These processes degrade material integrity, compromise structural performance, and ultimately threaten the safety and operational lifespan of aerospace vehicles. The link between corrosion and chemistry arises from the fact that corrosion is, at its core, an electrochemical process. It involves the oxidation of a metal, typically in the presence of an electrolyte, leading to the gradual deterioration of the material. An example of this is the atmospheric corrosion of aluminum alloys, a common material in aircraft construction. Exposure to moisture and salts in the air triggers electrochemical reactions that form aluminum oxide, weakening the alloy over time. Therefore, effective corrosion prevention strategies necessitate a thorough comprehension of the underlying chemical mechanisms driving these reactions.

Effective corrosion prevention in aerospace engineering involves several key strategies, each directly linked to chemical knowledge. These include the selection of corrosion-resistant materials, the application of protective coatings, and the implementation of corrosion monitoring and mitigation techniques. The choice of materials, such as stainless steels or titanium alloys, often stems from their inherent chemical resistance to oxidation and other forms of corrosion. Protective coatings, such as paints, sealants, and conversion coatings, act as barriers to prevent corrosive agents from reaching the underlying metal. The efficacy of these coatings depends on their chemical composition and their ability to form a stable, impermeable layer. Regular inspection and maintenance procedures, guided by chemical analysis techniques, are critical for detecting early signs of corrosion and implementing timely corrective measures. For instance, non-destructive testing methods like electrochemical impedance spectroscopy can assess the condition of coatings and detect hidden corrosion damage before it becomes structurally significant.

In summary, corrosion prevention is an indispensable aspect of aerospace engineering, requiring a solid foundation in chemistry. The chemical nature of corrosion dictates the need for materials selection, protective coatings, and monitoring methods grounded in chemical principles. Ignoring the chemical aspects of corrosion can have severe consequences, leading to structural failures and jeopardizing the safety and reliability of aerospace vehicles. Continuous research and development in corrosion-resistant materials and advanced protection techniques remain essential for ensuring the longevity and safety of aircraft and spacecraft in increasingly demanding operating environments.

4. Fuel Efficiency

Fuel efficiency in aerospace engineering is fundamentally intertwined with chemical principles. The combustion process within aircraft engines, the properties of the fuels themselves, and the materials used in engine construction are all subject to chemical laws. A greater understanding of chemistry facilitates the design of more efficient engines, leading to reduced fuel consumption and lower emissions. For example, knowledge of reaction kinetics allows engineers to optimize combustion chamber designs for complete fuel oxidation, maximizing energy extraction and minimizing unburned hydrocarbons in the exhaust. The development of alternative fuels, such as biofuels or synthetic kerosene, also requires a deep understanding of chemical synthesis and fuel property characterization. These fuels must meet stringent performance requirements while minimizing environmental impact, a balance achievable only through careful chemical engineering.

The role of chemistry extends to the materials science involved in engine construction. High-temperature alloys used in turbine blades and combustion liners must withstand extreme conditions and resist oxidation and corrosion. Their chemical composition and processing influence their performance and lifespan, directly affecting engine efficiency and maintenance requirements. Furthermore, research into novel materials, such as ceramic matrix composites, aims to improve engine performance by enabling higher operating temperatures, thus increasing thermodynamic efficiency. This involves manipulating the chemical composition and microstructure of these materials to achieve the desired properties. Moreover, catalysis plays a crucial role in after-treatment systems designed to reduce harmful emissions from aircraft engines. Catalytic converters rely on chemical reactions to transform pollutants such as nitrogen oxides and carbon monoxide into less harmful substances. Understanding the reaction mechanisms and optimizing the catalyst formulation are essential for achieving effective emission control.

In summary, chemical knowledge forms an indispensable foundation for enhancing fuel efficiency in aerospace engineering. It informs the design of combustion systems, the development of advanced fuels, the selection of high-performance materials, and the implementation of emission control technologies. Continuous advancements in these areas, driven by chemical innovation, are crucial for achieving sustainable aviation and reducing the environmental impact of air travel. Meeting increasingly stringent fuel efficiency standards and emission regulations requires a concerted effort to integrate chemical expertise into all aspects of aerospace engineering design and development.

5. Environmental Impact

The environmental consequences of aerospace activities are intrinsically linked to chemical principles. Aircraft emissions, rocket launches, and the production of aerospace materials all have direct and indirect impacts on the environment, necessitating a strong chemical understanding to mitigate adverse effects. Atmospheric chemistry plays a central role, as aircraft exhaust releases greenhouse gases (carbon dioxide, water vapor), nitrogen oxides, and particulate matter, altering the radiative balance of the atmosphere and contributing to climate change. Furthermore, the depletion of the ozone layer, historically linked to chlorofluorocarbons (CFCs) used in aviation, underscores the critical role of chemical regulations and alternative substance development.

Chemical knowledge is essential for developing cleaner propulsion systems and sustainable aerospace materials. Research efforts focus on optimizing combustion processes to minimize emissions, developing alternative fuels with reduced carbon footprints, and designing materials that are more environmentally friendly to produce and dispose of. For example, the development of sustainable aviation fuels (SAF), derived from biomass or waste materials, involves complex chemical processes to convert raw materials into fuels meeting stringent performance requirements. Furthermore, the design of lighter and more durable materials, like composites, can reduce aircraft weight and improve fuel efficiency, thereby indirectly reducing emissions. Accurate measurement and modeling of emissions rely on robust chemical analysis techniques, ensuring compliance with environmental regulations. The lifecycle assessment of aerospace materials, considering their environmental impact from production to disposal, requires a thorough understanding of chemical processes and their environmental consequences.

Addressing the environmental impact of aerospace activities necessitates a comprehensive approach grounded in chemical knowledge. Developing sustainable solutions requires expertise in combustion chemistry, materials science, atmospheric chemistry, and chemical engineering. By integrating these disciplines, the aerospace industry can strive to minimize its environmental footprint, fostering a more sustainable future for air and space travel. Continued research and innovation in these areas are critical for achieving significant reductions in emissions and waste, while maintaining the performance and safety standards essential for aerospace operations.

Frequently Asked Questions

This section addresses common inquiries regarding the significance of chemical knowledge for individuals pursuing careers in aerospace engineering. These questions and answers aim to provide clarity and guidance for prospective students and professionals in the field.

Question 1: Is a strong background in chemistry truly necessary for aerospace engineering?

A robust understanding of chemical principles is highly beneficial, if not essential, for several facets of aerospace engineering. These include materials science, propulsion systems, corrosion prevention, and the environmental impact of aerospace activities. While not every aerospace engineer will directly engage in chemical research, a fundamental grasp of these concepts enhances problem-solving abilities and informed decision-making.

Question 2: In what specific areas of aerospace engineering is chemistry most relevant?

Chemistry is particularly relevant in areas such as the selection and development of materials for airframes and engines, the design and optimization of propulsion systems (including fuel chemistry and combustion), the prevention of corrosion in aerospace structures, and the assessment and mitigation of the environmental impact of aircraft emissions.

Question 3: Can an individual succeed in aerospace engineering without taking chemistry courses?

While it may be possible to complete an aerospace engineering curriculum without extensive chemistry coursework, a lack of chemical understanding can limit an individual’s ability to fully grasp certain fundamental concepts and contribute to specific areas of research and development. A foundational knowledge of chemistry is strongly recommended for a well-rounded education.

Question 4: What specific chemistry topics are most important for aerospace engineers to understand?

Key chemistry topics for aerospace engineers include chemical bonding, material structure, thermodynamics, chemical kinetics, electrochemistry, and polymer chemistry. These topics provide the basis for understanding material properties, combustion processes, corrosion mechanisms, and environmental interactions.

Question 5: How does knowledge of chemistry contribute to innovation in aerospace engineering?

A strong chemical foundation empowers engineers to develop novel materials with enhanced properties, design more efficient propulsion systems with reduced emissions, and devise effective strategies for preventing corrosion and degradation in aerospace structures. Chemical knowledge is also critical for assessing and mitigating the environmental impact of aerospace activities, driving innovation in sustainable aviation technologies.

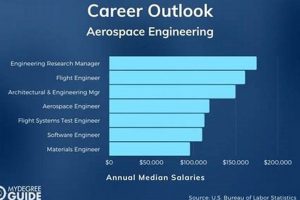

Question 6: Are there specific career paths within aerospace engineering where chemistry expertise is particularly valuable?

Career paths where chemistry expertise is particularly valuable include materials science and engineering (developing new alloys and composites), propulsion engineering (designing and optimizing fuel systems), corrosion engineering (developing protective coatings and mitigation strategies), and environmental engineering (assessing and reducing the environmental impact of aerospace activities).

In summary, the relationship between chemistry and aerospace engineering is substantial. A foundational understanding of chemical principles equips engineers with the necessary tools to tackle complex challenges, drive innovation, and contribute to the advancement of the field.

The subsequent section will provide a concluding overview, reinforcing the central arguments and offering a final perspective on the significance of chemistry in aerospace engineering.

Conclusion

This exploration of the inquiry, “do you need chemistry for aerospace engineering,” has demonstrated the significant role chemical principles play in the field. From the selection of materials to the design of propulsion systems, a grasp of chemistry underlies many critical aspects of aerospace engineering. The ability to understand and manipulate chemical processes is essential for developing innovative solutions to challenges related to performance, safety, and environmental impact.

Therefore, a foundational understanding of chemistry is not merely beneficial but a crucial element for success in aerospace engineering. As the field continues to evolve, and the demands on aircraft and spacecraft become increasingly complex, the need for engineers with a strong chemical background will only intensify. A commitment to chemical literacy will undoubtedly contribute to safer, more efficient, and sustainable aerospace technologies of the future.

![Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Top UC Berkeley Aerospace Engineering Masters Programs [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-647-300x200.jpg)