A West Virginia facility of a major aerospace and defense company specializing in the design, manufacture, and service of technologically advanced systems and products for the aviation and high-technology industries. This location likely supports various functions, possibly including engineering, manufacturing, testing, or customer service related to aircraft components or related aerospace technologies.

This facility’s presence in West Virginia signifies the state’s participation in the aerospace sector and can contribute to local economic development through job creation and investment. Historically, such facilities have played a crucial role in advancing aerospace technology and supporting both commercial and military aviation programs. Their operations can bring specialized skills and expertise to the region, fostering innovation and technological advancement.

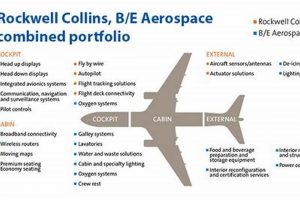

The specific operations conducted at this site are varied, ranging from the production of aircraft interior systems to the manufacture of complex electronic components. Understanding the details of these operations provides valuable insight into the broader contributions this particular facility makes to the aerospace industry and the local West Virginia community.

Operational Efficiency Tips

The following tips are geared towards enhancing operational efficiency, drawing from best practices typically observed at facilities like the Collins Aerospace WV location. These suggestions aim to improve productivity, reduce waste, and foster a culture of continuous improvement within a manufacturing or engineering environment.

Tip 1: Implement Lean Manufacturing Principles: Establish a robust Lean program to streamline processes, eliminate waste, and improve overall productivity. This includes implementing techniques like 5S, value stream mapping, and Kanban systems tailored to specific workflows.

Tip 2: Invest in Advanced Technology: Adopt automation and advanced manufacturing technologies to enhance precision, reduce manual labor, and improve product quality. Examples include robotic assembly lines, automated testing systems, and advanced data analytics for process optimization.

Tip 3: Emphasize Employee Training and Development: Provide ongoing training and development opportunities for employees to enhance their skills and knowledge. This ensures a highly skilled workforce capable of operating complex equipment and adapting to evolving technologies.

Tip 4: Foster a Culture of Continuous Improvement: Encourage employees to identify and implement process improvements. Establish feedback mechanisms, conduct regular audits, and implement a system for tracking and rewarding successful improvement initiatives.

Tip 5: Optimize Supply Chain Management: Implement efficient supply chain management practices to minimize lead times, reduce inventory costs, and ensure timely delivery of materials. This includes establishing strong relationships with suppliers and implementing real-time tracking systems.

Tip 6: Prioritize Quality Control: Implement stringent quality control measures throughout the manufacturing process to minimize defects and ensure product reliability. This includes rigorous testing protocols, statistical process control, and root cause analysis for any identified issues.

Adhering to these recommendations can lead to significant improvements in operational efficiency, increased productivity, and enhanced competitiveness within the aerospace industry. Continuous evaluation and adaptation are crucial for sustaining long-term success.

Moving forward, the application of these strategies will contribute to further advancements and innovation within the aerospace sector.

1. Manufacturing Capabilities

The manufacturing capabilities at the Collins Aerospace facility in West Virginia are central to its function as a key component of the broader aerospace industry. These capabilities encompass a spectrum of processes and technologies essential for producing high-quality, reliable components for aircraft and related systems.

- Precision Component Fabrication

This facet involves the use of advanced machining, forming, and assembly techniques to create intricate and precise parts. Examples include turbine blades, structural elements, and electronic housings. The stringent requirements of aerospace applications necessitate meticulous attention to detail and adherence to tight tolerances, influencing material selection and process control within the facility.

- Advanced Materials Processing

The facility likely utilizes advanced materials processing techniques to work with alloys, composites, and other specialized materials used in aerospace manufacturing. This may involve heat treatments, surface coatings, and non-destructive testing to ensure material integrity and performance under demanding operating conditions. These processes contribute to the enhanced durability and longevity of aircraft components.

- Electronics Manufacturing and Assembly

A significant aspect of manufacturing capabilities likely includes the production and assembly of electronic components and systems. This can range from circuit board fabrication to the integration of sensors and control systems. The precision and reliability of these electronic systems are critical for aircraft navigation, communication, and flight control, necessitating rigorous quality control and testing procedures.

- Testing and Quality Assurance

Comprehensive testing and quality assurance processes are integral to the manufacturing operations. These processes include functional testing, environmental testing, and compliance testing to verify that manufactured components meet stringent performance and safety standards. The facility utilizes specialized equipment and methodologies to simulate real-world operating conditions, ensuring the reliability of its products.

These manufacturing capabilities collectively underscore the significance of the West Virginia facility in the Collins Aerospace network. The specialized expertise and technological infrastructure contribute to the production of high-value components crucial for both commercial and military aviation. Continual investment in advanced manufacturing techniques and skilled workforce development are essential to maintaining the facility’s competitive edge and supporting the evolving needs of the aerospace industry.

2. Engineering Expertise

The operational efficacy and innovative capacity of the Collins Aerospace facility in West Virginia are directly attributable to its engineering expertise. This expertise manifests across diverse domains, encompassing design, development, testing, and continuous improvement of aerospace components and systems. The presence of a skilled engineering workforce within the facility is not merely an operational asset but the foundational element upon which the facility’s competitiveness and value proposition are built. For instance, the design and refinement of aircraft interior systems, a potential area of focus for the West Virginia location, demands specialized engineering knowledge encompassing materials science, structural analysis, and human factors. The engineering teams work to optimize designs for weight, durability, and passenger comfort, adhering to stringent safety regulations and performance standards. A consequence of strong engineering talent enables the rapid adaptation of existing products to meet new regulatory requirements or customer specifications, a common occurrence in the aerospace sector.

Further examples of this connection are evident in the development of advanced electronic components or avionics systems. Such systems demand electrical, mechanical, and software engineering talent to design, prototype, and validate complex functionalities. Engineering teams utilize simulation software and testing facilities to rigorously evaluate the performance and reliability of these systems under various operating conditions. Moreover, the engineering function also supports the continuous improvement of manufacturing processes, aiming to reduce costs, enhance efficiency, and minimize environmental impact. This frequently involves the implementation of lean manufacturing principles and the adoption of advanced automation technologies. Effective problem-solving in manufacturing often hinges on the ability of engineering teams to identify root causes of defects or inefficiencies and implement corrective actions. The application of engineering expertise can be seen in initiatives to optimize supply chain logistics or improve resource utilization, leading to greater overall efficiency.

In summary, engineering expertise forms the backbone of the Collins Aerospace facility in West Virginia. The facility’s ability to design, manufacture, and support technologically advanced aerospace systems depends critically on the capabilities of its engineering teams. Maintaining a strong engineering talent pool and fostering a culture of innovation are essential for ensuring the facility’s long-term success and its contribution to the advancement of the aerospace industry. Key challenges include keeping pace with rapidly evolving technologies, addressing the skills gap in engineering disciplines, and fostering collaboration between engineering teams and other functional areas within the organization.

3. Economic Impact

The economic impact of the Collins Aerospace facility in West Virginia represents a multifaceted contribution to the state and regional economy. This impact extends beyond direct employment and encompasses various interconnected elements.

- Direct Employment and Wages

The facility directly employs a workforce, providing wages and benefits to local residents. This employment generates income that circulates within the regional economy, supporting local businesses and services. For example, manufacturing jobs often pay higher wages compared to other sectors in the region, thus elevating the standard of living for the workforce.

- Indirect and Induced Impacts

The facility’s operations create indirect economic impacts through its supply chain. Local suppliers of goods and services benefit from contracts with the facility, leading to job creation and increased revenue for these businesses. Induced impacts arise from the spending of wages earned by employees, further stimulating economic activity in the retail, housing, and service sectors. A well-established supply chain network bolsters local industrial capabilities.

- Tax Revenue Generation

The facility contributes to state and local tax revenues through property taxes, corporate income taxes, and payroll taxes. These revenues can be used to fund public services such as education, infrastructure, and healthcare, thereby benefiting the broader community. Significant capital investments may yield long-term fiscal benefits.

- Technological Spillover and Workforce Development

The presence of an aerospace facility can lead to technological spillover, as expertise and innovation developed within the facility diffuse to other sectors of the economy. Moreover, the facility’s demand for skilled workers encourages workforce development initiatives, such as vocational training programs and partnerships with local educational institutions. This workforce development improves the skill base of the region, attracting other high-tech industries and enhancing economic competitiveness.

Collectively, these economic impacts highlight the significance of the Collins Aerospace facility in West Virginia. The facility’s operations generate jobs, support local businesses, contribute to tax revenues, and foster technological innovation. These impacts underscore the value of aerospace manufacturing in driving economic growth and development within the state.

4. Technological Innovation

Technological innovation forms a cornerstone of operations at the Collins Aerospace facility in West Virginia. The facility’s mandate, driven by the broader company’s strategic objectives, necessitates a commitment to advancing aerospace technology through research, development, and implementation. This commitment translates to tangible outcomes in various aspects of the facility’s activities. For instance, the implementation of advanced manufacturing techniques, such as additive manufacturing, to produce lightweight and durable aircraft components is a direct result of technological innovation. The facility may also engage in the development of more efficient and reliable electronic systems for aircraft, which contributes to enhanced safety and performance. It is the result of significant investment into new technologies and a proactive culture of technological advancement.

The importance of technological innovation as a component of this facility cannot be overstated. Aerospace is a highly competitive and technologically intensive industry. Companies that fail to innovate risk losing market share and falling behind competitors. For the Collins Aerospace facility in West Virginia, continuous innovation is essential for maintaining its relevance and contributing to the company’s overall success. This can be understood through the engineering design teams constantly seeking new methods to improve fuel efficiency, reduce emissions, and enhance passenger comfort, all fueled by access to cutting-edge technologies. The successful integration of new technologies leads to an enhanced product line, cost reduction, and the creation of high-skilled jobs within the community. These are tangible benefits driven by the facility’s investment in innovation.

In summary, the connection between technological innovation and the Collins Aerospace facility in West Virginia is fundamental. The facility’s success hinges on its ability to embrace and implement new technologies. This is because innovation is the engine of growth and competitiveness in the aerospace industry. Challenges remain, including the need to attract and retain highly skilled workers, to secure adequate funding for research and development, and to navigate the complex regulatory environment. However, the commitment to technological innovation remains a central tenet of the facility’s mission and strategy.

5. Community Engagement

Community engagement, in the context of the Collins Aerospace facility in West Virginia, represents a crucial dimension of its operations and corporate social responsibility. It demonstrates a reciprocal relationship, impacting both the company and the surrounding community.

- Educational Outreach Programs

These programs aim to foster interest in science, technology, engineering, and mathematics (STEM) fields among local students. This can involve partnering with schools, offering scholarships, or providing mentorship opportunities. For example, sponsoring local STEM competitions or hosting workshops can inspire students to pursue careers in aerospace, indirectly benefiting Collins Aerospace by creating a pipeline of potential future employees. These initiatives contribute to a more educated and skilled workforce in the region.

- Workforce Development Initiatives

These programs focus on equipping local residents with the skills and training necessary to secure employment at the facility. This can include collaborating with community colleges, offering apprenticeships, or providing on-the-job training programs. For instance, partnering with a local vocational school to provide specialized training in advanced manufacturing techniques can directly address the facility’s need for skilled workers. These initiatives contribute to local economic development by reducing unemployment and increasing household incomes.

- Charitable Contributions and Sponsorships

The facility may support local charitable organizations and community events through financial contributions, in-kind donations, or employee volunteerism. This can include sponsoring local sports teams, supporting food banks, or participating in community cleanup efforts. For example, donating to a local non-profit organization that provides services to disadvantaged families demonstrates a commitment to social responsibility. These activities enhance the company’s reputation and strengthen its ties to the community.

- Community Advisory Boards

Establishing advisory boards comprised of community members allows for open communication and feedback regarding the facility’s operations and potential impacts. These boards can provide valuable insights into local concerns and help the facility address issues proactively. For example, inviting local residents to participate in discussions about environmental stewardship or community development projects can foster trust and collaboration. This ensures that the facility operates in a manner that is responsive to the needs and concerns of the community.

These community engagement efforts demonstrate a commitment to being a responsible corporate citizen. By investing in education, workforce development, charitable activities, and open communication, the Collins Aerospace facility strengthens its relationships with the local community and contributes to its long-term sustainability. Such initiatives enhance the facility’s social license to operate and ensure its continued success within the region.

Frequently Asked Questions

This section addresses common inquiries regarding the Collins Aerospace facility located in West Virginia. The responses aim to provide factual and relevant information to stakeholders.

Question 1: What specific types of products are manufactured at the Collins Aerospace WV facility?

The specific product lines at the West Virginia facility are proprietary, but general types include aircraft interior components, electronic systems, and precision-engineered parts for aerospace applications. Specifics are subject to change based on market and customer demands.

Question 2: How many individuals are employed by Collins Aerospace at the West Virginia location?

The exact number of employees fluctuates based on production demands and economic conditions. However, the facility represents a significant employer in the region, contributing to the local economy.

Question 3: Does the Collins Aerospace WV facility engage in research and development activities?

While specific details are confidential, research and development activities related to aerospace technology likely occur at the facility. This is consistent with the company’s broader commitment to innovation.

Question 4: How does the Collins Aerospace WV facility contribute to the local West Virginia community?

The facility contributes to the community through direct employment, tax revenue generation, support for local suppliers, and participation in educational and charitable initiatives.

Question 5: What quality control measures are in place at the Collins Aerospace WV facility?

Stringent quality control measures, including rigorous testing and inspection protocols, are implemented throughout the manufacturing process to ensure that all products meet or exceed industry standards and regulatory requirements.

Question 6: How does the Collins Aerospace WV facility address environmental sustainability?

The facility likely adheres to environmental regulations and implements sustainable practices to minimize its environmental footprint. Specific initiatives may include waste reduction programs, energy efficiency measures, and compliance with environmental management systems.

The Collins Aerospace facility in West Virginia is an important component of the aerospace industry and the local economy. Its operations contribute to technological innovation, job creation, and community development.

The following section will provide a glossary of related terms.

Conclusion

This exploration has presented various facets of the Collins Aerospace WV facility, highlighting its manufacturing capabilities, engineering expertise, economic contributions, technological innovations, and community engagement. The facility’s activities are integral to the broader aerospace industry, providing crucial components and systems for both commercial and military applications. Its presence in West Virginia also signifies a commitment to regional economic development and the fostering of a skilled workforce.

Continued evaluation of the facility’s performance and its contributions to the aerospace sector and the local community is essential. As technology advances and the demands of the aerospace industry evolve, the Collins Aerospace WV facility must adapt and innovate to maintain its competitive edge and continue to serve as a valuable asset to the region.