The entities described are organizations engaged in the design, development, manufacturing, and maintenance of aircraft and spacecraft within a specific geographical location. These entities contribute significantly to the local economy and technological advancement. As an illustration, these businesses produce various components, including airframes, engines, avionics, and interior systems, contributing to the broader aerospace industry.

Their presence provides substantial economic advantages through job creation, attracting skilled labor, and fostering innovation. Historically, the area became a hub for aviation production due to its central location, open spaces, and entrepreneurial spirit, leading to significant contributions to both commercial and military aviation. This concentration of expertise continues to attract investment and drive regional growth.

This article will delve into the major players in the specified sector, their specialized areas of operation, and the overall impact they have on the region’s economy and technological landscape. Specific areas of focus will include manufacturing capabilities, research and development initiatives, and the skilled workforce that drives their success.

Succeeding within the aviation manufacturing landscape in Wichita, Kansas, requires a strategic approach, detailed planning, and a commitment to excellence. The following are crucial insights for businesses operating or seeking to establish a presence in this competitive environment.

Tip 1: Foster Strong Relationships with Local Institutions: Establish connections with Wichita State University’s National Institute for Aviation Research (NIAR) and other local educational institutions. These partnerships can provide access to research, talent pipelines, and collaborative opportunities. For example, sponsoring research projects or offering internships can strengthen ties and secure access to future employees.

Tip 2: Invest in Advanced Manufacturing Technologies: Remain competitive by adopting cutting-edge manufacturing processes and technologies, such as additive manufacturing, automation, and robotics. Implementing these technologies can improve efficiency, reduce production costs, and enhance product quality. Prioritize training employees on these new systems to maximize their benefits.

Tip 3: Comply with Stringent Regulatory Requirements: Maintain strict adherence to all applicable FAA regulations, AS9100 standards, and other relevant compliance requirements. Implement robust quality control systems and conduct regular audits to ensure ongoing compliance. Failure to comply can result in costly penalties and damage to reputation.

Tip 4: Cultivate a Highly Skilled Workforce: Recruit and retain top talent by offering competitive compensation, comprehensive benefits packages, and opportunities for professional development. Invest in employee training programs to enhance their skills and knowledge. A skilled workforce is critical to maintaining a competitive edge.

Tip 5: Diversify Product and Service Offerings: Reduce risk by diversifying product and service offerings to cater to a wide range of clients, including commercial airlines, defense contractors, and private aircraft owners. This diversification can provide stability during economic downturns or industry shifts.

Tip 6: Participate in Industry Associations and Events: Actively engage in industry associations and attend relevant events to network with peers, stay informed about emerging trends, and identify potential business opportunities. Participation strengthens visibility and facilitates collaboration within the sector.

Tip 7: Prioritize Cybersecurity and Data Protection: Implement robust cybersecurity measures to protect sensitive data from cyber threats. Adhere to industry best practices for data protection and compliance, including securing intellectual property and customer information. Cybersecurity breaches can have severe consequences for businesses in this sector.

Adherence to these recommendations will position organizations for sustained success, contributing to the vibrant aeronautical landscape in south-central Kansas. By focusing on innovation, collaboration, and a commitment to quality, businesses in this area can navigate the challenges and capitalize on the opportunities within this specialized sector.

The following sections of this document will explore the key players, specializations, and future outlook for the aerospace industry in the defined area.

1. Manufacturing Capabilities

The manufacturing capabilities within the aerospace sector in Wichita, Kansas, represent a foundational pillar, directly impacting the industry’s strength, innovation, and economic viability. The extent and sophistication of these capabilities determine the region’s competitiveness and influence on global aerospace markets.

- Advanced Composite Fabrication

The ability to fabricate complex components from advanced composite materials is a crucial aspect. These materials, offering high strength-to-weight ratios, are increasingly used in modern aircraft structures. Facilities with expertise in composite layup, curing, and non-destructive testing are essential for producing lighter, more fuel-efficient aircraft. Spirit AeroSystems, for instance, utilizes advanced composite manufacturing techniques in the production of fuselage sections for various aircraft, demonstrating the practical application of this capability within the region.

- Precision Machining and Tooling

The capacity for precision machining of metallic components and the creation of specialized tooling are critical. Aerospace components often require tight tolerances and complex geometries, necessitating advanced CNC machining centers and skilled machinists. The presence of companies specializing in high-precision machining allows local entities to efficiently produce critical parts for airframes, engines, and other systems. This capability directly supports the manufacturing of high-performance aerospace products.

- Assembly and Integration

The assembly and integration of individual components into larger subassemblies and complete aircraft structures represents a significant manufacturing capability. This involves skilled technicians, advanced assembly processes, and robust quality control procedures. Companies like Textron Aviation rely on efficient assembly lines to produce a range of aircraft, from business jets to single-engine piston aircraft. Effective integration ensures that all components function seamlessly together, contributing to the overall reliability and performance of the final product.

- Specialized Processes and Treatments

Certain aerospace components require specialized processes and treatments to enhance their durability, corrosion resistance, or other properties. These may include heat treating, surface finishing, plating, and non-destructive testing. Access to facilities offering these specialized services is crucial for ensuring the quality and longevity of aerospace components. The availability of these treatments within the region reduces lead times and enhances the overall manufacturing efficiency of companies operating there.

The manufacturing capabilities described are instrumental to aerospace operations. Wichita’s sustained prominence in aircraft design and production relies heavily on the continued development and refinement of these fundamental aspects of manufacturing processes.

2. Engineering Expertise

The concentration of engineering expertise forms a cornerstone of the aerospace sector located within Wichita, Kansas. The presence of a highly skilled engineering workforce directly impacts the design, development, testing, and certification of aircraft and related systems. This expertise permeates all aspects of operations, from initial conceptualization to the ongoing refinement of existing products. For example, the engineering teams at Spirit AeroSystems are instrumental in designing and analyzing airframe structures for major aircraft manufacturers. The quality of this engineering work directly influences the safety, efficiency, and overall performance of the aircraft.

Wichita’s status as a prominent aerospace hub is partially attributed to its collaborative ecosystem. Wichita State University’s National Institute for Aviation Research (NIAR) plays a crucial role in providing research capabilities and fostering a pipeline of engineering talent. NIAR conducts cutting-edge research in areas such as advanced materials, structural testing, and virtual reality simulation, which directly benefits local aerospace companies. Furthermore, the university’s engineering programs provide a steady stream of graduates equipped with the knowledge and skills necessary to contribute to the industry. This constant influx of new talent sustains innovation and enables continued growth within the sector.

In conclusion, engineering expertise is not merely an ancillary component but rather an indispensable element of the aerospace ecosystem located in Wichita, Kansas. It directly influences the design, manufacturing, and certification processes, thereby enhancing the region’s competitive advantage. Investing in education, research, and development within the engineering field is therefore crucial for maintaining Wichita’s position as a leader within the global aerospace industry. The ongoing collaboration between industry, academia, and government entities is essential for fostering innovation and ensuring a continuous supply of skilled engineers to meet the evolving needs of the sector.

3. Supply Chain Strength

The robustness of the supply chain supporting entities operating within the aerospace sector is a critical determinant of their operational efficiency, competitiveness, and overall success. For entities situated in Wichita, Kansas, a resilient supply chain ensures access to necessary raw materials, components, and specialized services required for aircraft manufacturing, maintenance, and modification. Disruptions in this supply chain, whether due to geopolitical instability, natural disasters, or logistical bottlenecks, can severely impact production schedules, increase costs, and erode market share. A well-functioning supply chain allows “aerospace companies wichita ks” to meet demanding production schedules and contractual obligations. Spirit AeroSystems, for example, relies on a complex network of suppliers to provide components for its fuselage manufacturing operations. Any delays or disruptions in this network can cascade through the entire production process, impacting delivery timelines for major aircraft manufacturers like Boeing and Airbus.

The geographical concentration of aerospace suppliers within the Wichita region contributes significantly to the agility and responsiveness of the supply chain. Local suppliers can offer shorter lead times, reduced transportation costs, and enhanced communication, facilitating closer collaboration and faster problem-solving. Furthermore, the presence of specialized service providers, such as those offering heat treating, plating, and non-destructive testing, streamlines the manufacturing process and reduces reliance on external sources. The development of a skilled workforce within the supply chain is also paramount. Training programs and apprenticeship opportunities ensure that suppliers have access to qualified personnel capable of meeting the demanding requirements of aerospace manufacturing. Wichita Area Technical College, for instance, provides training programs specifically tailored to the needs of the aerospace industry, thereby strengthening the local supply chain.

In summary, the strength of the supply chain is an essential factor in the success of “aerospace companies wichita ks.” A robust, agile, and localized supply chain provides a competitive advantage by ensuring access to necessary resources, reducing costs, and enhancing responsiveness. Maintaining and strengthening this supply chain requires ongoing investment in infrastructure, workforce development, and supplier relationships. Failure to address potential vulnerabilities within the supply chain can expose “aerospace companies wichita ks” to significant risks, impacting their ability to compete in the global aerospace market. Therefore, a proactive approach to supply chain management is crucial for sustaining the long-term viability of the aerospace sector in the region.

4. Workforce Availability

The availability of a skilled workforce is a critical determinant of the operational capacity and competitive positioning of organizations engaged in the aerospace sector within Wichita, Kansas. Without a qualified labor pool, firms face significant challenges in meeting production demands, innovating new technologies, and maintaining operational efficiency.

- Skilled Trades and Manufacturing Technicians

The presence of trained machinists, aircraft mechanics, welders, and other skilled tradespeople is essential for the manufacturing and maintenance of aircraft components and systems. These individuals possess the technical expertise required to operate complex machinery, adhere to strict quality control standards, and troubleshoot technical issues. The shortage of skilled trades in the United States presents an ongoing challenge for aerospace companies, including those in Wichita. Initiatives to promote vocational training and apprenticeships are crucial for addressing this gap.

- Engineering and Technical Professionals

Aerospace engineers, mechanical engineers, electrical engineers, and other technical professionals are responsible for the design, development, testing, and certification of aircraft and related technologies. These individuals possess advanced knowledge of aerodynamics, structural analysis, materials science, and other engineering principles. The availability of a qualified engineering workforce is crucial for driving innovation and ensuring the safety and reliability of aerospace products. Wichita State University’s engineering programs play a significant role in supplying the region with engineering talent.

- Supply Chain and Logistics Personnel

Efficient supply chain management is essential for ensuring the timely delivery of raw materials, components, and finished products. Supply chain managers, logistics coordinators, and procurement specialists are responsible for coordinating the flow of goods, managing inventory levels, and negotiating contracts with suppliers. The strength of the supply chain directly impacts the ability of aerospace companies to meet production deadlines and control costs. The proximity of suppliers and efficient transportation infrastructure are important factors in optimizing supply chain operations.

- Quality Assurance and Compliance Specialists

Adherence to strict quality control standards and regulatory requirements is paramount in the aerospace industry. Quality assurance engineers, compliance officers, and FAA-certified inspectors are responsible for ensuring that products and processes meet the highest standards of safety and reliability. These individuals possess a deep understanding of aviation regulations, quality management systems, and auditing procedures. A strong emphasis on quality assurance is essential for maintaining customer confidence and avoiding costly product recalls.

The availability of a qualified workforce is a linchpin for the ongoing success of “aerospace companies wichita ks.” Continued investment in workforce development programs, partnerships with educational institutions, and efforts to attract and retain skilled personnel are crucial for ensuring the region’s competitiveness in the global aerospace market. A shortage of qualified workers can hinder growth, limit innovation, and ultimately undermine the economic vitality of the aerospace sector in Wichita.

5. Economic Contribution

The economic contribution of aerospace companies in Wichita, Kansas, represents a significant portion of the region’s financial well-being. This contribution extends beyond direct employment figures, encompassing a wide range of economic activities and indirect benefits that stimulate growth and stability.

- Direct Employment and Wages

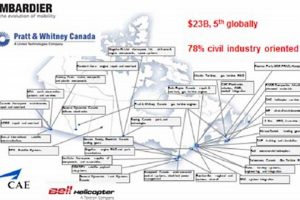

Aerospace companies serve as major employers, providing jobs across various skill levels, from manufacturing and engineering to administration and management. These positions offer competitive wages and benefits, contributing to the overall income levels and purchasing power of the local population. Spirit AeroSystems, Textron Aviation, and Bombardier, for example, collectively employ thousands of individuals in Wichita, representing a substantial portion of the region’s workforce. The wages earned by these employees contribute to local spending, supporting retail businesses, restaurants, and other service industries.

- Supply Chain Impact

The aerospace sector drives demand for a vast network of suppliers, ranging from manufacturers of raw materials and components to providers of specialized services such as heat treating and plating. These suppliers, many of whom are located within the Wichita region, benefit from the aerospace industry’s demand, creating additional jobs and economic activity. This multiplier effect amplifies the economic impact of aerospace companies, extending their reach beyond direct employment and wages. The success of these suppliers is intricately linked to the health and growth of the local aerospace sector.

- Tax Revenue Generation

Aerospace companies contribute significantly to local and state tax revenues through property taxes, sales taxes, and income taxes. These revenues support essential public services such as education, infrastructure, and public safety. The tax base generated by the aerospace sector helps to fund local government operations and improve the quality of life for residents. Fluctuations in the aerospace industry can therefore have a direct impact on the availability of public resources.

- Technology and Innovation Spillovers

The aerospace sector is a hotbed of technological innovation, driving advancements in materials science, manufacturing processes, and engineering design. These innovations often have spillover effects, benefiting other industries and sectors of the economy. For example, advanced composite materials developed for aircraft structures may find applications in automotive manufacturing, renewable energy, and other fields. This cross-pollination of ideas and technologies enhances the competitiveness of the broader economy and fosters long-term economic growth.

The facets outlined underscore the pivotal role of “aerospace companies wichita ks” in shaping the region’s economic landscape. Their impact resonates across employment, supply chains, public revenue, and innovation, cementing their position as economic engines within the local environment. Understanding and nurturing this sector is vital for sustainable regional prosperity.

6. Innovation Leadership

Innovation leadership, within the context of aerospace companies in Wichita, Kansas, is a crucial element determining the sector’s continued success and global competitiveness. It involves not only the development of new technologies but also the cultivation of a culture that encourages creativity, risk-taking, and continuous improvement. These attributes are essential for companies aiming to stay ahead in a rapidly evolving industry.

- Advanced Materials Research and Development

Innovation leadership in this area necessitates investment in the research and development of advanced materials, such as composites, alloys, and nanomaterials, which offer improved strength-to-weight ratios, enhanced durability, and resistance to extreme environments. Wichita State University’s National Institute for Aviation Research (NIAR) plays a critical role in this regard, conducting research on advanced materials and providing testing and certification services to aerospace companies. The adoption of these materials allows aerospace companies to build lighter, more fuel-efficient aircraft, reducing operating costs and environmental impact.

- Automation and Robotics Integration

Innovation leadership involves the integration of automation and robotics into manufacturing processes to improve efficiency, reduce costs, and enhance quality. This includes the deployment of robotic assembly lines, automated inspection systems, and computer-controlled machining centers. Companies that embrace automation can increase production capacity, reduce lead times, and minimize human error. For example, Spirit AeroSystems has invested heavily in automation to manufacture fuselage sections for commercial aircraft, demonstrating the practical application of this technology in the Wichita aerospace sector.

- Digitalization and Data Analytics

Innovation leadership requires the adoption of digital technologies and data analytics to optimize operations, improve decision-making, and enhance customer service. This includes the use of cloud computing, the Internet of Things (IoT), and artificial intelligence (AI) to collect, analyze, and interpret vast amounts of data generated by aircraft, manufacturing processes, and supply chains. By leveraging these technologies, aerospace companies can identify inefficiencies, predict maintenance needs, and personalize customer experiences. Textron Aviation, for example, utilizes data analytics to monitor the performance of its aircraft and provide predictive maintenance services to its customers.

- Sustainable Aviation Technologies

Innovation leadership demands a commitment to developing sustainable aviation technologies that reduce the environmental impact of air travel. This includes the development of more fuel-efficient engines, alternative fuels, and electric or hybrid-electric propulsion systems. As environmental regulations become increasingly stringent and consumer demand for sustainable travel grows, aerospace companies that invest in these technologies will gain a competitive advantage. The development of sustainable aviation technologies also aligns with broader societal goals of reducing greenhouse gas emissions and mitigating climate change.

The examples provided highlight the multifaceted nature of innovation leadership within Wichita’s aerospace industry. It encompasses not only technological advancements but also a strategic vision focused on efficiency, sustainability, and customer satisfaction. The ability of “aerospace companies wichita ks” to embrace and implement these innovations will ultimately determine their long-term success and contribution to the region’s economy.

Frequently Asked Questions Regarding Aerospace Companies in Wichita, KS

The following section addresses common inquiries about the aerospace sector centered in Wichita, Kansas. The aim is to provide clear and concise answers to facilitate a better understanding of this industry.

Question 1: What are the primary areas of specialization for organizations operating within the Wichita aerospace sector?

The aerospace organizations in Wichita, KS, primarily specialize in aircraft design, manufacturing, testing, and maintenance. Their activities span from producing entire aircraft to fabricating components for other aerospace entities.

Question 2: What are the major aerospace employers in Wichita, Kansas?

Key employers include Spirit AeroSystems, Textron Aviation (comprising Cessna, Beechcraft, and Hawker brands), and various suppliers and maintenance, repair, and overhaul (MRO) facilities. These entities collectively represent a significant portion of the regional aerospace workforce.

Question 3: How does Wichita State University contribute to the aerospace industry in the region?

Wichita State University, particularly its National Institute for Aviation Research (NIAR), provides research and development support, testing facilities, and a pipeline of skilled graduates for the aerospace sector. NIAR’s research capabilities are crucial for innovation and technological advancement within the industry.

Question 4: What impact do economic fluctuations have on the aerospace companies based in Wichita?

Aerospace companies located in Wichita, KS, are sensitive to economic cycles and changes in the global aviation market. Downturns in the economy or reduced demand for aircraft can lead to production cuts, workforce reductions, and financial challenges for these companies.

Question 5: What are the key challenges facing the aerospace industry in Wichita, Kansas?

Challenges include maintaining a skilled workforce, adapting to technological advancements (e.g., automation, composite materials), complying with evolving regulatory requirements, and competing in a global marketplace. These issues require ongoing strategic planning and investment.

Question 6: What is the long-term outlook for the aerospace industry in Wichita?

The long-term outlook is generally positive, driven by projected growth in air travel and demand for new aircraft. However, “aerospace companies wichita ks” must continue to innovate, adapt to changing market conditions, and address challenges related to workforce development and supply chain management to ensure sustained success.

This FAQ section offers a foundational understanding of the aerospace landscape in Wichita, Kansas. The information presented is intended to provide clarity and address common points of interest for those seeking to learn more about this sector.

The following section explores the future prospects and potential growth areas for the aerospace sector in Wichita, Kansas.

Conclusion

The preceding analysis has explored various facets of “aerospace companies wichita ks,” emphasizing their manufacturing capabilities, engineering expertise, supply chain dynamics, workforce considerations, economic contribution, and commitment to innovation. These elements collectively define the sector’s current standing and potential for future growth. The interactions between these factors form a complex ecosystem requiring careful navigation.

Continued vigilance regarding technological advancements, workforce development, and global market trends remains essential for the sustained prosperity of “aerospace companies wichita ks.” A proactive approach to addressing challenges and capitalizing on emerging opportunities will determine the region’s long-term competitiveness and contribution to the global aerospace industry. Further research and strategic initiatives are warranted to solidify Wichita’s position as a prominent aerospace hub.