Compensation for professionals specializing in the fabrication, repair, and maintenance of composite materials within the aviation and space industries is a critical factor in attracting and retaining skilled personnel. This remuneration reflects the expertise required to work with advanced materials like carbon fiber and epoxy resins, shaping them into components for aircraft and spacecraft.

The monetary value associated with this role is significant due to the precision and technical knowledge necessary for ensuring structural integrity and safety in aerospace applications. Furthermore, historical trends demonstrate that specialized skills in composite technology command competitive wages, influenced by factors such as experience, location, and specific industry demands.

Therefore, understanding the factors influencing income potential, regional variations in compensation, and the impact of experience and education on earnings is essential for individuals pursuing or currently working in this field. Exploring these elements will provide a comprehensive overview of the financial landscape for these specialized technicians.

Maximizing Compensation for Aerospace Composite Technicians

Strategic career planning and skill development are essential for optimizing earning potential in the specialized field of aerospace composite technology. The following tips provide guidance for achieving competitive compensation.

Tip 1: Acquire Industry-Recognized Certifications: Obtaining certifications, such as those offered by organizations like the FAA or specific composite material manufacturers, validates expertise and can lead to increased earning opportunities.

Tip 2: Specialize in High-Demand Skill Sets: Focusing on niche areas within composite technology, such as advanced repair techniques or Non-Destructive Testing (NDT), can position an individual as a highly sought-after expert.

Tip 3: Pursue Continuous Education and Training: Regularly updating knowledge and skills through workshops, seminars, and advanced courses ensures relevance in a rapidly evolving technological landscape.

Tip 4: Gain Experience with Diverse Composite Materials: Proficiency in working with a variety of composite materials, including carbon fiber, fiberglass, and Kevlar, broadens employment opportunities and enhances earning potential.

Tip 5: Seek Employment in High-Cost-of-Living Areas: Salaries often reflect the local cost of living. Consider seeking positions in metropolitan areas or regions with a high concentration of aerospace companies.

Tip 6: Network with Industry Professionals: Building connections with professionals in the aerospace and composite materials industries can provide insights into job opportunities and salary benchmarks.

Tip 7: Negotiate Strategically: Research industry salary standards thoroughly before negotiating a job offer or requesting a raise. Be prepared to articulate the value an individual brings to the organization.

By prioritizing skill development, specialization, and strategic career planning, technicians can significantly increase their earning potential within the aerospace composite materials field.

The final section will provide a concluding overview of the information presented and offer a perspective on the future outlook for professionals in this sector.

1. Experience Level

Experience level is a primary determinant of remuneration for professionals engaged in aerospace composite technology. As technicians accumulate practical experience, their proficiency in complex repairs, fabrication processes, and material handling increases. This enhanced skill set translates directly into higher earning potential. The progression from entry-level roles to senior technician positions demonstrates a clear correlation between years of experience and compensation. For instance, a technician with one year of experience typically earns less than a technician with five years of experience performing similar tasks.

The impact of experience is particularly evident in the ability to troubleshoot complex issues and implement efficient solutions. Seasoned technicians often possess a deeper understanding of composite material behavior, failure modes, and quality control procedures. Consider, for example, a composite repair requiring advanced techniques. A less experienced technician might require more time or guidance to complete the repair, potentially leading to increased labor costs or rework. An experienced technician, however, would likely execute the repair more efficiently, minimizing downtime and ensuring a higher quality outcome. This efficiency directly contributes to the value the technician provides to the employer.

In summary, experience level significantly influences compensation within the aerospace composite technician field. Increased experience leads to enhanced skills, improved efficiency, and a greater ability to handle complex tasks. This translates into higher earning potential, reflecting the value placed on expertise and proficiency in this highly specialized area. Understanding this connection is critical for both employers and technicians in establishing fair and competitive compensation structures.

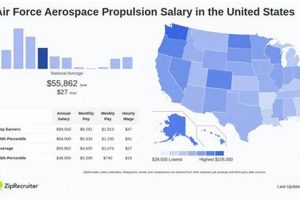

2. Geographic Location

Geographic location exerts a considerable influence on the earning potential of aerospace composite technicians. Regional variations in demand, cost of living, and industry concentration contribute to significant disparities in compensation.

- Regional Demand and Industry Clusters

Areas with a high concentration of aerospace manufacturing, maintenance, and repair operations typically offer more competitive salaries. For instance, states like Washington, California, and Texas, which host major aerospace companies and military installations, often present higher average compensation rates than regions with limited aerospace activity. The presence of large employers drives demand, leading to a more competitive labor market and increased wages.

- Cost of Living Adjustments

Salary levels often correlate with the cost of living in a particular area. Metropolitan areas with higher living expenses, such as housing, transportation, and utilities, tend to offer higher wages to compensate for these increased costs. Conversely, regions with a lower cost of living may offer lower salaries, as the overall financial burden on employees is reduced. Cost of living indices are often used to benchmark appropriate salary levels across different geographic areas.

- Proximity to Educational Institutions

The presence of specialized training programs and educational institutions offering degrees and certifications in composite materials can impact salary levels. Regions with a strong educational infrastructure often have a larger pool of qualified technicians, which can influence supply and demand dynamics. However, the availability of highly skilled professionals can also attract more employers, potentially offsetting any downward pressure on wages.

- Union Influence and Collective Bargaining

The presence of strong labor unions in certain geographic locations can influence compensation for aerospace composite technicians. Unions often negotiate collective bargaining agreements that establish minimum wage standards, benefits packages, and working conditions. Regions with active union representation may offer higher average salaries and improved benefits compared to areas with limited union presence.

In summary, geographic location is a crucial factor in determining the compensation for aerospace composite technicians. The interplay of regional demand, cost of living, educational infrastructure, and union influence collectively shapes the salary landscape, resulting in significant variations across different areas. Technicians should consider these factors when evaluating employment opportunities and negotiating compensation packages.

3. Certification Impact

The acquisition of industry-recognized certifications directly influences the compensation levels attainable by aerospace composite technicians. These credentials serve as verifiable proof of competence, validating a technician’s skills and knowledge to potential employers and clients. Their impact is multifaceted, affecting various aspects of employment and earning potential.

- Validation of Expertise

Certifications such as those offered by the FAA or composite material manufacturers, provide independent verification of a technician’s proficiency in specific techniques and processes. This validation reduces the perceived risk for employers, as it confirms the technician possesses the requisite skills to perform assigned tasks efficiently and safely. Certified technicians are often viewed as more reliable and capable, commanding higher wages as a result.

- Increased Marketability

Holding recognized certifications enhances a technician’s marketability, making them a more attractive candidate in a competitive job market. Employers often prioritize certified technicians, as these credentials demonstrate a commitment to professional development and adherence to industry standards. A technician with certifications may have access to a wider range of job opportunities and be better positioned to negotiate a higher salary.

- Compliance with Industry Standards

Many aerospace companies and regulatory bodies require technicians to hold specific certifications to perform certain tasks or work on particular types of aircraft. Compliance with these requirements is essential for maintaining operational licenses and ensuring adherence to safety regulations. Certified technicians are essential for ensuring that composite repairs and fabrications meet these standards, making them invaluable to employers.

- Potential for Advancement

Certifications can serve as a stepping stone for career advancement, opening doors to more senior roles with increased responsibilities and higher salaries. Employers often use certifications as a criterion for promotion, recognizing that certified technicians possess the skills and knowledge necessary to take on more challenging tasks and lead teams. The pursuit of advanced certifications can demonstrate a commitment to continuous learning and career progression.

In conclusion, the impact of certifications on the salaries of aerospace composite technicians is substantial. These credentials validate expertise, enhance marketability, ensure compliance with industry standards, and provide pathways for career advancement. Consequently, technicians who invest in obtaining relevant certifications are likely to experience increased earning potential and greater job security within the aerospace industry.

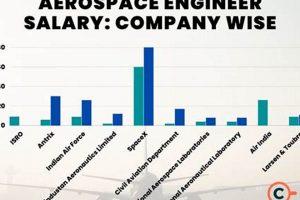

4. Employer Type

The nature of the employing organization significantly influences the compensation offered to aerospace composite technicians. Variations in salary and benefits packages are often contingent upon the employer’s size, financial resources, and specific sector within the aerospace industry.

- Large Aerospace Manufacturers

Major aerospace manufacturers, such as Boeing or Airbus, typically offer competitive salaries and comprehensive benefits packages. These companies possess substantial financial resources and often operate under union agreements, which establish standardized wage scales and working conditions. Technicians employed by these manufacturers may also have access to advanced training programs and opportunities for career advancement.

- Maintenance, Repair, and Overhaul (MRO) Facilities

MRO facilities specialize in the maintenance, repair, and overhaul of aircraft components and systems. Compensation in this sector can vary widely depending on the size and specialization of the facility. Larger MRO operations associated with major airlines may offer competitive salaries and benefits, while smaller independent repair shops may provide lower compensation packages. The specific types of composite repairs performed at the facility can also influence salary levels, with more complex repairs commanding higher wages.

- Government and Military Organizations

Government agencies and military organizations employ aerospace composite technicians to maintain and repair military aircraft and spacecraft. Salaries in this sector are often determined by government pay scales and civil service regulations. While the compensation may not always be as high as in the private sector, government employment typically offers stable job security and comprehensive benefits, including retirement plans and healthcare coverage. Locations with military bases or government aerospace facilities will typically have higher demand.

- Specialized Composite Repair Shops

Smaller, specialized composite repair shops often focus on niche markets, such as repairing composite structures for racing aircraft or high-performance vehicles. Compensation in this sector can be highly variable, depending on the shop’s size, reputation, and the complexity of the repairs performed. Technicians employed by these shops may have the opportunity to work on unique and challenging projects, but the job security and benefits packages may be less stable than in larger organizations. Niche composites will offer the highest reward

In summary, the type of employer significantly impacts the earning potential of aerospace composite technicians. Large manufacturers and government organizations often provide competitive salaries and comprehensive benefits, while MRO facilities and specialized repair shops can offer varying compensation packages depending on their size and specialization. Technicians should carefully consider these factors when evaluating employment opportunities and negotiating compensation.

5. Skills Specialization

Specialized skill sets within the aerospace composite technology field directly correlate with enhanced earning potential. The demand for technicians possessing expertise in niche areas significantly impacts compensation levels.

- Advanced Repair Techniques

Proficiency in advanced composite repair techniques, such as scarf repairs, bonded repairs, and vacuum-assisted resin transfer molding (VARTM), commands higher wages. These methods require extensive training and a deep understanding of material properties and structural mechanics. Technicians skilled in these areas are essential for maintaining the integrity of critical aircraft components, directly impacting flight safety and operational efficiency.

- Non-Destructive Testing (NDT)

Expertise in Non-Destructive Testing methods, including ultrasonic testing, radiography, and thermography, is highly valued. NDT technicians play a crucial role in identifying defects and assessing the structural integrity of composite components without causing damage. The ability to accurately interpret NDT data and identify potential issues before they become critical failures is essential for ensuring aircraft safety and compliance with regulatory standards.

- Material Science and Engineering

A strong foundation in material science and engineering principles is advantageous for technicians working with advanced composite materials. Understanding the properties of various fibers, resins, and adhesives, as well as their behavior under different environmental conditions, allows technicians to select appropriate materials and optimize fabrication processes. This knowledge is essential for ensuring the long-term durability and reliability of composite structures.

- Automation and Robotics

As aerospace manufacturing increasingly incorporates automation and robotics, technicians with expertise in programming, operating, and maintaining automated composite fabrication equipment are in high demand. These skills include proficiency in computer-aided design (CAD), computer-aided manufacturing (CAM), and robotic control systems. Technicians with these skills contribute to increased efficiency, reduced labor costs, and improved quality control in composite manufacturing processes.

In summary, the acquisition of specialized skills significantly elevates the earning potential for aerospace composite technicians. The demand for expertise in advanced repair techniques, NDT methods, material science, and automation reflects the increasing complexity and sophistication of composite technology within the aerospace industry. Technicians who invest in developing these specialized skills are well-positioned to command higher salaries and advance their careers in this rapidly evolving field.

Frequently Asked Questions About Compensation for Aerospace Composite Technicians

This section addresses common inquiries regarding the factors influencing income levels within the field of aerospace composite technology. The information provided aims to offer clarity and guidance to individuals pursuing or currently working in this profession.

Question 1: What is the typical starting remuneration for an aerospace composite technician with no prior experience?

Entry-level compensation is generally lower, reflecting the absence of practical experience. However, possessing relevant certifications or vocational training may positively influence initial salary offers. Geographic location also plays a crucial role, with higher cost-of-living areas potentially offering increased starting salaries.

Question 2: How does experience level correlate with increased earning potential in this field?

Earning potential exhibits a positive correlation with experience. Technicians accumulating several years of practical experience, demonstrating proficiency in advanced repair techniques or specialized skills, typically command higher wages. This increase reflects the enhanced value they bring to the employer.

Question 3: Which geographic locations offer the most competitive compensation packages for aerospace composite technicians?

Regions with a high concentration of aerospace manufacturing and maintenance operations, such as states like Washington, California, and Texas, often provide more competitive compensation packages. The increased demand for skilled technicians in these areas drives up salary levels.

Question 4: What certifications are most beneficial for maximizing earning potential as an aerospace composite technician?

Industry-recognized certifications, such as those offered by the FAA or specific composite material manufacturers, demonstrably enhance earning potential. These credentials validate expertise and compliance with industry standards, making certified technicians more attractive to employers.

Question 5: How does the type of employer (e.g., large manufacturer vs. small repair shop) influence salary expectations?

The type of employer significantly influences compensation. Large aerospace manufacturers typically offer more competitive salaries and comprehensive benefits compared to smaller, independent repair shops. Government and military organizations also provide stable employment with standardized pay scales.

Question 6: Are there specific skill specializations that command a premium in the aerospace composite technology sector?

Possessing specialized skills in areas such as advanced composite repair techniques, Non-Destructive Testing (NDT), or proficiency with automated fabrication equipment can substantially increase earning potential. These skills are highly valued due to the increasing complexity of composite materials and manufacturing processes.

Understanding these factors is crucial for individuals seeking to optimize their earning potential within the aerospace composite technology field. Strategic career planning, continuous skill development, and informed decision-making are essential for achieving financial success in this profession.

The following section provides a concluding summary of the information presented, offering a forward-looking perspective on the aerospace composite technician career path.

Aerospace Composite Technician Salary

The preceding analysis has explored the multifaceted factors influencing compensation within the aerospace composite technician field. From experience level and geographic location to certification impact, employer type, and skills specialization, a comprehensive understanding of these variables is crucial for both aspiring and current professionals. Earning potential is demonstrably linked to verifiable expertise and strategic career planning.

As the aerospace industry continues to evolve, demand for skilled composite technicians is projected to remain strong. Individuals who prioritize continuous learning, acquire specialized skills, and strategically navigate the employment landscape will be best positioned to achieve competitive compensation and contribute to the ongoing advancement of aerospace technology. Further research and diligent self-assessment are encouraged for those seeking long-term success in this critical sector.

![Aerospace Engineer Salary: CS vs Aero Eng? [2024] Innovating the Future of Flight with Reliable Aviation Solutions Aerospace Engineer Salary: CS vs Aero Eng? [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-71-300x200.jpg)

![[Guide] Bennett Aerospace Salaries: What to Expect (2024) Innovating the Future of Flight with Reliable Aviation Solutions [Guide] Bennett Aerospace Salaries: What to Expect (2024) | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-52-300x200.jpg)